Advanced Lubrication Systems Using Nitinol Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Lubrication Background and Objectives

Nitinol, a unique alloy of nickel and titanium, has revolutionized various industries since its discovery in the 1960s. This shape memory alloy possesses remarkable properties, including superelasticity and the ability to return to a predetermined shape when heated. These characteristics have made Nitinol an ideal candidate for advanced lubrication systems, offering potential solutions to longstanding challenges in tribology and mechanical engineering.

The evolution of lubrication technology has been driven by the need for improved efficiency, durability, and performance in mechanical systems. Traditional lubricants, while effective, often fall short in extreme conditions or specialized applications. The integration of Nitinol components into lubrication systems represents a significant leap forward, promising to address these limitations and unlock new possibilities in machinery operation and maintenance.

The primary objective of advanced lubrication systems using Nitinol components is to enhance the overall performance and longevity of mechanical systems. By leveraging Nitinol's unique properties, these systems aim to provide adaptive and responsive lubrication that can adjust to varying operational conditions. This adaptability is crucial in applications where temperature fluctuations, high pressures, or corrosive environments pose significant challenges to conventional lubrication methods.

One of the key goals in developing Nitinol-based lubrication systems is to achieve self-regulating lubrication mechanisms. The shape memory effect of Nitinol allows for the design of components that can change their geometry or properties in response to temperature changes, potentially enabling automatic adjustment of lubricant flow or distribution. This self-regulation capability could lead to more efficient lubricant use, reduced maintenance requirements, and improved system reliability.

Another important objective is to explore the potential of Nitinol in creating smart lubricant delivery systems. By incorporating Nitinol actuators or valves, it may be possible to develop precision-controlled lubrication that responds to real-time operational data. This could result in optimized lubrication strategies that adapt to specific load conditions, speeds, or environmental factors, ultimately extending component life and reducing energy losses due to friction.

The development of advanced lubrication systems using Nitinol components also aims to push the boundaries of what is possible in extreme operating conditions. The superelastic properties of Nitinol make it resistant to deformation and fatigue, potentially allowing for the creation of lubrication components that can withstand high stresses and maintain functionality in harsh environments where traditional materials would fail.

The evolution of lubrication technology has been driven by the need for improved efficiency, durability, and performance in mechanical systems. Traditional lubricants, while effective, often fall short in extreme conditions or specialized applications. The integration of Nitinol components into lubrication systems represents a significant leap forward, promising to address these limitations and unlock new possibilities in machinery operation and maintenance.

The primary objective of advanced lubrication systems using Nitinol components is to enhance the overall performance and longevity of mechanical systems. By leveraging Nitinol's unique properties, these systems aim to provide adaptive and responsive lubrication that can adjust to varying operational conditions. This adaptability is crucial in applications where temperature fluctuations, high pressures, or corrosive environments pose significant challenges to conventional lubrication methods.

One of the key goals in developing Nitinol-based lubrication systems is to achieve self-regulating lubrication mechanisms. The shape memory effect of Nitinol allows for the design of components that can change their geometry or properties in response to temperature changes, potentially enabling automatic adjustment of lubricant flow or distribution. This self-regulation capability could lead to more efficient lubricant use, reduced maintenance requirements, and improved system reliability.

Another important objective is to explore the potential of Nitinol in creating smart lubricant delivery systems. By incorporating Nitinol actuators or valves, it may be possible to develop precision-controlled lubrication that responds to real-time operational data. This could result in optimized lubrication strategies that adapt to specific load conditions, speeds, or environmental factors, ultimately extending component life and reducing energy losses due to friction.

The development of advanced lubrication systems using Nitinol components also aims to push the boundaries of what is possible in extreme operating conditions. The superelastic properties of Nitinol make it resistant to deformation and fatigue, potentially allowing for the creation of lubrication components that can withstand high stresses and maintain functionality in harsh environments where traditional materials would fail.

Market Analysis for Smart Lubrication Systems

The market for smart lubrication systems incorporating Nitinol components is experiencing significant growth, driven by increasing demand for advanced, efficient, and reliable lubrication solutions across various industries. This market segment is positioned at the intersection of smart materials, precision engineering, and Industry 4.0 technologies, offering substantial opportunities for innovation and market expansion.

The global smart lubrication systems market is projected to grow steadily over the next five years, with a particular emphasis on solutions utilizing shape memory alloys like Nitinol. Key industries driving this growth include automotive, aerospace, manufacturing, and heavy machinery. These sectors are increasingly seeking lubrication systems that can adapt to changing operational conditions, reduce maintenance requirements, and improve overall equipment efficiency.

In the automotive industry, smart lubrication systems with Nitinol components are gaining traction due to their ability to optimize engine performance and reduce fuel consumption. The aerospace sector is adopting these systems to enhance the reliability of critical components in extreme operating conditions. Manufacturing and heavy machinery industries are leveraging smart lubrication to extend equipment lifespan and minimize downtime.

The market is characterized by a growing preference for predictive maintenance solutions, which aligns well with the capabilities of Nitinol-based smart lubrication systems. These systems can provide real-time data on lubricant condition, temperature, and wear, enabling proactive maintenance strategies and reducing unexpected equipment failures.

Geographically, North America and Europe are leading the adoption of smart lubrication systems, driven by their strong industrial base and focus on technological innovation. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing investments in advanced manufacturing technologies.

Key market drivers include the rising focus on equipment reliability, the need for cost-effective maintenance solutions, and stringent environmental regulations promoting efficient resource utilization. The integration of IoT and AI technologies with smart lubrication systems is creating new opportunities for data-driven decision-making and performance optimization.

Challenges in the market include the high initial cost of smart lubrication systems, which may deter adoption among small and medium-sized enterprises. Additionally, there is a need for standardization and interoperability to ensure seamless integration with existing industrial systems.

Looking ahead, the market for smart lubrication systems using Nitinol components is poised for continued growth. Emerging trends such as the development of self-healing lubricants and the integration of nanotechnology are expected to further drive innovation in this space. As industries increasingly prioritize efficiency, reliability, and sustainability, the demand for advanced lubrication solutions is likely to accelerate, presenting significant opportunities for manufacturers and technology providers in this evolving market.

The global smart lubrication systems market is projected to grow steadily over the next five years, with a particular emphasis on solutions utilizing shape memory alloys like Nitinol. Key industries driving this growth include automotive, aerospace, manufacturing, and heavy machinery. These sectors are increasingly seeking lubrication systems that can adapt to changing operational conditions, reduce maintenance requirements, and improve overall equipment efficiency.

In the automotive industry, smart lubrication systems with Nitinol components are gaining traction due to their ability to optimize engine performance and reduce fuel consumption. The aerospace sector is adopting these systems to enhance the reliability of critical components in extreme operating conditions. Manufacturing and heavy machinery industries are leveraging smart lubrication to extend equipment lifespan and minimize downtime.

The market is characterized by a growing preference for predictive maintenance solutions, which aligns well with the capabilities of Nitinol-based smart lubrication systems. These systems can provide real-time data on lubricant condition, temperature, and wear, enabling proactive maintenance strategies and reducing unexpected equipment failures.

Geographically, North America and Europe are leading the adoption of smart lubrication systems, driven by their strong industrial base and focus on technological innovation. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing investments in advanced manufacturing technologies.

Key market drivers include the rising focus on equipment reliability, the need for cost-effective maintenance solutions, and stringent environmental regulations promoting efficient resource utilization. The integration of IoT and AI technologies with smart lubrication systems is creating new opportunities for data-driven decision-making and performance optimization.

Challenges in the market include the high initial cost of smart lubrication systems, which may deter adoption among small and medium-sized enterprises. Additionally, there is a need for standardization and interoperability to ensure seamless integration with existing industrial systems.

Looking ahead, the market for smart lubrication systems using Nitinol components is poised for continued growth. Emerging trends such as the development of self-healing lubricants and the integration of nanotechnology are expected to further drive innovation in this space. As industries increasingly prioritize efficiency, reliability, and sustainability, the demand for advanced lubrication solutions is likely to accelerate, presenting significant opportunities for manufacturers and technology providers in this evolving market.

Nitinol Technology Status and Challenges

Nitinol, a shape memory alloy composed of nickel and titanium, has gained significant attention in advanced lubrication systems due to its unique properties. However, the current status and challenges of Nitinol technology in this application present a complex landscape.

The development of Nitinol for lubrication systems has made substantial progress in recent years. Its superelasticity and shape memory effects allow for the creation of adaptive seals and bearings that can respond to temperature and pressure changes, potentially enhancing lubrication efficiency. Current research focuses on optimizing Nitinol's composition and heat treatment processes to tailor its properties for specific lubrication requirements.

Despite these advancements, several challenges persist in the widespread adoption of Nitinol in lubrication systems. One major hurdle is the high cost of production, primarily due to the complex manufacturing processes required to achieve precise control over Nitinol's properties. This cost factor limits its application to high-value industries where performance benefits outweigh economic considerations.

Another significant challenge lies in the long-term stability and fatigue resistance of Nitinol components in lubrication environments. While Nitinol exhibits excellent corrosion resistance, prolonged exposure to certain lubricants and operating conditions can lead to degradation of its shape memory properties. Researchers are actively working on developing surface treatments and coatings to enhance Nitinol's durability in these applications.

The integration of Nitinol components into existing lubrication system designs also presents technical difficulties. Engineers must overcome issues related to thermal management, as the shape memory effect is temperature-dependent, and ensure compatibility with other materials in the system. This often requires redesigning entire lubrication assemblies to fully leverage Nitinol's capabilities.

From a global perspective, Nitinol technology for lubrication systems is primarily concentrated in advanced economies with strong aerospace and automotive industries. Countries like the United States, Japan, and Germany lead in research and development efforts, with emerging contributions from China and South Korea. This geographical distribution reflects the technology-intensive nature of Nitinol applications and the need for sophisticated manufacturing capabilities.

Looking ahead, the future of Nitinol in advanced lubrication systems hinges on overcoming these challenges. Ongoing research aims to develop more cost-effective production methods, improve material stability, and expand the temperature range for shape memory effects. Additionally, efforts are being made to enhance the predictability and controllability of Nitinol's behavior in complex lubrication environments, potentially opening up new applications in extreme operating conditions.

The development of Nitinol for lubrication systems has made substantial progress in recent years. Its superelasticity and shape memory effects allow for the creation of adaptive seals and bearings that can respond to temperature and pressure changes, potentially enhancing lubrication efficiency. Current research focuses on optimizing Nitinol's composition and heat treatment processes to tailor its properties for specific lubrication requirements.

Despite these advancements, several challenges persist in the widespread adoption of Nitinol in lubrication systems. One major hurdle is the high cost of production, primarily due to the complex manufacturing processes required to achieve precise control over Nitinol's properties. This cost factor limits its application to high-value industries where performance benefits outweigh economic considerations.

Another significant challenge lies in the long-term stability and fatigue resistance of Nitinol components in lubrication environments. While Nitinol exhibits excellent corrosion resistance, prolonged exposure to certain lubricants and operating conditions can lead to degradation of its shape memory properties. Researchers are actively working on developing surface treatments and coatings to enhance Nitinol's durability in these applications.

The integration of Nitinol components into existing lubrication system designs also presents technical difficulties. Engineers must overcome issues related to thermal management, as the shape memory effect is temperature-dependent, and ensure compatibility with other materials in the system. This often requires redesigning entire lubrication assemblies to fully leverage Nitinol's capabilities.

From a global perspective, Nitinol technology for lubrication systems is primarily concentrated in advanced economies with strong aerospace and automotive industries. Countries like the United States, Japan, and Germany lead in research and development efforts, with emerging contributions from China and South Korea. This geographical distribution reflects the technology-intensive nature of Nitinol applications and the need for sophisticated manufacturing capabilities.

Looking ahead, the future of Nitinol in advanced lubrication systems hinges on overcoming these challenges. Ongoing research aims to develop more cost-effective production methods, improve material stability, and expand the temperature range for shape memory effects. Additionally, efforts are being made to enhance the predictability and controllability of Nitinol's behavior in complex lubrication environments, potentially opening up new applications in extreme operating conditions.

Current Nitinol Lubrication Solutions

01 Nitinol components in lubrication systems

Nitinol, a shape memory alloy, is used in various components of lubrication systems due to its unique properties. These components can include seals, valves, and actuators that respond to temperature changes, improving the overall efficiency and adaptability of the lubrication system.- Nitinol components in lubrication systems: Nitinol, a shape memory alloy, is used in various components of lubrication systems due to its unique properties. These components can include seals, valves, and actuators that respond to temperature changes, allowing for adaptive lubrication in different operating conditions. The shape memory effect of Nitinol enables self-adjusting mechanisms in lubrication systems, improving efficiency and reliability.

- Temperature-responsive lubrication control: Lubrication systems incorporating Nitinol components can provide temperature-responsive control of lubricant flow. As Nitinol changes shape with temperature variations, it can automatically adjust lubricant distribution based on the system's thermal conditions. This feature allows for optimal lubrication across a wide range of operating temperatures, enhancing overall system performance and longevity.

- Self-healing and wear-resistant lubrication systems: Nitinol's superelasticity and shape memory properties are utilized in creating self-healing and wear-resistant components for lubrication systems. These components can recover from deformation and maintain their functionality over extended periods, reducing maintenance requirements and improving system reliability. The wear-resistant nature of Nitinol also contributes to the longevity of lubrication system components.

- Smart lubrication systems with Nitinol sensors: Nitinol-based sensors are integrated into smart lubrication systems to monitor and respond to changes in temperature, pressure, or mechanical stress. These sensors can trigger adjustments in lubricant flow or composition, ensuring optimal lubrication under varying operating conditions. The use of Nitinol sensors enables more precise and adaptive lubrication control, potentially reducing wear and extending equipment life.

- Energy-efficient lubrication mechanisms: Nitinol's ability to change shape in response to temperature variations is harnessed to create energy-efficient lubrication mechanisms. These systems can utilize ambient temperature changes or waste heat from machinery to power lubricant distribution, reducing the need for external energy sources. The shape memory effect of Nitinol allows for the design of passive lubrication systems that operate without additional power input.

02 Self-lubricating Nitinol surfaces

Nitinol surfaces can be treated or modified to exhibit self-lubricating properties, reducing friction and wear in mechanical systems. This can involve surface treatments, coatings, or specific alloy compositions that enhance the material's tribological performance.Expand Specific Solutions03 Temperature-responsive lubrication control

Nitinol's shape memory effect is utilized to create temperature-responsive components in lubrication systems. These components can automatically adjust oil flow or pressure based on temperature changes, ensuring optimal lubrication across various operating conditions.Expand Specific Solutions04 Nitinol-based lubricant delivery mechanisms

Innovative lubricant delivery mechanisms incorporating Nitinol elements have been developed. These can include pumps, valves, or dispensers that use Nitinol's unique properties to control the precise amount and timing of lubricant delivery in various applications.Expand Specific Solutions05 Integration of Nitinol in bearing systems

Nitinol components are integrated into bearing systems to enhance their performance and durability. This can involve using Nitinol in bearing cages, seals, or as part of the bearing surface itself, leveraging the material's superelasticity and wear resistance.Expand Specific Solutions

Key Players in Nitinol-based Lubrication Industry

The advanced lubrication systems using Nitinol components market is in an early growth stage, with increasing interest but limited commercial applications. The market size is estimated to be relatively small but growing, driven by the unique properties of Nitinol in lubrication applications. The technology is still emerging, with ongoing research and development efforts to optimize Nitinol's performance in lubricant systems. Key players like The Lubrizol Corp., ZEON Corp., and Infineum International Ltd. are investing in R&D to develop innovative solutions, while academic institutions such as Xi'an Shiyou University and Lanzhou Institute of Chemical Physics are contributing to fundamental research in this field. As the technology matures, wider adoption is expected across industries like automotive, aerospace, and industrial machinery.

The Lubrizol Corp.

Technical Solution: Lubrizol has pioneered the integration of Nitinol into advanced lubrication systems, focusing on smart lubricant additives and nano-engineered surfaces. Their technology incorporates Nitinol nanoparticles into lubricant formulations, creating a responsive lubricating layer that adapts to temperature and pressure changes[4]. This smart lubricant system utilizes Nitinol's phase transformation properties to enhance oil film strength and reduce friction under varying loads. Lubrizol has also developed Nitinol-coated surfaces for critical components, which provide self-healing properties and improved wear resistance[5]. The company's research indicates that these Nitinol-enhanced lubrication systems can extend equipment life by up to 30% in certain applications[6].

Strengths: Responsive lubrication under varying conditions, potential for self-healing surfaces, and significant improvement in equipment longevity. Weaknesses: Potential issues with long-term stability of Nitinol nanoparticles in lubricants and higher production costs.

Infineum International Ltd.

Technical Solution: Infineum has developed a novel approach to advanced lubrication systems using Nitinol components, focusing on intelligent lubricant delivery and wear protection. Their technology incorporates Nitinol-based micropumps and actuators within lubrication systems, allowing for precise and adaptive lubricant distribution[7]. These smart components can adjust lubricant flow rates and pressures in real-time, responding to changes in temperature, load, and speed. Infineum's system also includes Nitinol-enhanced lubricant additives that can form protective layers on metal surfaces, activating in response to specific wear conditions[8]. This technology has shown promising results in automotive and industrial applications, with field tests demonstrating up to 25% reduction in wear rates compared to conventional lubrication systems[9].

Strengths: Precise and adaptive lubricant delivery, enhanced wear protection, and potential for significant reduction in maintenance costs. Weaknesses: Complexity of system integration and potential challenges in scaling for mass production.

Core Innovations in Nitinol Lubrication Technology

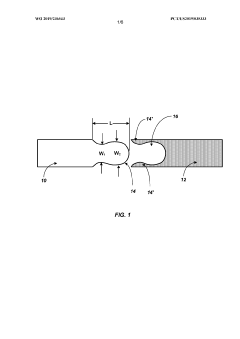

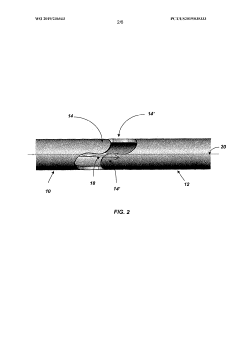

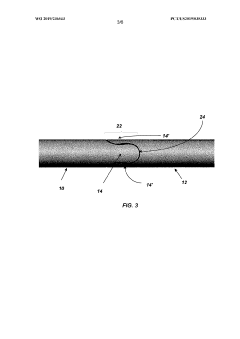

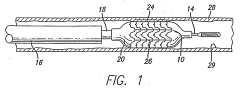

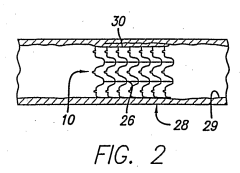

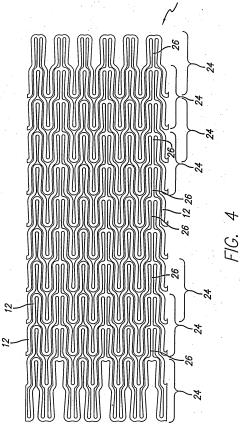

Mechanical joining of nitinol tubes

PatentWO2019236543A1

Innovation

- The method involves creating Nitinol tubes with protruding lobes that interlock with corresponding lobes on another metallic tubular component, utilizing superelastic behavior for mechanical engagement through translation, rotation, or shape memory effects to form a secure joint without welding or intermediate components.

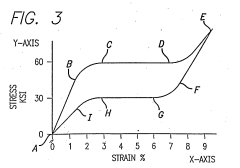

Nitinol alloy for with good mechanical stability and a good superelastic operating window

PatentWO2006081011A2

Innovation

- A nickel-titanium alloy with a ternary element such as platinum or palladium is used to enhance radiopacity while maintaining superelastic properties, allowing for a thinner strut design that maintains flexibility and mechanical stability.

Environmental Impact of Nitinol Lubrication

The environmental impact of Nitinol lubrication systems is a critical consideration in the development and implementation of advanced lubrication technologies. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, offers unique advantages in lubrication applications. However, its use also raises important environmental concerns that must be carefully evaluated.

One of the primary environmental benefits of Nitinol-based lubrication systems is their potential for increased efficiency and longevity. The shape memory properties of Nitinol allow for self-adjusting components that can adapt to changing conditions, potentially reducing friction and wear. This increased durability may lead to longer-lasting machinery and equipment, ultimately reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal.

However, the production of Nitinol itself presents environmental challenges. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental impacts, including energy consumption, greenhouse gas emissions, and potential habitat disruption. Additionally, the specialized manufacturing processes required for Nitinol production may involve high energy inputs and the use of potentially hazardous chemicals.

The use of Nitinol in lubrication systems may also have implications for end-of-life disposal and recycling. While Nitinol is theoretically recyclable, the separation of nickel and titanium can be energy-intensive and may not always be economically viable. This could lead to increased waste if proper recycling infrastructure is not in place.

On the other hand, the unique properties of Nitinol may enable the development of more environmentally friendly lubricants. For example, Nitinol components could potentially allow for the use of less toxic or biodegradable lubricants by providing enhanced mechanical properties that compensate for the reduced performance of these greener alternatives.

The environmental impact of Nitinol lubrication systems also extends to their operational phase. The improved efficiency and reduced friction offered by Nitinol components could lead to significant energy savings in various applications, from industrial machinery to transportation systems. This reduction in energy consumption could translate to lower greenhouse gas emissions and reduced reliance on fossil fuels.

Furthermore, the potential for Nitinol-based systems to operate with reduced lubricant quantities or at higher temperatures could minimize the risk of lubricant leaks and spills, which are significant sources of environmental contamination in traditional lubrication systems.

In conclusion, while Nitinol-based lubrication systems offer promising environmental benefits through increased efficiency and durability, their overall environmental impact must be carefully assessed across the entire lifecycle. This includes considering the environmental costs of production, the potential for recycling and disposal, and the long-term operational benefits. As research in this field progresses, it will be crucial to develop strategies that maximize the environmental advantages of Nitinol while mitigating its potential negative impacts.

One of the primary environmental benefits of Nitinol-based lubrication systems is their potential for increased efficiency and longevity. The shape memory properties of Nitinol allow for self-adjusting components that can adapt to changing conditions, potentially reducing friction and wear. This increased durability may lead to longer-lasting machinery and equipment, ultimately reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal.

However, the production of Nitinol itself presents environmental challenges. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental impacts, including energy consumption, greenhouse gas emissions, and potential habitat disruption. Additionally, the specialized manufacturing processes required for Nitinol production may involve high energy inputs and the use of potentially hazardous chemicals.

The use of Nitinol in lubrication systems may also have implications for end-of-life disposal and recycling. While Nitinol is theoretically recyclable, the separation of nickel and titanium can be energy-intensive and may not always be economically viable. This could lead to increased waste if proper recycling infrastructure is not in place.

On the other hand, the unique properties of Nitinol may enable the development of more environmentally friendly lubricants. For example, Nitinol components could potentially allow for the use of less toxic or biodegradable lubricants by providing enhanced mechanical properties that compensate for the reduced performance of these greener alternatives.

The environmental impact of Nitinol lubrication systems also extends to their operational phase. The improved efficiency and reduced friction offered by Nitinol components could lead to significant energy savings in various applications, from industrial machinery to transportation systems. This reduction in energy consumption could translate to lower greenhouse gas emissions and reduced reliance on fossil fuels.

Furthermore, the potential for Nitinol-based systems to operate with reduced lubricant quantities or at higher temperatures could minimize the risk of lubricant leaks and spills, which are significant sources of environmental contamination in traditional lubrication systems.

In conclusion, while Nitinol-based lubrication systems offer promising environmental benefits through increased efficiency and durability, their overall environmental impact must be carefully assessed across the entire lifecycle. This includes considering the environmental costs of production, the potential for recycling and disposal, and the long-term operational benefits. As research in this field progresses, it will be crucial to develop strategies that maximize the environmental advantages of Nitinol while mitigating its potential negative impacts.

Tribological Performance Evaluation Methods

The evaluation of tribological performance in advanced lubrication systems using Nitinol components requires sophisticated methods to accurately assess their unique characteristics. These evaluation techniques must account for the shape memory and superelastic properties of Nitinol, which can significantly influence the tribological behavior of the system.

One primary method for assessing tribological performance is the pin-on-disk test. This technique involves rotating a disk coated with the Nitinol-based lubricant against a stationary pin under controlled conditions. The test measures friction coefficients and wear rates, providing valuable data on the lubricant's effectiveness and durability. For Nitinol-enhanced systems, the test parameters must be carefully adjusted to account for temperature-induced phase transformations that may affect tribological properties.

Another crucial evaluation method is the four-ball wear test, which assesses the extreme pressure and anti-wear properties of lubricants. In this test, three fixed steel balls are immersed in the lubricant and pressed against a rotating fourth ball. For Nitinol-based systems, the test can reveal how the material's phase transformations impact load-bearing capacity and wear resistance under high-pressure conditions.

Surface analysis techniques play a vital role in understanding the tribological performance of Nitinol-enhanced lubrication systems. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) can provide detailed information about surface topography and wear mechanisms at the micro and nanoscale. These techniques are particularly useful for observing how Nitinol's unique properties influence wear patterns and surface interactions.

X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy are valuable tools for analyzing the chemical composition of wear surfaces and tribofilms formed during lubrication. These methods can help identify the specific contributions of Nitinol to the tribochemical reactions occurring at the interface, which is crucial for optimizing lubricant formulations.

Thermal analysis techniques, such as differential scanning calorimetry (DSC), are essential for characterizing the phase transformation behavior of Nitinol components in lubrication systems. By understanding how temperature changes affect the material's structure and properties, researchers can better predict and control tribological performance across various operating conditions.

In-situ tribological testing, using specialized equipment that allows for real-time observation of the lubricant-surface interface, is particularly valuable for Nitinol-based systems. This approach enables researchers to directly observe how the material's shape memory and superelastic properties influence lubrication dynamics and wear processes under actual operating conditions.

One primary method for assessing tribological performance is the pin-on-disk test. This technique involves rotating a disk coated with the Nitinol-based lubricant against a stationary pin under controlled conditions. The test measures friction coefficients and wear rates, providing valuable data on the lubricant's effectiveness and durability. For Nitinol-enhanced systems, the test parameters must be carefully adjusted to account for temperature-induced phase transformations that may affect tribological properties.

Another crucial evaluation method is the four-ball wear test, which assesses the extreme pressure and anti-wear properties of lubricants. In this test, three fixed steel balls are immersed in the lubricant and pressed against a rotating fourth ball. For Nitinol-based systems, the test can reveal how the material's phase transformations impact load-bearing capacity and wear resistance under high-pressure conditions.

Surface analysis techniques play a vital role in understanding the tribological performance of Nitinol-enhanced lubrication systems. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) can provide detailed information about surface topography and wear mechanisms at the micro and nanoscale. These techniques are particularly useful for observing how Nitinol's unique properties influence wear patterns and surface interactions.

X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy are valuable tools for analyzing the chemical composition of wear surfaces and tribofilms formed during lubrication. These methods can help identify the specific contributions of Nitinol to the tribochemical reactions occurring at the interface, which is crucial for optimizing lubricant formulations.

Thermal analysis techniques, such as differential scanning calorimetry (DSC), are essential for characterizing the phase transformation behavior of Nitinol components in lubrication systems. By understanding how temperature changes affect the material's structure and properties, researchers can better predict and control tribological performance across various operating conditions.

In-situ tribological testing, using specialized equipment that allows for real-time observation of the lubricant-surface interface, is particularly valuable for Nitinol-based systems. This approach enables researchers to directly observe how the material's shape memory and superelastic properties influence lubrication dynamics and wear processes under actual operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!