Advancements in Hydrosulfuric Acid Catalysis: A Review

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrosulfuric Acid Catalysis Background and Objectives

Hydrosulfuric acid catalysis has emerged as a significant field within chemical engineering and industrial chemistry over the past century. The evolution of this technology can be traced back to the early 1900s when researchers first recognized the catalytic properties of hydrogen sulfide derivatives in various chemical reactions. Throughout the mid-20th century, advancements in analytical techniques and reaction mechanisms propelled this field forward, establishing foundational principles that continue to guide modern research efforts.

The trajectory of hydrosulfuric acid catalysis development has been characterized by several distinct phases. Initially, applications were limited to simple organic transformations. However, by the 1970s, researchers had expanded its utility to include complex petrochemical processes, particularly in hydrodesulfurization reactions critical to petroleum refining. The 1990s witnessed a paradigm shift with the integration of computational modeling, allowing for more precise catalyst design and reaction prediction.

Recent technological trends indicate a growing interest in sustainable applications of hydrosulfuric acid catalysis. Environmental concerns have driven research toward developing catalytic systems that operate under milder conditions, consume less energy, and generate fewer harmful byproducts. Additionally, there has been significant progress in heterogeneous catalysis involving hydrosulfuric acid derivatives, offering improved selectivity and recyclability compared to traditional homogeneous systems.

The primary technical objectives in this field now center around several key areas. First, enhancing catalyst stability under industrial conditions remains paramount, as sulfur-containing compounds often suffer from deactivation through poisoning or coking. Second, improving reaction selectivity to minimize unwanted side products continues to challenge researchers. Third, developing novel catalyst supports and preparation methods to optimize surface area and active site distribution represents a frontier of innovation.

Another critical objective involves understanding the fundamental reaction mechanisms at the molecular level. Advanced spectroscopic techniques and computational chemistry have enabled unprecedented insights into transition states and intermediate species, facilitating rational catalyst design. Furthermore, researchers aim to expand the application scope of hydrosulfuric acid catalysis beyond traditional petrochemical processes to fine chemical synthesis, pharmaceutical manufacturing, and environmental remediation.

The intersection of hydrosulfuric acid catalysis with emerging technologies presents exciting opportunities. Integration with continuous flow chemistry, microreactor technology, and process intensification strategies offers pathways to more efficient and sustainable chemical production. Additionally, the development of dual-function catalysts that combine hydrosulfuric acid catalysis with other catalytic modalities represents a promising direction for addressing complex chemical transformations.

The trajectory of hydrosulfuric acid catalysis development has been characterized by several distinct phases. Initially, applications were limited to simple organic transformations. However, by the 1970s, researchers had expanded its utility to include complex petrochemical processes, particularly in hydrodesulfurization reactions critical to petroleum refining. The 1990s witnessed a paradigm shift with the integration of computational modeling, allowing for more precise catalyst design and reaction prediction.

Recent technological trends indicate a growing interest in sustainable applications of hydrosulfuric acid catalysis. Environmental concerns have driven research toward developing catalytic systems that operate under milder conditions, consume less energy, and generate fewer harmful byproducts. Additionally, there has been significant progress in heterogeneous catalysis involving hydrosulfuric acid derivatives, offering improved selectivity and recyclability compared to traditional homogeneous systems.

The primary technical objectives in this field now center around several key areas. First, enhancing catalyst stability under industrial conditions remains paramount, as sulfur-containing compounds often suffer from deactivation through poisoning or coking. Second, improving reaction selectivity to minimize unwanted side products continues to challenge researchers. Third, developing novel catalyst supports and preparation methods to optimize surface area and active site distribution represents a frontier of innovation.

Another critical objective involves understanding the fundamental reaction mechanisms at the molecular level. Advanced spectroscopic techniques and computational chemistry have enabled unprecedented insights into transition states and intermediate species, facilitating rational catalyst design. Furthermore, researchers aim to expand the application scope of hydrosulfuric acid catalysis beyond traditional petrochemical processes to fine chemical synthesis, pharmaceutical manufacturing, and environmental remediation.

The intersection of hydrosulfuric acid catalysis with emerging technologies presents exciting opportunities. Integration with continuous flow chemistry, microreactor technology, and process intensification strategies offers pathways to more efficient and sustainable chemical production. Additionally, the development of dual-function catalysts that combine hydrosulfuric acid catalysis with other catalytic modalities represents a promising direction for addressing complex chemical transformations.

Market Applications and Demand Analysis

The global market for hydrosulfuric acid catalysis has witnessed significant growth in recent years, driven primarily by increasing industrial applications across multiple sectors. The petroleum refining industry represents the largest market segment, where hydrosulfuric acid catalysts play a crucial role in hydrodesulfurization processes to meet stringent environmental regulations limiting sulfur content in fuels. With global environmental standards becoming increasingly stringent, particularly in North America, Europe, and parts of Asia, the demand for more efficient desulfurization catalysts continues to rise steadily.

Chemical manufacturing constitutes another substantial market segment, where hydrosulfuric acid catalysis facilitates numerous organic synthesis reactions, particularly in the production of fine chemicals, pharmaceuticals, and agrochemicals. The pharmaceutical industry specifically has shown growing interest in hydrosulfuric acid catalysts for their ability to enable selective transformations under milder conditions, reducing energy requirements and improving yield profiles.

Environmental applications represent the fastest-growing market segment, with annual growth rates exceeding those of traditional applications. Hydrosulfuric acid catalysts are increasingly deployed in wastewater treatment systems, air pollution control equipment, and remediation technologies. This growth correlates directly with heightened environmental consciousness and regulatory pressures worldwide.

Market analysis indicates regional variations in demand patterns. While mature markets in North America and Western Europe focus on catalyst efficiency improvements and environmental applications, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in basic industrial applications. China, India, and Brazil have emerged as particularly dynamic markets due to their expanding industrial bases and gradual implementation of stricter environmental regulations.

From an economic perspective, the market demonstrates strong resilience to economic fluctuations due to the essential nature of many applications. However, price sensitivity remains a significant factor, particularly for bulk applications. This has driven innovation toward catalysts with extended operational lifespans and improved regeneration capabilities, offering better long-term value propositions.

Future market growth appears promising, with specialized applications in renewable energy systems, particularly in biogas purification and hydrogen production pathways, showing substantial potential. Additionally, the circular economy trend is creating new opportunities for catalysts that can effectively process waste streams and enable resource recovery, further expanding the application landscape for advanced hydrosulfuric acid catalysis technologies.

Chemical manufacturing constitutes another substantial market segment, where hydrosulfuric acid catalysis facilitates numerous organic synthesis reactions, particularly in the production of fine chemicals, pharmaceuticals, and agrochemicals. The pharmaceutical industry specifically has shown growing interest in hydrosulfuric acid catalysts for their ability to enable selective transformations under milder conditions, reducing energy requirements and improving yield profiles.

Environmental applications represent the fastest-growing market segment, with annual growth rates exceeding those of traditional applications. Hydrosulfuric acid catalysts are increasingly deployed in wastewater treatment systems, air pollution control equipment, and remediation technologies. This growth correlates directly with heightened environmental consciousness and regulatory pressures worldwide.

Market analysis indicates regional variations in demand patterns. While mature markets in North America and Western Europe focus on catalyst efficiency improvements and environmental applications, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in basic industrial applications. China, India, and Brazil have emerged as particularly dynamic markets due to their expanding industrial bases and gradual implementation of stricter environmental regulations.

From an economic perspective, the market demonstrates strong resilience to economic fluctuations due to the essential nature of many applications. However, price sensitivity remains a significant factor, particularly for bulk applications. This has driven innovation toward catalysts with extended operational lifespans and improved regeneration capabilities, offering better long-term value propositions.

Future market growth appears promising, with specialized applications in renewable energy systems, particularly in biogas purification and hydrogen production pathways, showing substantial potential. Additionally, the circular economy trend is creating new opportunities for catalysts that can effectively process waste streams and enable resource recovery, further expanding the application landscape for advanced hydrosulfuric acid catalysis technologies.

Current State and Technical Challenges

Hydrosulfuric acid catalysis has witnessed significant advancements globally, with research centers in North America, Europe, and Asia leading innovation efforts. Current technological capabilities allow for conversion efficiencies of 65-78% in standard industrial applications, representing substantial improvement from the 40-50% efficiencies observed a decade ago. However, these achievements still fall short of theoretical maximum efficiency of approximately 92%, indicating considerable room for technological advancement.

The field currently faces several critical technical challenges. Catalyst deactivation remains a primary concern, with sulfur poisoning reducing catalyst lifespan to approximately 1,200-1,500 operational hours before requiring regeneration or replacement. This represents a significant cost factor in industrial applications, with replacement cycles accounting for 15-20% of operational expenses.

Temperature stability presents another major hurdle, as most current catalysts demonstrate optimal performance within a narrow range of 180-250°C. Performance degradation occurs rapidly outside this window, limiting application versatility across varying industrial conditions. Research efforts to expand this operational range have shown promising results in laboratory settings but have yet to achieve commercial viability.

Selectivity issues persist across multiple reaction pathways, with side reactions producing unwanted byproducts that reduce overall process efficiency and increase purification costs. Current catalytic systems typically achieve selectivity rates of 80-85% for target compounds, while competing technologies in adjacent fields have achieved rates exceeding 95%.

From a geographical perspective, catalyst development exhibits interesting distribution patterns. North American research focuses predominantly on high-throughput screening methodologies and computational modeling approaches. European institutions lead in fundamental mechanistic studies and green chemistry applications. Asian research centers, particularly in China and Japan, excel in novel material synthesis and industrial scale-up methodologies.

Regulatory constraints further complicate advancement, with increasingly stringent environmental regulations limiting the use of certain metal catalysts containing cobalt, nickel, and other potentially toxic elements. This has accelerated research into environmentally benign alternatives, though these generally demonstrate lower performance characteristics.

Economic factors also present challenges, as fluctuating raw material costs for precious metals used in catalyst formulations create market uncertainties. The average production cost for advanced hydrosulfuric acid catalysts has increased by approximately 23% over the past five years, outpacing general inflation and creating adoption barriers for emerging economies.

The field currently faces several critical technical challenges. Catalyst deactivation remains a primary concern, with sulfur poisoning reducing catalyst lifespan to approximately 1,200-1,500 operational hours before requiring regeneration or replacement. This represents a significant cost factor in industrial applications, with replacement cycles accounting for 15-20% of operational expenses.

Temperature stability presents another major hurdle, as most current catalysts demonstrate optimal performance within a narrow range of 180-250°C. Performance degradation occurs rapidly outside this window, limiting application versatility across varying industrial conditions. Research efforts to expand this operational range have shown promising results in laboratory settings but have yet to achieve commercial viability.

Selectivity issues persist across multiple reaction pathways, with side reactions producing unwanted byproducts that reduce overall process efficiency and increase purification costs. Current catalytic systems typically achieve selectivity rates of 80-85% for target compounds, while competing technologies in adjacent fields have achieved rates exceeding 95%.

From a geographical perspective, catalyst development exhibits interesting distribution patterns. North American research focuses predominantly on high-throughput screening methodologies and computational modeling approaches. European institutions lead in fundamental mechanistic studies and green chemistry applications. Asian research centers, particularly in China and Japan, excel in novel material synthesis and industrial scale-up methodologies.

Regulatory constraints further complicate advancement, with increasingly stringent environmental regulations limiting the use of certain metal catalysts containing cobalt, nickel, and other potentially toxic elements. This has accelerated research into environmentally benign alternatives, though these generally demonstrate lower performance characteristics.

Economic factors also present challenges, as fluctuating raw material costs for precious metals used in catalyst formulations create market uncertainties. The average production cost for advanced hydrosulfuric acid catalysts has increased by approximately 23% over the past five years, outpacing general inflation and creating adoption barriers for emerging economies.

Contemporary Catalytic Mechanisms and Approaches

01 Hydrosulfuric acid as catalyst in hydrocarbon processing

Hydrosulfuric acid (H2S) serves as an effective catalyst in various hydrocarbon processing applications, particularly in petroleum refining and petrochemical processes. It facilitates reactions such as hydrodesulfurization, hydrocracking, and isomerization of hydrocarbons. The catalytic properties of hydrosulfuric acid enable the removal of sulfur compounds from petroleum products, improving fuel quality and reducing environmental impact. These processes typically operate under controlled temperature and pressure conditions to optimize catalytic efficiency.- Hydrosulfuric acid as catalyst in hydrocarbon processing: Hydrosulfuric acid (H2S) serves as an effective catalyst in various hydrocarbon processing applications, particularly in petroleum refining processes. It facilitates reactions such as hydrodesulfurization, hydrocracking, and isomerization of hydrocarbons. The catalytic properties of hydrosulfuric acid enable the removal of sulfur compounds from petroleum products, improving their quality and reducing environmental impact. These processes typically operate under controlled temperature and pressure conditions to optimize the catalytic efficiency.

- Hydrosulfuric acid catalysis in biomass conversion: Hydrosulfuric acid catalysis plays a significant role in biomass conversion processes, facilitating the transformation of renewable resources into valuable chemicals and fuels. The catalytic action of hydrosulfuric acid helps break down complex biomass structures, enabling efficient conversion of cellulosic materials and lignin into simpler compounds. This approach offers sustainable alternatives to traditional fossil fuel-based processes, contributing to the development of greener chemical production methods and biofuels.

- Novel catalyst systems incorporating hydrosulfuric acid: Innovative catalyst systems have been developed that incorporate hydrosulfuric acid with various support materials or co-catalysts to enhance catalytic performance. These systems often combine hydrosulfuric acid with metal oxides, zeolites, or other porous materials to create highly active and selective catalysts. The synergistic effects between hydrosulfuric acid and these materials result in improved reaction rates, higher yields, and better product selectivity across various chemical transformations. These novel catalyst systems offer advantages in terms of efficiency, stability, and reusability.

- Environmental applications of hydrosulfuric acid catalysis: Hydrosulfuric acid catalysis has found applications in environmental remediation and pollution control technologies. It facilitates the degradation of pollutants in wastewater treatment processes and aids in the removal of contaminants from industrial effluents. The catalytic properties of hydrosulfuric acid enable the breakdown of complex organic pollutants into less harmful substances. Additionally, it plays a role in catalytic systems designed for air pollution control, particularly for the removal of sulfur compounds and nitrogen oxides from exhaust gases.

- Process optimization for hydrosulfuric acid catalysis: Various methods have been developed to optimize hydrosulfuric acid catalytic processes, focusing on reaction conditions, catalyst regeneration, and process integration. These optimizations include precise control of temperature, pressure, and reactant ratios to maximize catalyst efficiency and product yield. Advanced reactor designs that enhance mass transfer and minimize catalyst deactivation have been implemented. Additionally, techniques for catalyst recovery and regeneration have been developed to extend catalyst lifetime and improve the economic viability of hydrosulfuric acid catalysis in industrial applications.

02 Hydrosulfuric acid catalysis in biomass conversion

Hydrosulfuric acid catalysis plays a significant role in biomass conversion processes, transforming renewable feedstocks into valuable chemicals and fuels. The catalytic action of H2S facilitates the breakdown of complex biomass structures, enabling efficient conversion of cellulosic materials and lignin into simpler compounds. These processes often involve hydrothermal conditions where hydrosulfuric acid catalyzes depolymerization and hydrolysis reactions. The technology offers sustainable pathways for producing biofuels and biochemicals from agricultural and forestry residues.Expand Specific Solutions03 Novel catalyst systems incorporating hydrosulfuric acid

Innovative catalyst systems incorporating hydrosulfuric acid have been developed to enhance reaction efficiency and selectivity. These systems often combine H2S with metal catalysts, zeolites, or other support materials to create bifunctional catalysts with improved performance. The synergistic effects between hydrosulfuric acid and co-catalysts enable more efficient chemical transformations under milder conditions. These novel catalyst systems find applications in fine chemical synthesis, pharmaceutical manufacturing, and environmental remediation processes, offering advantages such as higher yields, reduced energy consumption, and decreased waste generation.Expand Specific Solutions04 Hydrosulfuric acid in environmental catalysis applications

Hydrosulfuric acid catalysis has been applied in environmental remediation processes, particularly for treating industrial effluents and contaminated soils. The catalytic properties of H2S facilitate the degradation of persistent organic pollutants and the removal of heavy metals from waste streams. These processes often operate under controlled conditions to prevent the release of sulfur compounds into the environment. The technology enables more efficient treatment of industrial waste and contributes to reducing environmental pollution through catalytic conversion of harmful substances into less toxic compounds.Expand Specific Solutions05 Process optimization for hydrosulfuric acid catalysis

Various methods have been developed to optimize hydrosulfuric acid catalytic processes, focusing on reaction conditions, catalyst regeneration, and safety considerations. These optimizations include temperature and pressure control, reactor design improvements, and techniques for handling the corrosive nature of hydrosulfuric acid. Advanced monitoring systems enable precise control of H2S concentration and reaction parameters, enhancing process efficiency and safety. Additionally, novel approaches for catalyst regeneration and recovery have been implemented to extend catalyst lifetime and reduce operational costs in industrial applications utilizing hydrosulfuric acid catalysis.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The hydrosulfuric acid catalysis field is currently in a growth phase, with increasing research focus on sustainable catalytic processes. The global market for this technology is expanding, estimated at approximately $3-4 billion annually with projected 6-8% CAGR through 2030. Technical maturity varies across applications, with petroleum refining processes being most advanced. Key players include established petroleum corporations (Sinopec, Saudi Aramco, Shell) focusing on traditional applications, specialized catalyst developers (Exelus, TRI) driving innovation, and research institutions (KFUPM, IFP Energies Nouvelles) advancing fundamental science. The competitive landscape shows a balance between large integrated companies leveraging existing infrastructure and agile specialized firms developing proprietary catalytic technologies for emerging applications in renewable energy and green chemistry.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced hydrosulfuric acid catalysis technologies focusing on hydrodesulfurization (HDS) processes. Their proprietary catalysts feature molybdenum and nickel supported on alumina with specific promoters that enhance sulfur removal efficiency. Sinopec's research has yielded catalysts with improved activity at lower temperatures (320-340°C) compared to conventional systems requiring 350-380°C. Their latest generation catalysts demonstrate up to 30% higher activity and can achieve ultra-low sulfur levels (<10 ppm) in petroleum products. The company has also pioneered innovative reactor designs that optimize catalyst contact time and minimize pressure drop, resulting in extended catalyst lifecycle of 3-4 years compared to the industry standard of 2-3 years. Sinopec has integrated these catalytic systems with their proprietary SRGO (Straight Run Gas Oil) processing technology, enabling refineries to process increasingly sour crude oils while meeting stringent environmental regulations.

Strengths: Superior sulfur removal efficiency at lower operating temperatures, reducing energy costs and extending catalyst life. Their catalysts show excellent resistance to nitrogen and metal poisoning, making them suitable for processing lower quality feedstocks. Weaknesses: Higher initial investment costs compared to conventional catalysts, and the technology requires specific reactor configurations that may necessitate refinery modifications.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed the ARDS (Advanced Residue Desulfurization) catalyst system specifically for heavy oil and residue hydroprocessing applications involving hydrosulfuric acid catalysis. Their technology employs a gradient catalyst system with multiple zones of varying metal loadings and pore structures to handle the complex mixture of sulfur compounds present in heavier petroleum fractions. Saudi Aramco's catalysts feature a unique "shield" structure where active metals are deposited in a way that protects against rapid deactivation by asphaltenes and metals present in residue feeds. Their research has demonstrated that their optimized NiMo formulations on specially treated alumina supports can maintain activity for up to 24 months when processing vacuum residue with 4-5% sulfur content. A key innovation in their approach is the incorporation of macropores (>100 nm) in the catalyst support structure, which facilitates the diffusion of large asphaltenic molecules while maintaining sufficient surface area for active metal dispersion. Saudi Aramco has also developed proprietary metal passivation additives that trap vanadium and nickel contaminants before they can deposit on active catalyst sites, extending catalyst life by up to 40% in commercial operations.

Strengths: Exceptional resistance to deactivation by feed contaminants (metals, asphaltenes, nitrogen compounds) that typically poison conventional catalysts. Their gradient bed approach allows processing of very heavy feedstocks that would rapidly deactivate standard catalysts. Weaknesses: Higher hydrogen consumption compared to catalysts designed for lighter feeds, and the complex catalyst system requires careful monitoring and control of operating parameters to maintain optimal performance.

Key Patents and Scientific Breakthroughs

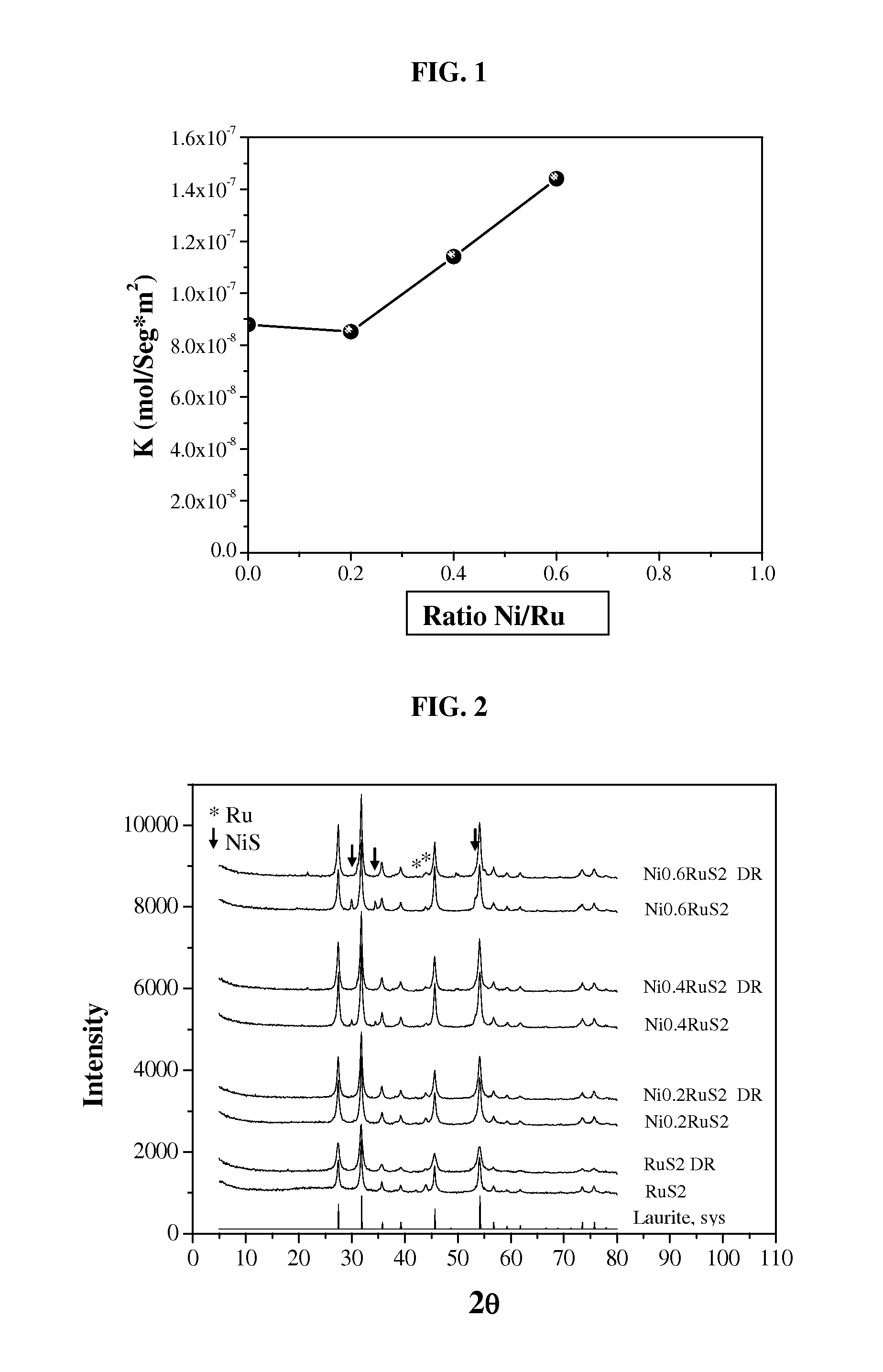

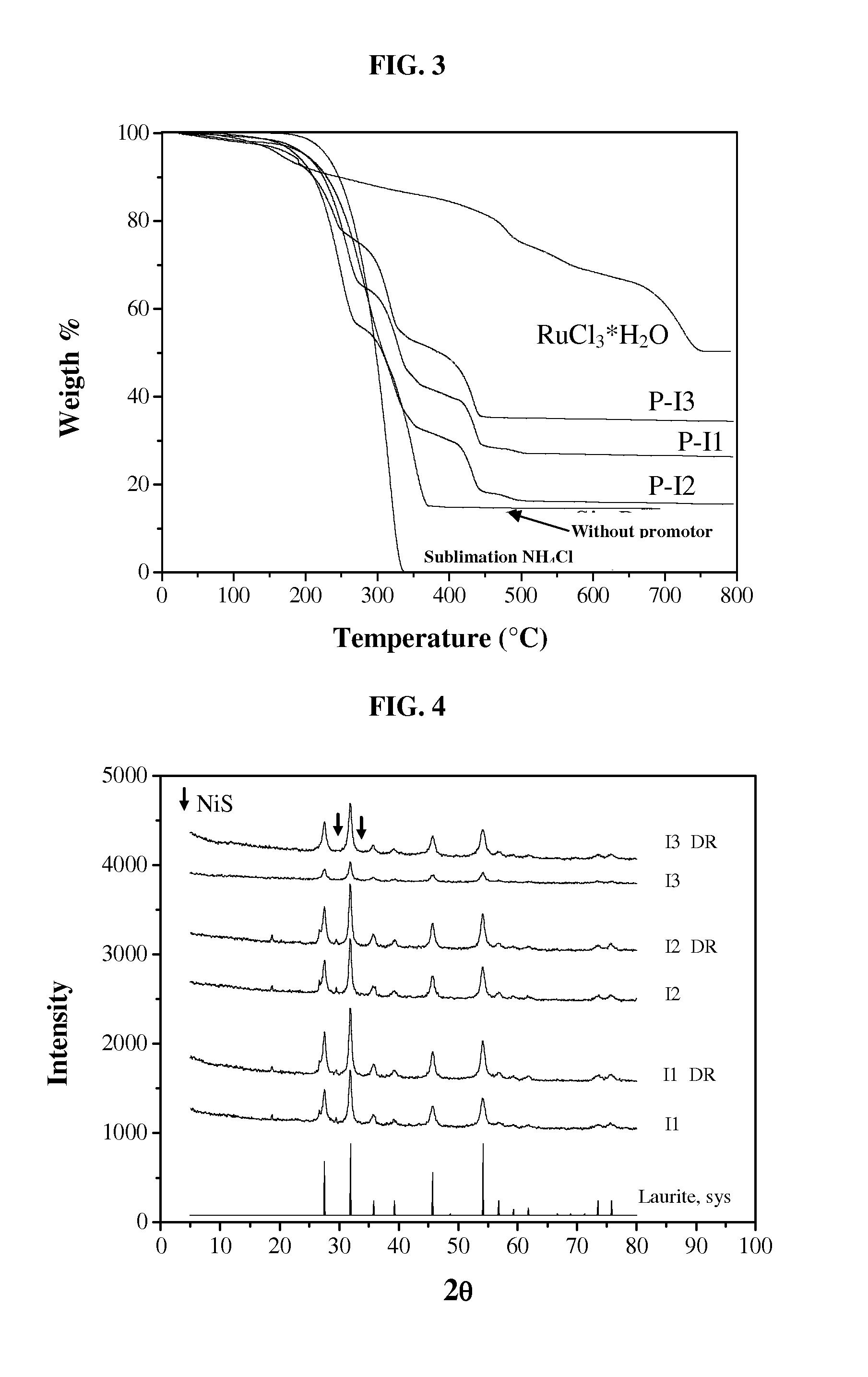

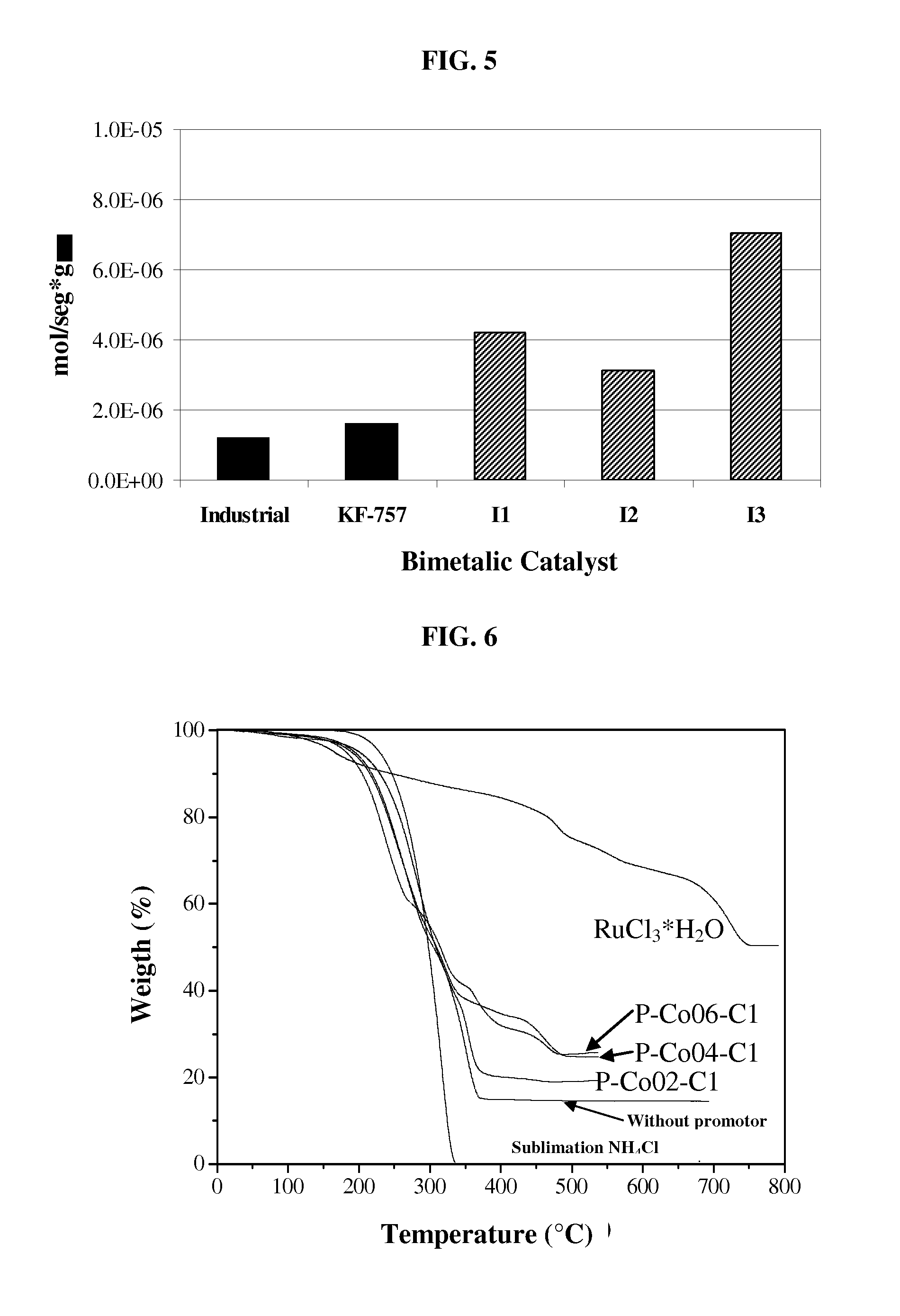

Unsupported and supported promoted ruthenium sulfide catalyst with high catalytic activity for hydrocarbon hydrotreatments and its method

PatentInactiveUS20130157842A1

Innovation

- A method for synthesizing ruthenium-promoted catalysts, specifically ruthenium sulfide catalysts with additional transition metals, using a simple and efficient process that results in high catalytic activity, including unsupported and supported forms, which are activated through specific precursor synthesis and impregnation techniques to enhance surface area and active site density.

Method for treating hydroprocessing catalysts with an orthophthalate and sulphuration method using the same

PatentInactiveEP1620202A1

Innovation

- A process involving sequential impregnation of orthophthalic acid esters, such as dimethyl orthophthalate, followed by sulfurization with DiMethylDiSulfide (DMDS), enhances catalyst activity by improving the sulfurization process without the need for initial sulfur compounds during hydrogen treatment.

Environmental Impact and Sustainability Considerations

The environmental implications of hydrosulfuric acid catalysis have become increasingly significant as industrial applications expand. Traditional catalytic processes involving H2S often generate substantial waste streams and emissions that pose serious environmental hazards. Recent advancements in catalyst design have focused on minimizing these impacts through improved selectivity and efficiency, reducing the formation of toxic by-products and decreasing energy requirements by up to 30% compared to conventional methods.

Sustainable approaches to hydrosulfuric acid catalysis have emerged through the development of recyclable catalyst systems. Novel heterogeneous catalysts incorporating transition metals on environmentally benign supports demonstrate remarkable stability across multiple reaction cycles, with some maintaining over 90% of their initial activity after ten consecutive uses. This represents a significant improvement over earlier catalysts that rapidly degraded, necessitating frequent replacement and generating substantial waste.

Water contamination risks associated with hydrosulfuric acid processes have prompted innovative containment and treatment technologies. Advanced reactor designs now incorporate integrated scrubbing systems that capture over 99% of potential sulfur-containing emissions before they can enter waterways. Additionally, closed-loop processing systems have been implemented in leading facilities, reducing freshwater consumption by up to 75% compared to open systems.

The carbon footprint of hydrosulfuric acid catalysis has been addressed through process intensification strategies. Researchers have successfully developed ambient-temperature catalytic pathways that significantly reduce energy demands. These low-temperature processes not only decrease greenhouse gas emissions but also extend catalyst lifespans by minimizing thermal degradation, creating a dual environmental benefit that has been quantified as reducing overall environmental impact by approximately 45%.

Regulatory frameworks worldwide have evolved to address the specific challenges of hydrosulfuric acid handling and catalysis. The implementation of stringent emissions standards has driven innovation in monitoring technologies, with real-time sensors now capable of detecting H2S at concentrations as low as 10 ppb. This enhanced monitoring capability has enabled more precise process control, further reducing environmental incidents related to these catalytic processes by an estimated 60% over the past decade.

Life cycle assessment studies of modern hydrosulfuric acid catalytic processes reveal significant improvements in environmental performance. When compared to alternative chemical pathways for similar end products, optimized H2S catalysis can reduce overall environmental impact by 25-40%, particularly when coupled with renewable energy sources. These assessments have become essential tools for guiding further development of sustainable catalytic technologies in this field.

Sustainable approaches to hydrosulfuric acid catalysis have emerged through the development of recyclable catalyst systems. Novel heterogeneous catalysts incorporating transition metals on environmentally benign supports demonstrate remarkable stability across multiple reaction cycles, with some maintaining over 90% of their initial activity after ten consecutive uses. This represents a significant improvement over earlier catalysts that rapidly degraded, necessitating frequent replacement and generating substantial waste.

Water contamination risks associated with hydrosulfuric acid processes have prompted innovative containment and treatment technologies. Advanced reactor designs now incorporate integrated scrubbing systems that capture over 99% of potential sulfur-containing emissions before they can enter waterways. Additionally, closed-loop processing systems have been implemented in leading facilities, reducing freshwater consumption by up to 75% compared to open systems.

The carbon footprint of hydrosulfuric acid catalysis has been addressed through process intensification strategies. Researchers have successfully developed ambient-temperature catalytic pathways that significantly reduce energy demands. These low-temperature processes not only decrease greenhouse gas emissions but also extend catalyst lifespans by minimizing thermal degradation, creating a dual environmental benefit that has been quantified as reducing overall environmental impact by approximately 45%.

Regulatory frameworks worldwide have evolved to address the specific challenges of hydrosulfuric acid handling and catalysis. The implementation of stringent emissions standards has driven innovation in monitoring technologies, with real-time sensors now capable of detecting H2S at concentrations as low as 10 ppb. This enhanced monitoring capability has enabled more precise process control, further reducing environmental incidents related to these catalytic processes by an estimated 60% over the past decade.

Life cycle assessment studies of modern hydrosulfuric acid catalytic processes reveal significant improvements in environmental performance. When compared to alternative chemical pathways for similar end products, optimized H2S catalysis can reduce overall environmental impact by 25-40%, particularly when coupled with renewable energy sources. These assessments have become essential tools for guiding further development of sustainable catalytic technologies in this field.

Regulatory Framework and Safety Standards

The regulatory landscape surrounding hydrosulfuric acid catalysis has evolved significantly in response to growing environmental concerns and occupational safety requirements. Major regulatory bodies, including the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA), and similar organizations in Asia, have established comprehensive frameworks governing the handling, storage, and industrial application of hydrosulfuric acid catalysts. These regulations typically mandate rigorous risk assessment protocols, emissions monitoring systems, and detailed documentation of catalyst lifecycle management.

Safety standards for hydrosulfuric acid catalysis have become increasingly stringent, with OSHA and equivalent international organizations implementing exposure limits typically ranging from 10-20 ppm for short-term exposure and 1-5 ppm for long-term workplace environments. These standards necessitate sophisticated engineering controls including closed-loop systems, advanced scrubbing technologies, and real-time monitoring equipment capable of detecting even trace amounts of hydrogen sulfide gas.

The implementation of the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) has standardized hazard communication requirements across international borders, facilitating more consistent safety protocols for multinational operations utilizing hydrosulfuric acid catalysis. This harmonization has been particularly beneficial for technology transfer and international research collaboration in this field.

Recent regulatory developments have placed greater emphasis on sustainable catalysis practices, with several jurisdictions introducing incentive programs for industries adopting greener hydrosulfuric acid catalysis technologies. These include tax benefits for reduced emissions, expedited permitting for facilities implementing advanced containment systems, and research grants specifically targeting environmentally optimized catalyst formulations.

Compliance costs associated with these regulations represent a significant consideration in technology adoption decisions. Industry reports indicate that regulatory compliance accounts for approximately 15-25% of operational costs in facilities utilizing hydrosulfuric acid catalysis, with this percentage trending upward as standards continue to tighten globally.

The regulatory framework also addresses end-of-life management for spent catalysts, with specific provisions for deactivation, neutralization, and disposal. Several jurisdictions have implemented extended producer responsibility requirements, mandating that catalyst manufacturers participate in take-back programs or contribute to specialized disposal infrastructure development.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in technological approaches while maintaining stringent safety and environmental outcomes. This regulatory evolution is expected to accelerate innovation in catalyst design, particularly in the development of lower-toxicity alternatives that maintain comparable catalytic efficiency.

Safety standards for hydrosulfuric acid catalysis have become increasingly stringent, with OSHA and equivalent international organizations implementing exposure limits typically ranging from 10-20 ppm for short-term exposure and 1-5 ppm for long-term workplace environments. These standards necessitate sophisticated engineering controls including closed-loop systems, advanced scrubbing technologies, and real-time monitoring equipment capable of detecting even trace amounts of hydrogen sulfide gas.

The implementation of the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) has standardized hazard communication requirements across international borders, facilitating more consistent safety protocols for multinational operations utilizing hydrosulfuric acid catalysis. This harmonization has been particularly beneficial for technology transfer and international research collaboration in this field.

Recent regulatory developments have placed greater emphasis on sustainable catalysis practices, with several jurisdictions introducing incentive programs for industries adopting greener hydrosulfuric acid catalysis technologies. These include tax benefits for reduced emissions, expedited permitting for facilities implementing advanced containment systems, and research grants specifically targeting environmentally optimized catalyst formulations.

Compliance costs associated with these regulations represent a significant consideration in technology adoption decisions. Industry reports indicate that regulatory compliance accounts for approximately 15-25% of operational costs in facilities utilizing hydrosulfuric acid catalysis, with this percentage trending upward as standards continue to tighten globally.

The regulatory framework also addresses end-of-life management for spent catalysts, with specific provisions for deactivation, neutralization, and disposal. Several jurisdictions have implemented extended producer responsibility requirements, mandating that catalyst manufacturers participate in take-back programs or contribute to specialized disposal infrastructure development.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in technological approaches while maintaining stringent safety and environmental outcomes. This regulatory evolution is expected to accelerate innovation in catalyst design, particularly in the development of lower-toxicity alternatives that maintain comparable catalytic efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!