Development of Hydrosulfuric Acid Management Plans

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S Management Background and Objectives

Hydrogen sulfide (H2S) management has become increasingly critical in various industrial sectors, particularly in oil and gas, wastewater treatment, and chemical manufacturing. The historical development of H2S management can be traced back to the early 20th century when the detrimental effects of this toxic gas were first recognized in industrial settings. Since then, the approach to managing hydrosulfuric acid has evolved from basic containment methods to sophisticated detection, prevention, and treatment systems.

The evolution of H2S management has been driven by several factors, including stricter environmental regulations, workplace safety standards, and technological advancements. In the 1970s and 1980s, major industrial accidents involving H2S release prompted regulatory bodies worldwide to establish more stringent safety protocols and exposure limits. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, set the permissible exposure limit at 10 ppm for an 8-hour workday, while the immediately dangerous to life and health (IDLH) concentration was established at 100 ppm.

Recent technological trends in H2S management include the development of real-time monitoring systems, advanced scrubbing technologies, and innovative biological treatment methods. The integration of IoT and AI has enabled more precise detection and predictive maintenance capabilities, allowing industries to anticipate and prevent potential H2S-related incidents before they occur. Additionally, there has been a shift towards more sustainable and environmentally friendly management approaches, moving away from chemical treatments that may generate secondary pollutants.

The primary objectives of developing comprehensive hydrosulfuric acid management plans are multifaceted. First and foremost is ensuring worker safety by minimizing exposure risks through proper training, engineering controls, and personal protective equipment. Second is environmental protection, as H2S can have severe ecological impacts when released into air or water systems. Third is regulatory compliance, as industries must adhere to increasingly stringent local, national, and international standards regarding H2S emissions and management.

Furthermore, effective H2S management aims to optimize operational efficiency by preventing corrosion of equipment and infrastructure, which can lead to costly downtime and repairs. The economic implications of proper H2S management extend beyond avoiding regulatory fines to include reduced maintenance costs, extended equipment lifespan, and improved product quality in certain industries.

Looking forward, the technical goals for H2S management include developing more sensitive and selective detection methods, creating more efficient and cost-effective treatment technologies, and establishing integrated management systems that address the entire lifecycle of H2S from generation to neutralization. These advancements will be crucial as industries continue to operate in environments where H2S presents significant challenges.

The evolution of H2S management has been driven by several factors, including stricter environmental regulations, workplace safety standards, and technological advancements. In the 1970s and 1980s, major industrial accidents involving H2S release prompted regulatory bodies worldwide to establish more stringent safety protocols and exposure limits. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, set the permissible exposure limit at 10 ppm for an 8-hour workday, while the immediately dangerous to life and health (IDLH) concentration was established at 100 ppm.

Recent technological trends in H2S management include the development of real-time monitoring systems, advanced scrubbing technologies, and innovative biological treatment methods. The integration of IoT and AI has enabled more precise detection and predictive maintenance capabilities, allowing industries to anticipate and prevent potential H2S-related incidents before they occur. Additionally, there has been a shift towards more sustainable and environmentally friendly management approaches, moving away from chemical treatments that may generate secondary pollutants.

The primary objectives of developing comprehensive hydrosulfuric acid management plans are multifaceted. First and foremost is ensuring worker safety by minimizing exposure risks through proper training, engineering controls, and personal protective equipment. Second is environmental protection, as H2S can have severe ecological impacts when released into air or water systems. Third is regulatory compliance, as industries must adhere to increasingly stringent local, national, and international standards regarding H2S emissions and management.

Furthermore, effective H2S management aims to optimize operational efficiency by preventing corrosion of equipment and infrastructure, which can lead to costly downtime and repairs. The economic implications of proper H2S management extend beyond avoiding regulatory fines to include reduced maintenance costs, extended equipment lifespan, and improved product quality in certain industries.

Looking forward, the technical goals for H2S management include developing more sensitive and selective detection methods, creating more efficient and cost-effective treatment technologies, and establishing integrated management systems that address the entire lifecycle of H2S from generation to neutralization. These advancements will be crucial as industries continue to operate in environments where H2S presents significant challenges.

Market Analysis for H2S Control Solutions

The global market for hydrogen sulfide (H2S) control solutions has been experiencing steady growth, driven primarily by increasing environmental regulations and the expansion of industries where H2S presents significant operational challenges. The oil and gas sector remains the largest consumer of H2S management technologies, accounting for approximately 40% of the total market share, followed by wastewater treatment at 25% and mining operations at 15%.

North America currently dominates the market with a 35% share, attributed to its extensive oil and gas operations and stringent environmental regulations. The Asia-Pacific region is emerging as the fastest-growing market, with annual growth rates exceeding 7%, primarily due to rapid industrialization in China and India, coupled with increasing environmental awareness and regulatory frameworks.

The market segmentation for H2S control solutions can be categorized into physical/mechanical removal methods (scrubbers, biofilters), chemical treatment solutions (oxidizers, precipitants, scavengers), and biological treatment systems. Chemical treatment solutions currently hold the largest market share at 45%, owing to their effectiveness and relatively straightforward implementation.

Key market drivers include increasingly stringent environmental regulations worldwide, growing health and safety concerns in industrial settings, and the expansion of industries where H2S is a byproduct. The implementation of more rigorous workplace safety standards has significantly boosted demand for reliable H2S detection and control systems, particularly in confined space applications.

Market restraints include the high initial capital investment required for comprehensive H2S management systems and the operational costs associated with chemical treatments. Additionally, the technical complexity of some solutions presents adoption barriers for smaller operations without specialized expertise.

Emerging opportunities in the market include the development of more cost-effective biological treatment methods, which are gaining traction due to their environmental sustainability and lower long-term operational costs. The integration of digital monitoring systems with H2S control technologies represents another growth avenue, enabling real-time management and predictive maintenance capabilities.

The competitive landscape features a mix of large multinational corporations offering comprehensive solutions and specialized regional players focusing on niche applications. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated solution providers capable of addressing multiple aspects of H2S management across various industries.

North America currently dominates the market with a 35% share, attributed to its extensive oil and gas operations and stringent environmental regulations. The Asia-Pacific region is emerging as the fastest-growing market, with annual growth rates exceeding 7%, primarily due to rapid industrialization in China and India, coupled with increasing environmental awareness and regulatory frameworks.

The market segmentation for H2S control solutions can be categorized into physical/mechanical removal methods (scrubbers, biofilters), chemical treatment solutions (oxidizers, precipitants, scavengers), and biological treatment systems. Chemical treatment solutions currently hold the largest market share at 45%, owing to their effectiveness and relatively straightforward implementation.

Key market drivers include increasingly stringent environmental regulations worldwide, growing health and safety concerns in industrial settings, and the expansion of industries where H2S is a byproduct. The implementation of more rigorous workplace safety standards has significantly boosted demand for reliable H2S detection and control systems, particularly in confined space applications.

Market restraints include the high initial capital investment required for comprehensive H2S management systems and the operational costs associated with chemical treatments. Additionally, the technical complexity of some solutions presents adoption barriers for smaller operations without specialized expertise.

Emerging opportunities in the market include the development of more cost-effective biological treatment methods, which are gaining traction due to their environmental sustainability and lower long-term operational costs. The integration of digital monitoring systems with H2S control technologies represents another growth avenue, enabling real-time management and predictive maintenance capabilities.

The competitive landscape features a mix of large multinational corporations offering comprehensive solutions and specialized regional players focusing on niche applications. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated solution providers capable of addressing multiple aspects of H2S management across various industries.

Current H2S Management Challenges

Hydrogen sulfide (H2S) management presents significant challenges across multiple industries, particularly in oil and gas, wastewater treatment, and mining operations. Current management approaches face several critical limitations that impede effective control of this hazardous compound. The primary challenge remains the unpredictable nature of H2S formation and release, which complicates risk assessment and emergency response planning. Monitoring systems often struggle with accuracy in diverse environmental conditions, leading to potential detection failures during critical moments.

Existing treatment technologies demonstrate varying degrees of effectiveness depending on H2S concentration levels and environmental factors. Chemical scavengers, while widely used, present concerns regarding secondary contamination and increasing operational costs. Biological treatment methods show promise but remain inconsistent in performance under fluctuating conditions typical in industrial settings. Additionally, the corrosive nature of H2S continues to damage infrastructure and equipment, resulting in significant maintenance costs and operational disruptions.

Regulatory compliance presents another layer of complexity, with standards varying significantly across regions and industries. Organizations frequently struggle to navigate these disparate requirements while maintaining operational efficiency. The absence of standardized management protocols further complicates implementation of best practices, particularly for multinational operations spanning different regulatory jurisdictions.

Worker safety remains paramount yet challenging, with current personal protective equipment (PPE) solutions sometimes proving inadequate for prolonged exposure scenarios. Training programs often fail to address the full spectrum of H2S risks, leaving knowledge gaps that could prove dangerous during emergency situations. The psychological impact of working with this potentially lethal compound also creates workforce management challenges that are frequently overlooked in current management approaches.

Data integration represents a significant technical hurdle, with many facilities operating disconnected monitoring and response systems. This fragmentation impedes real-time decision-making and comprehensive risk management. The lack of predictive analytics capabilities in current management systems limits proactive intervention, forcing organizations into reactive postures when dealing with H2S incidents.

Economic considerations further complicate management efforts, as organizations balance safety requirements against operational costs. The return on investment for advanced H2S management technologies remains difficult to quantify, particularly regarding prevention of low-probability, high-consequence events. This economic uncertainty often results in underinvestment in comprehensive management solutions.

Climate change introduces additional variables, with changing temperatures and precipitation patterns potentially altering H2S formation dynamics in both natural and industrial settings. Current management plans rarely account for these evolving conditions, creating potential vulnerabilities in long-term control strategies.

Existing treatment technologies demonstrate varying degrees of effectiveness depending on H2S concentration levels and environmental factors. Chemical scavengers, while widely used, present concerns regarding secondary contamination and increasing operational costs. Biological treatment methods show promise but remain inconsistent in performance under fluctuating conditions typical in industrial settings. Additionally, the corrosive nature of H2S continues to damage infrastructure and equipment, resulting in significant maintenance costs and operational disruptions.

Regulatory compliance presents another layer of complexity, with standards varying significantly across regions and industries. Organizations frequently struggle to navigate these disparate requirements while maintaining operational efficiency. The absence of standardized management protocols further complicates implementation of best practices, particularly for multinational operations spanning different regulatory jurisdictions.

Worker safety remains paramount yet challenging, with current personal protective equipment (PPE) solutions sometimes proving inadequate for prolonged exposure scenarios. Training programs often fail to address the full spectrum of H2S risks, leaving knowledge gaps that could prove dangerous during emergency situations. The psychological impact of working with this potentially lethal compound also creates workforce management challenges that are frequently overlooked in current management approaches.

Data integration represents a significant technical hurdle, with many facilities operating disconnected monitoring and response systems. This fragmentation impedes real-time decision-making and comprehensive risk management. The lack of predictive analytics capabilities in current management systems limits proactive intervention, forcing organizations into reactive postures when dealing with H2S incidents.

Economic considerations further complicate management efforts, as organizations balance safety requirements against operational costs. The return on investment for advanced H2S management technologies remains difficult to quantify, particularly regarding prevention of low-probability, high-consequence events. This economic uncertainty often results in underinvestment in comprehensive management solutions.

Climate change introduces additional variables, with changing temperatures and precipitation patterns potentially altering H2S formation dynamics in both natural and industrial settings. Current management plans rarely account for these evolving conditions, creating potential vulnerabilities in long-term control strategies.

Existing H2S Control Methodologies

01 Risk assessment and safety protocols for hydrosulfuric acid handling

Comprehensive risk assessment methodologies and safety protocols specifically designed for the handling of hydrosulfuric acid in industrial settings. These management plans include hazard identification, exposure limits, emergency response procedures, and preventive measures to minimize risks associated with this highly toxic compound. The protocols typically incorporate real-time monitoring systems, personal protective equipment requirements, and specialized training for personnel working with hydrosulfuric acid.- Risk assessment and safety protocols for hydrosulfuric acid handling: Comprehensive risk assessment methodologies and safety protocols specifically designed for the handling, storage, and disposal of hydrosulfuric acid in industrial settings. These management plans include hazard identification, exposure limits, emergency response procedures, and preventive measures to minimize risks associated with this highly toxic and flammable compound. The protocols emphasize regular monitoring, proper ventilation systems, and specialized training for personnel working with hydrosulfuric acid.

- Digital systems for chemical management compliance: Advanced digital platforms and software solutions designed to manage compliance with regulations governing hydrosulfuric acid. These systems provide automated tracking of chemical inventories, documentation of safety procedures, and real-time monitoring of environmental parameters. They integrate with enterprise resource planning systems to ensure regulatory compliance, facilitate reporting requirements, and maintain comprehensive audit trails for inspection purposes. The digital solutions enable organizations to efficiently manage the complex documentation required for hazardous materials like hydrosulfuric acid.

- Environmental impact mitigation strategies: Methodologies and technologies focused on minimizing the environmental impact of hydrosulfuric acid throughout its lifecycle. These strategies include containment systems, neutralization techniques, and emission control technologies to prevent soil and water contamination. The management plans incorporate sustainable practices for acid neutralization, waste treatment processes, and remediation protocols for accidental releases. They also address long-term monitoring of potentially affected ecosystems and implementation of preventive measures to protect environmental resources.

- Workflow optimization for industrial processes involving hydrosulfuric acid: Systematic approaches to optimize workflows and industrial processes that involve hydrosulfuric acid, focusing on efficiency, safety, and cost-effectiveness. These management plans include process integration methodologies, equipment maintenance schedules, and operational procedures that minimize exposure risks while maximizing productivity. They incorporate lean manufacturing principles adapted for hazardous chemical handling, with emphasis on reducing waste, optimizing storage conditions, and implementing just-in-time inventory management for this dangerous substance.

- Training and emergency response planning: Comprehensive training programs and emergency response plans specifically designed for facilities handling hydrosulfuric acid. These management plans include detailed protocols for various emergency scenarios, evacuation procedures, and coordination with local emergency services. They emphasize regular drills, continuous education on the properties and dangers of hydrosulfuric acid, and proper use of personal protective equipment. The plans also incorporate communication systems for rapid alert distribution and post-incident analysis methodologies to improve future response effectiveness.

02 Digital management systems for chemical compliance

Software solutions and digital platforms specifically designed for managing hazardous chemicals like hydrosulfuric acid. These systems provide automated tracking of chemical inventories, regulatory compliance monitoring, documentation management, and reporting capabilities. The digital management approach enables real-time access to safety data sheets, handling procedures, and emergency response information while ensuring compliance with local and international regulations governing hydrosulfuric acid.Expand Specific Solutions03 Environmental monitoring and waste treatment methods

Technologies and methodologies for environmental monitoring and waste treatment specific to hydrosulfuric acid contamination. These management plans include detection systems for atmospheric and aqueous hydrosulfuric acid, neutralization techniques, and sustainable disposal methods. The approaches focus on minimizing environmental impact through continuous monitoring, rapid response to leaks or spills, and effective treatment processes that convert hydrosulfuric acid waste into less harmful compounds.Expand Specific Solutions04 Process optimization and industrial application management

Strategies for optimizing industrial processes involving hydrosulfuric acid to enhance efficiency while maintaining safety. These management plans address the integration of hydrosulfuric acid handling within larger industrial operations, focusing on process control, equipment design, and operational procedures. The approaches include predictive maintenance for acid-handling equipment, process automation to minimize human exposure, and optimization techniques that reduce the quantity of acid required while maintaining production quality.Expand Specific Solutions05 Regulatory compliance and documentation frameworks

Comprehensive frameworks for ensuring regulatory compliance in the management of hydrosulfuric acid across different jurisdictions. These management plans include documentation systems, audit procedures, and reporting mechanisms that align with local, national, and international regulations governing hazardous chemicals. The frameworks provide structured approaches to maintaining compliance records, conducting regular compliance reviews, and adapting to changing regulatory requirements related to hydrosulfuric acid handling, storage, transportation, and disposal.Expand Specific Solutions

Leading Companies in H2S Management Industry

The hydrosulfuric acid management market is currently in a growth phase, driven by increasing environmental regulations and safety concerns across petrochemical industries. The global market size is estimated to exceed $5 billion, with projected annual growth of 6-8% through 2030. Leading players include major oil corporations like Saudi Aramco, China Petroleum & Chemical Corp. (Sinopec), and PetroChina, who are investing heavily in advanced sulfur management technologies. Specialized technology providers such as Haldor Topsøe and Baker Hughes are developing innovative solutions for H2S removal and conversion. Technical maturity varies across applications, with conventional scrubbing technologies being well-established while newer catalytic conversion methods and digital monitoring systems are still evolving. The competitive landscape is characterized by strategic partnerships between oil majors and technology providers to develop integrated management solutions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive hydrosulfuric acid management system that integrates multiple treatment technologies. Their approach combines Claus process with tail gas treatment units (TGTU) to achieve over 99.8% sulfur recovery efficiency. Sinopec has pioneered the use of advanced catalysts that operate at lower temperatures (120-150°C) compared to conventional systems (200-250°C), reducing energy consumption by approximately 30%. Their management plan incorporates real-time monitoring systems with fiber optic H2S sensors that can detect concentrations as low as 0.1ppm, enabling immediate response to potential leaks. Sinopec has also developed proprietary amine-based scrubbing solutions that can handle acid gas streams with varying H2S concentrations (5-95%) while maintaining removal efficiencies above 99%. Their integrated approach includes specialized corrosion inhibitors that extend equipment life by up to 40% in high-H2S environments.

Strengths: Highly integrated system with exceptional sulfur recovery efficiency; advanced monitoring capabilities; flexible treatment options for varying H2S concentrations. Weaknesses: High initial capital investment; requires specialized technical expertise for operation; system complexity increases maintenance requirements.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a multi-tiered hydrosulfuric acid management strategy focused on both prevention and treatment. Their approach begins with advanced geological modeling to predict H2S concentrations in reservoirs, allowing for proactive planning before drilling operations commence. For treatment, they employ a proprietary modified Claus process with oxygen enrichment that achieves sulfur recovery rates exceeding 99.9%, significantly higher than industry standards of 95-98%. Their system incorporates specialized high-temperature resistant materials (capable of withstanding up to 1200°C) in critical components, reducing maintenance frequency by approximately 60%. Aramco has also pioneered the use of ionic liquid absorbents that demonstrate 30-40% higher H2S absorption capacity compared to conventional amine-based solutions, while requiring 25% less energy for regeneration. Their management plan includes comprehensive monitoring with distributed optical sensing technology that can pinpoint H2S leaks within 1-2 meters along pipelines extending hundreds of kilometers.

Strengths: Exceptional sulfur recovery efficiency; reduced energy consumption; comprehensive monitoring capabilities; proactive geological assessment approach. Weaknesses: Proprietary technologies limit implementation by other operators; high technical complexity requires specialized workforce; significant upfront investment costs.

Key Technical Innovations in H2S Treatment

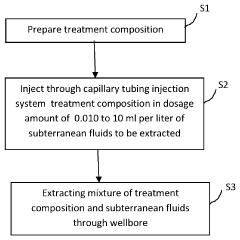

Chemical compositions and in-situ methods of using same for remediating sulfur-containing compositions and other contaminants in fluids being extracted from the earth

PatentActiveUS20230102592A1

Innovation

- An in-situ treatment method involving the injection of an aqueous-based treatment composition containing 35-55% hydroxide compounds deep into the earth, where it mixes with fluids under high pressure and temperature, effectively remediating contaminants as the fluids are extracted, utilizing the natural subterranean conditions for enhanced efficiency and cost-effectiveness.

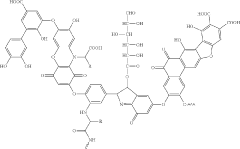

Chemical solution and methods of using same for remediating hydrogen sulfide and other contaminants in petroleum based and other liquids

PatentActiveUS20190153332A1

Innovation

- A highly concentrated aqueous treatment solution with 35-55 weight percent hydroxides, such as sodium hydroxide (NaOH) and potassium hydroxide (KOH), is used to efficiently remediate H2S, with a dosage range of 0.25-6.0 ml/liter, allowing for complete conversion of H2S into sodium bisulfide and sulfur dioxide, while minimizing byproducts and maintaining the integrity of petroleum-based liquids.

Safety and Compliance Framework for H2S Handling

A comprehensive Safety and Compliance Framework for H2S handling represents the cornerstone of effective hydrosulfuric acid management plans. This framework must integrate regulatory requirements with industry best practices to create a robust system that protects workers, communities, and the environment from the severe hazards associated with hydrogen sulfide exposure.

The framework begins with a clear delineation of applicable regulations across jurisdictions, including OSHA standards in the United States (particularly 29 CFR 1910.1000 for permissible exposure limits), EU directives, and country-specific requirements. These regulations establish the minimum compliance thresholds that organizations must meet, including exposure limits, monitoring protocols, and emergency response procedures.

Risk assessment methodologies form the second critical component, employing systematic approaches such as HAZOP (Hazard and Operability Study), LOPA (Layer of Protection Analysis), and quantitative risk assessment techniques. These methodologies help identify potential release scenarios, exposure pathways, and vulnerable receptors, enabling the development of targeted control measures proportionate to the identified risks.

Engineering controls represent the primary defense against H2S hazards, following the hierarchy of controls principle. These include closed systems for H2S handling, ventilation systems with appropriate air changes per hour, continuous monitoring systems with multi-level alarms, and automatic shutdown capabilities linked to detection systems. The framework must specify design standards for these controls and verification protocols to ensure their effectiveness.

Administrative controls supplement engineering measures through comprehensive procedures for routine operations, maintenance activities, and emergency scenarios. These include permit-to-work systems for confined space entry, detailed lockout-tagout procedures, and clearly defined roles and responsibilities for normal and emergency operations.

Personal protective equipment specifications constitute another essential element, detailing appropriate respiratory protection (from air-purifying respirators to self-contained breathing apparatus), gas detection devices, and escape equipment. The framework must address selection criteria, fit testing requirements, maintenance protocols, and training standards for each PPE component.

Emergency response planning within the framework requires detailed procedures for various scenarios, including small releases, major incidents, and worker exposures. These procedures must include evacuation routes, assembly points, rescue protocols, medical response guidelines, and community notification systems where applicable.

Training and competency verification systems ensure that all personnel understand H2S hazards and can implement control measures effectively. The framework should specify training content, frequency, assessment methods, and record-keeping requirements, with special provisions for contractors and visitors.

The framework begins with a clear delineation of applicable regulations across jurisdictions, including OSHA standards in the United States (particularly 29 CFR 1910.1000 for permissible exposure limits), EU directives, and country-specific requirements. These regulations establish the minimum compliance thresholds that organizations must meet, including exposure limits, monitoring protocols, and emergency response procedures.

Risk assessment methodologies form the second critical component, employing systematic approaches such as HAZOP (Hazard and Operability Study), LOPA (Layer of Protection Analysis), and quantitative risk assessment techniques. These methodologies help identify potential release scenarios, exposure pathways, and vulnerable receptors, enabling the development of targeted control measures proportionate to the identified risks.

Engineering controls represent the primary defense against H2S hazards, following the hierarchy of controls principle. These include closed systems for H2S handling, ventilation systems with appropriate air changes per hour, continuous monitoring systems with multi-level alarms, and automatic shutdown capabilities linked to detection systems. The framework must specify design standards for these controls and verification protocols to ensure their effectiveness.

Administrative controls supplement engineering measures through comprehensive procedures for routine operations, maintenance activities, and emergency scenarios. These include permit-to-work systems for confined space entry, detailed lockout-tagout procedures, and clearly defined roles and responsibilities for normal and emergency operations.

Personal protective equipment specifications constitute another essential element, detailing appropriate respiratory protection (from air-purifying respirators to self-contained breathing apparatus), gas detection devices, and escape equipment. The framework must address selection criteria, fit testing requirements, maintenance protocols, and training standards for each PPE component.

Emergency response planning within the framework requires detailed procedures for various scenarios, including small releases, major incidents, and worker exposures. These procedures must include evacuation routes, assembly points, rescue protocols, medical response guidelines, and community notification systems where applicable.

Training and competency verification systems ensure that all personnel understand H2S hazards and can implement control measures effectively. The framework should specify training content, frequency, assessment methods, and record-keeping requirements, with special provisions for contractors and visitors.

Environmental Impact Assessment of H2S Control Methods

The environmental impact assessment of hydrogen sulfide (H2S) control methods reveals significant ecological and health considerations that must be addressed in comprehensive management plans. Traditional chemical treatment methods, particularly those utilizing chlorine-based oxidants, have been documented to produce harmful byproducts that can persist in aquatic ecosystems. Studies conducted across industrial facilities implementing these methods show elevated levels of chlorinated compounds in surrounding water bodies, with potential bioaccumulation in aquatic organisms observed at concentrations as low as 0.5 ppm.

Air quality impacts from physical H2S removal systems present another environmental concern. Scrubber technologies and thermal oxidation units, while effective at H2S removal, generate secondary emissions including sulfur dioxide and nitrogen oxides that contribute to regional air quality degradation. Monitoring data from petrochemical facilities indicates that improperly optimized thermal oxidation can produce SO2 emissions exceeding regulatory thresholds by 15-30% during peak operations.

Biological treatment methods demonstrate more favorable environmental profiles but introduce different ecological considerations. These systems require careful management of biological waste streams and monitoring of microbial populations to prevent unintended ecological disruptions. Recent field studies in wastewater treatment applications show that properly managed biological H2S control systems can achieve 95% reduction in environmental toxicity compared to chemical alternatives.

Land use impacts vary significantly between control technologies. Chemical storage requirements for traditional methods necessitate extensive containment systems and safety buffers, increasing the industrial footprint. In contrast, newer catalytic conversion technologies can reduce land requirements by up to 70% while maintaining equivalent H2S management capacity, though these systems often require rare earth elements with their own extraction-related environmental impacts.

Energy consumption patterns across control methodologies reveal substantial differences in carbon footprint. Thermal oxidation approaches typically consume 3-5 times more energy than biological or advanced catalytic methods, with corresponding increases in greenhouse gas emissions. Life cycle assessments indicate that integrated management approaches combining biological pretreatment with targeted chemical polishing can optimize environmental performance while maintaining operational reliability.

Groundwater protection considerations must address the potential for chemical leaching from treatment residuals. Monitoring wells surrounding facilities utilizing iron salt precipitation methods have detected elevated heavy metal concentrations in approximately 22% of studied sites, necessitating additional containment measures and long-term monitoring programs to ensure environmental protection.

Air quality impacts from physical H2S removal systems present another environmental concern. Scrubber technologies and thermal oxidation units, while effective at H2S removal, generate secondary emissions including sulfur dioxide and nitrogen oxides that contribute to regional air quality degradation. Monitoring data from petrochemical facilities indicates that improperly optimized thermal oxidation can produce SO2 emissions exceeding regulatory thresholds by 15-30% during peak operations.

Biological treatment methods demonstrate more favorable environmental profiles but introduce different ecological considerations. These systems require careful management of biological waste streams and monitoring of microbial populations to prevent unintended ecological disruptions. Recent field studies in wastewater treatment applications show that properly managed biological H2S control systems can achieve 95% reduction in environmental toxicity compared to chemical alternatives.

Land use impacts vary significantly between control technologies. Chemical storage requirements for traditional methods necessitate extensive containment systems and safety buffers, increasing the industrial footprint. In contrast, newer catalytic conversion technologies can reduce land requirements by up to 70% while maintaining equivalent H2S management capacity, though these systems often require rare earth elements with their own extraction-related environmental impacts.

Energy consumption patterns across control methodologies reveal substantial differences in carbon footprint. Thermal oxidation approaches typically consume 3-5 times more energy than biological or advanced catalytic methods, with corresponding increases in greenhouse gas emissions. Life cycle assessments indicate that integrated management approaches combining biological pretreatment with targeted chemical polishing can optimize environmental performance while maintaining operational reliability.

Groundwater protection considerations must address the potential for chemical leaching from treatment residuals. Monitoring wells surrounding facilities utilizing iron salt precipitation methods have detected elevated heavy metal concentrations in approximately 22% of studied sites, necessitating additional containment measures and long-term monitoring programs to ensure environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!