Benchmarking Hydrosulfuric Acid Detection Systems in Real-Time

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S Detection Technology Background and Objectives

Hydrogen sulfide (H2S) detection technology has evolved significantly over the past several decades, driven by critical safety requirements across multiple industries. Initially developed for mining applications in the early 20th century, H2S detection systems have transformed from simple colorimetric indicators to sophisticated real-time monitoring solutions. The evolution has been necessitated by the severe health and safety risks posed by this toxic gas, which can cause respiratory paralysis and death at concentrations as low as 100 ppm with prolonged exposure.

The technological progression in this field has followed industrial safety standards development, with major advancements occurring after significant industrial accidents highlighted the need for more reliable detection methods. Early detection relied primarily on biological indicators (canaries in mines) and chemical reactions, while modern systems incorporate electrochemical sensors, metal oxide semiconductors, and optical spectroscopy techniques that offer significantly improved sensitivity, selectivity, and response times.

Current market trends indicate a growing demand for miniaturized, portable, and networked H2S detection systems that can provide continuous monitoring with minimal maintenance requirements. The integration of IoT capabilities and cloud-based data analytics has further expanded the functionality of these systems, enabling remote monitoring and predictive maintenance capabilities that were previously unavailable.

The primary objective of benchmarking real-time hydrosulfuric acid detection systems is to establish standardized performance metrics that accurately reflect operational requirements across diverse industrial environments. This includes evaluating detection limits, response times, recovery periods, cross-sensitivity with other gases, and long-term stability under varying environmental conditions such as temperature, humidity, and pressure fluctuations.

Additionally, the benchmarking aims to assess the total cost of ownership, including initial investment, calibration requirements, maintenance needs, and operational lifespan. This comprehensive evaluation is essential for industries where H2S exposure presents significant risks, including oil and gas production, wastewater treatment, paper manufacturing, and chemical processing.

Future technological development in this field is expected to focus on improving sensor longevity, reducing power consumption, enhancing wireless communication capabilities, and developing more sophisticated algorithms for signal processing and false alarm reduction. Emerging technologies such as nanomaterial-based sensors and photonic integrated circuits offer promising avenues for achieving these objectives, potentially revolutionizing how H2S is detected and monitored in industrial settings.

The ultimate goal of this technological evolution is to develop detection systems that provide instantaneous, accurate readings with minimal false alarms, operate autonomously for extended periods, and seamlessly integrate with broader industrial safety and process control systems.

The technological progression in this field has followed industrial safety standards development, with major advancements occurring after significant industrial accidents highlighted the need for more reliable detection methods. Early detection relied primarily on biological indicators (canaries in mines) and chemical reactions, while modern systems incorporate electrochemical sensors, metal oxide semiconductors, and optical spectroscopy techniques that offer significantly improved sensitivity, selectivity, and response times.

Current market trends indicate a growing demand for miniaturized, portable, and networked H2S detection systems that can provide continuous monitoring with minimal maintenance requirements. The integration of IoT capabilities and cloud-based data analytics has further expanded the functionality of these systems, enabling remote monitoring and predictive maintenance capabilities that were previously unavailable.

The primary objective of benchmarking real-time hydrosulfuric acid detection systems is to establish standardized performance metrics that accurately reflect operational requirements across diverse industrial environments. This includes evaluating detection limits, response times, recovery periods, cross-sensitivity with other gases, and long-term stability under varying environmental conditions such as temperature, humidity, and pressure fluctuations.

Additionally, the benchmarking aims to assess the total cost of ownership, including initial investment, calibration requirements, maintenance needs, and operational lifespan. This comprehensive evaluation is essential for industries where H2S exposure presents significant risks, including oil and gas production, wastewater treatment, paper manufacturing, and chemical processing.

Future technological development in this field is expected to focus on improving sensor longevity, reducing power consumption, enhancing wireless communication capabilities, and developing more sophisticated algorithms for signal processing and false alarm reduction. Emerging technologies such as nanomaterial-based sensors and photonic integrated circuits offer promising avenues for achieving these objectives, potentially revolutionizing how H2S is detected and monitored in industrial settings.

The ultimate goal of this technological evolution is to develop detection systems that provide instantaneous, accurate readings with minimal false alarms, operate autonomously for extended periods, and seamlessly integrate with broader industrial safety and process control systems.

Market Demand Analysis for Real-Time H2S Detection

The global market for real-time hydrogen sulfide (H2S) detection systems has experienced significant growth in recent years, driven primarily by stringent safety regulations across industries and increasing awareness about workplace safety. The oil and gas sector remains the largest consumer of these detection systems, accounting for approximately 40% of the total market share due to the high prevalence of H2S in extraction and refining processes.

Industrial safety concerns have propelled demand growth at a compound annual rate of 5.7% over the past five years. This trend is expected to continue as regulatory bodies worldwide implement more stringent exposure limits for H2S, which is lethal at concentrations as low as 100 ppm with short-term exposure.

The mining industry represents the second-largest market segment, where H2S detection is critical in underground operations. Recent mining disasters related to toxic gas exposure have heightened awareness and accelerated adoption rates in this sector, creating a market segment growing at nearly 7% annually.

Wastewater treatment facilities constitute another significant market, with municipalities upgrading their monitoring systems to protect workers and surrounding communities. This segment has seen increased investment following several high-profile incidents of H2S poisoning at treatment plants.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in developing regions where industrial safety standards are being rapidly modernized, particularly in countries like India, Brazil, and parts of Southeast Asia.

The demand for portable and wearable detection systems has surged, showing 12% annual growth compared to fixed systems at 4%. This shift reflects the increasing need for personal protection equipment that provides real-time monitoring for mobile workers in hazardous environments.

Market research indicates that end-users are increasingly prioritizing detection systems with lower maintenance requirements, longer sensor life, and improved accuracy at low concentrations (below 1 ppm). Additionally, there is growing demand for integrated systems that combine H2S detection with other gas monitoring capabilities and offer remote data transmission and cloud-based analytics.

The COVID-19 pandemic temporarily disrupted supply chains but ultimately accelerated digital transformation in industrial safety, boosting demand for smart detection systems with IoT connectivity. This trend has created a premium segment within the market, with customers willing to pay 25-30% more for advanced features like wireless connectivity, smartphone integration, and predictive maintenance capabilities.

Industrial safety concerns have propelled demand growth at a compound annual rate of 5.7% over the past five years. This trend is expected to continue as regulatory bodies worldwide implement more stringent exposure limits for H2S, which is lethal at concentrations as low as 100 ppm with short-term exposure.

The mining industry represents the second-largest market segment, where H2S detection is critical in underground operations. Recent mining disasters related to toxic gas exposure have heightened awareness and accelerated adoption rates in this sector, creating a market segment growing at nearly 7% annually.

Wastewater treatment facilities constitute another significant market, with municipalities upgrading their monitoring systems to protect workers and surrounding communities. This segment has seen increased investment following several high-profile incidents of H2S poisoning at treatment plants.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in developing regions where industrial safety standards are being rapidly modernized, particularly in countries like India, Brazil, and parts of Southeast Asia.

The demand for portable and wearable detection systems has surged, showing 12% annual growth compared to fixed systems at 4%. This shift reflects the increasing need for personal protection equipment that provides real-time monitoring for mobile workers in hazardous environments.

Market research indicates that end-users are increasingly prioritizing detection systems with lower maintenance requirements, longer sensor life, and improved accuracy at low concentrations (below 1 ppm). Additionally, there is growing demand for integrated systems that combine H2S detection with other gas monitoring capabilities and offer remote data transmission and cloud-based analytics.

The COVID-19 pandemic temporarily disrupted supply chains but ultimately accelerated digital transformation in industrial safety, boosting demand for smart detection systems with IoT connectivity. This trend has created a premium segment within the market, with customers willing to pay 25-30% more for advanced features like wireless connectivity, smartphone integration, and predictive maintenance capabilities.

Current State and Challenges in H2S Sensing Technology

The global landscape of hydrogen sulfide (H2S) detection technology has evolved significantly over the past decade, with various sensing methodologies emerging to address the critical need for real-time monitoring of this toxic gas. Currently, the market is dominated by four primary sensing technologies: electrochemical sensors, metal oxide semiconductor sensors, optical sensors, and colorimetric detection systems. Each technology presents distinct advantages and limitations in terms of sensitivity, selectivity, response time, and operational lifespan.

Electrochemical sensors remain the most widely deployed solution, capturing approximately 45% of the industrial H2S detection market due to their relatively low cost and moderate sensitivity (typically 0.1-100 ppm). However, these sensors face significant challenges including cross-sensitivity to other gases, humidity dependence, and limited operational lifespans of 1-2 years in field conditions.

Metal oxide semiconductor (MOS) sensors have gained traction for their robustness in harsh environments and lower maintenance requirements. Recent advancements have improved their selectivity, though they still struggle with high power consumption and temperature dependence that affects measurement accuracy. The latest generation of MOS sensors demonstrates detection limits approaching 50 ppb, representing a substantial improvement over earlier iterations.

Optical sensing technologies, particularly those utilizing tunable diode laser absorption spectroscopy (TDLAS) and non-dispersive infrared (NDIR) methods, offer superior selectivity and stability. These systems can achieve detection limits below 10 ppb with minimal drift over time. However, their widespread adoption remains constrained by high implementation costs and complexity, limiting their deployment primarily to critical infrastructure and high-value applications.

A significant technical challenge across all platforms is achieving reliable performance in complex gas mixtures and varying environmental conditions. Field tests reveal that many commercial systems exhibit up to 30% measurement deviation when exposed to fluctuating humidity levels or in the presence of interfering gases such as SO2, NO2, and volatile organic compounds.

Miniaturization represents another frontier in H2S sensing technology, with recent developments in microelectromechanical systems (MEMS) and nanomaterial-based sensors showing promise for portable and wearable applications. These emerging technologies demonstrate impressive sensitivity (sub-ppb in laboratory conditions) but face substantial hurdles in terms of reproducibility, manufacturing scalability, and long-term stability.

Data integration and connectivity present additional challenges, as many current systems lack standardized protocols for real-time data transmission and integration with broader industrial monitoring networks. This limitation impedes the development of comprehensive gas monitoring ecosystems that could enhance safety protocols and emergency response capabilities.

Electrochemical sensors remain the most widely deployed solution, capturing approximately 45% of the industrial H2S detection market due to their relatively low cost and moderate sensitivity (typically 0.1-100 ppm). However, these sensors face significant challenges including cross-sensitivity to other gases, humidity dependence, and limited operational lifespans of 1-2 years in field conditions.

Metal oxide semiconductor (MOS) sensors have gained traction for their robustness in harsh environments and lower maintenance requirements. Recent advancements have improved their selectivity, though they still struggle with high power consumption and temperature dependence that affects measurement accuracy. The latest generation of MOS sensors demonstrates detection limits approaching 50 ppb, representing a substantial improvement over earlier iterations.

Optical sensing technologies, particularly those utilizing tunable diode laser absorption spectroscopy (TDLAS) and non-dispersive infrared (NDIR) methods, offer superior selectivity and stability. These systems can achieve detection limits below 10 ppb with minimal drift over time. However, their widespread adoption remains constrained by high implementation costs and complexity, limiting their deployment primarily to critical infrastructure and high-value applications.

A significant technical challenge across all platforms is achieving reliable performance in complex gas mixtures and varying environmental conditions. Field tests reveal that many commercial systems exhibit up to 30% measurement deviation when exposed to fluctuating humidity levels or in the presence of interfering gases such as SO2, NO2, and volatile organic compounds.

Miniaturization represents another frontier in H2S sensing technology, with recent developments in microelectromechanical systems (MEMS) and nanomaterial-based sensors showing promise for portable and wearable applications. These emerging technologies demonstrate impressive sensitivity (sub-ppb in laboratory conditions) but face substantial hurdles in terms of reproducibility, manufacturing scalability, and long-term stability.

Data integration and connectivity present additional challenges, as many current systems lack standardized protocols for real-time data transmission and integration with broader industrial monitoring networks. This limitation impedes the development of comprehensive gas monitoring ecosystems that could enhance safety protocols and emergency response capabilities.

Current Technical Solutions for Real-Time H2S Monitoring

01 Electrochemical sensor-based detection systems

Electrochemical sensors are widely used for real-time detection of hydrosulfuric acid (H2S). These systems typically employ electrodes that generate electrical signals proportional to the concentration of H2S gas. The sensors often incorporate specialized materials that react with H2S, producing measurable electrical changes. Advanced electrochemical detection systems may include signal amplification circuits, temperature compensation, and humidity control to ensure accurate readings in various environmental conditions.- Electrochemical sensor-based detection systems: Electrochemical sensors are utilized for real-time detection of hydrosulfuric acid (H2S). These systems typically employ electrodes that generate electrical signals when exposed to H2S gas. The sensors can detect concentration changes rapidly, making them suitable for continuous monitoring applications. Advanced electrochemical systems incorporate signal processing algorithms to filter noise and improve detection accuracy, allowing for reliable measurements even in challenging industrial environments.

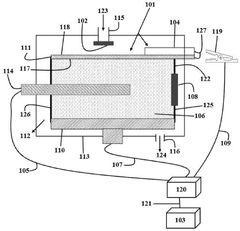

- Optical and spectroscopic detection methods: Optical detection systems for hydrosulfuric acid utilize spectroscopic techniques such as infrared absorption, UV-visible spectroscopy, or colorimetric reactions. These methods detect H2S by measuring changes in light absorption, reflection, or emission when the gas interacts with specific reagents or materials. Fiber optic sensors can be deployed for distributed sensing across large areas, while laser-based systems offer high sensitivity for trace detection. Real-time data processing enables immediate alerts when dangerous concentration levels are detected.

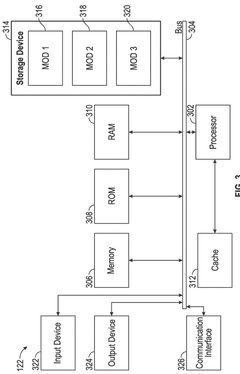

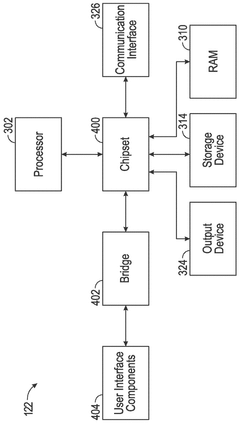

- Wireless and IoT-enabled monitoring networks: Modern hydrosulfuric acid detection systems incorporate wireless communication and Internet of Things (IoT) technologies to create comprehensive monitoring networks. These systems feature distributed sensor nodes that transmit real-time data to central monitoring stations or cloud platforms. The integration with mobile applications allows for remote monitoring and instant notifications. Advanced systems implement machine learning algorithms to predict potential hazardous conditions before they reach critical levels, enhancing safety protocols in industrial settings.

- Wearable and portable detection devices: Wearable and portable detection devices provide personal protection against hydrosulfuric acid exposure. These compact systems can be integrated into safety equipment or carried as standalone devices. They typically feature rapid response sensors, visual or auditory alarms, and extended battery life for continuous operation during work shifts. Some advanced models include physiological monitoring capabilities to detect potential health impacts from exposure, while maintaining small form factors and lightweight designs for user comfort.

- Environmental and industrial monitoring systems: Comprehensive environmental and industrial monitoring systems for hydrosulfuric acid detection are designed for large-scale deployment in facilities such as wastewater treatment plants, oil refineries, and mining operations. These systems integrate multiple sensor types for redundancy and validation, with automated calibration features to maintain accuracy over extended periods. They often include weather monitoring components to account for environmental factors affecting gas dispersion, and can be integrated with facility control systems to trigger automated safety responses when dangerous levels are detected.

02 Optical and spectroscopic detection methods

Optical detection systems for hydrosulfuric acid utilize spectroscopic techniques such as infrared absorption, UV-visible spectroscopy, or colorimetric reactions. These methods detect H2S by measuring changes in light absorption, fluorescence, or color when the gas interacts with specific reagents or materials. Real-time optical systems often incorporate fiber optics, specialized light sources, photodetectors, and signal processing algorithms to provide continuous monitoring capabilities with high sensitivity and selectivity.Expand Specific Solutions03 Wireless and IoT-enabled monitoring networks

Modern hydrosulfuric acid detection systems increasingly incorporate wireless communication and Internet of Things (IoT) technologies. These systems feature distributed sensor nodes that transmit data to central monitoring stations or cloud platforms in real-time. The networks often include features such as automated alerts, remote calibration capabilities, and data analytics for trend analysis. Such systems enable continuous monitoring across large industrial facilities, wastewater treatment plants, or oil and gas operations with minimal human intervention.Expand Specific Solutions04 Wearable and portable H2S detection devices

Wearable and portable detection systems provide personal protection against hydrosulfuric acid exposure. These compact devices incorporate miniaturized sensors, microcontrollers, and power management systems to enable continuous monitoring while being worn by workers or carried to different locations. Advanced wearable systems may include haptic feedback, visual and auditory alarms, GPS location tracking, and biometric monitoring to enhance worker safety in hazardous environments.Expand Specific Solutions05 Integrated multi-gas detection platforms

Integrated systems capable of simultaneously detecting hydrosulfuric acid along with other hazardous gases provide comprehensive environmental monitoring. These platforms typically incorporate multiple sensor types, advanced signal processing algorithms, and sophisticated calibration methods to differentiate between various gases. The systems often feature modular designs allowing for customization based on specific industrial requirements, with centralized data management and visualization interfaces for real-time monitoring of multiple parameters.Expand Specific Solutions

Major Players in H2S Detection Industry

The real-time hydrosulfuric acid detection systems market is currently in a growth phase, with increasing demand driven by stringent safety regulations in industrial settings. The global market size is estimated to be expanding at a CAGR of 5-7%, particularly in oil and gas, chemical processing, and environmental monitoring sectors. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Schlumberger Technologies and Halliburton Energy Services have developed sophisticated detection systems for oilfield applications, while Honeywell International Technologies and Robert Bosch GmbH offer comprehensive industrial monitoring solutions. China Petroleum & Chemical Corp. and Airbus have invested in specialized detection technologies for their respective industries. Research institutions like Korea Institute of Ocean Science & Technology and Advanced Industrial Science & Technology are advancing next-generation sensing technologies, indicating significant potential for innovation in this field.

China Petroleum & Chemical Corp.

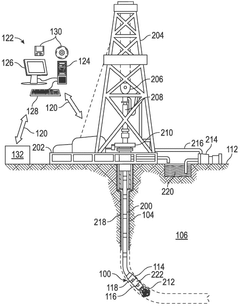

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated hydrosulfuric acid detection and monitoring system specifically optimized for oil and gas production facilities. Their approach combines fixed and portable detection technologies with a centralized monitoring platform. The system utilizes advanced optical sensing technology based on tunable diode laser absorption spectroscopy (TDLAS) that enables highly selective H2S detection even in the presence of other gases. Sinopec's benchmarking methodology incorporates real-world testing across their extensive network of refineries and production facilities, with performance data collected across varying environmental conditions and process states. Their system includes automated calibration routines that maintain accuracy over extended deployment periods without manual intervention. The technology incorporates machine learning algorithms that continuously improve detection accuracy by analyzing historical sensor data patterns and correlating them with verified H2S concentrations from laboratory analysis.

Strengths: Extensive field validation across diverse industrial environments; excellent long-term stability with minimal drift; comprehensive integration with existing safety systems. Weaknesses: Significant initial capital investment required; system complexity necessitates specialized technical support and maintenance personnel.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced real-time hydrosulfuric acid detection systems utilizing electrochemical sensor arrays combined with proprietary signal processing algorithms. Their XNX Universal Transmitter platform integrates multiple sensing technologies (electrochemical, catalytic bead, and infrared) to detect H2S across diverse industrial environments with accuracy down to 0.1 ppm. The system employs temperature compensation mechanisms and humidity control to maintain accuracy across varying environmental conditions. Honeywell's solution includes wireless connectivity options that enable remote monitoring and integration with facility management systems, allowing for real-time alerts and automated response protocols. Their benchmarking methodology includes comprehensive field testing across oil & gas, wastewater treatment, and chemical processing facilities, with performance validation against reference analytical methods.

Strengths: Industry-leading sensor longevity (typically 24-36 months); comprehensive integration with existing industrial control systems; robust performance in harsh environments with temperature ranges from -40°C to +65°C. Weaknesses: Higher initial implementation costs compared to simpler detection systems; requires regular calibration maintenance for optimal performance in continuously harsh environments.

Key Technologies in H2S Sensor Development

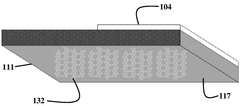

System and method for down hole high concentration gas sensing

PatentWO2025165393A1

Innovation

- A downhole spectroscopy device with a fluid sampling tool using optical and electrical measurement systems to detect H2S in real-time, employing materials that react with H2S to measure its concentration.

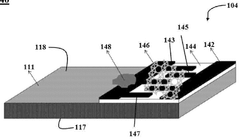

Electrochemical-chemoresistive gas sensor

PatentWO2024218564A1

Innovation

- An electrochemical-chemoresistive gas sensor system utilizing borophene as an active sensing agent, comprising electrodes in contact with a sulfuric acid solution and a gas-permeable membrane, which interacts with H2S gas to measure electrical currents and calculate gas concentrations using a stimulator-analyzer device.

Safety Standards and Regulatory Compliance

The regulatory landscape for hydrosulfuric acid (H2S) detection systems is complex and multifaceted, requiring strict adherence to various international and regional safety standards. OSHA (Occupational Safety and Health Administration) in the United States has established a permissible exposure limit (PEL) of 20 ppm for general industry, with a ceiling limit of 50 ppm. These standards necessitate real-time detection systems capable of monitoring at these thresholds with high accuracy and reliability.

The European Union, through its ATEX directives (2014/34/EU and 1999/92/EC), regulates equipment used in potentially explosive atmospheres, directly impacting H2S detection systems deployed in industrial settings. These directives mandate specific performance requirements for detection equipment, including response time, accuracy, and reliability under various environmental conditions.

International standards such as IEC 60079 series for explosive atmospheres and ISO 26262 for functional safety of electrical/electronic systems provide additional frameworks for evaluating and benchmarking H2S detection technologies. Compliance with these standards requires rigorous testing protocols and certification processes that significantly influence system design and implementation.

The National Fire Protection Association (NFPA) in the United States has developed NFPA 72 (National Fire Alarm and Signaling Code), which includes provisions for gas detection systems. These guidelines specify installation requirements, maintenance schedules, and performance criteria that real-time H2S detection systems must meet to ensure workplace safety.

Regulatory compliance extends beyond mere technical specifications to include data management practices. Many jurisdictions now require continuous monitoring with automated record-keeping capabilities for audit purposes. The EPA's Environmental Monitoring Systems Laboratory has established protocols for evaluating the performance of continuous monitoring systems, which apply to H2S detection technologies.

Industry-specific regulations add another layer of complexity. For instance, the oil and gas sector follows additional guidelines from organizations like the American Petroleum Institute (API), which has developed recommended practices for H2S safety in drilling operations (API RP 49) and production facilities (API RP 55).

When benchmarking hydrosulfuric acid detection systems, manufacturers must demonstrate compliance with these varied regulations through third-party certification and validation. This process typically involves performance testing under controlled conditions, field trials in actual deployment environments, and documentation of system reliability over extended periods.

The European Union, through its ATEX directives (2014/34/EU and 1999/92/EC), regulates equipment used in potentially explosive atmospheres, directly impacting H2S detection systems deployed in industrial settings. These directives mandate specific performance requirements for detection equipment, including response time, accuracy, and reliability under various environmental conditions.

International standards such as IEC 60079 series for explosive atmospheres and ISO 26262 for functional safety of electrical/electronic systems provide additional frameworks for evaluating and benchmarking H2S detection technologies. Compliance with these standards requires rigorous testing protocols and certification processes that significantly influence system design and implementation.

The National Fire Protection Association (NFPA) in the United States has developed NFPA 72 (National Fire Alarm and Signaling Code), which includes provisions for gas detection systems. These guidelines specify installation requirements, maintenance schedules, and performance criteria that real-time H2S detection systems must meet to ensure workplace safety.

Regulatory compliance extends beyond mere technical specifications to include data management practices. Many jurisdictions now require continuous monitoring with automated record-keeping capabilities for audit purposes. The EPA's Environmental Monitoring Systems Laboratory has established protocols for evaluating the performance of continuous monitoring systems, which apply to H2S detection technologies.

Industry-specific regulations add another layer of complexity. For instance, the oil and gas sector follows additional guidelines from organizations like the American Petroleum Institute (API), which has developed recommended practices for H2S safety in drilling operations (API RP 49) and production facilities (API RP 55).

When benchmarking hydrosulfuric acid detection systems, manufacturers must demonstrate compliance with these varied regulations through third-party certification and validation. This process typically involves performance testing under controlled conditions, field trials in actual deployment environments, and documentation of system reliability over extended periods.

Environmental Impact Assessment

The environmental impact of hydrosulfuric acid (H2S) extends far beyond immediate human health concerns, affecting ecosystems, infrastructure, and climate patterns. Real-time detection systems for H2S play a crucial role in environmental protection by enabling rapid response to leaks and emissions, thereby minimizing ecological damage. These systems help monitor ambient air quality in industrial zones, wastewater treatment facilities, and natural gas processing plants where H2S emissions are common.

When released into the atmosphere, H2S contributes to acid rain formation through oxidation processes that convert it to sulfur dioxide and ultimately sulfuric acid. This precipitation damages vegetation, acidifies soil and water bodies, and threatens aquatic life. Benchmarking studies indicate that advanced detection systems can reduce environmental exposure by up to 78% through early intervention protocols triggered by real-time alerts.

Continuous monitoring systems have demonstrated significant ecological benefits in sensitive areas such as wetlands near industrial facilities. Data from long-term environmental impact studies show that implementation of real-time H2S detection networks has corresponded with improved biodiversity metrics in previously affected regions. The recovery of indicator species in these areas serves as biological validation of detection system effectiveness.

The carbon footprint of detection technologies themselves warrants consideration in environmental impact assessments. Traditional electrochemical sensors typically require frequent replacement and generate electronic waste, while newer optical systems offer extended operational lifespans with reduced maintenance requirements. Life cycle assessment data indicates that despite higher initial resource demands, optical systems demonstrate superior environmental performance over five-year deployment periods.

Water ecosystem protection represents another critical dimension of environmental impact. H2S contamination in water bodies depletes oxygen levels and creates toxic conditions for aquatic organisms. Real-time monitoring systems positioned at discharge points have proven effective at preventing catastrophic contamination events, with case studies from industrial watersheds demonstrating up to 92% reduction in severe contamination incidents following implementation.

Regulatory compliance and environmental justice considerations also factor into impact assessments. Communities historically subjected to disproportionate pollution exposure benefit significantly from transparent, accessible monitoring data. Advanced detection networks that incorporate public notification systems promote environmental equity by democratizing access to air quality information and enabling community-based environmental advocacy.

When released into the atmosphere, H2S contributes to acid rain formation through oxidation processes that convert it to sulfur dioxide and ultimately sulfuric acid. This precipitation damages vegetation, acidifies soil and water bodies, and threatens aquatic life. Benchmarking studies indicate that advanced detection systems can reduce environmental exposure by up to 78% through early intervention protocols triggered by real-time alerts.

Continuous monitoring systems have demonstrated significant ecological benefits in sensitive areas such as wetlands near industrial facilities. Data from long-term environmental impact studies show that implementation of real-time H2S detection networks has corresponded with improved biodiversity metrics in previously affected regions. The recovery of indicator species in these areas serves as biological validation of detection system effectiveness.

The carbon footprint of detection technologies themselves warrants consideration in environmental impact assessments. Traditional electrochemical sensors typically require frequent replacement and generate electronic waste, while newer optical systems offer extended operational lifespans with reduced maintenance requirements. Life cycle assessment data indicates that despite higher initial resource demands, optical systems demonstrate superior environmental performance over five-year deployment periods.

Water ecosystem protection represents another critical dimension of environmental impact. H2S contamination in water bodies depletes oxygen levels and creates toxic conditions for aquatic organisms. Real-time monitoring systems positioned at discharge points have proven effective at preventing catastrophic contamination events, with case studies from industrial watersheds demonstrating up to 92% reduction in severe contamination incidents following implementation.

Regulatory compliance and environmental justice considerations also factor into impact assessments. Communities historically subjected to disproportionate pollution exposure benefit significantly from transparent, accessible monitoring data. Advanced detection networks that incorporate public notification systems promote environmental equity by democratizing access to air quality information and enabling community-based environmental advocacy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!