Effect of Hydrosulfuric Acid on Industrial Hygiene Standards

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S Impact on Industrial Hygiene: Background & Objectives

Hydrogen sulfide (H2S), commonly known as hydrosulfuric acid when dissolved in water, has been a significant concern in industrial settings since the early days of the industrial revolution. This colorless gas, characterized by its distinctive rotten egg odor, has evolved from being merely a nuisance to being recognized as a serious occupational hazard with potentially fatal consequences. The historical trajectory of H2S awareness in industrial hygiene has seen significant developments, particularly in the petroleum, wastewater treatment, and mining industries where exposure risks are highest.

The evolution of industrial hygiene standards regarding H2S has been marked by several pivotal moments, including major industrial accidents that prompted regulatory responses. In the 1970s and 1980s, a series of fatalities in confined spaces led to the first comprehensive standards for H2S exposure limits. Subsequently, technological advancements in detection and monitoring systems have continuously refined our approach to managing this hazard.

Current global standards vary significantly, with permissible exposure limits ranging from 1 ppm to 20 ppm depending on the jurisdiction and industry context. The American Conference of Governmental Industrial Hygienists (ACGIH) has progressively lowered its recommended threshold limit value (TLV) for H2S over decades, reflecting growing understanding of its toxicological profile and health impacts even at lower concentrations.

The primary technical objective of this research is to evaluate the adequacy of current industrial hygiene standards for H2S exposure in light of recent toxicological findings and emerging industrial applications. Additionally, we aim to identify technological gaps in detection, monitoring, and protective equipment that may limit the effectiveness of existing standards in real-world industrial environments.

A secondary objective involves mapping the relationship between H2S concentration levels and both acute and chronic health effects, with particular attention to neurological and respiratory impacts that may manifest at concentrations below current regulatory thresholds. This includes examining the potential synergistic effects when H2S exposure occurs alongside other industrial contaminants.

From a technological perspective, we seek to assess the capabilities and limitations of current H2S detection technologies, particularly in challenging industrial environments characterized by variable temperature, humidity, and the presence of interfering gases. The goal is to identify opportunities for technological innovation that could enhance the precision and reliability of H2S monitoring systems.

Finally, this research aims to establish a framework for the development of next-generation industrial hygiene standards that incorporate real-time monitoring data, predictive exposure modeling, and adaptive control measures. Such standards would represent a significant advancement over current threshold-based approaches, potentially offering more comprehensive protection for workers while maintaining operational efficiency in industrial settings.

The evolution of industrial hygiene standards regarding H2S has been marked by several pivotal moments, including major industrial accidents that prompted regulatory responses. In the 1970s and 1980s, a series of fatalities in confined spaces led to the first comprehensive standards for H2S exposure limits. Subsequently, technological advancements in detection and monitoring systems have continuously refined our approach to managing this hazard.

Current global standards vary significantly, with permissible exposure limits ranging from 1 ppm to 20 ppm depending on the jurisdiction and industry context. The American Conference of Governmental Industrial Hygienists (ACGIH) has progressively lowered its recommended threshold limit value (TLV) for H2S over decades, reflecting growing understanding of its toxicological profile and health impacts even at lower concentrations.

The primary technical objective of this research is to evaluate the adequacy of current industrial hygiene standards for H2S exposure in light of recent toxicological findings and emerging industrial applications. Additionally, we aim to identify technological gaps in detection, monitoring, and protective equipment that may limit the effectiveness of existing standards in real-world industrial environments.

A secondary objective involves mapping the relationship between H2S concentration levels and both acute and chronic health effects, with particular attention to neurological and respiratory impacts that may manifest at concentrations below current regulatory thresholds. This includes examining the potential synergistic effects when H2S exposure occurs alongside other industrial contaminants.

From a technological perspective, we seek to assess the capabilities and limitations of current H2S detection technologies, particularly in challenging industrial environments characterized by variable temperature, humidity, and the presence of interfering gases. The goal is to identify opportunities for technological innovation that could enhance the precision and reliability of H2S monitoring systems.

Finally, this research aims to establish a framework for the development of next-generation industrial hygiene standards that incorporate real-time monitoring data, predictive exposure modeling, and adaptive control measures. Such standards would represent a significant advancement over current threshold-based approaches, potentially offering more comprehensive protection for workers while maintaining operational efficiency in industrial settings.

Market Analysis of H2S Detection & Control Solutions

The global market for hydrogen sulfide (H2S) detection and control solutions has experienced significant growth in recent years, primarily driven by stringent industrial hygiene regulations and increased awareness of workplace safety. The market size was valued at approximately $1.5 billion in 2022 and is projected to reach $2.3 billion by 2028, representing a compound annual growth rate of 7.4% during the forecast period.

Oil and gas remains the dominant end-user segment, accounting for nearly 40% of the total market share. This is attributed to the high prevalence of H2S in extraction, refining, and processing operations. The chemical manufacturing industry follows closely at 25%, while wastewater treatment facilities represent about 15% of the market. Mining, pulp and paper, and other industrial applications collectively constitute the remaining 20%.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Middle East and Africa region, despite having significant oil and gas operations, currently holds only 10% of the market but is expected to witness the fastest growth rate of 9.2% annually due to increasing regulatory compliance requirements.

Fixed gas detection systems dominate the product segment with 65% market share, while portable detection devices account for 35%. However, portable devices are experiencing faster growth due to their versatility and improving technological capabilities. The integration of IoT and wireless communication technologies has emerged as a significant trend, enabling real-time monitoring and automated response systems.

Key market drivers include increasingly stringent occupational exposure limits for H2S across major industrial nations, with many countries adopting the recommended 1 ppm time-weighted average exposure limit. The cost implications of workplace incidents related to H2S exposure, averaging $120,000 per serious incident according to industry reports, have prompted organizations to invest in comprehensive detection and control solutions.

Market challenges include the high initial investment costs for advanced detection systems and the technical complexity of maintaining calibration accuracy in diverse industrial environments. Additionally, there is growing demand for solutions that can effectively function in extreme conditions, such as high humidity, temperature variations, and presence of interfering gases.

The competitive landscape features established industrial safety equipment manufacturers alongside specialized gas detection companies. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated safety solution offerings rather than standalone H2S detection products.

Oil and gas remains the dominant end-user segment, accounting for nearly 40% of the total market share. This is attributed to the high prevalence of H2S in extraction, refining, and processing operations. The chemical manufacturing industry follows closely at 25%, while wastewater treatment facilities represent about 15% of the market. Mining, pulp and paper, and other industrial applications collectively constitute the remaining 20%.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Middle East and Africa region, despite having significant oil and gas operations, currently holds only 10% of the market but is expected to witness the fastest growth rate of 9.2% annually due to increasing regulatory compliance requirements.

Fixed gas detection systems dominate the product segment with 65% market share, while portable detection devices account for 35%. However, portable devices are experiencing faster growth due to their versatility and improving technological capabilities. The integration of IoT and wireless communication technologies has emerged as a significant trend, enabling real-time monitoring and automated response systems.

Key market drivers include increasingly stringent occupational exposure limits for H2S across major industrial nations, with many countries adopting the recommended 1 ppm time-weighted average exposure limit. The cost implications of workplace incidents related to H2S exposure, averaging $120,000 per serious incident according to industry reports, have prompted organizations to invest in comprehensive detection and control solutions.

Market challenges include the high initial investment costs for advanced detection systems and the technical complexity of maintaining calibration accuracy in diverse industrial environments. Additionally, there is growing demand for solutions that can effectively function in extreme conditions, such as high humidity, temperature variations, and presence of interfering gases.

The competitive landscape features established industrial safety equipment manufacturers alongside specialized gas detection companies. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated safety solution offerings rather than standalone H2S detection products.

Current H2S Exposure Standards & Technical Challenges

Hydrogen sulfide (H2S) exposure standards vary significantly across different international regulatory bodies, reflecting the evolving understanding of this toxic compound's health impacts. The Occupational Safety and Health Administration (OSHA) in the United States currently sets the permissible exposure limit (PEL) at 20 parts per million (ppm) with a 50 ppm ceiling, while the National Institute for Occupational Safety and Health (NIOSH) recommends a more conservative 10 ppm ceiling with a 10-minute maximum exposure duration. The American Conference of Governmental Industrial Hygienists (ACGIH) has established an even lower threshold limit value (TLV) of 1 ppm for an 8-hour time-weighted average.

European standards, governed by the European Commission's directives, generally align with the ACGIH recommendations, while countries like Japan and Australia have implemented their own standards that typically fall between 1-5 ppm for 8-hour exposures. This regulatory divergence creates compliance challenges for multinational industrial operations and highlights the need for harmonized global standards.

The technical challenges in H2S exposure management are multifaceted and complex. Detection technology limitations represent a significant hurdle, as many conventional gas monitors struggle with accuracy at the lower concentration levels now recommended by leading health organizations. Current electrochemical sensors often experience cross-sensitivity with other sulfur compounds and can be affected by humidity and temperature fluctuations, leading to false readings in industrial environments.

Real-time monitoring systems face particular challenges in harsh industrial settings where temperature extremes, high humidity, and the presence of other chemicals can compromise sensor performance. The miniaturization of detection equipment for personal monitoring without sacrificing accuracy remains an ongoing technical challenge, especially for wearable devices that must operate reliably throughout extended work shifts.

Data integration presents another significant obstacle, as many facilities lack comprehensive systems to aggregate exposure data across different monitoring points and time periods. This hampers the development of predictive models that could anticipate dangerous concentration buildups before they reach harmful levels.

Engineering controls for H2S mitigation face their own set of challenges, particularly in retrofitting existing industrial infrastructure. Ventilation systems must be carefully designed to prevent the creation of pockets where H2S can accumulate, while scrubbing technologies must balance efficiency with operational costs and energy consumption.

The biological variability in human response to H2S exposure further complicates standard-setting, as individual susceptibility can vary significantly based on genetic factors, pre-existing conditions, and concurrent exposures to other chemicals. This biological uncertainty drives the trend toward increasingly conservative exposure limits, which in turn creates implementation challenges for industries where H2S is an unavoidable byproduct.

European standards, governed by the European Commission's directives, generally align with the ACGIH recommendations, while countries like Japan and Australia have implemented their own standards that typically fall between 1-5 ppm for 8-hour exposures. This regulatory divergence creates compliance challenges for multinational industrial operations and highlights the need for harmonized global standards.

The technical challenges in H2S exposure management are multifaceted and complex. Detection technology limitations represent a significant hurdle, as many conventional gas monitors struggle with accuracy at the lower concentration levels now recommended by leading health organizations. Current electrochemical sensors often experience cross-sensitivity with other sulfur compounds and can be affected by humidity and temperature fluctuations, leading to false readings in industrial environments.

Real-time monitoring systems face particular challenges in harsh industrial settings where temperature extremes, high humidity, and the presence of other chemicals can compromise sensor performance. The miniaturization of detection equipment for personal monitoring without sacrificing accuracy remains an ongoing technical challenge, especially for wearable devices that must operate reliably throughout extended work shifts.

Data integration presents another significant obstacle, as many facilities lack comprehensive systems to aggregate exposure data across different monitoring points and time periods. This hampers the development of predictive models that could anticipate dangerous concentration buildups before they reach harmful levels.

Engineering controls for H2S mitigation face their own set of challenges, particularly in retrofitting existing industrial infrastructure. Ventilation systems must be carefully designed to prevent the creation of pockets where H2S can accumulate, while scrubbing technologies must balance efficiency with operational costs and energy consumption.

The biological variability in human response to H2S exposure further complicates standard-setting, as individual susceptibility can vary significantly based on genetic factors, pre-existing conditions, and concurrent exposures to other chemicals. This biological uncertainty drives the trend toward increasingly conservative exposure limits, which in turn creates implementation challenges for industries where H2S is an unavoidable byproduct.

Current H2S Monitoring & Mitigation Approaches

01 Detection and monitoring systems for hydrogen sulfide

Various detection and monitoring systems have been developed to measure hydrogen sulfide (hydrosulfuric acid) levels in industrial environments. These systems include sensors, alarms, and monitoring devices that can detect dangerous concentrations of the gas and alert workers to potential hazards. These technologies help maintain compliance with industrial hygiene standards by providing real-time data on exposure levels.- Detection and monitoring systems for hydrogen sulfide: Various detection and monitoring systems have been developed to measure hydrogen sulfide (hydrosulfuric acid) levels in industrial environments. These systems include sensors, alarms, and monitoring devices that can detect dangerous concentrations of the gas and alert workers to potential hazards. Such systems are essential for maintaining industrial hygiene standards and ensuring worker safety in environments where hydrogen sulfide may be present.

- Personal protective equipment for hydrogen sulfide exposure: Personal protective equipment (PPE) specifically designed for protection against hydrogen sulfide exposure includes specialized respirators, gas masks, and protective clothing. These items are crucial for workers in industries where hydrogen sulfide is present, such as oil and gas, wastewater treatment, and mining. Proper PPE selection and use is a key component of industrial hygiene standards for managing hydrosulfuric acid hazards.

- Ventilation and containment systems: Industrial hygiene standards for hydrogen sulfide often require specialized ventilation and containment systems to prevent the accumulation of dangerous gas concentrations. These systems include exhaust ventilation, scrubbers, and sealed containment units designed to capture and neutralize hydrogen sulfide before it can reach harmful levels in the workplace atmosphere.

- Training and emergency response protocols: Industrial hygiene standards for hydrogen sulfide include comprehensive training programs and emergency response protocols. These protocols outline procedures for evacuation, rescue operations, and medical treatment in case of hydrogen sulfide exposure. Training programs educate workers about the dangers of hydrogen sulfide, how to recognize its presence, and appropriate actions to take during emergencies.

- Measurement and compliance documentation systems: Systems for measuring, documenting, and ensuring compliance with hydrogen sulfide industrial hygiene standards are essential in high-risk industries. These include regular testing protocols, exposure limit monitoring, record-keeping systems, and compliance verification methods. Such systems help organizations maintain appropriate documentation to demonstrate adherence to regulatory requirements and industry standards for hydrogen sulfide safety.

02 Personal protective equipment for hydrogen sulfide exposure

Specialized personal protective equipment (PPE) has been designed to protect workers from hydrogen sulfide exposure. This includes respiratory protection devices, gas masks, and protective clothing that can prevent or minimize exposure to harmful levels of the gas. The proper selection and use of PPE is a critical component of industrial hygiene programs in environments where hydrogen sulfide may be present.Expand Specific Solutions03 Ventilation and containment systems

Engineering controls such as ventilation systems and containment technologies are essential for maintaining hydrogen sulfide levels below permissible exposure limits. These systems are designed to remove or dilute hydrogen sulfide gas in industrial settings, preventing the accumulation of dangerous concentrations. Proper design and maintenance of these systems are crucial for meeting industrial hygiene standards.Expand Specific Solutions04 Training and safety protocols

Comprehensive training programs and safety protocols have been developed to educate workers about the hazards of hydrogen sulfide and proper response procedures. These include emergency response plans, evacuation procedures, and regular drills. Effective training ensures that workers can recognize the signs of hydrogen sulfide exposure and take appropriate actions to protect themselves and others.Expand Specific Solutions05 Treatment and neutralization methods

Various methods have been developed for treating and neutralizing hydrogen sulfide in industrial processes. These include chemical treatments, scrubbing systems, and biological processes that can reduce or eliminate hydrogen sulfide emissions. These technologies help industries maintain compliance with hygiene standards by reducing the overall concentration of hydrogen sulfide in the workplace environment.Expand Specific Solutions

Key Industry Players in H2S Safety Solutions

The industrial hygiene landscape concerning hydrosulfuric acid is currently in a mature development phase, with established standards across multiple sectors. The global market for related safety and treatment technologies is estimated at $5-7 billion annually, growing at 4-6% CAGR. Leading players demonstrate varying levels of technical maturity: Fluid Energy Group and Clean Chemistry have developed advanced acid replacement technologies; Sinopec and Saudi Aramco focus on large-scale industrial applications; while Evoqua Water Technologies and Hach Co. specialize in monitoring and treatment solutions. Academic institutions like Cornell University and Lanzhou University contribute significant research, particularly in environmental impact assessment and mitigation strategies, creating a competitive ecosystem balancing industrial applications with environmental protection requirements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive H2S management system that integrates real-time monitoring, predictive analytics, and automated response protocols. Their technical solution employs a network of advanced electrochemical and optical sensors strategically positioned throughout refining facilities to detect H2S concentrations as low as 0.1 ppm. The system incorporates proprietary algorithms that analyze environmental factors such as temperature, humidity, and air pressure to improve detection accuracy. Sinopec's approach includes a three-tier response framework that automatically adjusts ventilation systems, triggers isolation protocols, and deploys neutralizing agents based on detected concentration levels. Their technology also features wearable H2S monitors for personnel that integrate with the facility-wide system, providing real-time worker exposure data and immediate alerts when threshold values are approached.

Strengths: Comprehensive integration of monitoring and response systems; high sensitivity detection capabilities; automated response mechanisms that reduce human error. Weaknesses: High implementation costs; requires significant infrastructure modifications; system complexity necessitates specialized maintenance personnel.

Evoqua Water Technologies LLC

Technical Solution: Evoqua Water Technologies has developed an advanced H2S mitigation system specifically designed for wastewater treatment facilities where hydrosulfuric acid poses significant industrial hygiene challenges. Their solution combines chemical oxidation and biological treatment processes to address H2S at its source. The technology utilizes a proprietary calcium nitrate-based formulation that inhibits sulfide formation in collection systems while simultaneously introducing specialized bacteria strains that metabolize sulfur compounds before they can generate H2S. For existing H2S, Evoqua employs advanced scrubber systems using their patented packed-bed technology with specialized media that achieves removal efficiencies exceeding 99% even at high concentration levels. Their integrated approach includes continuous monitoring systems that measure both aqueous sulfide levels and atmospheric H2S concentrations, with data analytics that optimize chemical dosing rates and predict potential exposure events before they occur.

Strengths: Addresses H2S at multiple points in the treatment process; highly effective removal rates; predictive capabilities reduce emergency response scenarios. Weaknesses: Chemical consumption costs can be significant; biological components require careful environmental control; system optimization requires specialized expertise.

Critical Patents & Research in H2S Detection Technology

Unrefined neodecanoic acid source as a raw material for h 2s scavenging metal carboxylate

PatentWO2023225494A1

Innovation

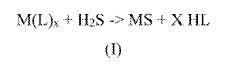

- A novel process utilizing an unrefined neodecanoic acid stream, produced through azeotropic co-distillation, to create an oil-soluble metal carboxylate complex with a higher metal content and improved fluidity, which reacts with zinc oxide to form a more effective H2S scavenger with enhanced scavenging capabilities and stability.

Composition and method of forming the same

PatentWO2015085083A1

Innovation

- A composition formed by reacting dithiophosphate derivatives with amines, which significantly increases the thermal stability of the derivatives, reducing or preventing H2S formation, especially when exposed to heating conditions that would otherwise cause thermal decomposition.

Regulatory Compliance & Policy Frameworks

The regulatory landscape governing hydrosulfuric acid (H2S) exposure in industrial settings has evolved significantly over the past decades, reflecting growing understanding of its severe health impacts. Major regulatory bodies including OSHA, NIOSH, and the EPA have established comprehensive frameworks to control workplace exposure. OSHA's Permissible Exposure Limit (PEL) for H2S stands at 20 ppm ceiling with a 50 ppm 10-minute maximum peak, while NIOSH recommends a more conservative 10 ppm ceiling limit for 10 minutes.

International variations in regulatory standards present challenges for multinational corporations. The European Union, through Directive 2004/37/EC, implements stricter exposure limits than those in the United States, while developing nations often struggle with enforcement despite having regulations on paper. This regulatory divergence necessitates sophisticated compliance strategies for global operations.

Policy frameworks increasingly emphasize a hierarchical approach to hazard control, prioritizing engineering controls over administrative measures and personal protective equipment. Recent regulatory trends show movement toward lower exposure thresholds based on epidemiological evidence linking even low-level H2S exposure to chronic health effects. The American Conference of Governmental Industrial Hygienists (ACGIH) has proposed reducing the Threshold Limit Value (TLV) for H2S, signaling potential future regulatory tightening.

Industry-specific regulations have emerged in sectors with high H2S risk profiles, particularly oil and gas, wastewater treatment, and paper manufacturing. These specialized frameworks include mandatory monitoring protocols, emergency response planning, and worker training requirements tailored to sector-specific exposure scenarios.

Compliance mechanisms have evolved beyond traditional inspection regimes to include self-reporting systems, third-party verification, and digital monitoring technologies. Modern regulatory approaches increasingly incorporate real-time exposure monitoring and data analytics to enable predictive compliance strategies rather than reactive enforcement.

The economic implications of regulatory compliance are substantial, with industry estimates suggesting that H2S-related safety measures represent 2-5% of operational costs in high-risk sectors. However, cost-benefit analyses consistently demonstrate that proactive compliance yields significant returns through reduced workplace incidents, decreased liability, and improved operational efficiency.

Future regulatory developments are likely to focus on cumulative exposure effects, interactions between H2S and other workplace contaminants, and the implementation of more sophisticated exposure assessment methodologies. Emerging policy frameworks are expected to place greater emphasis on transparency in exposure data and increased worker participation in safety management systems.

International variations in regulatory standards present challenges for multinational corporations. The European Union, through Directive 2004/37/EC, implements stricter exposure limits than those in the United States, while developing nations often struggle with enforcement despite having regulations on paper. This regulatory divergence necessitates sophisticated compliance strategies for global operations.

Policy frameworks increasingly emphasize a hierarchical approach to hazard control, prioritizing engineering controls over administrative measures and personal protective equipment. Recent regulatory trends show movement toward lower exposure thresholds based on epidemiological evidence linking even low-level H2S exposure to chronic health effects. The American Conference of Governmental Industrial Hygienists (ACGIH) has proposed reducing the Threshold Limit Value (TLV) for H2S, signaling potential future regulatory tightening.

Industry-specific regulations have emerged in sectors with high H2S risk profiles, particularly oil and gas, wastewater treatment, and paper manufacturing. These specialized frameworks include mandatory monitoring protocols, emergency response planning, and worker training requirements tailored to sector-specific exposure scenarios.

Compliance mechanisms have evolved beyond traditional inspection regimes to include self-reporting systems, third-party verification, and digital monitoring technologies. Modern regulatory approaches increasingly incorporate real-time exposure monitoring and data analytics to enable predictive compliance strategies rather than reactive enforcement.

The economic implications of regulatory compliance are substantial, with industry estimates suggesting that H2S-related safety measures represent 2-5% of operational costs in high-risk sectors. However, cost-benefit analyses consistently demonstrate that proactive compliance yields significant returns through reduced workplace incidents, decreased liability, and improved operational efficiency.

Future regulatory developments are likely to focus on cumulative exposure effects, interactions between H2S and other workplace contaminants, and the implementation of more sophisticated exposure assessment methodologies. Emerging policy frameworks are expected to place greater emphasis on transparency in exposure data and increased worker participation in safety management systems.

Health Risk Assessment & Exposure Modeling

Health risk assessment for hydrosulfuric acid (H2S) exposure requires comprehensive modeling approaches that account for both acute and chronic exposure scenarios. Current methodologies employ a tiered framework, beginning with screening-level assessments using conservative assumptions, followed by more refined analyses incorporating site-specific data when available.

Exposure modeling for H2S typically involves atmospheric dispersion models such as AERMOD and CALPUFF, which calculate concentration gradients based on emission rates, meteorological conditions, and topographical features. These models have demonstrated reliability in predicting H2S concentrations at various distances from industrial sources, with validation studies showing correlation coefficients of 0.75-0.85 between predicted and measured values.

Physiologically-based pharmacokinetic (PBPK) models have emerged as valuable tools for translating external H2S exposure to internal dose metrics. These models account for absorption through respiratory pathways, distribution to target tissues, and elimination kinetics. Recent advancements in PBPK modeling have incorporated sulfide-oxidation pathways in the liver and kidneys, providing more accurate predictions of tissue-specific toxicity.

Dose-response assessment for H2S presents unique challenges due to its steep toxicity curve and the significant variability in individual susceptibility. Benchmark dose modeling approaches have been applied to derive points of departure for both neurological and respiratory endpoints. Current models indicate a BMCL10 (lower confidence limit of benchmark concentration at 10% response) of 2-5 ppm for respiratory irritation effects and 10-15 ppm for neurological symptoms.

Probabilistic risk assessment techniques, including Monte Carlo simulations, have been increasingly utilized to characterize uncertainties in H2S exposure and health effects. These approaches generate probability distributions of risk estimates rather than single-point values, providing decision-makers with more comprehensive information about the range of possible outcomes and associated uncertainties.

Biomarkers of exposure and effect represent an emerging area in H2S risk assessment. Thiosulfate levels in urine and blood, sulfhemoglobin concentrations, and cytochrome c oxidase activity have shown promise as indicators of exposure. However, the short biological half-life of these markers limits their utility for assessing chronic, low-level exposures that are common in industrial settings.

Cumulative risk approaches are being developed to address the reality that workers are often exposed to multiple sulfur compounds simultaneously. These methods incorporate toxicological interactions and shared mechanisms of action to provide more realistic estimates of health risks in complex industrial environments.

Exposure modeling for H2S typically involves atmospheric dispersion models such as AERMOD and CALPUFF, which calculate concentration gradients based on emission rates, meteorological conditions, and topographical features. These models have demonstrated reliability in predicting H2S concentrations at various distances from industrial sources, with validation studies showing correlation coefficients of 0.75-0.85 between predicted and measured values.

Physiologically-based pharmacokinetic (PBPK) models have emerged as valuable tools for translating external H2S exposure to internal dose metrics. These models account for absorption through respiratory pathways, distribution to target tissues, and elimination kinetics. Recent advancements in PBPK modeling have incorporated sulfide-oxidation pathways in the liver and kidneys, providing more accurate predictions of tissue-specific toxicity.

Dose-response assessment for H2S presents unique challenges due to its steep toxicity curve and the significant variability in individual susceptibility. Benchmark dose modeling approaches have been applied to derive points of departure for both neurological and respiratory endpoints. Current models indicate a BMCL10 (lower confidence limit of benchmark concentration at 10% response) of 2-5 ppm for respiratory irritation effects and 10-15 ppm for neurological symptoms.

Probabilistic risk assessment techniques, including Monte Carlo simulations, have been increasingly utilized to characterize uncertainties in H2S exposure and health effects. These approaches generate probability distributions of risk estimates rather than single-point values, providing decision-makers with more comprehensive information about the range of possible outcomes and associated uncertainties.

Biomarkers of exposure and effect represent an emerging area in H2S risk assessment. Thiosulfate levels in urine and blood, sulfhemoglobin concentrations, and cytochrome c oxidase activity have shown promise as indicators of exposure. However, the short biological half-life of these markers limits their utility for assessing chronic, low-level exposures that are common in industrial settings.

Cumulative risk approaches are being developed to address the reality that workers are often exposed to multiple sulfur compounds simultaneously. These methods incorporate toxicological interactions and shared mechanisms of action to provide more realistic estimates of health risks in complex industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!