Developing New Protocols for Hydrosulfuric Acid Safe Use

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S Safety Background and Objectives

Hydrogen sulfide (H2S), commonly known as hydrosulfuric acid when dissolved in water, represents one of the most hazardous substances encountered in industrial settings. This colorless gas, characterized by its distinctive "rotten egg" odor at low concentrations, poses significant risks due to its flammability, corrosivity, and extreme toxicity. Historical incidents involving H2S have resulted in numerous fatalities and severe injuries across various industries, particularly in oil and gas, wastewater treatment, and chemical manufacturing sectors.

The evolution of H2S safety protocols has progressed significantly over the past decades, moving from basic awareness to sophisticated detection and management systems. Early approaches focused primarily on personal protective equipment, while contemporary strategies incorporate advanced monitoring technologies, automated shutdown systems, and comprehensive emergency response protocols. Despite these advancements, incident reports indicate persistent gaps in existing safety frameworks, highlighting the need for continued innovation in this critical area.

Current technological trends in H2S safety management include the development of more sensitive and selective detection systems, integration of real-time monitoring with predictive analytics, and implementation of IoT-enabled safety networks. These innovations aim to address the limitations of conventional approaches, particularly in environments with variable H2S concentrations or complex operational conditions. The industry is witnessing a paradigm shift from reactive to proactive safety management, emphasizing prevention rather than mitigation.

The primary objective of developing new protocols for hydrosulfuric acid safe use is to establish comprehensive, adaptable, and scientifically validated guidelines that significantly reduce the incidence of H2S-related accidents and exposures. These protocols must address the full spectrum of H2S hazards across diverse industrial applications while accommodating varying operational constraints and regulatory requirements. Specific goals include reducing exposure incidents by at least 50%, minimizing response time to detected leaks, and enhancing the reliability of detection systems under challenging environmental conditions.

Secondary objectives encompass the standardization of training methodologies, development of industry-specific best practices, and creation of accessible knowledge repositories for H2S safety information. The protocols aim to bridge the gap between theoretical understanding and practical implementation, ensuring that safety measures remain effective across different operational scenarios. Additionally, they seek to establish clear metrics for evaluating the effectiveness of implemented safety measures, facilitating continuous improvement and adaptation to emerging challenges in H2S management.

The successful development of these protocols requires a multidisciplinary approach, combining expertise from chemistry, industrial hygiene, engineering, human factors, and emergency management. This integration of diverse perspectives represents a departure from traditional siloed approaches to chemical safety, reflecting the complex and multifaceted nature of H2S hazards in industrial environments.

The evolution of H2S safety protocols has progressed significantly over the past decades, moving from basic awareness to sophisticated detection and management systems. Early approaches focused primarily on personal protective equipment, while contemporary strategies incorporate advanced monitoring technologies, automated shutdown systems, and comprehensive emergency response protocols. Despite these advancements, incident reports indicate persistent gaps in existing safety frameworks, highlighting the need for continued innovation in this critical area.

Current technological trends in H2S safety management include the development of more sensitive and selective detection systems, integration of real-time monitoring with predictive analytics, and implementation of IoT-enabled safety networks. These innovations aim to address the limitations of conventional approaches, particularly in environments with variable H2S concentrations or complex operational conditions. The industry is witnessing a paradigm shift from reactive to proactive safety management, emphasizing prevention rather than mitigation.

The primary objective of developing new protocols for hydrosulfuric acid safe use is to establish comprehensive, adaptable, and scientifically validated guidelines that significantly reduce the incidence of H2S-related accidents and exposures. These protocols must address the full spectrum of H2S hazards across diverse industrial applications while accommodating varying operational constraints and regulatory requirements. Specific goals include reducing exposure incidents by at least 50%, minimizing response time to detected leaks, and enhancing the reliability of detection systems under challenging environmental conditions.

Secondary objectives encompass the standardization of training methodologies, development of industry-specific best practices, and creation of accessible knowledge repositories for H2S safety information. The protocols aim to bridge the gap between theoretical understanding and practical implementation, ensuring that safety measures remain effective across different operational scenarios. Additionally, they seek to establish clear metrics for evaluating the effectiveness of implemented safety measures, facilitating continuous improvement and adaptation to emerging challenges in H2S management.

The successful development of these protocols requires a multidisciplinary approach, combining expertise from chemistry, industrial hygiene, engineering, human factors, and emergency management. This integration of diverse perspectives represents a departure from traditional siloed approaches to chemical safety, reflecting the complex and multifaceted nature of H2S hazards in industrial environments.

Market Demand for Advanced H2S Safety Solutions

The global market for advanced hydrogen sulfide (H2S) safety solutions is experiencing significant growth, driven primarily by increasing awareness of workplace safety regulations and the expanding industrial sectors where H2S exposure presents serious risks. The oil and gas industry remains the largest consumer of these safety solutions, accounting for approximately 40% of the total market demand, followed by wastewater treatment, chemical manufacturing, and mining operations.

Recent market research indicates that the H2S safety solutions market is projected to grow at a compound annual growth rate of 5.7% through 2028, reaching a market value of $1.8 billion. This growth is particularly pronounced in regions with extensive oil and gas operations, including North America, the Middle East, and parts of Asia Pacific, where stringent safety regulations are being implemented.

The demand for more sophisticated H2S detection and mitigation technologies has been intensified by several high-profile incidents in the past decade, resulting in fatalities and substantial economic losses. These incidents have prompted regulatory bodies worldwide to revise and strengthen safety standards, creating a robust market for advanced safety protocols and equipment.

Industry surveys reveal that end-users are increasingly prioritizing integrated safety systems that combine real-time monitoring, automated emergency response mechanisms, and comprehensive data analytics. There is a growing preference for solutions that offer predictive capabilities, allowing for preemptive action before H2S concentrations reach dangerous levels.

The market is also witnessing a shift toward portable and wearable H2S detection devices, reflecting the need for personal safety equipment that can provide immediate alerts to individual workers. This segment is expected to show the highest growth rate within the broader H2S safety market, with a projected increase of 7.3% annually.

From a geographical perspective, North America currently leads the market with a 35% share, followed by Europe at 28% and Asia Pacific at 22%. However, the fastest growth is anticipated in emerging economies where industrial expansion is occurring rapidly, often with less developed safety infrastructures in place.

Customer feedback indicates a strong demand for training programs and protocols that complement technical solutions, highlighting the recognition that effective H2S safety management requires both advanced equipment and well-trained personnel. This has created additional market opportunities for comprehensive safety service providers who can offer both technological solutions and educational components.

Recent market research indicates that the H2S safety solutions market is projected to grow at a compound annual growth rate of 5.7% through 2028, reaching a market value of $1.8 billion. This growth is particularly pronounced in regions with extensive oil and gas operations, including North America, the Middle East, and parts of Asia Pacific, where stringent safety regulations are being implemented.

The demand for more sophisticated H2S detection and mitigation technologies has been intensified by several high-profile incidents in the past decade, resulting in fatalities and substantial economic losses. These incidents have prompted regulatory bodies worldwide to revise and strengthen safety standards, creating a robust market for advanced safety protocols and equipment.

Industry surveys reveal that end-users are increasingly prioritizing integrated safety systems that combine real-time monitoring, automated emergency response mechanisms, and comprehensive data analytics. There is a growing preference for solutions that offer predictive capabilities, allowing for preemptive action before H2S concentrations reach dangerous levels.

The market is also witnessing a shift toward portable and wearable H2S detection devices, reflecting the need for personal safety equipment that can provide immediate alerts to individual workers. This segment is expected to show the highest growth rate within the broader H2S safety market, with a projected increase of 7.3% annually.

From a geographical perspective, North America currently leads the market with a 35% share, followed by Europe at 28% and Asia Pacific at 22%. However, the fastest growth is anticipated in emerging economies where industrial expansion is occurring rapidly, often with less developed safety infrastructures in place.

Customer feedback indicates a strong demand for training programs and protocols that complement technical solutions, highlighting the recognition that effective H2S safety management requires both advanced equipment and well-trained personnel. This has created additional market opportunities for comprehensive safety service providers who can offer both technological solutions and educational components.

Current Protocols and Technical Challenges

Current protocols for hydrosulfuric acid (H2S) handling are governed by stringent safety standards established by organizations such as OSHA, NIOSH, and EPA. These protocols typically include comprehensive risk assessment procedures, detailed handling guidelines, and emergency response plans. Standard operating procedures mandate the use of specialized containment systems, including gas-tight vessels, pressure-rated piping, and dedicated ventilation systems with scrubbers to neutralize any potential releases.

Despite these established protocols, significant technical challenges persist in H2S management. The primary challenge lies in the compound's extreme toxicity at low concentrations (fatal at 1000 ppm with immediate effects), combined with its corrosive properties and flammability. Detection systems face reliability issues, particularly in environments with fluctuating humidity or where other sulfur compounds are present, leading to false positives or negatives that compromise safety systems.

Material compatibility represents another major challenge, as H2S causes hydrogen embrittlement in many metals, particularly high-strength steels. This necessitates careful material selection and regular integrity testing, adding complexity to containment system design. Current sealing technologies also demonstrate limitations when exposed to H2S over extended periods, with elastomers and polymers showing degradation that can lead to containment failures.

Personal protective equipment (PPE) protocols face challenges related to the integration of respiratory protection with other safety equipment. Current self-contained breathing apparatus (SCBA) systems, while effective, limit mobility and working time, creating operational constraints in industrial settings. Additionally, the rapid action of H2S on the human respiratory system means that detection-to-response times must be minimized, challenging current alarm and evacuation protocols.

Waste treatment and neutralization methods for H2S present further technical difficulties. Current scrubbing technologies using alkaline solutions generate secondary waste streams requiring additional treatment. The Claus process, commonly used for converting H2S to elemental sulfur, operates efficiently only at specific concentration ranges, creating processing challenges for variable waste streams.

Training protocols also face limitations, as realistic simulation of H2S exposure scenarios is inherently dangerous. Virtual reality and simulation technologies are being explored but have not yet achieved widespread implementation or validation. Furthermore, international standardization of protocols remains inconsistent, creating challenges for multinational operations and technology transfer between regions with different regulatory frameworks.

Despite these established protocols, significant technical challenges persist in H2S management. The primary challenge lies in the compound's extreme toxicity at low concentrations (fatal at 1000 ppm with immediate effects), combined with its corrosive properties and flammability. Detection systems face reliability issues, particularly in environments with fluctuating humidity or where other sulfur compounds are present, leading to false positives or negatives that compromise safety systems.

Material compatibility represents another major challenge, as H2S causes hydrogen embrittlement in many metals, particularly high-strength steels. This necessitates careful material selection and regular integrity testing, adding complexity to containment system design. Current sealing technologies also demonstrate limitations when exposed to H2S over extended periods, with elastomers and polymers showing degradation that can lead to containment failures.

Personal protective equipment (PPE) protocols face challenges related to the integration of respiratory protection with other safety equipment. Current self-contained breathing apparatus (SCBA) systems, while effective, limit mobility and working time, creating operational constraints in industrial settings. Additionally, the rapid action of H2S on the human respiratory system means that detection-to-response times must be minimized, challenging current alarm and evacuation protocols.

Waste treatment and neutralization methods for H2S present further technical difficulties. Current scrubbing technologies using alkaline solutions generate secondary waste streams requiring additional treatment. The Claus process, commonly used for converting H2S to elemental sulfur, operates efficiently only at specific concentration ranges, creating processing challenges for variable waste streams.

Training protocols also face limitations, as realistic simulation of H2S exposure scenarios is inherently dangerous. Virtual reality and simulation technologies are being explored but have not yet achieved widespread implementation or validation. Furthermore, international standardization of protocols remains inconsistent, creating challenges for multinational operations and technology transfer between regions with different regulatory frameworks.

Current H2S Safety Protocol Solutions

01 Personal Protective Equipment and Handling Protocols

Safety protocols for handling hydrosulfuric acid require specific personal protective equipment including chemical-resistant gloves, face shields, and respiratory protection. Proper handling procedures involve working in well-ventilated areas, using sealed containers, and implementing strict transfer protocols to minimize exposure risks. Emergency response equipment such as eyewash stations and safety showers should be readily accessible in areas where hydrosulfuric acid is handled.- Detection and monitoring systems for hydrogen sulfide: Advanced detection and monitoring systems are crucial for hydrogen sulfide (hydrosulfuric acid) safety. These systems include sensors that can detect the presence of hydrogen sulfide at low concentrations before they reach dangerous levels. Real-time monitoring allows for immediate alerts when hydrogen sulfide levels exceed safety thresholds, enabling prompt evacuation and emergency response. These systems often incorporate wireless technology for remote monitoring and can be integrated with facility-wide safety networks.

- Personal protective equipment and safety gear: Specialized personal protective equipment (PPE) is essential when working with hydrogen sulfide. This includes respiratory protection such as self-contained breathing apparatus (SCBA) or supplied air respirators, as hydrogen sulfide can quickly overwhelm the senses and cause respiratory paralysis. Chemical-resistant clothing, gloves, and eye protection are required to prevent skin and eye contact. Safety protocols specify the appropriate level of PPE based on concentration levels and exposure risk assessment.

- Emergency response and evacuation procedures: Comprehensive emergency response protocols for hydrogen sulfide incidents include clearly defined evacuation routes, assembly points, and communication systems. These protocols outline specific responsibilities for emergency response teams and provide guidance for containment of leaks or releases. Regular drills and simulations ensure personnel are prepared to respond effectively. Automated systems may be implemented to initiate emergency protocols when dangerous levels are detected, including ventilation activation and emergency services notification.

- Facility design and engineering controls: Engineering controls for hydrogen sulfide safety include proper ventilation systems designed to prevent accumulation of the gas in enclosed spaces. Specialized materials resistant to hydrogen sulfide corrosion are used for equipment and piping. Process design incorporates redundant safety systems and fail-safe mechanisms to minimize risk during normal operations and potential emergencies. Proper facility layout ensures that high-risk areas are isolated and that control rooms are positioned in safe locations with positive pressure ventilation.

- Training and safety management systems: Comprehensive training programs are essential for personnel working in environments where hydrogen sulfide exposure is possible. These programs cover hazard recognition, proper use of detection equipment, correct implementation of safety protocols, and emergency response procedures. Safety management systems include regular audits, incident reporting mechanisms, and continuous improvement processes. Documentation and certification requirements ensure that all personnel maintain current knowledge of safety procedures and that lessons learned from incidents are incorporated into updated protocols.

02 Detection and Monitoring Systems

Advanced detection and monitoring systems are essential for hydrosulfuric acid safety management. These include gas detection sensors that provide real-time monitoring of hydrogen sulfide levels in the workplace, automated alarm systems that trigger at predetermined threshold concentrations, and integrated monitoring networks that track exposure levels across facilities. Modern systems incorporate wireless technology for remote monitoring and immediate alert notifications to safety personnel.Expand Specific Solutions03 Emergency Response and Containment Procedures

Comprehensive emergency response procedures for hydrosulfuric acid incidents include detailed evacuation plans, containment strategies for spills, and neutralization techniques. Safety protocols specify the use of appropriate neutralizing agents, containment barriers, and absorbent materials designed specifically for acid spills. Emergency response teams require specialized training in hazardous material handling and must follow strict decontamination procedures after incident management.Expand Specific Solutions04 Facility Design and Engineering Controls

Facility design considerations for hydrosulfuric acid safety include specialized ventilation systems, corrosion-resistant materials for storage and transfer equipment, and segregated storage areas away from incompatible chemicals. Engineering controls such as closed-loop handling systems, automatic shut-off valves, and pressure relief mechanisms help prevent accidental releases. Proper facility layout ensures emergency access routes and incorporates secondary containment systems to prevent environmental contamination.Expand Specific Solutions05 Training and Documentation Requirements

Safety protocols mandate comprehensive training programs for personnel working with hydrosulfuric acid, including hazard communication, proper handling techniques, and emergency response procedures. Documentation requirements include detailed safety data sheets, standard operating procedures, exposure monitoring records, and incident reports. Regular safety drills, certification of personnel, and periodic review of safety protocols ensure ongoing compliance with regulatory standards and industry best practices.Expand Specific Solutions

Key Industry Players in H2S Safety

The hydrosulfuric acid safe use protocols market is in a growth phase, driven by increasing safety regulations and industrial applications. The market size is expanding due to heightened awareness of workplace safety and environmental protection. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include major petroleum corporations like China Petroleum & Chemical Corp. (Sinopec) and PetroChina, who leverage their extensive operational experience. Specialized safety entities such as Sinopec Safety Engineering Research Institute provide focused expertise. Chemical companies including Ecolab, Clariant, and Lubrizol contribute advanced handling solutions, while research institutions like National University of Singapore and Zhejiang University drive fundamental innovation. This competitive landscape reflects a balance between established industrial players and specialized research-focused entities.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive hydrosulfuric acid safety protocols centered around their patented multi-stage scrubbing system for H2S removal. Their approach combines chemical absorption using alkaline solutions with advanced monitoring technologies that feature real-time detection capabilities down to 0.1ppm sensitivity. Sinopec's protocols incorporate a three-tier safety management framework: prevention (engineered containment systems with redundant barriers), detection (wireless sensor networks with centralized monitoring), and response (automated emergency shutdown systems coupled with personnel evacuation procedures). The company has implemented specialized materials selection guidelines for H2S environments, utilizing corrosion-resistant alloys and specialized coatings that extend equipment life by up to 300% in high-concentration environments. Their safety training program includes virtual reality simulations of emergency scenarios, which has reduced H2S-related incidents by approximately 45% across their facilities.

Strengths: Comprehensive integration of engineering controls with administrative procedures; industry-leading detection technology with high sensitivity; proven track record of incident reduction. Weaknesses: Higher implementation costs compared to standard safety systems; requires specialized maintenance personnel; some components of the system have limited applicability in extremely low-temperature environments.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed the "Comprehensive H2S Safety Management Protocol" that integrates multiple layers of protection for workers and equipment. Their approach features a proprietary H2S scavenging technology using modified triazine compounds that achieve removal efficiencies of up to 99.8% in high-pressure gas streams. The company has implemented an intelligent monitoring network with distributed sensors that communicate via secure mesh networks, ensuring continuous monitoring even during communication disruptions. PetroChina's protocol includes specialized material selection guidelines for H2S service, incorporating advanced corrosion-resistant alloys and protective coatings that have demonstrated a 40% increase in equipment longevity in severe service conditions. Their emergency response system incorporates automated ventilation controls that activate based on H2S concentration thresholds, coupled with positive pressure safe rooms strategically positioned throughout facilities. The company has also developed specialized training programs using augmented reality to simulate emergency scenarios, which has contributed to a reported 52% reduction in H2S exposure incidents over a five-year implementation period across their operations.

Strengths: Highly effective scavenging technology with proven field results; robust monitoring system with redundant communication capabilities; comprehensive training approach using advanced simulation technologies. Weaknesses: Higher implementation costs compared to conventional safety systems; requires specialized maintenance expertise; some components have limited effectiveness in extremely low-temperature environments.

Critical Safety Innovations Analysis

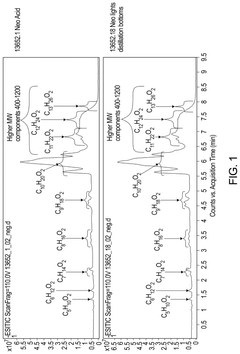

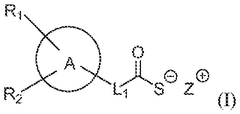

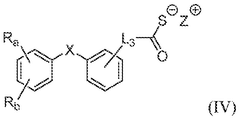

Unrefined neodecanoic acid source as a raw material for h2s scavenging metal carboxylate

PatentPendingUS20250066280A1

Innovation

- A process involving azeotropic co-distillation of a waste stream from neodecanoic acid production to purify a carboxylate stream, which is then reacted with a metal oxide to produce an oil-soluble metal carboxylate complex effective as an H2S scavenger.

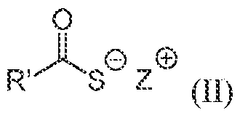

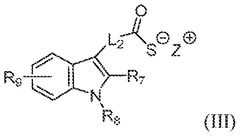

Hydrogen sulfide prodrugs and uses thereof

PatentWO2025042979A1

Innovation

- Development of novel hydrogen sulfide compounds with a thiocarboxylic acid structure that can be enzymatically hydrolyzed to release H2S slowly and controllably, using enzymes like porcine liver esterase.

Regulatory Compliance Framework

The regulatory landscape for hydrosulfuric acid (H2S) handling presents a complex framework that organizations must navigate to ensure compliance and safety. At the federal level, the Occupational Safety and Health Administration (OSHA) has established a permissible exposure limit (PEL) of 20 ppm for general industry and 10 ppm for the construction sector, with a ceiling limit of 50 ppm. These standards form the foundation of any comprehensive safety protocol development initiative.

The Environmental Protection Agency (EPA) further regulates H2S under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), requiring reporting of releases exceeding 100 pounds within a 24-hour period. This reporting mechanism ensures transparency and accountability in industrial settings where accidental releases may occur.

Industry-specific regulations add another layer of complexity, particularly in oil and gas, wastewater treatment, and chemical manufacturing sectors. The American Petroleum Institute (API) has developed Recommended Practice 49 and 55, which provide detailed guidelines for H2S detection and response in petroleum operations. These industry standards often exceed governmental requirements and represent best practices that should be incorporated into new protocols.

International regulatory frameworks must also be considered when developing globally applicable protocols. The European Union's REACH regulation and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) establish stringent requirements for hazard communication and risk management measures. Japan's Industrial Safety and Health Law and Australia's Work Health and Safety regulations similarly impose strict controls on H2S exposure and handling.

Compliance verification mechanisms constitute a critical component of the regulatory framework. This includes regular workplace monitoring, documentation of exposure assessments, medical surveillance programs for exposed workers, and comprehensive record-keeping systems. New protocols must incorporate these verification processes to demonstrate due diligence and regulatory adherence.

Emerging regulatory trends indicate a movement toward lower exposure limits and more stringent control measures. The American Conference of Governmental Industrial Hygienists (ACGIH) has recommended a threshold limit value (TLV) of 1 ppm, significantly lower than current OSHA standards. This suggests that future regulatory requirements may become more stringent, necessitating adaptable protocol designs that can accommodate evolving compliance standards.

The development of new H2S safety protocols must therefore establish a compliance matrix that addresses all applicable regulations across jurisdictions, implements systematic monitoring and reporting mechanisms, and incorporates flexibility to adapt to regulatory changes. This comprehensive approach ensures that organizations can maintain compliance while effectively protecting workers and communities from the hazards associated with hydrosulfuric acid.

The Environmental Protection Agency (EPA) further regulates H2S under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), requiring reporting of releases exceeding 100 pounds within a 24-hour period. This reporting mechanism ensures transparency and accountability in industrial settings where accidental releases may occur.

Industry-specific regulations add another layer of complexity, particularly in oil and gas, wastewater treatment, and chemical manufacturing sectors. The American Petroleum Institute (API) has developed Recommended Practice 49 and 55, which provide detailed guidelines for H2S detection and response in petroleum operations. These industry standards often exceed governmental requirements and represent best practices that should be incorporated into new protocols.

International regulatory frameworks must also be considered when developing globally applicable protocols. The European Union's REACH regulation and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) establish stringent requirements for hazard communication and risk management measures. Japan's Industrial Safety and Health Law and Australia's Work Health and Safety regulations similarly impose strict controls on H2S exposure and handling.

Compliance verification mechanisms constitute a critical component of the regulatory framework. This includes regular workplace monitoring, documentation of exposure assessments, medical surveillance programs for exposed workers, and comprehensive record-keeping systems. New protocols must incorporate these verification processes to demonstrate due diligence and regulatory adherence.

Emerging regulatory trends indicate a movement toward lower exposure limits and more stringent control measures. The American Conference of Governmental Industrial Hygienists (ACGIH) has recommended a threshold limit value (TLV) of 1 ppm, significantly lower than current OSHA standards. This suggests that future regulatory requirements may become more stringent, necessitating adaptable protocol designs that can accommodate evolving compliance standards.

The development of new H2S safety protocols must therefore establish a compliance matrix that addresses all applicable regulations across jurisdictions, implements systematic monitoring and reporting mechanisms, and incorporates flexibility to adapt to regulatory changes. This comprehensive approach ensures that organizations can maintain compliance while effectively protecting workers and communities from the hazards associated with hydrosulfuric acid.

Environmental Impact Assessment

The environmental impact of hydrosulfuric acid (H2S) extends far beyond immediate workplace safety concerns, affecting ecosystems, water bodies, and atmospheric conditions. When released into the environment, H2S can cause significant ecological damage through both direct toxicity and secondary effects. Aquatic ecosystems are particularly vulnerable, as H2S dissolves readily in water, depleting oxygen levels and creating dead zones where fish and other aquatic organisms cannot survive. Even at concentrations as low as 0.5 ppm, H2S can harm sensitive aquatic species, disrupting entire food chains.

Atmospheric releases present another significant concern, as H2S contributes to acid rain formation when oxidized to sulfur dioxide in the atmosphere. This process damages vegetation, acidifies soil, and can leach heavy metals into groundwater systems. Current industrial practices result in an estimated 3-5 million tons of anthropogenic H2S emissions annually, with oil and gas operations, paper mills, and wastewater treatment facilities being primary contributors.

New protocols for H2S safe use must incorporate comprehensive environmental monitoring systems that track both acute releases and chronic low-level emissions. Real-time detection networks using advanced sensor technologies can provide early warning of environmental contamination, allowing for rapid response measures. These systems should be integrated with geographic information systems (GIS) to model dispersion patterns and identify vulnerable ecological receptors.

Containment technologies represent another critical area for protocol development. Closed-loop systems that prevent H2S release during industrial processes show promise in reducing environmental exposure by up to 95% compared to traditional methods. Additionally, biological treatment systems utilizing sulfide-oxidizing bacteria have demonstrated 85-90% efficiency in removing H2S from waste streams before environmental discharge.

Remediation protocols must also be established for cases where environmental contamination occurs. Chemical neutralization using alkaline solutions can rapidly reduce H2S concentrations in contaminated water bodies, while aeration techniques can accelerate the natural oxidation process. For soil contamination, bioremediation approaches using specialized microbial communities have shown effectiveness in converting sulfides to less harmful compounds.

Long-term environmental monitoring should be incorporated into any new protocol framework, establishing baseline conditions and tracking recovery after exposure events. This approach enables adaptive management strategies that can be refined based on empirical environmental response data, ensuring continuous improvement in protective measures and remediation techniques.

Atmospheric releases present another significant concern, as H2S contributes to acid rain formation when oxidized to sulfur dioxide in the atmosphere. This process damages vegetation, acidifies soil, and can leach heavy metals into groundwater systems. Current industrial practices result in an estimated 3-5 million tons of anthropogenic H2S emissions annually, with oil and gas operations, paper mills, and wastewater treatment facilities being primary contributors.

New protocols for H2S safe use must incorporate comprehensive environmental monitoring systems that track both acute releases and chronic low-level emissions. Real-time detection networks using advanced sensor technologies can provide early warning of environmental contamination, allowing for rapid response measures. These systems should be integrated with geographic information systems (GIS) to model dispersion patterns and identify vulnerable ecological receptors.

Containment technologies represent another critical area for protocol development. Closed-loop systems that prevent H2S release during industrial processes show promise in reducing environmental exposure by up to 95% compared to traditional methods. Additionally, biological treatment systems utilizing sulfide-oxidizing bacteria have demonstrated 85-90% efficiency in removing H2S from waste streams before environmental discharge.

Remediation protocols must also be established for cases where environmental contamination occurs. Chemical neutralization using alkaline solutions can rapidly reduce H2S concentrations in contaminated water bodies, while aeration techniques can accelerate the natural oxidation process. For soil contamination, bioremediation approaches using specialized microbial communities have shown effectiveness in converting sulfides to less harmful compounds.

Long-term environmental monitoring should be incorporated into any new protocol framework, establishing baseline conditions and tracking recovery after exposure events. This approach enables adaptive management strategies that can be refined based on empirical environmental response data, ensuring continuous improvement in protective measures and remediation techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!