Comparing Membrane Technologies for Hydrosulfuric Acid Filtration

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Filtration Technology Background and Objectives

Membrane filtration technology has evolved significantly over the past century, with major advancements occurring since the 1960s when synthetic polymer membranes were first commercialized. The technology has transformed from simple mechanical sieves to sophisticated selective barriers capable of molecular separation at the nanoscale. This evolution has been driven by increasing demands for more efficient separation processes across various industries, particularly in water treatment, chemical processing, and environmental protection applications.

In the context of hydrosulfuric acid (H₂S) filtration, membrane technologies have gained prominence due to their ability to effectively separate this corrosive compound from gas and liquid streams without the extensive energy requirements of traditional separation methods. The historical trajectory shows a shift from conventional absorption and adsorption techniques toward membrane-based solutions that offer higher selectivity, lower energy consumption, and reduced environmental impact.

Current membrane technology trends for H₂S filtration include the development of more chemically resistant materials, hybrid membrane systems that combine different separation mechanisms, and the integration of catalytic functions within membrane structures. These innovations aim to address the persistent challenges of membrane fouling, chemical degradation, and performance decline in harsh acidic environments.

The technical objectives of this research focus on comparing various membrane technologies specifically for hydrosulfuric acid filtration applications. This includes evaluating polymeric membranes (such as polyimides, PTFE, and polysulfones), ceramic membranes, and emerging materials like graphene oxide and metal-organic frameworks (MOFs). The assessment aims to determine optimal membrane configurations based on separation efficiency, chemical stability, operational lifespan, and economic viability.

A critical objective is to identify membrane technologies that can withstand the highly corrosive nature of H₂S while maintaining consistent separation performance over extended operational periods. This requires examining membrane materials that resist chemical degradation, structural modifications that enhance selectivity, and surface treatments that minimize fouling in acidic environments.

Additionally, this research seeks to establish quantifiable performance metrics for comparing different membrane technologies, including H₂S removal efficiency, pressure drop characteristics, energy consumption, and total cost of ownership. These metrics will provide a comprehensive framework for evaluating the suitability of various membrane solutions for specific industrial applications.

The ultimate goal is to map the technological landscape of membrane-based H₂S filtration systems and identify promising directions for future development, particularly focusing on innovations that could overcome current limitations in selectivity, durability, and cost-effectiveness. This will support strategic decision-making for research investment and technology adoption in industries where H₂S removal is critical.

In the context of hydrosulfuric acid (H₂S) filtration, membrane technologies have gained prominence due to their ability to effectively separate this corrosive compound from gas and liquid streams without the extensive energy requirements of traditional separation methods. The historical trajectory shows a shift from conventional absorption and adsorption techniques toward membrane-based solutions that offer higher selectivity, lower energy consumption, and reduced environmental impact.

Current membrane technology trends for H₂S filtration include the development of more chemically resistant materials, hybrid membrane systems that combine different separation mechanisms, and the integration of catalytic functions within membrane structures. These innovations aim to address the persistent challenges of membrane fouling, chemical degradation, and performance decline in harsh acidic environments.

The technical objectives of this research focus on comparing various membrane technologies specifically for hydrosulfuric acid filtration applications. This includes evaluating polymeric membranes (such as polyimides, PTFE, and polysulfones), ceramic membranes, and emerging materials like graphene oxide and metal-organic frameworks (MOFs). The assessment aims to determine optimal membrane configurations based on separation efficiency, chemical stability, operational lifespan, and economic viability.

A critical objective is to identify membrane technologies that can withstand the highly corrosive nature of H₂S while maintaining consistent separation performance over extended operational periods. This requires examining membrane materials that resist chemical degradation, structural modifications that enhance selectivity, and surface treatments that minimize fouling in acidic environments.

Additionally, this research seeks to establish quantifiable performance metrics for comparing different membrane technologies, including H₂S removal efficiency, pressure drop characteristics, energy consumption, and total cost of ownership. These metrics will provide a comprehensive framework for evaluating the suitability of various membrane solutions for specific industrial applications.

The ultimate goal is to map the technological landscape of membrane-based H₂S filtration systems and identify promising directions for future development, particularly focusing on innovations that could overcome current limitations in selectivity, durability, and cost-effectiveness. This will support strategic decision-making for research investment and technology adoption in industries where H₂S removal is critical.

Market Analysis for H2S Filtration Solutions

The global market for hydrogen sulfide (H2S) filtration solutions has experienced significant growth in recent years, driven primarily by stringent environmental regulations and increasing industrial activities in oil and gas, wastewater treatment, and chemical processing sectors. The market size for H2S removal technologies was valued at approximately $1.5 billion in 2022 and is projected to reach $2.3 billion by 2028, representing a compound annual growth rate of 7.4%.

Membrane-based filtration technologies for H2S removal have emerged as a particularly promising segment within this market, currently accounting for about 23% of the total market share. This segment is expected to grow at an accelerated rate of 9.2% annually, outpacing traditional filtration methods due to its superior efficiency and reduced operational costs.

Regionally, North America dominates the H2S filtration market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (24%). The Asia-Pacific region, however, is witnessing the fastest growth rate at 10.5% annually, primarily due to rapid industrialization in China and India, coupled with increasingly stringent environmental regulations in these countries.

By industry vertical, the oil and gas sector remains the largest consumer of H2S filtration solutions, accounting for 42% of the total market. Wastewater treatment follows at 27%, while chemical processing and mining collectively represent about 22% of market demand. The biogas industry, though currently a smaller segment at 9%, is showing the most rapid growth at 12.3% annually as renewable energy initiatives gain momentum globally.

Customer demand is increasingly shifting toward membrane technologies that offer higher removal efficiency, lower energy consumption, and reduced chemical usage. Market surveys indicate that 68% of industrial customers prioritize operational efficiency over initial capital expenditure, suggesting a favorable outlook for advanced membrane technologies despite their potentially higher upfront costs.

The competitive landscape features both established players and innovative startups. Traditional filtration companies are expanding their membrane technology portfolios through R&D investments and strategic acquisitions. Meanwhile, specialized membrane technology startups have secured significant venture capital funding, with investments in this space reaching $420 million in 2022 alone.

Market challenges include the high initial cost of advanced membrane systems and technical limitations in handling extremely high H2S concentrations. However, these challenges are gradually being addressed through technological innovations and economies of scale in manufacturing.

Membrane-based filtration technologies for H2S removal have emerged as a particularly promising segment within this market, currently accounting for about 23% of the total market share. This segment is expected to grow at an accelerated rate of 9.2% annually, outpacing traditional filtration methods due to its superior efficiency and reduced operational costs.

Regionally, North America dominates the H2S filtration market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (24%). The Asia-Pacific region, however, is witnessing the fastest growth rate at 10.5% annually, primarily due to rapid industrialization in China and India, coupled with increasingly stringent environmental regulations in these countries.

By industry vertical, the oil and gas sector remains the largest consumer of H2S filtration solutions, accounting for 42% of the total market. Wastewater treatment follows at 27%, while chemical processing and mining collectively represent about 22% of market demand. The biogas industry, though currently a smaller segment at 9%, is showing the most rapid growth at 12.3% annually as renewable energy initiatives gain momentum globally.

Customer demand is increasingly shifting toward membrane technologies that offer higher removal efficiency, lower energy consumption, and reduced chemical usage. Market surveys indicate that 68% of industrial customers prioritize operational efficiency over initial capital expenditure, suggesting a favorable outlook for advanced membrane technologies despite their potentially higher upfront costs.

The competitive landscape features both established players and innovative startups. Traditional filtration companies are expanding their membrane technology portfolios through R&D investments and strategic acquisitions. Meanwhile, specialized membrane technology startups have secured significant venture capital funding, with investments in this space reaching $420 million in 2022 alone.

Market challenges include the high initial cost of advanced membrane systems and technical limitations in handling extremely high H2S concentrations. However, these challenges are gradually being addressed through technological innovations and economies of scale in manufacturing.

Current Membrane Technologies and Technical Barriers

Membrane technologies for hydrosulfuric acid filtration have evolved significantly over the past decades, with several distinct approaches currently dominating the market. Polymeric membranes represent the most widely adopted solution, particularly those fabricated from polysulfone (PSF), polyethersulfone (PES), and polytetrafluoroethylene (PTFE). These materials offer reasonable chemical resistance to H2S environments while maintaining adequate filtration efficiency. PTFE membranes, specifically, demonstrate superior acid resistance but often come with higher manufacturing costs and more complex fabrication processes.

Ceramic membranes constitute another major category, typically composed of alumina, zirconia, or silica. These membranes exhibit exceptional thermal stability and chemical resistance, making them particularly valuable for high-temperature H2S filtration applications in industrial settings. Their mechanical robustness allows for extended operational lifespans even under harsh conditions, though their brittleness can pose challenges in certain installation configurations.

Composite membranes, combining polymeric substrates with ceramic or metallic surface layers, have emerged as a promising middle-ground solution. These hybrid structures attempt to leverage the flexibility and cost-effectiveness of polymers while incorporating the superior chemical resistance of inorganic materials. Thin-film composite (TFC) membranes with specialized coatings have shown particular promise in laboratory settings.

Despite these advancements, significant technical barriers persist in hydrosulfuric acid filtration. Membrane fouling remains perhaps the most pervasive challenge, as sulfur compounds and associated contaminants rapidly accumulate on membrane surfaces, dramatically reducing filtration efficiency and operational lifespans. Current anti-fouling strategies, including surface modifications and cleaning protocols, provide only partial solutions.

Chemical degradation presents another substantial obstacle, particularly for polymer-based membranes. Extended exposure to H2S and associated acidic compounds causes gradual deterioration of membrane materials, compromising both selectivity and permeability characteristics. This degradation accelerates at elevated temperatures and pressures, limiting application in many industrial contexts.

Selectivity-permeability trade-offs continue to constrain membrane performance. Membranes with high H2S selectivity typically demonstrate reduced permeability, necessitating larger membrane areas and higher energy inputs to achieve desired filtration rates. Conversely, high-permeability membranes often lack the selectivity required for effective acid separation.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes frequently encounter difficulties in manufacturing consistency, module design, and system integration when scaled to commercial applications. The complex interplay between membrane properties, module configuration, and operational parameters creates significant engineering challenges that have yet to be fully resolved.

Ceramic membranes constitute another major category, typically composed of alumina, zirconia, or silica. These membranes exhibit exceptional thermal stability and chemical resistance, making them particularly valuable for high-temperature H2S filtration applications in industrial settings. Their mechanical robustness allows for extended operational lifespans even under harsh conditions, though their brittleness can pose challenges in certain installation configurations.

Composite membranes, combining polymeric substrates with ceramic or metallic surface layers, have emerged as a promising middle-ground solution. These hybrid structures attempt to leverage the flexibility and cost-effectiveness of polymers while incorporating the superior chemical resistance of inorganic materials. Thin-film composite (TFC) membranes with specialized coatings have shown particular promise in laboratory settings.

Despite these advancements, significant technical barriers persist in hydrosulfuric acid filtration. Membrane fouling remains perhaps the most pervasive challenge, as sulfur compounds and associated contaminants rapidly accumulate on membrane surfaces, dramatically reducing filtration efficiency and operational lifespans. Current anti-fouling strategies, including surface modifications and cleaning protocols, provide only partial solutions.

Chemical degradation presents another substantial obstacle, particularly for polymer-based membranes. Extended exposure to H2S and associated acidic compounds causes gradual deterioration of membrane materials, compromising both selectivity and permeability characteristics. This degradation accelerates at elevated temperatures and pressures, limiting application in many industrial contexts.

Selectivity-permeability trade-offs continue to constrain membrane performance. Membranes with high H2S selectivity typically demonstrate reduced permeability, necessitating larger membrane areas and higher energy inputs to achieve desired filtration rates. Conversely, high-permeability membranes often lack the selectivity required for effective acid separation.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes frequently encounter difficulties in manufacturing consistency, module design, and system integration when scaled to commercial applications. The complex interplay between membrane properties, module configuration, and operational parameters creates significant engineering challenges that have yet to be fully resolved.

Comparative Analysis of Existing Membrane Solutions

01 Membrane filtration systems for water treatment

Membrane filtration technologies are widely used in water treatment processes to remove contaminants, particles, and microorganisms. These systems utilize various membrane types with different pore sizes to achieve specific filtration objectives. Advanced membrane filtration systems incorporate features such as cross-flow filtration, backwashing capabilities, and anti-fouling mechanisms to maintain efficiency and extend membrane life in water purification applications.- Membrane filtration systems for water treatment: Membrane filtration technologies are widely used in water treatment processes to remove contaminants, particles, and microorganisms. These systems employ various membrane types with different pore sizes to achieve specific filtration objectives. Advanced membrane filtration systems can incorporate multiple stages of filtration to enhance efficiency and effectiveness in producing clean water for industrial, municipal, or residential use.

- Innovative membrane materials and structures: Development of novel membrane materials and structures has significantly improved filtration performance. These innovations include composite membranes, nanomaterials-enhanced membranes, and specially structured membranes with controlled porosity. Advanced materials provide benefits such as increased durability, improved selectivity, enhanced flux rates, and reduced fouling, leading to more efficient and cost-effective filtration processes.

- Membrane bioreactor technologies: Membrane bioreactor (MBR) systems combine biological treatment processes with membrane filtration to provide high-quality effluent. These systems integrate activated sludge processes with membrane separation, eliminating the need for secondary clarification. MBR technologies offer advantages including smaller footprint, higher treatment efficiency, and superior effluent quality compared to conventional treatment methods.

- Anti-fouling and membrane cleaning technologies: Membrane fouling is a significant challenge in filtration systems that reduces efficiency and increases operational costs. Various technologies have been developed to address this issue, including physical cleaning methods, chemical cleaning protocols, and membrane surface modifications. Advanced anti-fouling strategies incorporate specialized coatings, hydrodynamic improvements, and automated cleaning systems to maintain membrane performance over extended periods.

- Specialized membrane applications in industrial processes: Membrane filtration technologies have been adapted for specialized industrial applications beyond conventional water treatment. These include food and beverage processing, pharmaceutical manufacturing, gas separation, and resource recovery from waste streams. Customized membrane systems are designed to meet specific industry requirements, such as high temperature resistance, chemical compatibility, or selective separation of valuable components.

02 Industrial membrane separation processes

Membrane technologies are employed in various industrial separation processes to isolate, concentrate, or purify specific components from complex mixtures. These applications include gas separation, liquid filtration, and molecular fractionation across different industries. Industrial membrane systems are designed for high throughput, resistance to harsh chemical environments, and integration with existing process equipment to enhance production efficiency while reducing energy consumption.Expand Specific Solutions03 Novel membrane materials and structures

Innovations in membrane materials and structures have led to enhanced filtration performance and specialized applications. These advancements include composite membranes, functionalized surfaces, and nano-engineered materials that offer improved selectivity, flux rates, and resistance to fouling. Novel membrane structures may incorporate multiple layers, gradient porosity, or embedded active components to achieve specific separation characteristics while maintaining mechanical integrity under operational conditions.Expand Specific Solutions04 Membrane bioreactor systems

Membrane bioreactor (MBR) systems combine biological treatment processes with membrane filtration for wastewater treatment applications. These systems integrate activated sludge processes with membrane separation to achieve high-quality effluent while operating at higher biomass concentrations than conventional treatment methods. MBR technologies offer advantages including smaller footprint, improved effluent quality, and potential for water reuse in municipal and industrial applications.Expand Specific Solutions05 Membrane module design and operation

The design and operational parameters of membrane modules significantly impact filtration performance and system efficiency. Various module configurations such as hollow fiber, spiral wound, tubular, and flat sheet designs are utilized based on specific application requirements. Innovations in module design focus on optimizing flow distribution, minimizing concentration polarization, facilitating cleaning procedures, and enhancing energy efficiency during operation while maximizing effective membrane surface area.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The membrane technology market for hydrosulfuric acid filtration is currently in a growth phase, with increasing demand driven by stringent environmental regulations and industrial needs for efficient gas separation solutions. The global market size is estimated to be expanding at a CAGR of 7-9%, fueled by applications in petrochemical, natural gas processing, and wastewater treatment sectors. From a technological maturity perspective, the landscape shows varied development levels, with established players like 3M Innovative Properties, DuPont Safety & Construction, and Toray Industries leading with advanced polymer-based membranes. China Petroleum & Chemical Corp. and Sumitomo Chemical are investing heavily in next-generation ceramic and composite membranes, while research institutions like Nanjing Tech University and The Regents of the University of California are pioneering breakthrough technologies in selective permeation and acid-resistant materials that could reshape the competitive landscape.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced fluoropolymer membrane technologies specifically designed for hydrosulfuric acid filtration applications. Their proprietary technology utilizes perfluorinated polymers with enhanced chemical resistance to withstand the highly corrosive nature of H2S environments. The membranes feature a composite structure with a thin selective layer supported by a porous substrate, optimizing both permeability and selectivity. 3M's approach incorporates surface modification techniques to improve membrane wettability and reduce fouling during operation. Their systems typically operate at moderate pressures (5-15 bar) and achieve H2S removal efficiencies exceeding 99% in industrial applications. The membranes are manufactured using a patented extrusion and stretching process that creates a uniform microporous structure with controlled pore size distribution, critical for consistent separation performance.

Strengths: Exceptional chemical resistance to H2S and acidic environments; long operational lifetime (3-5 years) compared to industry average; modular design allowing scalability for different applications. Weaknesses: Higher initial capital investment compared to conventional technologies; requires specialized maintenance protocols; performance can degrade in the presence of certain organic contaminants.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary ceramic-polymer composite membranes specifically designed for hydrosulfuric acid filtration in petroleum refining applications. Their technology utilizes a ceramic substrate (primarily alumina-based) with a thickness of 1-2 mm that provides exceptional mechanical and thermal stability, coated with a specialized fluoropolymer selective layer approximately 0.5 μm thick. This hybrid approach combines the chemical resistance of fluoropolymers with the structural integrity of ceramics. Sinopec's manufacturing process involves precision sol-gel techniques for the ceramic substrate followed by controlled dip-coating of the polymer layer. Their membranes operate effectively at temperatures up to 150°C and pressures of 20-40 bar, achieving H2S removal efficiencies of 97-99% in industrial applications. The technology incorporates specialized surface treatments to enhance acid resistance and reduce fouling potential. Sinopec has deployed these membranes across multiple refineries, demonstrating consistent performance in high-sulfur crude processing environments with operational lifetimes exceeding 3 years.

Strengths: Exceptional thermal and mechanical stability allowing operation in harsh refinery conditions; resistance to chemical cleaning agents enabling effective maintenance protocols; lower replacement frequency compared to polymer-only membranes. Weaknesses: Higher manufacturing complexity and associated costs; heavier weight and larger footprint compared to polymer membrane systems; requires specialized installation and handling procedures.

Key Patents and Technical Innovations in H2S Filtration

Membranes for the separation of h 2s from h 2s-co 2 mixtures

PatentWO2023192701A1

Innovation

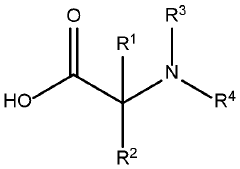

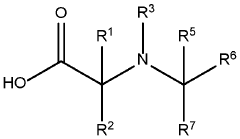

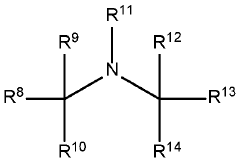

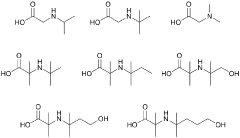

- Development of selective membranes comprising a gas permeable support layer and a selective polymer layer with a sterically hindered amine or salt as a mobile carrier, which exhibits high H2S/CO2 selectivity, allowing for efficient separation of H2S from CO2 at elevated temperatures and pressures.

Process for the removal in the well of the acid components from hydrocarbons and related well

PatentWO2017175206A1

Innovation

- A process involving direct contact between an aqueous phase, preferably water or sea water, and hydrocarbons within the extraction well to absorb acid components at high pressures, reducing the need for surface treatment plants and solvent regeneration, and allowing for efficient acid component removal with lower energy costs.

Environmental Impact and Sustainability Considerations

The environmental impact of membrane technologies for hydrosulfuric acid filtration represents a critical consideration in industrial applications. Traditional filtration methods often generate significant waste streams and require extensive energy inputs, contributing to larger carbon footprints. Membrane technologies, by comparison, typically offer reduced environmental impacts through lower energy consumption, decreased chemical usage, and minimized waste production. Polymeric membranes generally require 20-40% less energy than conventional separation processes, translating to substantial reductions in greenhouse gas emissions over operational lifetimes.

Material sustainability varies significantly across membrane types. Ceramic membranes demonstrate exceptional durability with lifespans often exceeding 10 years, reducing replacement frequency and associated material consumption. Polymeric membranes, while typically requiring replacement every 3-5 years, often incorporate recyclable materials that mitigate end-of-life environmental impacts. PTFE membranes present particular challenges due to their fluoropolymer composition, which resists environmental degradation and complicates disposal processes.

Water conservation represents another significant environmental advantage of membrane filtration systems. These technologies typically reduce process water requirements by 30-60% compared to conventional chemical scrubbing methods for H₂S removal. This conservation aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in water-stressed industrial regions.

Life cycle assessment (LCA) studies indicate that membrane technologies for H₂S filtration generally demonstrate favorable environmental profiles when evaluated across manufacturing, operation, and disposal phases. Carbon footprint analyses reveal that despite energy-intensive manufacturing processes, the operational efficiencies of membrane systems typically offset initial environmental costs within 1-3 years of deployment, depending on application scale and specific membrane composition.

Regulatory compliance represents an increasingly important sustainability driver. Membrane technologies facilitate adherence to stricter emissions standards for sulfur compounds, helping industries avoid penalties while reducing environmental harm. The ability to capture and potentially valorize sulfur compounds rather than releasing them as emissions provides both environmental and potential economic benefits through resource recovery pathways.

Future sustainability improvements focus on developing bio-based membrane materials, enhancing energy efficiency through operational optimizations, and extending membrane lifespans through advanced material science. Research into self-cleaning membrane surfaces shows particular promise for reducing chemical cleaning requirements and extending operational lifetimes by 30-50%, further improving the environmental profile of these filtration technologies.

Material sustainability varies significantly across membrane types. Ceramic membranes demonstrate exceptional durability with lifespans often exceeding 10 years, reducing replacement frequency and associated material consumption. Polymeric membranes, while typically requiring replacement every 3-5 years, often incorporate recyclable materials that mitigate end-of-life environmental impacts. PTFE membranes present particular challenges due to their fluoropolymer composition, which resists environmental degradation and complicates disposal processes.

Water conservation represents another significant environmental advantage of membrane filtration systems. These technologies typically reduce process water requirements by 30-60% compared to conventional chemical scrubbing methods for H₂S removal. This conservation aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in water-stressed industrial regions.

Life cycle assessment (LCA) studies indicate that membrane technologies for H₂S filtration generally demonstrate favorable environmental profiles when evaluated across manufacturing, operation, and disposal phases. Carbon footprint analyses reveal that despite energy-intensive manufacturing processes, the operational efficiencies of membrane systems typically offset initial environmental costs within 1-3 years of deployment, depending on application scale and specific membrane composition.

Regulatory compliance represents an increasingly important sustainability driver. Membrane technologies facilitate adherence to stricter emissions standards for sulfur compounds, helping industries avoid penalties while reducing environmental harm. The ability to capture and potentially valorize sulfur compounds rather than releasing them as emissions provides both environmental and potential economic benefits through resource recovery pathways.

Future sustainability improvements focus on developing bio-based membrane materials, enhancing energy efficiency through operational optimizations, and extending membrane lifespans through advanced material science. Research into self-cleaning membrane surfaces shows particular promise for reducing chemical cleaning requirements and extending operational lifetimes by 30-50%, further improving the environmental profile of these filtration technologies.

Regulatory Framework for Industrial Gas Filtration Systems

The regulatory landscape governing industrial gas filtration systems, particularly those handling hydrosulfuric acid (H2S), is complex and multifaceted. At the international level, organizations such as the International Organization for Standardization (ISO) have established standards like ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety, which indirectly impact filtration system requirements.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act, which regulates emissions of hazardous air pollutants including H2S. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses industrial processes that may release H2S. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits (PEL) for H2S at 20 ppm ceiling with a 50 ppm maximum peak for 10 minutes.

The European Union implements stricter controls through the Industrial Emissions Directive (2010/75/EU), which requires the application of Best Available Techniques (BAT) for pollution prevention. The REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) further governs the handling of hazardous substances including H2S. European standards EN 13725 and EN 14181 provide guidelines for odor measurement and quality assurance of automated measuring systems.

In Asia, regulatory frameworks vary significantly by country. China's Ministry of Ecology and Environment has implemented the "Three-Year Action Plan for Winning the Blue Sky Defense Battle," which includes stringent requirements for industrial gas treatment. Japan's Air Pollution Control Act sets specific standards for sulfur compounds, while South Korea's Clean Air Conservation Act establishes emission standards for various industrial processes.

Membrane technology certification for H2S filtration must comply with industry-specific standards. For oil and gas applications, API (American Petroleum Institute) standards such as API 521 and API 14C are relevant. For chemical processing industries, ASME (American Society of Mechanical Engineers) codes like ASME B31.3 for process piping must be considered.

Compliance documentation requirements typically include performance test reports, material safety data sheets, maintenance records, and certification of compliance with applicable standards. Many jurisdictions also mandate regular emissions monitoring and reporting, with frequencies ranging from continuous monitoring to quarterly assessments depending on facility size and emission potential.

Recent regulatory trends indicate a move toward more stringent emission limits for H2S and other sulfur compounds, with increasing focus on total sulfur management rather than individual compound control. There is also growing emphasis on leak detection and repair (LDAR) programs specifically targeting fugitive emissions from filtration systems and associated equipment.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act, which regulates emissions of hazardous air pollutants including H2S. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses industrial processes that may release H2S. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits (PEL) for H2S at 20 ppm ceiling with a 50 ppm maximum peak for 10 minutes.

The European Union implements stricter controls through the Industrial Emissions Directive (2010/75/EU), which requires the application of Best Available Techniques (BAT) for pollution prevention. The REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) further governs the handling of hazardous substances including H2S. European standards EN 13725 and EN 14181 provide guidelines for odor measurement and quality assurance of automated measuring systems.

In Asia, regulatory frameworks vary significantly by country. China's Ministry of Ecology and Environment has implemented the "Three-Year Action Plan for Winning the Blue Sky Defense Battle," which includes stringent requirements for industrial gas treatment. Japan's Air Pollution Control Act sets specific standards for sulfur compounds, while South Korea's Clean Air Conservation Act establishes emission standards for various industrial processes.

Membrane technology certification for H2S filtration must comply with industry-specific standards. For oil and gas applications, API (American Petroleum Institute) standards such as API 521 and API 14C are relevant. For chemical processing industries, ASME (American Society of Mechanical Engineers) codes like ASME B31.3 for process piping must be considered.

Compliance documentation requirements typically include performance test reports, material safety data sheets, maintenance records, and certification of compliance with applicable standards. Many jurisdictions also mandate regular emissions monitoring and reporting, with frequencies ranging from continuous monitoring to quarterly assessments depending on facility size and emission potential.

Recent regulatory trends indicate a move toward more stringent emission limits for H2S and other sulfur compounds, with increasing focus on total sulfur management rather than individual compound control. There is also growing emphasis on leak detection and repair (LDAR) programs specifically targeting fugitive emissions from filtration systems and associated equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!