Advancements in Polyurethane for Smart Clothing

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Smart Fabric Evolution

The evolution of polyurethane (PU) in smart clothing represents a significant advancement in the field of wearable technology. This journey began in the mid-20th century with the discovery of polyurethane, a versatile polymer known for its flexibility, durability, and adaptability. Initially used in industrial applications, PU gradually found its way into the textile industry due to its unique properties.

The 1970s and 1980s saw the first applications of PU in sportswear and outdoor clothing, primarily as waterproof coatings. This marked the beginning of PU's integration into functional fabrics. As technology progressed, so did the capabilities of PU-based materials. The 1990s witnessed the development of breathable PU membranes, which revolutionized outdoor apparel by offering both waterproofing and moisture-wicking properties.

The turn of the millennium brought about a paradigm shift in the concept of smart clothing. Researchers began exploring ways to incorporate electronic components into fabrics, and PU played a crucial role in this integration. Its flexibility and ability to be formulated into various forms made it an ideal candidate for creating conductive pathways and protective layers for embedded electronics.

In the early 2000s, the focus shifted towards developing PU-based materials with enhanced properties such as shape memory and self-healing capabilities. These advancements laid the groundwork for truly interactive and responsive smart clothing. By the mid-2010s, PU-based smart fabrics were capable of changing color, adapting to temperature changes, and even monitoring vital signs.

Recent years have seen a surge in research aimed at improving the sustainability and biocompatibility of PU-based smart fabrics. Efforts to develop bio-based polyurethanes and improve recycling processes have gained momentum, addressing environmental concerns associated with synthetic materials.

The latest frontier in PU smart fabric evolution involves the integration of nanotechnology. Nanoparticle-infused PU materials are being developed to enhance properties such as antimicrobial resistance, UV protection, and even energy harvesting capabilities. These advancements are paving the way for a new generation of multifunctional smart clothing that can adapt to user needs and environmental conditions in real-time.

As we look to the future, the evolution of PU in smart clothing continues to accelerate. Ongoing research focuses on improving the seamless integration of electronics, enhancing durability and washability, and developing new functionalities such as haptic feedback and advanced sensing capabilities. The convergence of material science, electronics, and biotechnology promises to unlock even more innovative applications for PU-based smart fabrics in the coming years.

The 1970s and 1980s saw the first applications of PU in sportswear and outdoor clothing, primarily as waterproof coatings. This marked the beginning of PU's integration into functional fabrics. As technology progressed, so did the capabilities of PU-based materials. The 1990s witnessed the development of breathable PU membranes, which revolutionized outdoor apparel by offering both waterproofing and moisture-wicking properties.

The turn of the millennium brought about a paradigm shift in the concept of smart clothing. Researchers began exploring ways to incorporate electronic components into fabrics, and PU played a crucial role in this integration. Its flexibility and ability to be formulated into various forms made it an ideal candidate for creating conductive pathways and protective layers for embedded electronics.

In the early 2000s, the focus shifted towards developing PU-based materials with enhanced properties such as shape memory and self-healing capabilities. These advancements laid the groundwork for truly interactive and responsive smart clothing. By the mid-2010s, PU-based smart fabrics were capable of changing color, adapting to temperature changes, and even monitoring vital signs.

Recent years have seen a surge in research aimed at improving the sustainability and biocompatibility of PU-based smart fabrics. Efforts to develop bio-based polyurethanes and improve recycling processes have gained momentum, addressing environmental concerns associated with synthetic materials.

The latest frontier in PU smart fabric evolution involves the integration of nanotechnology. Nanoparticle-infused PU materials are being developed to enhance properties such as antimicrobial resistance, UV protection, and even energy harvesting capabilities. These advancements are paving the way for a new generation of multifunctional smart clothing that can adapt to user needs and environmental conditions in real-time.

As we look to the future, the evolution of PU in smart clothing continues to accelerate. Ongoing research focuses on improving the seamless integration of electronics, enhancing durability and washability, and developing new functionalities such as haptic feedback and advanced sensing capabilities. The convergence of material science, electronics, and biotechnology promises to unlock even more innovative applications for PU-based smart fabrics in the coming years.

Smart Clothing Market Analysis

The smart clothing market has been experiencing significant growth in recent years, driven by advancements in wearable technology, increasing health consciousness, and the growing demand for functional apparel. The integration of polyurethane in smart clothing has opened up new possibilities for enhanced performance and comfort, contributing to the market's expansion.

The global smart clothing market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many traditional apparel segments. This growth is attributed to the rising adoption of smart textiles in various applications, including sports and fitness, healthcare, military, and fashion industries.

In the sports and fitness sector, smart clothing embedded with polyurethane-based sensors has gained traction among professional athletes and fitness enthusiasts. These garments offer real-time monitoring of vital signs, muscle activity, and performance metrics, enabling users to optimize their training and recovery processes.

The healthcare industry has also shown increasing interest in smart clothing solutions. Polyurethane-based wearables are being developed for remote patient monitoring, chronic disease management, and elderly care. These applications have the potential to revolutionize healthcare delivery and improve patient outcomes.

Military and defense sectors are exploring smart clothing technologies for enhanced soldier performance and safety. Polyurethane-based smart textiles are being incorporated into uniforms and protective gear to monitor physiological parameters, detect environmental hazards, and provide improved thermal regulation.

Fashion and lifestyle brands are embracing smart clothing as a means of differentiation and innovation. Polyurethane-based smart fabrics are being used to create garments with adaptive properties, such as color-changing capabilities or temperature regulation, appealing to tech-savvy consumers seeking unique and functional apparel.

The market for smart clothing faces some challenges, including high production costs, concerns about data privacy and security, and the need for improved durability and washability. However, ongoing research and development in polyurethane technologies are addressing these issues, potentially leading to more widespread adoption.

Geographically, North America and Europe currently dominate the smart clothing market, owing to their advanced technological infrastructure and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, rapid urbanization, and a growing tech-savvy population.

As the smart clothing market continues to evolve, collaborations between textile manufacturers, technology companies, and fashion brands are becoming more prevalent. These partnerships are crucial for developing innovative products that seamlessly integrate advanced polyurethane materials with cutting-edge electronics and software solutions.

The global smart clothing market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many traditional apparel segments. This growth is attributed to the rising adoption of smart textiles in various applications, including sports and fitness, healthcare, military, and fashion industries.

In the sports and fitness sector, smart clothing embedded with polyurethane-based sensors has gained traction among professional athletes and fitness enthusiasts. These garments offer real-time monitoring of vital signs, muscle activity, and performance metrics, enabling users to optimize their training and recovery processes.

The healthcare industry has also shown increasing interest in smart clothing solutions. Polyurethane-based wearables are being developed for remote patient monitoring, chronic disease management, and elderly care. These applications have the potential to revolutionize healthcare delivery and improve patient outcomes.

Military and defense sectors are exploring smart clothing technologies for enhanced soldier performance and safety. Polyurethane-based smart textiles are being incorporated into uniforms and protective gear to monitor physiological parameters, detect environmental hazards, and provide improved thermal regulation.

Fashion and lifestyle brands are embracing smart clothing as a means of differentiation and innovation. Polyurethane-based smart fabrics are being used to create garments with adaptive properties, such as color-changing capabilities or temperature regulation, appealing to tech-savvy consumers seeking unique and functional apparel.

The market for smart clothing faces some challenges, including high production costs, concerns about data privacy and security, and the need for improved durability and washability. However, ongoing research and development in polyurethane technologies are addressing these issues, potentially leading to more widespread adoption.

Geographically, North America and Europe currently dominate the smart clothing market, owing to their advanced technological infrastructure and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, rapid urbanization, and a growing tech-savvy population.

As the smart clothing market continues to evolve, collaborations between textile manufacturers, technology companies, and fashion brands are becoming more prevalent. These partnerships are crucial for developing innovative products that seamlessly integrate advanced polyurethane materials with cutting-edge electronics and software solutions.

PU Challenges in Wearables

The integration of polyurethane (PU) into smart clothing presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is achieving the delicate balance between flexibility and durability. While PU offers excellent elasticity, it often struggles to maintain its structural integrity over extended periods of wear and repeated movements, particularly in areas subject to high stress such as elbows and knees.

Another critical challenge lies in the incorporation of electronic components into PU-based fabrics. The material's inherent properties can interfere with the conductivity and performance of embedded sensors and circuits. This interference may lead to inconsistent data collection and reduced functionality of smart features, limiting the overall effectiveness of the wearable technology.

Moisture management poses a substantial hurdle in PU-based smart clothing. Although PU can be engineered to have varying degrees of breathability, achieving optimal moisture wicking and thermal regulation while maintaining the material's smart capabilities remains a complex task. This challenge is particularly pronounced in applications requiring prolonged wear or use in diverse environmental conditions.

The manufacturing process of PU-integrated smart textiles presents its own set of difficulties. Ensuring uniform distribution of smart components throughout the fabric while maintaining the material's desired physical properties requires advanced production techniques. Additionally, the scalability of these manufacturing processes to meet potential market demands is an ongoing concern for industry players.

Biocompatibility and skin sensitivity issues also pose significant challenges. As smart clothing is designed for direct and prolonged contact with the skin, ensuring that PU formulations do not cause irritation or allergic reactions is crucial. This necessitates extensive testing and potentially limits the range of additives and treatments that can be used to enhance the material's smart functionalities.

Lastly, the environmental impact of PU-based smart clothing is a growing concern. While polyurethane offers durability and versatility, its production and disposal can have negative environmental consequences. Developing eco-friendly PU formulations and implementing effective recycling methods for smart textiles are essential challenges that need to be addressed to ensure the sustainability of this technology in the long term.

Another critical challenge lies in the incorporation of electronic components into PU-based fabrics. The material's inherent properties can interfere with the conductivity and performance of embedded sensors and circuits. This interference may lead to inconsistent data collection and reduced functionality of smart features, limiting the overall effectiveness of the wearable technology.

Moisture management poses a substantial hurdle in PU-based smart clothing. Although PU can be engineered to have varying degrees of breathability, achieving optimal moisture wicking and thermal regulation while maintaining the material's smart capabilities remains a complex task. This challenge is particularly pronounced in applications requiring prolonged wear or use in diverse environmental conditions.

The manufacturing process of PU-integrated smart textiles presents its own set of difficulties. Ensuring uniform distribution of smart components throughout the fabric while maintaining the material's desired physical properties requires advanced production techniques. Additionally, the scalability of these manufacturing processes to meet potential market demands is an ongoing concern for industry players.

Biocompatibility and skin sensitivity issues also pose significant challenges. As smart clothing is designed for direct and prolonged contact with the skin, ensuring that PU formulations do not cause irritation or allergic reactions is crucial. This necessitates extensive testing and potentially limits the range of additives and treatments that can be used to enhance the material's smart functionalities.

Lastly, the environmental impact of PU-based smart clothing is a growing concern. While polyurethane offers durability and versatility, its production and disposal can have negative environmental consequences. Developing eco-friendly PU formulations and implementing effective recycling methods for smart textiles are essential challenges that need to be addressed to ensure the sustainability of this technology in the long term.

Current PU Smart Fabric Solutions

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.

- Polyurethane applications in coatings and films: This point covers the use of polyurethane in various coating and film applications. It includes formulations for protective coatings, adhesive films, and specialty surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.

- Polyurethane foam technology: This category encompasses innovations in polyurethane foam production and properties. It includes methods for creating various types of foams, such as flexible, rigid, or viscoelastic foams. The technology may involve specific blowing agents, catalysts, or processing techniques to achieve desired foam characteristics like density, cell structure, or thermal insulation properties.

- Polyurethane in textile and fiber applications: This point focuses on the use of polyurethane in textile and fiber-related applications. It includes methods for incorporating polyurethane into fabrics, creating polyurethane fibers, or developing polyurethane-based finishes for textiles. These applications may enhance properties such as elasticity, moisture management, or durability of textile products.

- Environmentally friendly polyurethane innovations: This category covers developments in more sustainable and environmentally friendly polyurethane technologies. It includes bio-based polyurethane formulations, recycling methods for polyurethane materials, and innovations to reduce the environmental impact of polyurethane production and use. These developments may focus on using renewable resources, improving biodegradability, or reducing harmful emissions.

02 Polyurethane applications in coatings and films

This point covers the use of polyurethane in various coating and film applications. It includes formulations for protective coatings, adhesive films, and surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses innovations in polyurethane foam production and properties. It includes advancements in foam formulations, manufacturing processes, and the development of specialized foams for specific applications such as insulation, cushioning, or structural components.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This point focuses on the use of polyurethane in textile and fiber-related applications. It includes innovations in polyurethane-based fibers, coatings for fabrics, and treatments for improving textile properties such as water resistance, breathability, or durability.Expand Specific Solutions05 Environmentally friendly polyurethane technologies

This category covers advancements in developing more environmentally friendly polyurethane materials and processes. It includes bio-based polyurethanes, recyclable formulations, and production methods that reduce environmental impact or improve sustainability.Expand Specific Solutions

Smart Fabric Industry Leaders

The smart clothing market, driven by advancements in polyurethane technology, is in a growth phase with increasing market size and technological maturity. Major players like BASF Corp., Covestro, and DuPont are leading innovation in this field. The market is characterized by a mix of established chemical companies and specialized textile manufacturers, such as Haining Xingao Fiber Co. and Kolon Glotech. Academic institutions like Donghua University and Tiangong University are contributing to research and development. The technology is evolving rapidly, with companies like Intel Corp. exploring integration of electronics into smart fabrics. As the market expands, collaborations between material scientists, textile engineers, and electronics experts are becoming crucial for advancing polyurethane-based smart clothing solutions.

BASF Corp.

Technical Solution: BASF has developed a range of innovative polyurethane materials for smart clothing applications. Their Elastollan® TPU (Thermoplastic Polyurethane) is a key component in creating flexible and durable smart textiles. This material can be embedded with sensors and conductive elements, allowing for the integration of electronic functionalities into fabrics. BASF's polyurethane technology also includes breathable membranes and moisture-wicking coatings, enhancing the comfort and performance of smart clothing. Additionally, they have developed bio-based polyurethanes, addressing the growing demand for sustainable materials in the smart textile industry.

Strengths: Versatility in applications, high durability, and ability to integrate electronic components. Weaknesses: May require specialized manufacturing processes and potentially higher production costs compared to traditional textiles.

Covestro Intellectual Property GmbH & Co. KG

Technical Solution: Covestro has pioneered the development of INSQIN® technology, a water-based polyurethane (PU) solution specifically designed for textile applications, including smart clothing. This innovative approach allows for the creation of breathable, flexible, and durable PU coatings without the use of solvents. The INSQIN® technology enables the integration of electronic components and sensors into textiles while maintaining comfort and performance. Covestro has also developed thermoplastic polyurethanes (TPUs) that can be used in 3D printing of customized smart clothing components, offering new possibilities for personalized wearable technology.

Strengths: Eco-friendly water-based solution, versatility in application methods, and compatibility with various textile substrates. Weaknesses: May require specific equipment for application and potentially higher initial investment for manufacturers.

Key PU Smart Textile Innovations

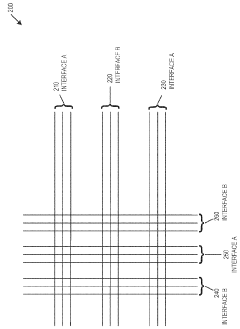

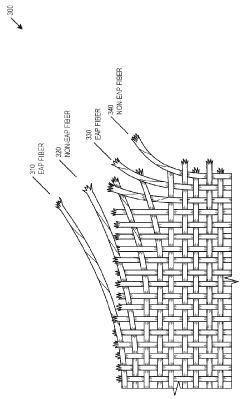

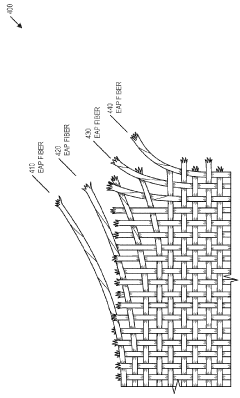

Wearable adaptive electroactive polymer fabric

PatentInactiveUS20180092415A1

Innovation

- Incorporating Electroactive Polymers (EAP) into smart fabrics that can change textile density based on voltage and current inputs, allowing for adaptive adjustments in garment structure and breathability, such as through the opening or closing of micro-holes, in response to various triggers like weather, activity, or user preferences.

POLYURETHANE PERSONAL IMPROVEMENT UNDER AND OUTER CLOTHES and PRODUCTION METHOD

PatentInactiveTR202001757A2

Innovation

- Polyurethane-based fabric for sweat-enhancing clothing applicable to a wide range of garment types.

- Versatile production method for both inner and outer garments using polyurethane material.

- Integration of sweat-enhancing properties into various clothing items, including shapewear and athletic wear.

Sustainability in Smart PU Textiles

Sustainability in smart polyurethane (PU) textiles has become a critical focus in the advancement of smart clothing technology. As the demand for intelligent garments grows, so does the need for eco-friendly materials and production processes. The integration of sustainable practices in smart PU textiles addresses environmental concerns while enhancing the overall performance and longevity of smart clothing.

One of the primary sustainability initiatives in smart PU textiles involves the development of bio-based polyurethanes. These materials are derived from renewable resources such as plant oils, reducing reliance on petroleum-based raw materials. Bio-based PU not only decreases the carbon footprint of smart clothing production but also offers improved biodegradability at the end of the product lifecycle.

Recycling and upcycling processes have also gained traction in the smart PU textile industry. Innovative techniques allow for the recovery and reprocessing of polyurethane materials, minimizing waste and conserving resources. These recycled PU materials can be incorporated into new smart clothing products without compromising their functional properties.

Water-based polyurethane systems have emerged as a sustainable alternative to solvent-based formulations. These systems significantly reduce volatile organic compound (VOC) emissions during production, creating a safer working environment and minimizing environmental impact. Water-based PU coatings also offer excellent durability and flexibility, making them ideal for smart clothing applications.

Energy-efficient manufacturing processes play a crucial role in enhancing the sustainability of smart PU textiles. Advanced production technologies, such as low-temperature curing and precision coating methods, reduce energy consumption while maintaining product quality. These innovations contribute to a more sustainable supply chain for smart clothing manufacturers.

The development of self-healing PU materials represents a significant advancement in sustainability for smart textiles. These materials can repair minor damage autonomously, extending the lifespan of smart clothing and reducing the need for premature replacement. Self-healing PU contributes to a circular economy model by minimizing waste and conserving resources.

Nanotechnology integration in smart PU textiles offers opportunities for enhanced sustainability. Nanoparticles can be incorporated into PU materials to improve their performance, durability, and functionality. This allows for the creation of thinner, lighter smart clothing that requires fewer raw materials while maintaining or even surpassing the capabilities of traditional textiles.

As the smart clothing industry continues to evolve, the focus on sustainability in smart PU textiles will likely intensify. Future developments may include the integration of biodegradable electronic components, advanced recycling technologies, and the use of artificial intelligence to optimize material formulations for maximum sustainability and performance. These advancements will pave the way for a new generation of eco-friendly, high-performance smart clothing that meets the growing demand for sustainable fashion and wearable technology.

One of the primary sustainability initiatives in smart PU textiles involves the development of bio-based polyurethanes. These materials are derived from renewable resources such as plant oils, reducing reliance on petroleum-based raw materials. Bio-based PU not only decreases the carbon footprint of smart clothing production but also offers improved biodegradability at the end of the product lifecycle.

Recycling and upcycling processes have also gained traction in the smart PU textile industry. Innovative techniques allow for the recovery and reprocessing of polyurethane materials, minimizing waste and conserving resources. These recycled PU materials can be incorporated into new smart clothing products without compromising their functional properties.

Water-based polyurethane systems have emerged as a sustainable alternative to solvent-based formulations. These systems significantly reduce volatile organic compound (VOC) emissions during production, creating a safer working environment and minimizing environmental impact. Water-based PU coatings also offer excellent durability and flexibility, making them ideal for smart clothing applications.

Energy-efficient manufacturing processes play a crucial role in enhancing the sustainability of smart PU textiles. Advanced production technologies, such as low-temperature curing and precision coating methods, reduce energy consumption while maintaining product quality. These innovations contribute to a more sustainable supply chain for smart clothing manufacturers.

The development of self-healing PU materials represents a significant advancement in sustainability for smart textiles. These materials can repair minor damage autonomously, extending the lifespan of smart clothing and reducing the need for premature replacement. Self-healing PU contributes to a circular economy model by minimizing waste and conserving resources.

Nanotechnology integration in smart PU textiles offers opportunities for enhanced sustainability. Nanoparticles can be incorporated into PU materials to improve their performance, durability, and functionality. This allows for the creation of thinner, lighter smart clothing that requires fewer raw materials while maintaining or even surpassing the capabilities of traditional textiles.

As the smart clothing industry continues to evolve, the focus on sustainability in smart PU textiles will likely intensify. Future developments may include the integration of biodegradable electronic components, advanced recycling technologies, and the use of artificial intelligence to optimize material formulations for maximum sustainability and performance. These advancements will pave the way for a new generation of eco-friendly, high-performance smart clothing that meets the growing demand for sustainable fashion and wearable technology.

Wearable PU Safety Standards

The development of smart clothing incorporating polyurethane (PU) materials has necessitated the establishment of comprehensive safety standards to ensure consumer protection and product reliability. These standards address various aspects of wearable PU technology, including chemical safety, electrical safety, and performance requirements.

Chemical safety standards for wearable PU focus on limiting the use of potentially harmful substances in the manufacturing process. Regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in the European Union and similar standards in other regions set strict guidelines for the use of chemicals in PU production. These standards typically specify maximum allowable concentrations for substances like phthalates, formaldehyde, and heavy metals, which may be present in PU materials or additives.

Electrical safety standards are crucial for smart clothing that incorporates electronic components within PU-based materials. Organizations like the International Electrotechnical Commission (IEC) have developed specific standards for wearable electronics, such as IEC 63203, which addresses safety requirements for electronic textiles. These standards cover aspects like insulation, grounding, and protection against electric shock, ensuring that the integration of electronics with PU materials does not pose risks to users.

Performance requirements for wearable PU in smart clothing encompass a range of factors, including durability, flexibility, and washability. Standards organizations like ASTM International and ISO have developed test methods to evaluate the performance of PU materials in wearable applications. These tests assess properties such as tensile strength, tear resistance, and abrasion resistance, as well as the material's ability to withstand repeated washing and wear cycles without degradation of its smart functionalities.

Biocompatibility and skin safety standards are particularly important for wearable PU products that come into direct contact with the skin. Standards like ISO 10993 provide guidelines for evaluating the biological safety of materials used in medical devices, which are often applied to smart clothing applications. These standards require testing for skin irritation, sensitization, and cytotoxicity to ensure that PU materials used in close contact with the skin do not cause adverse reactions.

Flame retardancy standards are also relevant for certain applications of wearable PU, especially in protective clothing or in environments where fire safety is a concern. Standards such as EN ISO 11612 specify requirements for protective clothing against heat and flame, which may be applicable to smart clothing incorporating PU materials.

As the field of smart clothing continues to evolve, safety standards for wearable PU are likely to undergo further refinement and expansion. Regulatory bodies and standards organizations are working to keep pace with technological advancements, addressing emerging concerns such as data privacy and security in smart clothing applications. The ongoing development of these standards will play a crucial role in ensuring the safe and responsible integration of PU-based smart materials in wearable technology.

Chemical safety standards for wearable PU focus on limiting the use of potentially harmful substances in the manufacturing process. Regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in the European Union and similar standards in other regions set strict guidelines for the use of chemicals in PU production. These standards typically specify maximum allowable concentrations for substances like phthalates, formaldehyde, and heavy metals, which may be present in PU materials or additives.

Electrical safety standards are crucial for smart clothing that incorporates electronic components within PU-based materials. Organizations like the International Electrotechnical Commission (IEC) have developed specific standards for wearable electronics, such as IEC 63203, which addresses safety requirements for electronic textiles. These standards cover aspects like insulation, grounding, and protection against electric shock, ensuring that the integration of electronics with PU materials does not pose risks to users.

Performance requirements for wearable PU in smart clothing encompass a range of factors, including durability, flexibility, and washability. Standards organizations like ASTM International and ISO have developed test methods to evaluate the performance of PU materials in wearable applications. These tests assess properties such as tensile strength, tear resistance, and abrasion resistance, as well as the material's ability to withstand repeated washing and wear cycles without degradation of its smart functionalities.

Biocompatibility and skin safety standards are particularly important for wearable PU products that come into direct contact with the skin. Standards like ISO 10993 provide guidelines for evaluating the biological safety of materials used in medical devices, which are often applied to smart clothing applications. These standards require testing for skin irritation, sensitization, and cytotoxicity to ensure that PU materials used in close contact with the skin do not cause adverse reactions.

Flame retardancy standards are also relevant for certain applications of wearable PU, especially in protective clothing or in environments where fire safety is a concern. Standards such as EN ISO 11612 specify requirements for protective clothing against heat and flame, which may be applicable to smart clothing incorporating PU materials.

As the field of smart clothing continues to evolve, safety standards for wearable PU are likely to undergo further refinement and expansion. Regulatory bodies and standards organizations are working to keep pace with technological advancements, addressing emerging concerns such as data privacy and security in smart clothing applications. The ongoing development of these standards will play a crucial role in ensuring the safe and responsible integration of PU-based smart materials in wearable technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!