Advances in Lithium Iron Phosphate Battery Pack Design and Integration

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

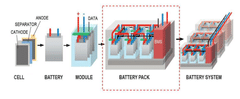

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their introduction in the late 1990s. Initially developed as a safer alternative to lithium cobalt oxide (LCO) batteries, LFP technology has seen remarkable advancements in energy density, cycle life, and cost-effectiveness over the past two decades.

The early 2000s marked the beginning of commercial LFP battery production, with initial applications primarily in portable electronics and power tools. During this period, researchers focused on improving the material synthesis and electrode fabrication processes to enhance the battery's performance characteristics.

A major breakthrough came in the mid-2000s with the development of nano-scale LFP particles. This innovation dramatically improved the battery's power density and rate capability, making it suitable for electric vehicle applications. Concurrently, advancements in carbon coating techniques further enhanced the material's conductivity and stability.

The late 2000s and early 2010s saw a surge in LFP battery adoption for electric vehicles, particularly in China. This period was characterized by significant improvements in cell design and manufacturing processes, leading to increased energy density and reduced production costs.

In recent years, the focus has shifted towards optimizing battery pack design and integration. Advanced thermal management systems, improved battery management systems (BMS), and innovative cell-to-pack technologies have emerged as key areas of development. These advancements have not only enhanced the overall performance of LFP battery packs but also simplified their integration into various applications.

The evolution of LFP batteries has also been marked by continuous improvements in safety features. Enhanced separator technologies, advanced electrolyte formulations, and robust pack designs have further solidified LFP's position as one of the safest lithium-ion battery chemistries available.

Looking ahead, the LFP battery evolution is expected to continue with a focus on increasing energy density through material innovations and cell design optimizations. Researchers are exploring doping strategies, novel cathode architectures, and advanced electrolytes to push the boundaries of LFP technology. Additionally, efforts are being made to develop more sustainable and environmentally friendly production processes, aligning with the growing emphasis on circular economy principles in the battery industry.

The early 2000s marked the beginning of commercial LFP battery production, with initial applications primarily in portable electronics and power tools. During this period, researchers focused on improving the material synthesis and electrode fabrication processes to enhance the battery's performance characteristics.

A major breakthrough came in the mid-2000s with the development of nano-scale LFP particles. This innovation dramatically improved the battery's power density and rate capability, making it suitable for electric vehicle applications. Concurrently, advancements in carbon coating techniques further enhanced the material's conductivity and stability.

The late 2000s and early 2010s saw a surge in LFP battery adoption for electric vehicles, particularly in China. This period was characterized by significant improvements in cell design and manufacturing processes, leading to increased energy density and reduced production costs.

In recent years, the focus has shifted towards optimizing battery pack design and integration. Advanced thermal management systems, improved battery management systems (BMS), and innovative cell-to-pack technologies have emerged as key areas of development. These advancements have not only enhanced the overall performance of LFP battery packs but also simplified their integration into various applications.

The evolution of LFP batteries has also been marked by continuous improvements in safety features. Enhanced separator technologies, advanced electrolyte formulations, and robust pack designs have further solidified LFP's position as one of the safest lithium-ion battery chemistries available.

Looking ahead, the LFP battery evolution is expected to continue with a focus on increasing energy density through material innovations and cell design optimizations. Researchers are exploring doping strategies, novel cathode architectures, and advanced electrolytes to push the boundaries of LFP technology. Additionally, efforts are being made to develop more sustainable and environmentally friendly production processes, aligning with the growing emphasis on circular economy principles in the battery industry.

Market Demand Analysis

The market demand for lithium iron phosphate (LFP) battery packs has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. This surge in demand is primarily attributed to the superior safety, longer lifespan, and lower cost of LFP batteries compared to other lithium-ion chemistries.

In the automotive sector, LFP batteries are gaining traction, particularly in the mass-market EV segment. Major automakers are incorporating LFP battery packs into their electric vehicle lineups, recognizing the technology's cost-effectiveness and reliability. This trend is especially prominent in China, where LFP batteries have become the dominant chemistry for electric vehicles.

The energy storage market is another key driver for LFP battery pack demand. Grid-scale energy storage projects and residential battery systems are increasingly utilizing LFP technology due to its safety profile and cycle life advantages. As renewable energy integration accelerates, the need for efficient and durable energy storage solutions continues to grow, further boosting the demand for LFP battery packs.

Commercial and industrial applications are also contributing to the market expansion. Electric buses, trucks, and other heavy-duty vehicles are adopting LFP battery packs, leveraging their robust performance and lower total cost of ownership. Additionally, the marine and aviation industries are exploring LFP technology for various applications, opening new market opportunities.

The global push for sustainability and carbon neutrality is further propelling the demand for LFP battery packs. Governments worldwide are implementing stricter emissions regulations and offering incentives for clean energy technologies, which indirectly benefits the LFP battery market. This regulatory landscape is expected to continue driving market growth in the coming years.

Despite the positive market outlook, challenges remain in the LFP battery pack industry. The lower energy density of LFP batteries compared to other lithium-ion chemistries can be a limiting factor in certain applications where weight and space are critical considerations. However, ongoing advancements in LFP battery pack design and integration are addressing these limitations, potentially expanding the technology's applicability across various sectors.

The market for LFP battery packs is projected to grow substantially in the next decade. This growth is expected to be fueled by continued improvements in energy density, cost reductions through economies of scale, and the development of more efficient manufacturing processes. As the technology matures and its benefits become more widely recognized, LFP battery packs are poised to play a crucial role in the global transition towards sustainable energy solutions.

In the automotive sector, LFP batteries are gaining traction, particularly in the mass-market EV segment. Major automakers are incorporating LFP battery packs into their electric vehicle lineups, recognizing the technology's cost-effectiveness and reliability. This trend is especially prominent in China, where LFP batteries have become the dominant chemistry for electric vehicles.

The energy storage market is another key driver for LFP battery pack demand. Grid-scale energy storage projects and residential battery systems are increasingly utilizing LFP technology due to its safety profile and cycle life advantages. As renewable energy integration accelerates, the need for efficient and durable energy storage solutions continues to grow, further boosting the demand for LFP battery packs.

Commercial and industrial applications are also contributing to the market expansion. Electric buses, trucks, and other heavy-duty vehicles are adopting LFP battery packs, leveraging their robust performance and lower total cost of ownership. Additionally, the marine and aviation industries are exploring LFP technology for various applications, opening new market opportunities.

The global push for sustainability and carbon neutrality is further propelling the demand for LFP battery packs. Governments worldwide are implementing stricter emissions regulations and offering incentives for clean energy technologies, which indirectly benefits the LFP battery market. This regulatory landscape is expected to continue driving market growth in the coming years.

Despite the positive market outlook, challenges remain in the LFP battery pack industry. The lower energy density of LFP batteries compared to other lithium-ion chemistries can be a limiting factor in certain applications where weight and space are critical considerations. However, ongoing advancements in LFP battery pack design and integration are addressing these limitations, potentially expanding the technology's applicability across various sectors.

The market for LFP battery packs is projected to grow substantially in the next decade. This growth is expected to be fueled by continued improvements in energy density, cost reductions through economies of scale, and the development of more efficient manufacturing processes. As the technology matures and its benefits become more widely recognized, LFP battery packs are poised to play a crucial role in the global transition towards sustainable energy solutions.

Technical Challenges

Lithium Iron Phosphate (LFP) battery pack design and integration face several significant technical challenges that require innovative solutions. One of the primary obstacles is the lower energy density of LFP cells compared to other lithium-ion chemistries. This necessitates larger battery packs to achieve equivalent energy storage, posing difficulties in vehicle design and weight management.

Thermal management remains a critical issue in LFP battery pack design. While LFP cells are generally more thermally stable than other lithium-ion variants, efficient heat dissipation is still crucial for optimal performance and longevity. Engineers must develop advanced cooling systems that can maintain uniform temperature distribution across the pack, particularly in high-power applications.

The integration of Battery Management Systems (BMS) presents another complex challenge. LFP cells have a flatter voltage curve during discharge, making it more difficult for BMS to accurately estimate the state of charge. This requires more sophisticated algorithms and sensing technologies to ensure precise monitoring and control of the battery pack's performance and health.

Packaging and structural design of LFP battery packs pose additional hurdles. The need for larger packs to compensate for lower energy density demands innovative approaches to maximize space utilization while maintaining structural integrity and crash safety standards. This often involves complex trade-offs between energy capacity, weight, and vehicle design constraints.

Manufacturing scalability and cost-effectiveness are ongoing challenges in LFP battery pack production. While LFP cells are generally less expensive than other lithium-ion chemistries, the larger pack sizes required can offset some of these cost advantages. Developing efficient, automated assembly processes for these larger packs is crucial for maintaining competitive pricing in the electric vehicle market.

Durability and cycle life optimization remain areas of focus for LFP battery pack design. Although LFP cells inherently offer good cycle life, maximizing this advantage in real-world applications requires careful consideration of factors such as depth of discharge, charging protocols, and overall pack design to minimize cell degradation over time.

Lastly, the integration of LFP battery packs with vehicle systems presents unique challenges. The different voltage characteristics and power delivery profiles of LFP batteries compared to other chemistries necessitate adaptations in motor controllers, power electronics, and charging systems. Engineers must develop solutions that optimize the interaction between the battery pack and other vehicle components to maximize overall system efficiency and performance.

Thermal management remains a critical issue in LFP battery pack design. While LFP cells are generally more thermally stable than other lithium-ion variants, efficient heat dissipation is still crucial for optimal performance and longevity. Engineers must develop advanced cooling systems that can maintain uniform temperature distribution across the pack, particularly in high-power applications.

The integration of Battery Management Systems (BMS) presents another complex challenge. LFP cells have a flatter voltage curve during discharge, making it more difficult for BMS to accurately estimate the state of charge. This requires more sophisticated algorithms and sensing technologies to ensure precise monitoring and control of the battery pack's performance and health.

Packaging and structural design of LFP battery packs pose additional hurdles. The need for larger packs to compensate for lower energy density demands innovative approaches to maximize space utilization while maintaining structural integrity and crash safety standards. This often involves complex trade-offs between energy capacity, weight, and vehicle design constraints.

Manufacturing scalability and cost-effectiveness are ongoing challenges in LFP battery pack production. While LFP cells are generally less expensive than other lithium-ion chemistries, the larger pack sizes required can offset some of these cost advantages. Developing efficient, automated assembly processes for these larger packs is crucial for maintaining competitive pricing in the electric vehicle market.

Durability and cycle life optimization remain areas of focus for LFP battery pack design. Although LFP cells inherently offer good cycle life, maximizing this advantage in real-world applications requires careful consideration of factors such as depth of discharge, charging protocols, and overall pack design to minimize cell degradation over time.

Lastly, the integration of LFP battery packs with vehicle systems presents unique challenges. The different voltage characteristics and power delivery profiles of LFP batteries compared to other chemistries necessitate adaptations in motor controllers, power electronics, and charging systems. Engineers must develop solutions that optimize the interaction between the battery pack and other vehicle components to maximize overall system efficiency and performance.

Current Pack Designs

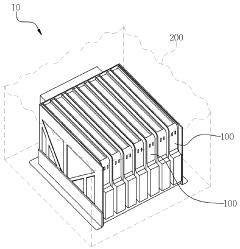

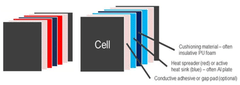

01 Battery pack design and structure

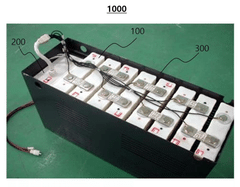

Lithium iron phosphate battery packs are designed with specific structures to optimize performance and safety. This includes the arrangement of cells, thermal management systems, and protective enclosures. The design focuses on maximizing energy density while ensuring proper heat dissipation and mechanical protection.- Battery pack design and structure: Lithium iron phosphate battery packs are designed with specific structures to optimize performance and safety. This includes the arrangement of cells, thermal management systems, and protective enclosures. The design focuses on maximizing energy density while ensuring proper heat dissipation and mechanical protection.

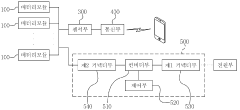

- Battery management system integration: Integration of advanced battery management systems (BMS) is crucial for lithium iron phosphate battery packs. The BMS monitors cell voltages, temperatures, and overall pack health, ensuring optimal performance and longevity. It also manages charging and discharging processes, balancing cells, and providing safety features such as overcharge and over-discharge protection.

- Thermal management solutions: Effective thermal management is essential for lithium iron phosphate battery packs to maintain optimal operating temperatures. This includes the use of cooling systems, heat sinks, and thermal interface materials. Proper thermal management enhances battery performance, extends lifespan, and improves safety by preventing overheating and thermal runaway.

- Integration with power electronics: Lithium iron phosphate battery packs are integrated with power electronics components such as inverters, converters, and charge controllers. This integration optimizes power flow, improves efficiency, and enables seamless operation in various applications, including electric vehicles and renewable energy storage systems.

- Safety features and protection mechanisms: Lithium iron phosphate battery packs incorporate various safety features and protection mechanisms. These include fuses, circuit breakers, isolation switches, and pressure relief valves. Advanced monitoring systems detect abnormal conditions and trigger appropriate safety responses, ensuring the overall safety and reliability of the battery pack in different operating environments.

02 Battery management system integration

Integration of advanced battery management systems (BMS) is crucial for lithium iron phosphate battery packs. The BMS monitors cell voltages, temperatures, and state of charge, ensuring optimal performance and longevity. It also provides protection against overcharging, over-discharging, and thermal runaway.Expand Specific Solutions03 Thermal management and cooling solutions

Effective thermal management is essential for lithium iron phosphate battery packs to maintain optimal operating temperatures. This includes the implementation of cooling systems, such as liquid cooling or air cooling, to prevent overheating and ensure consistent performance across various environmental conditions.Expand Specific Solutions04 Cell balancing and charge control

Advanced cell balancing techniques and charge control mechanisms are implemented in lithium iron phosphate battery packs to ensure uniform charging and discharging of individual cells. This helps maximize the overall capacity utilization and extends the lifespan of the battery pack.Expand Specific Solutions05 Integration with power electronics and systems

Lithium iron phosphate battery packs are designed for seamless integration with power electronics and larger energy systems. This includes compatibility with inverters, chargers, and energy management systems, as well as considerations for scalability and modularity to meet various application requirements.Expand Specific Solutions

Key Industry Players

The lithium iron phosphate (LFP) battery pack design and integration market is in a growth phase, driven by increasing demand for electric vehicles and energy storage systems. The global market size is projected to expand significantly in the coming years, with major players like LG Energy Solution, BYD, and CATL leading the charge. Technological advancements are rapidly improving energy density, charging speeds, and overall performance of LFP batteries. Companies such as Murata Manufacturing, Panasonic, and A123 Systems are investing heavily in R&D to enhance LFP technology. The competitive landscape is intensifying as both established manufacturers and innovative startups like Cadenza Innovation and Nano One Materials strive to develop cutting-edge solutions for next-generation LFP battery packs.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced LFP battery packs with a focus on modular design and scalability. Their packs feature high-density cell stacking and innovative cooling systems, including immersion cooling technology for improved thermal management[7]. LG has also implemented smart battery management systems that utilize artificial intelligence to optimize charging and discharging processes, extending battery life and improving overall efficiency[8]. Their LFP packs incorporate advanced safety features such as flame-retardant materials and multi-layer protection against thermal runaway[9].

Strengths: Advanced thermal management, AI-driven battery management, modular design for various applications. Weaknesses: Potentially higher cost due to advanced features.

Panasonic Holdings Corp.

Technical Solution: Panasonic has made significant advancements in LFP battery pack design, focusing on high energy density and improved manufacturing processes. Their approach includes the development of high-capacity LFP cells and innovative pack architectures that maximize volumetric efficiency[10]. Panasonic's packs feature advanced electrode designs and electrolyte formulations that enhance power output and fast-charging capabilities. They have also implemented sophisticated battery management systems that provide accurate state-of-charge estimation and predictive maintenance capabilities[11].

Strengths: High energy density, improved fast-charging capabilities, advanced BMS. Weaknesses: Relatively new to LFP technology compared to some competitors.

Core LFP Innovations

Lithium-Iron Phosphate Battery Pack

PatentInactiveKR1020230050865A

Innovation

- A lithium-iron phosphate battery pack equipped with a sensor unit to measure current, voltage, and temperature, and a communication unit to transmit this information to a user's mobile device or PC, allowing real-time monitoring and notification of remaining capacity.

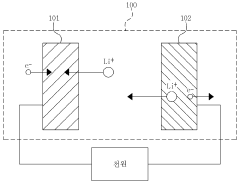

Lithium iron phosphate battery pack

PatentActiveKR1020220165968A

Innovation

- A filler with thermal conductivity, flame retardancy, and electrical insulation is injected into the empty space within the battery pack case, eliminating the space and providing a heat transfer passage.

Safety Regulations

Safety regulations play a crucial role in the advancement of Lithium Iron Phosphate (LFP) battery pack design and integration. As the demand for safer and more reliable energy storage solutions grows, regulatory bodies worldwide have implemented stringent safety standards to ensure the safe operation of LFP battery systems.

One of the primary safety concerns addressed by regulations is thermal runaway prevention. Regulatory bodies require manufacturers to implement robust thermal management systems and incorporate fail-safe mechanisms to prevent the propagation of thermal events within battery packs. This has led to innovations in cell-to-cell isolation techniques and the development of advanced cooling systems.

Electrical safety is another key focus area of safety regulations. Standards mandate the use of high-quality insulation materials, proper wiring practices, and the implementation of advanced battery management systems (BMS) to monitor and control voltage, current, and temperature. These regulations have driven improvements in BMS algorithms and hardware design, enhancing overall system reliability.

Transportation safety regulations have also significantly influenced LFP battery pack design. UN 38.3 testing requirements, for instance, ensure that battery packs can withstand the rigors of shipping and handling. This has led to advancements in structural design and packaging materials, making LFP battery packs more robust and resistant to physical damage.

Fire safety regulations have prompted the development of fire-resistant materials and improved enclosure designs. Many jurisdictions now require battery packs to undergo extensive fire testing, including abuse tests and propagation resistance evaluations. This has resulted in the integration of fire suppression systems and the use of intumescent materials in battery pack construction.

Environmental and disposal regulations have also shaped LFP battery pack design. Requirements for recyclability and proper end-of-life management have encouraged manufacturers to develop modular designs that facilitate easier disassembly and material recovery. This has led to innovations in battery pack architecture and the use of more environmentally friendly materials.

Compliance with electromagnetic compatibility (EMC) regulations has driven advancements in shielding techniques and filter designs for LFP battery packs. These improvements have reduced electromagnetic interference, enhancing the compatibility of battery systems with other electronic components in various applications.

As safety regulations continue to evolve, they will undoubtedly spur further innovations in LFP battery pack design and integration. The ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions will be crucial in developing standards that balance safety requirements with technological advancements, ultimately leading to safer and more efficient energy storage solutions.

One of the primary safety concerns addressed by regulations is thermal runaway prevention. Regulatory bodies require manufacturers to implement robust thermal management systems and incorporate fail-safe mechanisms to prevent the propagation of thermal events within battery packs. This has led to innovations in cell-to-cell isolation techniques and the development of advanced cooling systems.

Electrical safety is another key focus area of safety regulations. Standards mandate the use of high-quality insulation materials, proper wiring practices, and the implementation of advanced battery management systems (BMS) to monitor and control voltage, current, and temperature. These regulations have driven improvements in BMS algorithms and hardware design, enhancing overall system reliability.

Transportation safety regulations have also significantly influenced LFP battery pack design. UN 38.3 testing requirements, for instance, ensure that battery packs can withstand the rigors of shipping and handling. This has led to advancements in structural design and packaging materials, making LFP battery packs more robust and resistant to physical damage.

Fire safety regulations have prompted the development of fire-resistant materials and improved enclosure designs. Many jurisdictions now require battery packs to undergo extensive fire testing, including abuse tests and propagation resistance evaluations. This has resulted in the integration of fire suppression systems and the use of intumescent materials in battery pack construction.

Environmental and disposal regulations have also shaped LFP battery pack design. Requirements for recyclability and proper end-of-life management have encouraged manufacturers to develop modular designs that facilitate easier disassembly and material recovery. This has led to innovations in battery pack architecture and the use of more environmentally friendly materials.

Compliance with electromagnetic compatibility (EMC) regulations has driven advancements in shielding techniques and filter designs for LFP battery packs. These improvements have reduced electromagnetic interference, enhancing the compatibility of battery systems with other electronic components in various applications.

As safety regulations continue to evolve, they will undoubtedly spur further innovations in LFP battery pack design and integration. The ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions will be crucial in developing standards that balance safety requirements with technological advancements, ultimately leading to safer and more efficient energy storage solutions.

Thermal Management

Thermal management is a critical aspect of lithium iron phosphate (LFP) battery pack design and integration. As LFP batteries continue to gain popularity in various applications, including electric vehicles and energy storage systems, effective thermal management becomes increasingly important for ensuring optimal performance, safety, and longevity.

LFP batteries generate heat during charging and discharging processes, which can significantly impact their performance and lifespan. Excessive heat can lead to accelerated degradation of battery components, reduced efficiency, and potential safety hazards. Conversely, extremely low temperatures can result in decreased power output and capacity. Therefore, maintaining an optimal temperature range is crucial for maximizing battery performance and longevity.

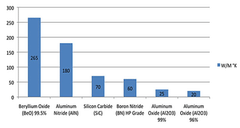

Recent advances in thermal management for LFP battery packs focus on both active and passive cooling strategies. Active cooling systems typically involve the use of liquid coolants or forced air circulation to regulate battery temperature. These systems offer precise temperature control but may increase the overall complexity and cost of the battery pack. Passive cooling methods, on the other hand, rely on heat dissipation through conductive materials and strategic pack design to manage thermal loads.

One notable innovation in thermal management is the development of phase change materials (PCMs) for LFP battery packs. PCMs absorb excess heat during battery operation and release it when the temperature drops, helping to maintain a more stable thermal environment. This approach can be particularly effective in applications with intermittent usage patterns or in regions with significant temperature fluctuations.

Another area of advancement is the integration of thermal management systems with battery management systems (BMS). This integration allows for real-time monitoring and control of battery temperature, enabling more efficient and adaptive thermal regulation. Advanced algorithms can predict thermal behavior based on usage patterns and environmental conditions, allowing for proactive temperature management.

The design of battery pack enclosures has also evolved to improve thermal management. New materials with enhanced thermal conductivity and innovative structural designs that promote better heat dissipation are being incorporated into LFP battery packs. These advancements contribute to more uniform temperature distribution within the pack, reducing hotspots and improving overall thermal stability.

As the demand for high-performance LFP battery packs continues to grow, research into novel thermal management solutions is ongoing. Areas of focus include the development of smart thermal materials, advanced cooling fluids, and more efficient heat exchange mechanisms. These innovations aim to further enhance the thermal performance of LFP battery packs, ultimately leading to improved safety, longer lifespan, and increased energy density in various applications.

LFP batteries generate heat during charging and discharging processes, which can significantly impact their performance and lifespan. Excessive heat can lead to accelerated degradation of battery components, reduced efficiency, and potential safety hazards. Conversely, extremely low temperatures can result in decreased power output and capacity. Therefore, maintaining an optimal temperature range is crucial for maximizing battery performance and longevity.

Recent advances in thermal management for LFP battery packs focus on both active and passive cooling strategies. Active cooling systems typically involve the use of liquid coolants or forced air circulation to regulate battery temperature. These systems offer precise temperature control but may increase the overall complexity and cost of the battery pack. Passive cooling methods, on the other hand, rely on heat dissipation through conductive materials and strategic pack design to manage thermal loads.

One notable innovation in thermal management is the development of phase change materials (PCMs) for LFP battery packs. PCMs absorb excess heat during battery operation and release it when the temperature drops, helping to maintain a more stable thermal environment. This approach can be particularly effective in applications with intermittent usage patterns or in regions with significant temperature fluctuations.

Another area of advancement is the integration of thermal management systems with battery management systems (BMS). This integration allows for real-time monitoring and control of battery temperature, enabling more efficient and adaptive thermal regulation. Advanced algorithms can predict thermal behavior based on usage patterns and environmental conditions, allowing for proactive temperature management.

The design of battery pack enclosures has also evolved to improve thermal management. New materials with enhanced thermal conductivity and innovative structural designs that promote better heat dissipation are being incorporated into LFP battery packs. These advancements contribute to more uniform temperature distribution within the pack, reducing hotspots and improving overall thermal stability.

As the demand for high-performance LFP battery packs continues to grow, research into novel thermal management solutions is ongoing. Areas of focus include the development of smart thermal materials, advanced cooling fluids, and more efficient heat exchange mechanisms. These innovations aim to further enhance the thermal performance of LFP battery packs, ultimately leading to improved safety, longer lifespan, and increased energy density in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!