Testing and Validation Protocols for Lithium Iron Phosphate Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Testing Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent technology in the energy storage landscape, particularly in electric vehicles and renewable energy systems. The development of LFP batteries can be traced back to the late 1990s when researchers at the University of Texas discovered the potential of LiFePO4 as a cathode material. Since then, the technology has undergone significant advancements, driven by the growing demand for safer, more cost-effective, and environmentally friendly energy storage solutions.

The evolution of LFP batteries has been marked by continuous improvements in energy density, cycle life, and manufacturing processes. Early iterations faced challenges related to low electrical conductivity and slow lithium-ion diffusion, which limited their practical applications. However, subsequent research and development efforts have addressed these issues through various strategies, including carbon coating, particle size reduction, and doping with conductive materials.

As the technology matured, LFP batteries gained traction in various industries, with the automotive sector being a primary driver of adoption. The inherent safety characteristics of LFP chemistry, coupled with its long cycle life and thermal stability, have made it an attractive option for electric vehicle manufacturers seeking to balance performance, cost, and safety considerations.

The current technological landscape for LFP batteries is characterized by ongoing efforts to further enhance their performance and reduce production costs. Key areas of focus include improving energy density to compete with other lithium-ion chemistries, optimizing electrode structures for faster charging capabilities, and developing more efficient manufacturing techniques to scale up production.

Given this background, the primary objectives of LFP battery testing and validation protocols are multifaceted. First and foremost, these protocols aim to ensure the safety and reliability of LFP batteries across a wide range of operating conditions. This includes evaluating their performance under extreme temperatures, high charge and discharge rates, and prolonged cycling.

Additionally, testing protocols seek to accurately assess and validate the key performance metrics of LFP batteries, such as capacity retention, power capability, and thermal behavior. These assessments are crucial for predicting battery life, optimizing battery management systems, and informing design decisions for various applications.

Another critical objective is to standardize testing methodologies across the industry, enabling meaningful comparisons between different LFP battery products and technologies. This standardization is essential for fostering innovation, facilitating quality control, and supporting regulatory compliance in diverse markets and applications.

Furthermore, as the LFP battery technology continues to evolve, testing protocols must adapt to address emerging challenges and opportunities. This includes developing new methods to evaluate advanced LFP formulations, assessing the impact of novel manufacturing processes, and validating the performance of LFP batteries in next-generation energy storage systems.

The evolution of LFP batteries has been marked by continuous improvements in energy density, cycle life, and manufacturing processes. Early iterations faced challenges related to low electrical conductivity and slow lithium-ion diffusion, which limited their practical applications. However, subsequent research and development efforts have addressed these issues through various strategies, including carbon coating, particle size reduction, and doping with conductive materials.

As the technology matured, LFP batteries gained traction in various industries, with the automotive sector being a primary driver of adoption. The inherent safety characteristics of LFP chemistry, coupled with its long cycle life and thermal stability, have made it an attractive option for electric vehicle manufacturers seeking to balance performance, cost, and safety considerations.

The current technological landscape for LFP batteries is characterized by ongoing efforts to further enhance their performance and reduce production costs. Key areas of focus include improving energy density to compete with other lithium-ion chemistries, optimizing electrode structures for faster charging capabilities, and developing more efficient manufacturing techniques to scale up production.

Given this background, the primary objectives of LFP battery testing and validation protocols are multifaceted. First and foremost, these protocols aim to ensure the safety and reliability of LFP batteries across a wide range of operating conditions. This includes evaluating their performance under extreme temperatures, high charge and discharge rates, and prolonged cycling.

Additionally, testing protocols seek to accurately assess and validate the key performance metrics of LFP batteries, such as capacity retention, power capability, and thermal behavior. These assessments are crucial for predicting battery life, optimizing battery management systems, and informing design decisions for various applications.

Another critical objective is to standardize testing methodologies across the industry, enabling meaningful comparisons between different LFP battery products and technologies. This standardization is essential for fostering innovation, facilitating quality control, and supporting regulatory compliance in diverse markets and applications.

Furthermore, as the LFP battery technology continues to evolve, testing protocols must adapt to address emerging challenges and opportunities. This includes developing new methods to evaluate advanced LFP formulations, assessing the impact of novel manufacturing processes, and validating the performance of LFP batteries in next-generation energy storage systems.

Market Demand for LFP Battery Validation

The market demand for Lithium Iron Phosphate (LFP) battery validation has been experiencing significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. As LFP batteries gain popularity due to their safety, long cycle life, and cost-effectiveness, the need for robust testing and validation protocols has become paramount.

The automotive sector represents a major driver for LFP battery validation demand. With many automakers shifting towards LFP chemistry for their entry-level and mid-range EV models, there is a growing need for comprehensive testing to ensure battery performance, safety, and longevity. This demand is further amplified by stringent regulatory requirements and consumer expectations for reliable and safe EV batteries.

In the energy storage sector, LFP batteries are increasingly being deployed for grid-scale applications and residential systems. This expansion has created a substantial market for validation services to verify the batteries' ability to withstand frequent charge-discharge cycles, operate efficiently under various environmental conditions, and maintain long-term stability.

The demand for LFP battery validation is also influenced by the global push towards sustainability and energy transition. As countries set ambitious targets for renewable energy integration and carbon reduction, the role of energy storage becomes more critical, thereby increasing the need for validated and reliable LFP battery solutions.

Geographically, the market demand for LFP battery validation is particularly strong in regions with a robust EV industry and renewable energy initiatives. China, being the largest producer and consumer of LFP batteries, leads the demand for validation services. However, other markets such as Europe and North America are rapidly catching up as they accelerate their EV adoption and renewable energy integration.

The industrial sector is another significant contributor to the demand for LFP battery validation. As manufacturers increasingly incorporate LFP batteries into various applications, from forklifts to backup power systems, the need for specialized testing protocols tailored to these diverse use cases has grown substantially.

Market analysts project that the global LFP battery market will continue its upward trajectory, with a corresponding increase in demand for validation services. This growth is expected to drive innovation in testing methodologies, equipment, and standards, as the industry seeks to keep pace with evolving battery technologies and applications.

The automotive sector represents a major driver for LFP battery validation demand. With many automakers shifting towards LFP chemistry for their entry-level and mid-range EV models, there is a growing need for comprehensive testing to ensure battery performance, safety, and longevity. This demand is further amplified by stringent regulatory requirements and consumer expectations for reliable and safe EV batteries.

In the energy storage sector, LFP batteries are increasingly being deployed for grid-scale applications and residential systems. This expansion has created a substantial market for validation services to verify the batteries' ability to withstand frequent charge-discharge cycles, operate efficiently under various environmental conditions, and maintain long-term stability.

The demand for LFP battery validation is also influenced by the global push towards sustainability and energy transition. As countries set ambitious targets for renewable energy integration and carbon reduction, the role of energy storage becomes more critical, thereby increasing the need for validated and reliable LFP battery solutions.

Geographically, the market demand for LFP battery validation is particularly strong in regions with a robust EV industry and renewable energy initiatives. China, being the largest producer and consumer of LFP batteries, leads the demand for validation services. However, other markets such as Europe and North America are rapidly catching up as they accelerate their EV adoption and renewable energy integration.

The industrial sector is another significant contributor to the demand for LFP battery validation. As manufacturers increasingly incorporate LFP batteries into various applications, from forklifts to backup power systems, the need for specialized testing protocols tailored to these diverse use cases has grown substantially.

Market analysts project that the global LFP battery market will continue its upward trajectory, with a corresponding increase in demand for validation services. This growth is expected to drive innovation in testing methodologies, equipment, and standards, as the industry seeks to keep pace with evolving battery technologies and applications.

Current Challenges in LFP Battery Testing

The testing and validation of Lithium Iron Phosphate (LFP) batteries present several significant challenges that researchers and manufacturers must address to ensure the reliability, safety, and performance of these energy storage devices. One of the primary challenges is the development of standardized testing protocols that can accurately assess the long-term performance and degradation of LFP batteries. The unique characteristics of LFP chemistry, including its flat voltage profile and high thermal stability, require specialized testing methods that differ from those used for other lithium-ion chemistries.

Another major challenge lies in accurately predicting the state of health (SOH) and remaining useful life of LFP batteries. Traditional methods based on capacity fade and internal resistance increase are less effective for LFP cells due to their stable voltage characteristics throughout most of the discharge cycle. This necessitates the development of more sophisticated algorithms and diagnostic tools that can provide reliable SOH estimates for LFP batteries in various applications.

The thermal management of LFP batteries during testing also presents significant challenges. While LFP chemistry is known for its thermal stability, ensuring uniform temperature distribution across large battery packs during charge-discharge cycles and abuse tests remains crucial. Inadequate thermal management can lead to inconsistent test results and potentially mask performance issues or safety concerns.

Accelerated aging tests pose another challenge in LFP battery validation. Developing protocols that can accurately simulate years of real-world usage in a compressed timeframe, while maintaining relevance to actual operating conditions, is critical for predicting long-term performance and reliability. This is particularly challenging for LFP batteries, which have shown excellent cycle life under normal conditions but may exhibit different degradation mechanisms under accelerated testing.

Safety testing of LFP batteries also presents unique challenges. While LFP chemistry is generally considered safer than other lithium-ion chemistries, comprehensive safety protocols must still be developed to address potential failure modes specific to LFP cells. This includes testing for thermal runaway under extreme conditions, assessing the impact of manufacturing defects, and evaluating the effectiveness of safety mechanisms in large-scale battery systems.

Furthermore, the validation of LFP batteries for emerging applications, such as electric vehicles and grid-scale energy storage, requires the development of new testing methodologies. These must account for diverse usage patterns, environmental conditions, and integration with complex power management systems. Ensuring that laboratory tests accurately reflect real-world performance in these applications remains a significant challenge in the field of LFP battery testing and validation.

Another major challenge lies in accurately predicting the state of health (SOH) and remaining useful life of LFP batteries. Traditional methods based on capacity fade and internal resistance increase are less effective for LFP cells due to their stable voltage characteristics throughout most of the discharge cycle. This necessitates the development of more sophisticated algorithms and diagnostic tools that can provide reliable SOH estimates for LFP batteries in various applications.

The thermal management of LFP batteries during testing also presents significant challenges. While LFP chemistry is known for its thermal stability, ensuring uniform temperature distribution across large battery packs during charge-discharge cycles and abuse tests remains crucial. Inadequate thermal management can lead to inconsistent test results and potentially mask performance issues or safety concerns.

Accelerated aging tests pose another challenge in LFP battery validation. Developing protocols that can accurately simulate years of real-world usage in a compressed timeframe, while maintaining relevance to actual operating conditions, is critical for predicting long-term performance and reliability. This is particularly challenging for LFP batteries, which have shown excellent cycle life under normal conditions but may exhibit different degradation mechanisms under accelerated testing.

Safety testing of LFP batteries also presents unique challenges. While LFP chemistry is generally considered safer than other lithium-ion chemistries, comprehensive safety protocols must still be developed to address potential failure modes specific to LFP cells. This includes testing for thermal runaway under extreme conditions, assessing the impact of manufacturing defects, and evaluating the effectiveness of safety mechanisms in large-scale battery systems.

Furthermore, the validation of LFP batteries for emerging applications, such as electric vehicles and grid-scale energy storage, requires the development of new testing methodologies. These must account for diverse usage patterns, environmental conditions, and integration with complex power management systems. Ensuring that laboratory tests accurately reflect real-world performance in these applications remains a significant challenge in the field of LFP battery testing and validation.

Existing LFP Battery Testing Methodologies

01 Electrode material composition and preparation

Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

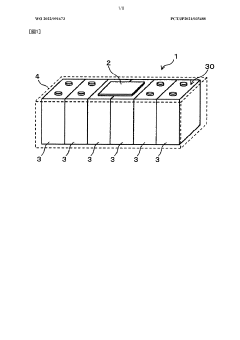

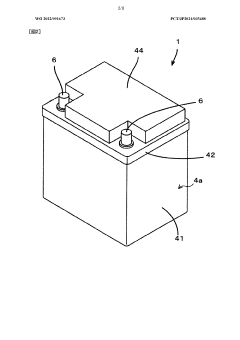

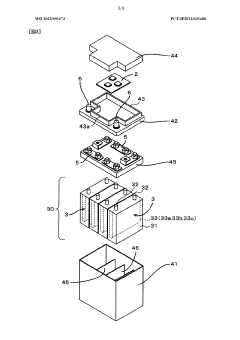

- Battery cell design and assembly: Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.

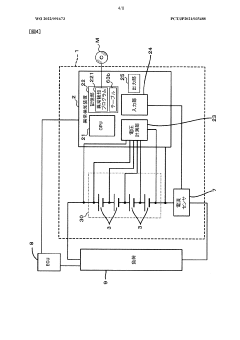

- Battery management systems: Development of sophisticated battery management systems for lithium iron phosphate batteries. These systems focus on optimizing charging and discharging processes, thermal management, state-of-charge estimation, and overall battery performance monitoring to enhance efficiency and longevity.

- Manufacturing processes and scalability: Innovations in manufacturing processes and scalability of lithium iron phosphate batteries. This includes advancements in production techniques, quality control measures, and cost-effective scaling methods to meet growing demand in various applications such as electric vehicles and energy storage systems.

- Battery pack integration and application-specific designs: Developments in integrating lithium iron phosphate batteries into various applications and creating application-specific designs. This involves optimizing battery pack configurations, thermal management systems, and safety features for use in electric vehicles, renewable energy storage, and other specialized applications.

02 Battery cell design and assembly

Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.Expand Specific Solutions03 Battery management and control systems

Development of sophisticated battery management and control systems for lithium iron phosphate batteries. This includes advanced algorithms for state-of-charge estimation, thermal management, and cell balancing to optimize battery performance and longevity.Expand Specific Solutions04 Manufacturing processes and scalability

Innovations in manufacturing processes and scalability of lithium iron phosphate batteries. This covers advancements in production techniques, automation, quality control, and cost reduction strategies to enable mass production of high-quality batteries.Expand Specific Solutions05 Application-specific battery designs

Development of lithium iron phosphate batteries tailored for specific applications. This includes customized designs for electric vehicles, grid energy storage, and portable electronics, focusing on optimizing performance characteristics such as power output, charging speed, and cycle life for each use case.Expand Specific Solutions

Key Players in LFP Battery Testing Industry

The testing and validation protocols for Lithium Iron Phosphate (LFP) batteries are in a mature stage of development, reflecting the technology's established position in the energy storage market. The global LFP battery market is experiencing significant growth, driven by increasing demand for electric vehicles and renewable energy storage solutions. Key players like BYD, CATL, and LG Energy Solution are leading the field, with continuous improvements in battery performance and safety protocols. Established automotive manufacturers such as Toyota and Stellantis are also investing heavily in LFP technology, indicating its growing importance in the industry. Research institutions like Chongqing University and IIT Bombay are contributing to advancements in testing methodologies, further solidifying the technology's reliability and efficiency.

BYD Co., Ltd.

Technical Solution: BYD has developed advanced testing and validation protocols for Lithium Iron Phosphate (LFP) batteries, focusing on safety, performance, and longevity. Their approach includes accelerated life testing, thermal runaway prevention, and state-of-health monitoring. BYD's Blade Battery, which uses LFP chemistry, undergoes rigorous testing including nail penetration tests and heat exposure up to 300°C without ignition[1]. They employ advanced battery management systems (BMS) to continuously monitor cell voltage, temperature, and current, ensuring optimal performance and safety. BYD also utilizes artificial intelligence and big data analytics to predict battery degradation and optimize charging strategies, significantly extending battery life[2].

Strengths: Industry-leading safety standards, innovative cell design, and advanced BMS. Weaknesses: Higher initial cost compared to some competitors, and potential limitations in energy density compared to other lithium-ion chemistries.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented comprehensive testing and validation protocols for LFP batteries, emphasizing reliability and performance optimization. Their approach includes advanced cycling tests, environmental stress screening, and precise capacity retention analysis. LG utilizes state-of-the-art equipment for electrochemical impedance spectroscopy (EIS) to assess battery health and degradation mechanisms[3]. They have also developed proprietary algorithms for more accurate state-of-charge (SOC) and state-of-health (SOH) estimations, crucial for LFP batteries known for their flat voltage profiles. LG's validation process includes extensive field testing in various climatic conditions to ensure real-world performance matches laboratory results[4].

Strengths: Cutting-edge diagnostic tools, extensive global testing facilities, and strong focus on quality control. Weaknesses: Relatively new to LFP technology compared to some competitors, potentially leading to a learning curve in mass production.

Core Innovations in LFP Battery Validation

Method of testing lithium-ion secondary battery, and method of producing lithium-ion secondary battery using the same

PatentPendingUS20240201283A1

Innovation

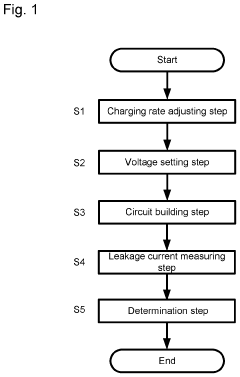

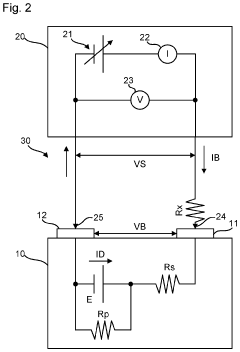

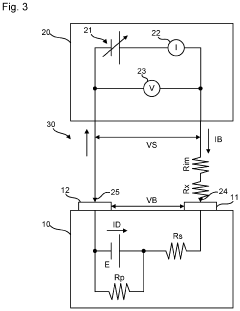

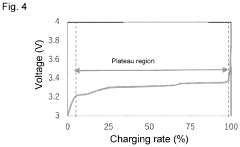

- Adjusting the charging rate of lithium-ion secondary batteries to the plateau region (25-35% or 70-90%) and setting the test power supply voltage equal to the battery voltage, then measuring the leakage current until it converges, with options to adjust the test power supply voltage over time or set it higher than the battery voltage to enhance convergence speed.

Abnormality detection method, abnormality detection device, power storage device, and computer program

PatentWO2022091673A1

Innovation

- The method involves using a mixture of lithium iron phosphate and a lithium transition metal oxide as positive electrode active materials, where the ratio of the latter is 5% or more, allowing for voltage measurement near the charging end point to detect anomalies by identifying voltage differences and current integration, enabling accurate estimation of the state of each power storage element.

Safety Standards for LFP Battery Testing

Safety standards for LFP battery testing are crucial for ensuring the reliability, performance, and safety of lithium iron phosphate (LFP) batteries. These standards encompass a comprehensive set of protocols and guidelines that manufacturers, testing laboratories, and regulatory bodies must adhere to when evaluating LFP batteries.

The primary focus of these safety standards is to assess the battery's behavior under various conditions, including normal operation, abuse, and extreme environmental factors. One key aspect is thermal runaway testing, which evaluates the battery's response to high temperatures and potential internal short circuits. This test typically involves subjecting the battery to controlled heating conditions and monitoring its behavior to ensure it does not pose a fire or explosion risk.

Electrical safety testing is another critical component of LFP battery safety standards. This includes evaluating the battery's performance during overcharging, over-discharging, and short-circuit scenarios. These tests aim to verify that the battery management system (BMS) functions correctly and can protect the cells from potentially hazardous conditions.

Mechanical integrity tests are also essential in safety standards for LFP batteries. These tests assess the battery's ability to withstand physical stress, such as impacts, vibrations, and crush forces. The goal is to ensure that the battery remains safe and functional even when subjected to mechanical abuse that may occur during transportation or in real-world applications.

Environmental testing is another crucial aspect of LFP battery safety standards. This includes evaluating the battery's performance and safety in extreme temperatures, high humidity, and varying atmospheric pressures. These tests help determine the battery's suitability for different applications and environments, ensuring it maintains its safety characteristics across a wide range of conditions.

Cycle life and capacity retention tests are also incorporated into safety standards, as they indirectly relate to safety by ensuring the battery maintains its performance characteristics over time. A battery that degrades rapidly or unexpectedly could potentially lead to safety issues if not properly managed or replaced.

Standardized reporting and documentation requirements are integral to LFP battery safety standards. These ensure that test results are consistently recorded, analyzed, and communicated across the industry. This transparency helps manufacturers, regulators, and end-users make informed decisions about battery selection and implementation.

Lastly, safety standards for LFP battery testing often include guidelines for handling, storage, and transportation of batteries during and after testing. These protocols are designed to minimize risks associated with potentially damaged or compromised batteries resulting from the testing process.

The primary focus of these safety standards is to assess the battery's behavior under various conditions, including normal operation, abuse, and extreme environmental factors. One key aspect is thermal runaway testing, which evaluates the battery's response to high temperatures and potential internal short circuits. This test typically involves subjecting the battery to controlled heating conditions and monitoring its behavior to ensure it does not pose a fire or explosion risk.

Electrical safety testing is another critical component of LFP battery safety standards. This includes evaluating the battery's performance during overcharging, over-discharging, and short-circuit scenarios. These tests aim to verify that the battery management system (BMS) functions correctly and can protect the cells from potentially hazardous conditions.

Mechanical integrity tests are also essential in safety standards for LFP batteries. These tests assess the battery's ability to withstand physical stress, such as impacts, vibrations, and crush forces. The goal is to ensure that the battery remains safe and functional even when subjected to mechanical abuse that may occur during transportation or in real-world applications.

Environmental testing is another crucial aspect of LFP battery safety standards. This includes evaluating the battery's performance and safety in extreme temperatures, high humidity, and varying atmospheric pressures. These tests help determine the battery's suitability for different applications and environments, ensuring it maintains its safety characteristics across a wide range of conditions.

Cycle life and capacity retention tests are also incorporated into safety standards, as they indirectly relate to safety by ensuring the battery maintains its performance characteristics over time. A battery that degrades rapidly or unexpectedly could potentially lead to safety issues if not properly managed or replaced.

Standardized reporting and documentation requirements are integral to LFP battery safety standards. These ensure that test results are consistently recorded, analyzed, and communicated across the industry. This transparency helps manufacturers, regulators, and end-users make informed decisions about battery selection and implementation.

Lastly, safety standards for LFP battery testing often include guidelines for handling, storage, and transportation of batteries during and after testing. These protocols are designed to minimize risks associated with potentially damaged or compromised batteries resulting from the testing process.

Environmental Impact of LFP Battery Testing

The environmental impact of Lithium Iron Phosphate (LFP) battery testing is a critical consideration in the development and validation of these energy storage systems. As the demand for LFP batteries continues to grow, particularly in electric vehicles and renewable energy applications, it is essential to assess and mitigate the ecological footprint of testing protocols.

LFP battery testing involves various processes that can potentially affect the environment. One of the primary concerns is the energy consumption during long-term cycling and performance tests. These procedures often require continuous charge and discharge cycles, which can consume significant amounts of electricity. To address this issue, many testing facilities are implementing renewable energy sources, such as solar panels or wind turbines, to power their testing equipment, thereby reducing the carbon footprint associated with grid electricity usage.

Water usage is another environmental factor to consider in LFP battery testing. Thermal management systems used to maintain optimal battery temperatures during testing may require substantial amounts of water for cooling purposes. Advanced testing facilities are increasingly adopting closed-loop cooling systems and water recycling technologies to minimize water consumption and reduce wastewater generation.

The disposal of electrolytes and other chemical components used in LFP batteries during testing also poses environmental challenges. Proper handling and disposal protocols are crucial to prevent soil and water contamination. Many testing facilities have implemented strict waste management procedures, including the use of specialized containment systems and partnerships with certified recycling companies to ensure the safe and environmentally responsible disposal of hazardous materials.

Emissions from LFP battery testing, particularly in the event of thermal runaway or other safety-related tests, can impact air quality. Modern testing facilities are equipped with advanced ventilation systems and air filtration technologies to capture and neutralize potentially harmful gases and particulates released during these procedures. Additionally, the development of more efficient testing protocols that minimize the need for destructive testing has helped reduce the overall emissions associated with LFP battery validation.

The life cycle assessment of LFP batteries, including the testing phase, is an emerging area of focus for researchers and industry professionals. By analyzing the environmental impact of each stage of battery development, including testing, manufacturers can identify opportunities for improvement and implement more sustainable practices. This holistic approach to environmental impact assessment is driving innovations in testing methodologies, such as the use of artificial intelligence and machine learning to optimize test parameters and reduce resource consumption.

As the LFP battery industry continues to evolve, there is a growing emphasis on developing standardized testing protocols that not only ensure battery performance and safety but also minimize environmental impact. Collaborative efforts between battery manufacturers, testing facilities, and environmental agencies are leading to the establishment of best practices and guidelines for environmentally responsible LFP battery testing.

LFP battery testing involves various processes that can potentially affect the environment. One of the primary concerns is the energy consumption during long-term cycling and performance tests. These procedures often require continuous charge and discharge cycles, which can consume significant amounts of electricity. To address this issue, many testing facilities are implementing renewable energy sources, such as solar panels or wind turbines, to power their testing equipment, thereby reducing the carbon footprint associated with grid electricity usage.

Water usage is another environmental factor to consider in LFP battery testing. Thermal management systems used to maintain optimal battery temperatures during testing may require substantial amounts of water for cooling purposes. Advanced testing facilities are increasingly adopting closed-loop cooling systems and water recycling technologies to minimize water consumption and reduce wastewater generation.

The disposal of electrolytes and other chemical components used in LFP batteries during testing also poses environmental challenges. Proper handling and disposal protocols are crucial to prevent soil and water contamination. Many testing facilities have implemented strict waste management procedures, including the use of specialized containment systems and partnerships with certified recycling companies to ensure the safe and environmentally responsible disposal of hazardous materials.

Emissions from LFP battery testing, particularly in the event of thermal runaway or other safety-related tests, can impact air quality. Modern testing facilities are equipped with advanced ventilation systems and air filtration technologies to capture and neutralize potentially harmful gases and particulates released during these procedures. Additionally, the development of more efficient testing protocols that minimize the need for destructive testing has helped reduce the overall emissions associated with LFP battery validation.

The life cycle assessment of LFP batteries, including the testing phase, is an emerging area of focus for researchers and industry professionals. By analyzing the environmental impact of each stage of battery development, including testing, manufacturers can identify opportunities for improvement and implement more sustainable practices. This holistic approach to environmental impact assessment is driving innovations in testing methodologies, such as the use of artificial intelligence and machine learning to optimize test parameters and reduce resource consumption.

As the LFP battery industry continues to evolve, there is a growing emphasis on developing standardized testing protocols that not only ensure battery performance and safety but also minimize environmental impact. Collaborative efforts between battery manufacturers, testing facilities, and environmental agencies are leading to the establishment of best practices and guidelines for environmentally responsible LFP battery testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!