Lithium Iron Phosphate Batteries in Back-Up Power Solutions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their inception in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has seen continuous improvements in performance, cost-effectiveness, and reliability, particularly in back-up power applications.

The early 2000s marked the beginning of commercial production for LFP batteries. During this phase, the focus was on improving energy density and cycle life. Researchers worked on optimizing the cathode material structure and developing more efficient manufacturing processes. By the mid-2000s, LFP batteries had already shown promise in electric vehicles and stationary energy storage systems.

From 2010 to 2015, there was a surge in research and development activities aimed at enhancing the power density and charge-discharge rates of LFP batteries. This period saw the introduction of nano-scale materials and advanced coating techniques, which significantly improved the battery's performance in high-power applications, making them increasingly suitable for back-up power solutions.

The years 2015 to 2020 witnessed a shift towards cost reduction and scalability. Manufacturers focused on streamlining production processes and improving raw material utilization. This led to a substantial decrease in the cost per kilowatt-hour of LFP batteries, making them more competitive in the energy storage market, especially for large-scale back-up power systems.

Recent developments from 2020 onwards have centered on further enhancing the energy density and longevity of LFP batteries. Innovations in cathode material doping and electrolyte formulations have pushed the boundaries of LFP technology. These advancements have resulted in LFP batteries with higher capacity retention and improved performance under extreme temperature conditions, crucial factors for reliable back-up power solutions.

The evolution of LFP batteries has also been marked by improvements in battery management systems (BMS). Advanced BMS technologies have enabled more precise control over charging and discharging processes, leading to optimized battery performance and extended lifespan. This has been particularly beneficial in back-up power applications where reliability and longevity are paramount.

Looking ahead, the LFP battery evolution is expected to continue with a focus on sustainability and integration with smart grid technologies. Research is underway to develop more environmentally friendly production methods and to improve the recyclability of LFP batteries. Additionally, efforts are being made to enhance the batteries' ability to provide grid stabilization services, further solidifying their role in modern back-up power solutions.

The early 2000s marked the beginning of commercial production for LFP batteries. During this phase, the focus was on improving energy density and cycle life. Researchers worked on optimizing the cathode material structure and developing more efficient manufacturing processes. By the mid-2000s, LFP batteries had already shown promise in electric vehicles and stationary energy storage systems.

From 2010 to 2015, there was a surge in research and development activities aimed at enhancing the power density and charge-discharge rates of LFP batteries. This period saw the introduction of nano-scale materials and advanced coating techniques, which significantly improved the battery's performance in high-power applications, making them increasingly suitable for back-up power solutions.

The years 2015 to 2020 witnessed a shift towards cost reduction and scalability. Manufacturers focused on streamlining production processes and improving raw material utilization. This led to a substantial decrease in the cost per kilowatt-hour of LFP batteries, making them more competitive in the energy storage market, especially for large-scale back-up power systems.

Recent developments from 2020 onwards have centered on further enhancing the energy density and longevity of LFP batteries. Innovations in cathode material doping and electrolyte formulations have pushed the boundaries of LFP technology. These advancements have resulted in LFP batteries with higher capacity retention and improved performance under extreme temperature conditions, crucial factors for reliable back-up power solutions.

The evolution of LFP batteries has also been marked by improvements in battery management systems (BMS). Advanced BMS technologies have enabled more precise control over charging and discharging processes, leading to optimized battery performance and extended lifespan. This has been particularly beneficial in back-up power applications where reliability and longevity are paramount.

Looking ahead, the LFP battery evolution is expected to continue with a focus on sustainability and integration with smart grid technologies. Research is underway to develop more environmentally friendly production methods and to improve the recyclability of LFP batteries. Additionally, efforts are being made to enhance the batteries' ability to provide grid stabilization services, further solidifying their role in modern back-up power solutions.

Market Demand Analysis

The market demand for lithium iron phosphate (LiFePO4) batteries in back-up power solutions has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for reliable and efficient energy storage systems across various sectors, including telecommunications, data centers, and renewable energy installations.

In the telecommunications industry, the rapid expansion of 5G networks has created a substantial demand for robust back-up power solutions. LiFePO4 batteries are particularly well-suited for this application due to their long cycle life, high safety profile, and excellent thermal stability. As telecom operators continue to invest in infrastructure upgrades, the market for LiFePO4 batteries in this sector is expected to grow steadily.

Data centers represent another key market for LiFePO4 batteries in back-up power applications. With the exponential growth of cloud computing, big data, and artificial intelligence, the need for uninterrupted power supply in data centers has become critical. LiFePO4 batteries offer advantages such as fast charging capabilities, high energy density, and low maintenance requirements, making them an attractive option for data center operators seeking reliable back-up power solutions.

The renewable energy sector is also driving demand for LiFePO4 batteries. As solar and wind power installations continue to increase globally, the need for efficient energy storage systems to manage intermittent power generation has grown correspondingly. LiFePO4 batteries are well-positioned to meet this demand due to their ability to handle deep discharge cycles and their long service life.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading the global demand for LiFePO4 batteries in back-up power solutions. This is attributed to the region's robust manufacturing capabilities, government support for clean energy initiatives, and rapid technological advancements. North America and Europe are also showing strong growth potential, driven by increasing investments in renewable energy and the modernization of power infrastructure.

The market for LiFePO4 batteries in back-up power solutions is characterized by intense competition among established players and new entrants. This competition is driving innovation in battery technology, leading to improvements in energy density, cycle life, and overall performance. As a result, the market is witnessing a trend towards more cost-effective and efficient LiFePO4 battery solutions.

Looking ahead, the market demand for LiFePO4 batteries in back-up power applications is projected to continue its upward trajectory. Factors such as the growing emphasis on grid stability, the increasing adoption of electric vehicles, and the rising awareness of environmental sustainability are expected to further boost demand. Additionally, ongoing research and development efforts aimed at enhancing battery performance and reducing costs are likely to expand the market potential for LiFePO4 batteries in back-up power solutions across various industries.

In the telecommunications industry, the rapid expansion of 5G networks has created a substantial demand for robust back-up power solutions. LiFePO4 batteries are particularly well-suited for this application due to their long cycle life, high safety profile, and excellent thermal stability. As telecom operators continue to invest in infrastructure upgrades, the market for LiFePO4 batteries in this sector is expected to grow steadily.

Data centers represent another key market for LiFePO4 batteries in back-up power applications. With the exponential growth of cloud computing, big data, and artificial intelligence, the need for uninterrupted power supply in data centers has become critical. LiFePO4 batteries offer advantages such as fast charging capabilities, high energy density, and low maintenance requirements, making them an attractive option for data center operators seeking reliable back-up power solutions.

The renewable energy sector is also driving demand for LiFePO4 batteries. As solar and wind power installations continue to increase globally, the need for efficient energy storage systems to manage intermittent power generation has grown correspondingly. LiFePO4 batteries are well-positioned to meet this demand due to their ability to handle deep discharge cycles and their long service life.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading the global demand for LiFePO4 batteries in back-up power solutions. This is attributed to the region's robust manufacturing capabilities, government support for clean energy initiatives, and rapid technological advancements. North America and Europe are also showing strong growth potential, driven by increasing investments in renewable energy and the modernization of power infrastructure.

The market for LiFePO4 batteries in back-up power solutions is characterized by intense competition among established players and new entrants. This competition is driving innovation in battery technology, leading to improvements in energy density, cycle life, and overall performance. As a result, the market is witnessing a trend towards more cost-effective and efficient LiFePO4 battery solutions.

Looking ahead, the market demand for LiFePO4 batteries in back-up power applications is projected to continue its upward trajectory. Factors such as the growing emphasis on grid stability, the increasing adoption of electric vehicles, and the rising awareness of environmental sustainability are expected to further boost demand. Additionally, ongoing research and development efforts aimed at enhancing battery performance and reducing costs are likely to expand the market potential for LiFePO4 batteries in back-up power solutions across various industries.

Technical Challenges

The development and implementation of lithium iron phosphate (LiFePO4) batteries in back-up power solutions face several significant technical challenges. These challenges stem from the unique characteristics of LiFePO4 batteries and the demanding requirements of back-up power applications.

One of the primary challenges is the relatively low energy density of LiFePO4 batteries compared to other lithium-ion chemistries. While LiFePO4 batteries offer excellent safety and long cycle life, their energy density is typically around 90-120 Wh/kg, which is lower than that of lithium cobalt oxide (LiCoO2) or lithium nickel manganese cobalt oxide (NMC) batteries. This lower energy density can result in larger and heavier battery systems, potentially limiting their application in space-constrained back-up power installations.

Another significant challenge is the voltage characteristics of LiFePO4 cells. These batteries have a relatively flat discharge curve, which, while beneficial for maintaining stable power output, can make it difficult to accurately determine the state of charge (SOC). This complicates battery management and monitoring systems, potentially leading to inefficient utilization of the battery's capacity or unexpected power failures if the SOC is not accurately tracked.

The charging efficiency of LiFePO4 batteries at low temperatures presents another hurdle. These batteries exhibit reduced charging efficiency and increased internal resistance at temperatures below 0°C, which can be problematic in outdoor or uncontrolled environmental applications. This characteristic necessitates the development of advanced thermal management systems to maintain optimal battery performance across a wide range of operating conditions.

Balancing cell voltages within large LiFePO4 battery packs is another technical challenge. As back-up power systems often require high-capacity battery banks, ensuring uniform charging and discharging across all cells is crucial for maximizing system performance and longevity. Developing efficient and cost-effective battery management systems (BMS) that can accurately monitor and balance large numbers of cells remains an ongoing challenge.

The integration of LiFePO4 batteries with existing power infrastructure and control systems also presents technical difficulties. Many legacy back-up power systems are designed for lead-acid batteries, and adapting these systems to work optimally with LiFePO4 batteries requires significant engineering efforts. This includes redesigning charge controllers, inverters, and monitoring systems to account for the different voltage profiles and charging characteristics of LiFePO4 batteries.

Lastly, while LiFePO4 batteries are known for their long cycle life, predicting and managing their long-term performance in back-up power applications remains challenging. Developing accurate models for capacity fade and performance degradation over extended periods, especially under various usage patterns and environmental conditions typical of back-up power scenarios, is crucial for system reliability and maintenance planning.

One of the primary challenges is the relatively low energy density of LiFePO4 batteries compared to other lithium-ion chemistries. While LiFePO4 batteries offer excellent safety and long cycle life, their energy density is typically around 90-120 Wh/kg, which is lower than that of lithium cobalt oxide (LiCoO2) or lithium nickel manganese cobalt oxide (NMC) batteries. This lower energy density can result in larger and heavier battery systems, potentially limiting their application in space-constrained back-up power installations.

Another significant challenge is the voltage characteristics of LiFePO4 cells. These batteries have a relatively flat discharge curve, which, while beneficial for maintaining stable power output, can make it difficult to accurately determine the state of charge (SOC). This complicates battery management and monitoring systems, potentially leading to inefficient utilization of the battery's capacity or unexpected power failures if the SOC is not accurately tracked.

The charging efficiency of LiFePO4 batteries at low temperatures presents another hurdle. These batteries exhibit reduced charging efficiency and increased internal resistance at temperatures below 0°C, which can be problematic in outdoor or uncontrolled environmental applications. This characteristic necessitates the development of advanced thermal management systems to maintain optimal battery performance across a wide range of operating conditions.

Balancing cell voltages within large LiFePO4 battery packs is another technical challenge. As back-up power systems often require high-capacity battery banks, ensuring uniform charging and discharging across all cells is crucial for maximizing system performance and longevity. Developing efficient and cost-effective battery management systems (BMS) that can accurately monitor and balance large numbers of cells remains an ongoing challenge.

The integration of LiFePO4 batteries with existing power infrastructure and control systems also presents technical difficulties. Many legacy back-up power systems are designed for lead-acid batteries, and adapting these systems to work optimally with LiFePO4 batteries requires significant engineering efforts. This includes redesigning charge controllers, inverters, and monitoring systems to account for the different voltage profiles and charging characteristics of LiFePO4 batteries.

Lastly, while LiFePO4 batteries are known for their long cycle life, predicting and managing their long-term performance in back-up power applications remains challenging. Developing accurate models for capacity fade and performance degradation over extended periods, especially under various usage patterns and environmental conditions typical of back-up power scenarios, is crucial for system reliability and maintenance planning.

Current LFP Solutions

01 Electrode material composition and preparation

Lithium iron phosphate batteries utilize specific electrode material compositions and preparation methods to enhance performance. This includes optimizing the ratio of active materials, conductive additives, and binders. Advanced synthesis techniques, such as hydrothermal or solid-state methods, are employed to produce high-quality cathode materials with improved crystallinity and particle morphology.- Electrode material composition and structure: Innovations in electrode material composition and structure for lithium iron phosphate batteries focus on improving energy density, cycling stability, and rate performance. This includes developing novel cathode materials, optimizing particle size and morphology, and incorporating conductive coatings or dopants to enhance electronic conductivity.

- Electrolyte formulations: Advanced electrolyte formulations are designed to enhance the performance and safety of lithium iron phosphate batteries. These may include novel electrolyte additives, non-flammable or solid-state electrolytes, and ionic liquids to improve ionic conductivity, reduce side reactions, and enhance thermal stability.

- Battery management and control systems: Sophisticated battery management and control systems are developed to optimize the performance, safety, and longevity of lithium iron phosphate batteries. These systems may include advanced algorithms for state-of-charge estimation, thermal management, and cell balancing techniques.

- Manufacturing processes and scalability: Innovations in manufacturing processes aim to improve the scalability and cost-effectiveness of lithium iron phosphate battery production. This includes developing new synthesis methods, optimizing production parameters, and implementing advanced quality control measures to ensure consistent performance and reliability.

- Battery pack design and integration: Advancements in battery pack design and integration focus on optimizing the overall performance, safety, and thermal management of lithium iron phosphate battery systems. This includes innovative cooling systems, modular designs for easy maintenance and replacement, and improved packaging for various applications such as electric vehicles and energy storage systems.

02 Electrolyte formulations for improved performance

Specialized electrolyte formulations are developed to enhance the performance of lithium iron phosphate batteries. These formulations may include additives to improve ionic conductivity, reduce side reactions, and enhance the stability of the solid electrolyte interphase (SEI) layer. Novel electrolyte compositions can lead to improved cycling stability, rate capability, and overall battery life.Expand Specific Solutions03 Battery management and thermal control systems

Advanced battery management systems (BMS) and thermal control strategies are crucial for optimizing the performance and safety of lithium iron phosphate batteries. These systems monitor and regulate battery parameters such as voltage, current, and temperature. Efficient thermal management techniques, including active and passive cooling methods, are implemented to maintain optimal operating conditions and extend battery life.Expand Specific Solutions04 Nanostructured materials for enhanced performance

Incorporating nanostructured materials in lithium iron phosphate batteries can significantly improve their performance. Nanoparticles, nanocomposites, and other nanostructured forms of active materials can enhance the electrode's surface area, reduce diffusion distances, and improve the overall electrochemical properties. This approach leads to increased energy density, power density, and faster charging capabilities.Expand Specific Solutions05 Doping and surface modification techniques

Doping and surface modification techniques are employed to enhance the intrinsic properties of lithium iron phosphate materials. These methods involve introducing small amounts of foreign elements or creating specialized surface coatings to improve electronic conductivity, structural stability, and electrochemical performance. Such modifications can lead to improved capacity retention, rate capability, and cycling stability of the batteries.Expand Specific Solutions

Key Industry Players

The research on Lithium Iron Phosphate Batteries in Back-Up Power Solutions is in a growth phase, with increasing market size due to rising demand for reliable energy storage. The technology is maturing rapidly, driven by advancements from key players like BYD, CATL, and Panasonic Energy. These companies are investing heavily in R&D to improve battery performance, longevity, and cost-effectiveness. The competitive landscape is intensifying as both established manufacturers and new entrants vie for market share, leading to accelerated innovation and expanded applications in various sectors, including data centers, telecommunications, and renewable energy integration.

BYD Co., Ltd.

Technical Solution: BYD has developed advanced Lithium Iron Phosphate (LFP) batteries for back-up power solutions, focusing on their Blade Battery technology. This innovative design increases energy density by 50% compared to traditional LFP batteries[1]. The Blade Battery utilizes a cell-to-pack (CTP) structure, eliminating the need for module housing, thus improving space utilization and reducing weight[2]. BYD's LFP batteries incorporate a proprietary heat management system that enhances safety and extends battery life. The company has also implemented AI-driven battery management systems (BMS) to optimize charging and discharging cycles, potentially increasing the battery's lifespan by up to 20%[3]. For back-up power applications, BYD offers scalable solutions ranging from residential to utility-scale installations, with modular designs allowing for easy expansion and maintenance.

Strengths: High energy density, improved safety, long lifespan, and scalability. Weaknesses: Higher initial cost compared to some competitors, potential supply chain dependencies for raw materials.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a cutting-edge LFP battery technology for back-up power solutions, focusing on their CTP (cell-to-pack) technology. This approach increases energy density by up to 40% compared to conventional LFP batteries[4]. CATL's LFP batteries feature a unique cooling system that allows for rapid charging and improved thermal management, crucial for back-up power applications. The company has also introduced its First-to-Last (F2L) battery management system, which optimizes the performance of each cell in the pack, potentially extending battery life by up to 30%[5]. CATL's back-up power solutions incorporate modular designs, allowing for flexible capacity expansion from kilowatt to megawatt scales. Additionally, CATL has developed advanced fire-resistant technologies, significantly enhancing the safety of their LFP batteries in various environmental conditions.

Strengths: High energy density, advanced thermal management, flexible scalability, and enhanced safety features. Weaknesses: Relatively higher cost, potential challenges in global market expansion due to geopolitical factors.

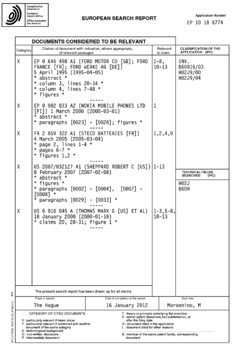

Core LFP Innovations

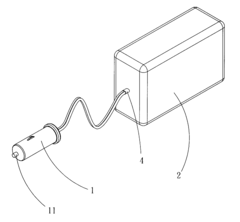

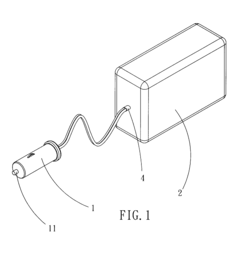

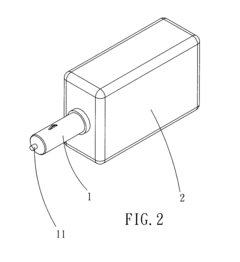

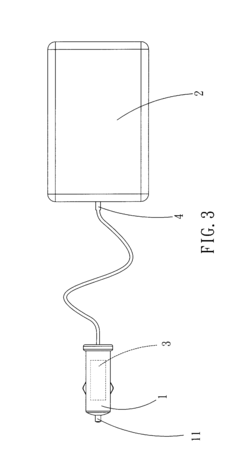

Backup power supply for a vehicle

PatentInactiveUS20110260540A1

Innovation

- A backup power supply system comprising a rechargeable lithium iron phosphate battery and a motor electronic appliance connected to the vehicle's power system via a switching mechanism, allowing the battery to supply power during lead-acid battery replacement, with features like a voltage stabilizer and over-load-prohibiting circuit to prevent damage.

Backup power supply for a vehicle

PatentInactiveEP2378625A3

Innovation

- A backup power system comprising a rechargeable lithium iron phosphate battery, a motor electronic appliance, and a switching mechanism that connects to the vehicle's power system, allowing the battery to supply power during lead-acid battery replacement, with features like voltage stabilization and over-load protection.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of lithium iron phosphate (LiFePO4) batteries for back-up power solutions. These regulations are designed to ensure the safe operation, storage, and transportation of these energy storage systems, minimizing potential risks to users, property, and the environment.

One of the primary safety standards governing LiFePO4 batteries is the IEC 62619, which outlines safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard covers various aspects, including electrical, mechanical, and environmental safety considerations. It also specifies testing procedures to evaluate the safety performance of these batteries under normal and abnormal operating conditions.

In addition to IEC 62619, the UN38.3 regulation is essential for the transportation of lithium-ion batteries, including LiFePO4 cells. This regulation mandates a series of tests to ensure the safety of batteries during shipping, including altitude simulation, thermal cycling, vibration, shock, and external short circuit tests. Compliance with UN38.3 is mandatory for air, sea, and land transportation of lithium batteries.

For stationary energy storage applications, such as back-up power systems, the UL 1973 standard is particularly relevant. This standard addresses the safety of battery systems for use in light electric rail applications and stationary applications, covering areas such as electrical safety, fire prevention, and thermal management.

The National Fire Protection Association (NFPA) has also developed standards specifically for energy storage systems, including NFPA 855. This standard provides requirements for the installation, operation, and maintenance of energy storage systems, including those based on LiFePO4 technology. It addresses fire prevention, suppression, and control measures for these systems.

In the context of back-up power solutions, the IEEE 1635 standard is noteworthy. While not specific to LiFePO4 batteries, it provides guidelines for the ventilation and thermal management of stationary battery installations, which are critical aspects of safety in back-up power applications.

As the adoption of LiFePO4 batteries in back-up power solutions continues to grow, regulatory bodies are continuously updating and developing new safety standards. For instance, the IEC 63056 standard, which is currently under development, aims to provide specific safety requirements for LiFePO4 batteries used in stationary energy storage systems.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in ensuring the reliability and market acceptance of LiFePO4-based back-up power solutions. Manufacturers and system integrators must stay informed about the latest regulatory developments and incorporate these safety standards into their product design and implementation processes.

One of the primary safety standards governing LiFePO4 batteries is the IEC 62619, which outlines safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard covers various aspects, including electrical, mechanical, and environmental safety considerations. It also specifies testing procedures to evaluate the safety performance of these batteries under normal and abnormal operating conditions.

In addition to IEC 62619, the UN38.3 regulation is essential for the transportation of lithium-ion batteries, including LiFePO4 cells. This regulation mandates a series of tests to ensure the safety of batteries during shipping, including altitude simulation, thermal cycling, vibration, shock, and external short circuit tests. Compliance with UN38.3 is mandatory for air, sea, and land transportation of lithium batteries.

For stationary energy storage applications, such as back-up power systems, the UL 1973 standard is particularly relevant. This standard addresses the safety of battery systems for use in light electric rail applications and stationary applications, covering areas such as electrical safety, fire prevention, and thermal management.

The National Fire Protection Association (NFPA) has also developed standards specifically for energy storage systems, including NFPA 855. This standard provides requirements for the installation, operation, and maintenance of energy storage systems, including those based on LiFePO4 technology. It addresses fire prevention, suppression, and control measures for these systems.

In the context of back-up power solutions, the IEEE 1635 standard is noteworthy. While not specific to LiFePO4 batteries, it provides guidelines for the ventilation and thermal management of stationary battery installations, which are critical aspects of safety in back-up power applications.

As the adoption of LiFePO4 batteries in back-up power solutions continues to grow, regulatory bodies are continuously updating and developing new safety standards. For instance, the IEC 63056 standard, which is currently under development, aims to provide specific safety requirements for LiFePO4 batteries used in stationary energy storage systems.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in ensuring the reliability and market acceptance of LiFePO4-based back-up power solutions. Manufacturers and system integrators must stay informed about the latest regulatory developments and incorporate these safety standards into their product design and implementation processes.

Environmental Impact

The environmental impact of lithium iron phosphate (LiFePO4) batteries in back-up power solutions is a critical consideration in their adoption and long-term sustainability. These batteries offer several environmental advantages compared to traditional lead-acid batteries and other lithium-ion chemistries.

LiFePO4 batteries are inherently safer and more stable, reducing the risk of thermal runaway and fire hazards. This enhanced safety profile minimizes the potential for environmental contamination due to accidents or improper disposal. Additionally, the materials used in LiFePO4 batteries are generally less toxic and more environmentally friendly than those found in other battery types.

The long cycle life of LiFePO4 batteries contributes significantly to their positive environmental impact. With the ability to withstand thousands of charge-discharge cycles, these batteries require less frequent replacement, reducing the overall demand for raw materials and energy associated with battery production. This longevity also translates to less electronic waste over time, alleviating the burden on waste management systems and landfills.

In terms of raw material sourcing, LiFePO4 batteries rely less on rare earth elements and conflict minerals compared to some other lithium-ion technologies. The iron and phosphate used in these batteries are abundant and widely available, reducing the environmental and social impacts associated with mining operations.

The energy density of LiFePO4 batteries, while lower than some other lithium-ion chemistries, is still significantly higher than lead-acid batteries. This higher energy density allows for more compact and lightweight back-up power solutions, potentially reducing transportation-related emissions and material usage in supporting infrastructure.

End-of-life considerations for LiFePO4 batteries are also favorable from an environmental perspective. The materials used in these batteries are more easily recyclable than those in other lithium-ion chemistries. Recycling processes for LiFePO4 batteries are becoming increasingly efficient, allowing for the recovery of valuable materials and further reducing the environmental footprint of these energy storage solutions.

In the context of back-up power applications, LiFePO4 batteries contribute to the overall sustainability of power systems. Their ability to provide reliable and efficient energy storage supports the integration of renewable energy sources, helping to reduce reliance on fossil fuel-based backup generators and their associated emissions.

LiFePO4 batteries are inherently safer and more stable, reducing the risk of thermal runaway and fire hazards. This enhanced safety profile minimizes the potential for environmental contamination due to accidents or improper disposal. Additionally, the materials used in LiFePO4 batteries are generally less toxic and more environmentally friendly than those found in other battery types.

The long cycle life of LiFePO4 batteries contributes significantly to their positive environmental impact. With the ability to withstand thousands of charge-discharge cycles, these batteries require less frequent replacement, reducing the overall demand for raw materials and energy associated with battery production. This longevity also translates to less electronic waste over time, alleviating the burden on waste management systems and landfills.

In terms of raw material sourcing, LiFePO4 batteries rely less on rare earth elements and conflict minerals compared to some other lithium-ion technologies. The iron and phosphate used in these batteries are abundant and widely available, reducing the environmental and social impacts associated with mining operations.

The energy density of LiFePO4 batteries, while lower than some other lithium-ion chemistries, is still significantly higher than lead-acid batteries. This higher energy density allows for more compact and lightweight back-up power solutions, potentially reducing transportation-related emissions and material usage in supporting infrastructure.

End-of-life considerations for LiFePO4 batteries are also favorable from an environmental perspective. The materials used in these batteries are more easily recyclable than those in other lithium-ion chemistries. Recycling processes for LiFePO4 batteries are becoming increasingly efficient, allowing for the recovery of valuable materials and further reducing the environmental footprint of these energy storage solutions.

In the context of back-up power applications, LiFePO4 batteries contribute to the overall sustainability of power systems. Their ability to provide reliable and efficient energy storage supports the integration of renewable energy sources, helping to reduce reliance on fossil fuel-based backup generators and their associated emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!