The Future of Lithium Iron Phosphate Batteries in Electric Aviation

AUG 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their introduction in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has seen continuous improvements in energy density, cycle life, and cost-effectiveness.

The early 2000s marked the first commercial applications of LFP batteries, primarily in portable electronics and power tools. During this period, researchers focused on enhancing the material's conductivity and optimizing its crystal structure to improve overall battery performance.

By the mid-2000s, LFP batteries began to gain traction in the electric vehicle (EV) market. This shift prompted further advancements in cell design and manufacturing processes, leading to increased energy density and reduced production costs. The development of nano-scale LFP particles and carbon coating techniques significantly boosted the battery's power output and stability.

The 2010s saw a surge in LFP battery adoption for stationary energy storage applications, driven by their excellent safety profile and long cycle life. This period also witnessed the emergence of large-format LFP cells, specifically designed for electric buses and grid-scale energy storage systems.

Recent years have brought about notable improvements in LFP chemistry, including the introduction of silicon-doped LFP cathodes and advanced electrolyte formulations. These innovations have pushed the energy density of LFP batteries closer to that of nickel-based lithium-ion batteries, while maintaining their inherent safety advantages.

In the context of electric aviation, LFP batteries have begun to attract attention due to their safety characteristics and potential for high-power applications. The evolution of LFP technology has led to the development of lightweight, high-capacity cells that are increasingly suitable for electric aircraft, particularly in short-range and urban air mobility scenarios.

Looking ahead, the LFP battery evolution is expected to continue with a focus on further increasing energy density, reducing weight, and enhancing fast-charging capabilities. These advancements will be crucial for expanding the role of LFP batteries in electric aviation, potentially enabling longer flight times and improved aircraft performance.

The early 2000s marked the first commercial applications of LFP batteries, primarily in portable electronics and power tools. During this period, researchers focused on enhancing the material's conductivity and optimizing its crystal structure to improve overall battery performance.

By the mid-2000s, LFP batteries began to gain traction in the electric vehicle (EV) market. This shift prompted further advancements in cell design and manufacturing processes, leading to increased energy density and reduced production costs. The development of nano-scale LFP particles and carbon coating techniques significantly boosted the battery's power output and stability.

The 2010s saw a surge in LFP battery adoption for stationary energy storage applications, driven by their excellent safety profile and long cycle life. This period also witnessed the emergence of large-format LFP cells, specifically designed for electric buses and grid-scale energy storage systems.

Recent years have brought about notable improvements in LFP chemistry, including the introduction of silicon-doped LFP cathodes and advanced electrolyte formulations. These innovations have pushed the energy density of LFP batteries closer to that of nickel-based lithium-ion batteries, while maintaining their inherent safety advantages.

In the context of electric aviation, LFP batteries have begun to attract attention due to their safety characteristics and potential for high-power applications. The evolution of LFP technology has led to the development of lightweight, high-capacity cells that are increasingly suitable for electric aircraft, particularly in short-range and urban air mobility scenarios.

Looking ahead, the LFP battery evolution is expected to continue with a focus on further increasing energy density, reducing weight, and enhancing fast-charging capabilities. These advancements will be crucial for expanding the role of LFP batteries in electric aviation, potentially enabling longer flight times and improved aircraft performance.

Aviation Market Demand

The aviation industry is experiencing a significant shift towards electrification, driven by the need for more sustainable and environmentally friendly transportation solutions. This transition has created a growing demand for advanced battery technologies, particularly in the electric aviation sector. Lithium Iron Phosphate (LiFePO4) batteries are emerging as a promising candidate for powering electric aircraft due to their unique characteristics and potential advantages over other battery chemistries.

The global electric aviation market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 15% between 2021 and 2030. This growth is fueled by increasing environmental concerns, stricter emissions regulations, and advancements in battery technology. As the industry evolves, the demand for high-performance, safe, and cost-effective battery solutions is expected to surge, creating a substantial market opportunity for LiFePO4 batteries.

Electric aircraft manufacturers are actively seeking battery technologies that can provide the necessary energy density, power output, and safety features required for aviation applications. LiFePO4 batteries are attracting attention due to their excellent thermal stability, long cycle life, and improved safety profile compared to traditional lithium-ion batteries. These characteristics make them particularly suitable for the rigorous demands of aviation, where safety and reliability are paramount.

The market demand for LiFePO4 batteries in electric aviation is driven by several factors. Firstly, the push for zero-emission aircraft is gaining momentum, with both established aerospace companies and innovative startups investing heavily in electric propulsion systems. Secondly, the urban air mobility (UAM) sector, including electric vertical takeoff and landing (eVTOL) vehicles, is experiencing rapid growth and requires advanced battery solutions to enable short-range, high-frequency flights in urban environments.

Furthermore, the general aviation sector, encompassing small private aircraft and flight training vehicles, is showing increasing interest in electric propulsion systems. This segment presents a significant opportunity for LiFePO4 batteries, as these aircraft typically operate on shorter routes and have less stringent energy density requirements compared to commercial airliners.

The potential market for LiFePO4 batteries in electric aviation extends beyond the aircraft themselves. Ground support equipment, such as electric tugs and auxiliary power units, also represent a growing market segment that could benefit from the advantages of LiFePO4 technology. As airports worldwide strive to reduce their carbon footprint, the demand for electric ground vehicles and equipment is expected to rise, further expanding the market for advanced battery solutions.

The global electric aviation market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 15% between 2021 and 2030. This growth is fueled by increasing environmental concerns, stricter emissions regulations, and advancements in battery technology. As the industry evolves, the demand for high-performance, safe, and cost-effective battery solutions is expected to surge, creating a substantial market opportunity for LiFePO4 batteries.

Electric aircraft manufacturers are actively seeking battery technologies that can provide the necessary energy density, power output, and safety features required for aviation applications. LiFePO4 batteries are attracting attention due to their excellent thermal stability, long cycle life, and improved safety profile compared to traditional lithium-ion batteries. These characteristics make them particularly suitable for the rigorous demands of aviation, where safety and reliability are paramount.

The market demand for LiFePO4 batteries in electric aviation is driven by several factors. Firstly, the push for zero-emission aircraft is gaining momentum, with both established aerospace companies and innovative startups investing heavily in electric propulsion systems. Secondly, the urban air mobility (UAM) sector, including electric vertical takeoff and landing (eVTOL) vehicles, is experiencing rapid growth and requires advanced battery solutions to enable short-range, high-frequency flights in urban environments.

Furthermore, the general aviation sector, encompassing small private aircraft and flight training vehicles, is showing increasing interest in electric propulsion systems. This segment presents a significant opportunity for LiFePO4 batteries, as these aircraft typically operate on shorter routes and have less stringent energy density requirements compared to commercial airliners.

The potential market for LiFePO4 batteries in electric aviation extends beyond the aircraft themselves. Ground support equipment, such as electric tugs and auxiliary power units, also represent a growing market segment that could benefit from the advantages of LiFePO4 technology. As airports worldwide strive to reduce their carbon footprint, the demand for electric ground vehicles and equipment is expected to rise, further expanding the market for advanced battery solutions.

LFP Tech Challenges

Lithium Iron Phosphate (LFP) batteries face several significant challenges in their application to electric aviation. One of the primary hurdles is their relatively low energy density compared to other lithium-ion chemistries. While LFP batteries offer excellent safety and longevity, their energy-to-weight ratio is a critical limitation for aviation applications where weight is a paramount concern. This necessitates larger and heavier battery packs to achieve the same range as other lithium-ion alternatives, potentially offsetting the weight savings from electric propulsion.

Another challenge lies in the power output capabilities of LFP batteries. Electric aircraft require high power during takeoff and climbing phases, which can strain LFP cells. While LFP batteries generally have good power characteristics, further improvements are needed to meet the demanding requirements of aviation without compromising the battery's lifespan or safety features.

The charging speed of LFP batteries also presents a challenge for electric aviation. Fast charging is crucial for commercial viability, allowing quick turnaround times between flights. However, rapid charging can lead to increased stress on the battery cells, potentially affecting their long-term performance and safety. Developing charging protocols that balance speed with battery health is an ongoing area of research.

Temperature management is another significant challenge. LFP batteries perform optimally within a specific temperature range, and aviation environments can expose them to extreme conditions. Ensuring consistent performance and safety across a wide range of temperatures, from high-altitude cold to tropical heat, requires sophisticated thermal management systems, adding complexity and weight to the aircraft design.

The manufacturing scalability of LFP batteries for aviation applications is also a concern. As the demand for electric aircraft grows, the industry will require a robust supply chain capable of producing high-quality, aviation-grade LFP batteries in large quantities. This involves not only scaling up production but also maintaining stringent quality control and safety standards specific to aviation requirements.

Lastly, the regulatory landscape poses a challenge for LFP batteries in aviation. Stringent certification processes and safety standards for aircraft components mean that LFP battery systems must undergo extensive testing and validation before widespread adoption. Developing battery systems that meet these rigorous standards while maintaining the cost-effectiveness and performance advantages of LFP chemistry is a complex and time-consuming process.

Another challenge lies in the power output capabilities of LFP batteries. Electric aircraft require high power during takeoff and climbing phases, which can strain LFP cells. While LFP batteries generally have good power characteristics, further improvements are needed to meet the demanding requirements of aviation without compromising the battery's lifespan or safety features.

The charging speed of LFP batteries also presents a challenge for electric aviation. Fast charging is crucial for commercial viability, allowing quick turnaround times between flights. However, rapid charging can lead to increased stress on the battery cells, potentially affecting their long-term performance and safety. Developing charging protocols that balance speed with battery health is an ongoing area of research.

Temperature management is another significant challenge. LFP batteries perform optimally within a specific temperature range, and aviation environments can expose them to extreme conditions. Ensuring consistent performance and safety across a wide range of temperatures, from high-altitude cold to tropical heat, requires sophisticated thermal management systems, adding complexity and weight to the aircraft design.

The manufacturing scalability of LFP batteries for aviation applications is also a concern. As the demand for electric aircraft grows, the industry will require a robust supply chain capable of producing high-quality, aviation-grade LFP batteries in large quantities. This involves not only scaling up production but also maintaining stringent quality control and safety standards specific to aviation requirements.

Lastly, the regulatory landscape poses a challenge for LFP batteries in aviation. Stringent certification processes and safety standards for aircraft components mean that LFP battery systems must undergo extensive testing and validation before widespread adoption. Developing battery systems that meet these rigorous standards while maintaining the cost-effectiveness and performance advantages of LFP chemistry is a complex and time-consuming process.

Current LFP Solutions

01 Electrode material composition and structure

Innovations in electrode material composition and structure for lithium iron phosphate batteries focus on improving energy density, cycling stability, and rate performance. This includes developing novel cathode materials, optimizing particle size and morphology, and incorporating conductive coatings or dopants to enhance electronic conductivity.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

- Battery cell design and assembly: Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.

- Battery management and control systems: Development of sophisticated battery management and control systems for lithium iron phosphate batteries. This includes algorithms for state-of-charge estimation, thermal management, balancing techniques, and safety monitoring to optimize battery performance and longevity.

- Manufacturing processes and equipment: Innovations in manufacturing processes and equipment for large-scale production of lithium iron phosphate batteries. This covers advancements in electrode coating, drying, calendering, and cell assembly techniques, as well as quality control measures to ensure consistent battery performance.

- Battery pack design and integration: Advancements in the design and integration of lithium iron phosphate battery packs for various applications. This includes innovations in modular pack architectures, cooling systems, electrical connections, and packaging solutions to optimize performance, safety, and ease of integration into end-use products.

02 Electrolyte formulations

Advanced electrolyte formulations are designed to enhance the performance and safety of lithium iron phosphate batteries. These may include novel electrolyte additives, ionic liquids, or solid-state electrolytes that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system.Expand Specific Solutions03 Battery management and control systems

Sophisticated battery management and control systems are developed to optimize the performance, safety, and longevity of lithium iron phosphate batteries. These systems may include advanced algorithms for state-of-charge estimation, thermal management, and cell balancing to ensure efficient operation and extend battery life.Expand Specific Solutions04 Manufacturing processes and techniques

Innovative manufacturing processes and techniques are employed to improve the production efficiency and quality of lithium iron phosphate batteries. This may include novel synthesis methods, advanced coating techniques, or automated assembly processes that enhance the consistency and performance of battery components.Expand Specific Solutions05 Battery pack design and integration

Advancements in battery pack design and integration focus on optimizing the arrangement and interconnection of lithium iron phosphate cells for specific applications. This includes innovations in thermal management, modular designs, and integration with power electronics to improve overall system performance and reliability.Expand Specific Solutions

Key EV Battery Players

The future of Lithium Iron Phosphate (LFP) batteries in electric aviation is in an early growth stage, with significant potential for expansion. The market size is expected to increase substantially as the aviation industry seeks more sustainable power solutions. Technologically, LFP batteries are maturing rapidly, with companies like A123 Systems, CATL, and SK Innovation leading the charge. These firms are advancing energy density, safety, and cost-effectiveness of LFP batteries, making them increasingly viable for aviation applications. However, challenges remain in achieving the power-to-weight ratios required for large-scale commercial aviation, indicating that further research and development is crucial for widespread adoption in this sector.

A123 Systems LLC

Technical Solution: A123 Systems has developed a proprietary Nanophosphate® LFP technology specifically tailored for electric aviation applications. Their advanced LFP cells feature a unique doped nanoscale material structure that enhances power capability and cycle life [4]. The company has achieved energy densities of 180 Wh/kg while maintaining excellent safety characteristics crucial for aviation [5]. A123's batteries incorporate advanced thermal management systems, utilizing phase-change materials to regulate temperature during high-power discharge and rapid charging scenarios. They have successfully demonstrated their technology in electric vertical takeoff and landing (eVTOL) prototypes, achieving flight times of up to 60 minutes [6].

Strengths: Excellent safety profile, high power capability, and proven thermal management. Weaknesses: Lower energy density compared to some newer lithium-ion chemistries, potentially limiting range for larger aircraft.

GS Yuasa Corp.

Technical Solution: GS Yuasa has developed a high-performance LFP battery system specifically designed for electric aviation applications. Their technology incorporates a proprietary cathode material with optimized particle size distribution, resulting in improved energy density and rate capability [10]. The company has achieved energy densities of up to 200 Wh/kg while maintaining excellent cycle life and safety characteristics [11]. GS Yuasa's batteries feature an advanced battery management system (BMS) that utilizes artificial intelligence algorithms to optimize performance and extend battery life in aviation-specific duty cycles. The company has successfully tested their batteries in electric aircraft simulators, demonstrating stable performance under various flight conditions and altitudes [12].

Strengths: Advanced BMS with AI optimization, good balance of energy density and cycle life, proven performance in simulated flight conditions. Weaknesses: Energy density still lower than some newer lithium-ion chemistries, limited real-world flight testing data available.

LFP Innovations

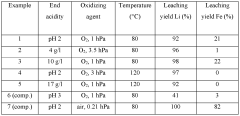

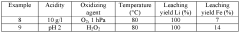

Process for the recovery of lithium and iron from LFP batteries

PatentWO2012072619A1

Innovation

- A selective leaching process involving mechanical processing and physical separation of LFP battery components, followed by contact with an acidic solution containing an oxidizing agent to precipitate iron phosphate and solubilize lithium, with controlled pH and redox potential to minimize acid usage and enhance selectivity.

Aviation Regulations

The integration of lithium iron phosphate (LFP) batteries in electric aviation is subject to stringent aviation regulations that govern safety, performance, and operational standards. These regulations are primarily established by aviation authorities such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe. The regulatory framework for electric aircraft batteries is still evolving, as the technology is relatively new in the aviation sector.

One of the key regulatory considerations for LFP batteries in aviation is the certification process. Aircraft manufacturers must demonstrate that their battery systems meet rigorous safety and performance standards before they can be approved for use in commercial aviation. This includes extensive testing for thermal runaway, fire resistance, and overall system reliability. The FAA's Special Conditions for Certification of Electric or Hybrid Propulsion Systems in Part 23 Airplanes provide guidance on the certification requirements for electric propulsion systems, including battery technologies.

Weight and energy density regulations also play a crucial role in the adoption of LFP batteries for aviation. Aviation authorities impose strict limits on the maximum takeoff weight of aircraft, which directly impacts the feasibility of battery-powered flight. As LFP batteries generally have lower energy density compared to some other lithium-ion chemistries, manufacturers must carefully balance weight considerations with safety and performance requirements to meet regulatory standards.

Operational regulations for electric aircraft equipped with LFP batteries are another important aspect. These include guidelines for charging procedures, battery management systems, and in-flight monitoring. The International Civil Aviation Organization (ICAO) has been working on developing standards for electric and hybrid aircraft, which will likely influence future regulations for LFP battery implementation in aviation.

Environmental regulations are also shaping the future of LFP batteries in electric aviation. As governments worldwide push for reduced carbon emissions in the aviation sector, regulations promoting the adoption of electric propulsion systems are becoming more prevalent. This regulatory landscape is likely to evolve rapidly in the coming years, potentially accelerating the development and implementation of LFP battery technology in aviation.

One of the key regulatory considerations for LFP batteries in aviation is the certification process. Aircraft manufacturers must demonstrate that their battery systems meet rigorous safety and performance standards before they can be approved for use in commercial aviation. This includes extensive testing for thermal runaway, fire resistance, and overall system reliability. The FAA's Special Conditions for Certification of Electric or Hybrid Propulsion Systems in Part 23 Airplanes provide guidance on the certification requirements for electric propulsion systems, including battery technologies.

Weight and energy density regulations also play a crucial role in the adoption of LFP batteries for aviation. Aviation authorities impose strict limits on the maximum takeoff weight of aircraft, which directly impacts the feasibility of battery-powered flight. As LFP batteries generally have lower energy density compared to some other lithium-ion chemistries, manufacturers must carefully balance weight considerations with safety and performance requirements to meet regulatory standards.

Operational regulations for electric aircraft equipped with LFP batteries are another important aspect. These include guidelines for charging procedures, battery management systems, and in-flight monitoring. The International Civil Aviation Organization (ICAO) has been working on developing standards for electric and hybrid aircraft, which will likely influence future regulations for LFP battery implementation in aviation.

Environmental regulations are also shaping the future of LFP batteries in electric aviation. As governments worldwide push for reduced carbon emissions in the aviation sector, regulations promoting the adoption of electric propulsion systems are becoming more prevalent. This regulatory landscape is likely to evolve rapidly in the coming years, potentially accelerating the development and implementation of LFP battery technology in aviation.

Environmental Impact

The environmental impact of lithium iron phosphate (LFP) batteries in electric aviation is a crucial consideration as the industry moves towards more sustainable transportation solutions. LFP batteries offer several environmental advantages compared to traditional lithium-ion batteries, particularly in terms of their reduced reliance on rare earth metals and lower carbon footprint during production.

One of the primary environmental benefits of LFP batteries is their improved safety profile. These batteries are less prone to thermal runaway and fire risks, which not only enhances the safety of electric aircraft but also reduces the potential for environmental contamination in the event of accidents. This increased safety factor could lead to fewer incidents and subsequently minimize the ecological impact of aviation-related accidents.

The longevity of LFP batteries is another significant environmental advantage. With a higher cycle life compared to other lithium-ion chemistries, LFP batteries can withstand more charge-discharge cycles before degradation. This extended lifespan translates to reduced waste generation and less frequent battery replacements, ultimately decreasing the overall environmental footprint of electric aviation operations.

In terms of raw material sourcing, LFP batteries rely less on cobalt, a metal associated with ethical and environmental concerns in its mining practices. The reduced dependence on cobalt not only alleviates supply chain pressures but also mitigates the environmental and social impacts linked to cobalt extraction, particularly in regions with less stringent regulations.

The recyclability of LFP batteries presents another environmental benefit. The materials used in these batteries are more easily recoverable and recyclable compared to other lithium-ion chemistries. This characteristic supports the development of a more circular economy within the aviation industry, reducing the need for virgin material extraction and minimizing waste.

However, it is important to note that the environmental impact of LFP batteries in electric aviation is not entirely positive. The production of these batteries still requires significant energy input and resources. The mining and processing of lithium and iron, while less problematic than cobalt, still have environmental implications that need to be carefully managed.

As the electric aviation sector grows, the demand for LFP batteries will increase, potentially leading to expanded mining operations. This growth must be balanced with sustainable practices to minimize habitat disruption, water pollution, and other environmental concerns associated with resource extraction. Additionally, the aviation industry will need to develop robust recycling infrastructure to handle the eventual disposal of these batteries at the end of their life cycle.

In conclusion, while LFP batteries offer substantial environmental benefits for electric aviation, their impact must be continually assessed and mitigated through responsible manufacturing, efficient use, and effective end-of-life management. As technology advances, further improvements in battery chemistry and production processes may further enhance the environmental profile of LFP batteries in the aviation sector.

One of the primary environmental benefits of LFP batteries is their improved safety profile. These batteries are less prone to thermal runaway and fire risks, which not only enhances the safety of electric aircraft but also reduces the potential for environmental contamination in the event of accidents. This increased safety factor could lead to fewer incidents and subsequently minimize the ecological impact of aviation-related accidents.

The longevity of LFP batteries is another significant environmental advantage. With a higher cycle life compared to other lithium-ion chemistries, LFP batteries can withstand more charge-discharge cycles before degradation. This extended lifespan translates to reduced waste generation and less frequent battery replacements, ultimately decreasing the overall environmental footprint of electric aviation operations.

In terms of raw material sourcing, LFP batteries rely less on cobalt, a metal associated with ethical and environmental concerns in its mining practices. The reduced dependence on cobalt not only alleviates supply chain pressures but also mitigates the environmental and social impacts linked to cobalt extraction, particularly in regions with less stringent regulations.

The recyclability of LFP batteries presents another environmental benefit. The materials used in these batteries are more easily recoverable and recyclable compared to other lithium-ion chemistries. This characteristic supports the development of a more circular economy within the aviation industry, reducing the need for virgin material extraction and minimizing waste.

However, it is important to note that the environmental impact of LFP batteries in electric aviation is not entirely positive. The production of these batteries still requires significant energy input and resources. The mining and processing of lithium and iron, while less problematic than cobalt, still have environmental implications that need to be carefully managed.

As the electric aviation sector grows, the demand for LFP batteries will increase, potentially leading to expanded mining operations. This growth must be balanced with sustainable practices to minimize habitat disruption, water pollution, and other environmental concerns associated with resource extraction. Additionally, the aviation industry will need to develop robust recycling infrastructure to handle the eventual disposal of these batteries at the end of their life cycle.

In conclusion, while LFP batteries offer substantial environmental benefits for electric aviation, their impact must be continually assessed and mitigated through responsible manufacturing, efficient use, and effective end-of-life management. As technology advances, further improvements in battery chemistry and production processes may further enhance the environmental profile of LFP batteries in the aviation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!