Impact of Charge-Discharge Rates on Lithium Iron Phosphate Battery Efficiency

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their inception in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has seen remarkable advancements in performance, efficiency, and cost-effectiveness over the past two decades.

The early 2000s marked the beginning of commercial production for LFP batteries, with a focus on improving energy density and cycle life. During this period, researchers concentrated on optimizing the cathode material's structure and composition to enhance its electrochemical properties. The introduction of nano-scale particles and carbon coating techniques led to substantial improvements in conductivity and overall battery performance.

By the mid-2000s, LFP batteries started gaining traction in various applications, particularly in electric vehicles and stationary energy storage systems. This period saw the development of advanced manufacturing processes, resulting in more consistent and higher-quality battery cells. The implementation of improved electrolyte formulations and separator materials further contributed to enhanced safety and longevity.

The late 2000s and early 2010s witnessed a surge in research efforts aimed at addressing the relatively lower energy density of LFP batteries compared to other lithium-ion chemistries. Scientists explored doping techniques, introducing small amounts of other elements into the cathode material to boost its capacity and voltage. Concurrently, advancements in battery management systems allowed for more efficient utilization of LFP cells, maximizing their performance and lifespan.

In recent years, the focus has shifted towards optimizing LFP batteries for fast charging capabilities and high-rate performance. Researchers have made significant strides in understanding and mitigating the impact of charge-discharge rates on battery efficiency. Novel electrode designs, such as 3D-structured cathodes and advanced conductive coatings, have emerged to facilitate rapid ion transport and minimize capacity loss during high-rate cycling.

The evolution of LFP batteries has also been marked by continuous improvements in manufacturing processes and economies of scale. This has led to a substantial reduction in production costs, making LFP technology increasingly competitive in the global battery market. The development of large-format cells and modular battery pack designs has further expanded the application range of LFP batteries, particularly in the automotive and grid storage sectors.

Looking ahead, the LFP battery evolution is expected to continue with a focus on pushing the boundaries of energy density while maintaining its inherent safety advantages. Emerging research areas include the exploration of solid-state electrolytes compatible with LFP chemistry and the development of advanced cathode architectures to further enhance rate capability and cycle life.

The early 2000s marked the beginning of commercial production for LFP batteries, with a focus on improving energy density and cycle life. During this period, researchers concentrated on optimizing the cathode material's structure and composition to enhance its electrochemical properties. The introduction of nano-scale particles and carbon coating techniques led to substantial improvements in conductivity and overall battery performance.

By the mid-2000s, LFP batteries started gaining traction in various applications, particularly in electric vehicles and stationary energy storage systems. This period saw the development of advanced manufacturing processes, resulting in more consistent and higher-quality battery cells. The implementation of improved electrolyte formulations and separator materials further contributed to enhanced safety and longevity.

The late 2000s and early 2010s witnessed a surge in research efforts aimed at addressing the relatively lower energy density of LFP batteries compared to other lithium-ion chemistries. Scientists explored doping techniques, introducing small amounts of other elements into the cathode material to boost its capacity and voltage. Concurrently, advancements in battery management systems allowed for more efficient utilization of LFP cells, maximizing their performance and lifespan.

In recent years, the focus has shifted towards optimizing LFP batteries for fast charging capabilities and high-rate performance. Researchers have made significant strides in understanding and mitigating the impact of charge-discharge rates on battery efficiency. Novel electrode designs, such as 3D-structured cathodes and advanced conductive coatings, have emerged to facilitate rapid ion transport and minimize capacity loss during high-rate cycling.

The evolution of LFP batteries has also been marked by continuous improvements in manufacturing processes and economies of scale. This has led to a substantial reduction in production costs, making LFP technology increasingly competitive in the global battery market. The development of large-format cells and modular battery pack designs has further expanded the application range of LFP batteries, particularly in the automotive and grid storage sectors.

Looking ahead, the LFP battery evolution is expected to continue with a focus on pushing the boundaries of energy density while maintaining its inherent safety advantages. Emerging research areas include the exploration of solid-state electrolytes compatible with LFP chemistry and the development of advanced cathode architectures to further enhance rate capability and cycle life.

Market Demand Analysis

The market demand for lithium iron phosphate (LFP) batteries has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. The efficiency of these batteries, particularly in relation to charge-discharge rates, plays a crucial role in meeting the evolving needs of various industries.

In the automotive sector, the demand for LFP batteries has surged due to their superior safety profile, longer cycle life, and lower cost compared to other lithium-ion chemistries. As EV manufacturers strive to improve charging speeds and overall vehicle performance, the impact of charge-discharge rates on LFP battery efficiency has become a critical factor in product development and market competitiveness.

The renewable energy sector has also contributed to the growing demand for LFP batteries, particularly in grid-scale energy storage applications. The ability of these batteries to handle high charge-discharge rates efficiently is essential for managing peak loads, integrating intermittent renewable sources, and ensuring grid stability. This has led to increased interest in optimizing LFP battery performance under various charging and discharging conditions.

Consumer electronics and portable devices represent another significant market segment where LFP battery efficiency is gaining importance. As users demand faster charging times and longer battery life, manufacturers are exploring ways to improve the charge-discharge efficiency of LFP batteries in these applications.

The industrial and commercial sectors are also driving demand for LFP batteries with enhanced charge-discharge efficiency. Applications such as material handling equipment, backup power systems, and telecommunications infrastructure require batteries that can deliver high power output and withstand frequent cycling without significant degradation.

Market trends indicate a growing preference for fast-charging capabilities across all sectors. This has intensified research and development efforts focused on improving LFP battery efficiency at higher charge-discharge rates. Manufacturers are investing in advanced electrode materials, electrolyte formulations, and battery management systems to enhance performance and meet market demands.

The global push for sustainability and reduced carbon emissions has further amplified the market demand for efficient energy storage solutions. LFP batteries, with their potential for improved charge-discharge efficiency, are well-positioned to address these environmental concerns and support the transition to cleaner energy systems.

As the market continues to evolve, there is an increasing emphasis on developing LFP batteries that can maintain high efficiency across a wide range of charge-discharge rates. This versatility is crucial for addressing the diverse needs of different applications and ensuring optimal performance in various operating conditions.

In the automotive sector, the demand for LFP batteries has surged due to their superior safety profile, longer cycle life, and lower cost compared to other lithium-ion chemistries. As EV manufacturers strive to improve charging speeds and overall vehicle performance, the impact of charge-discharge rates on LFP battery efficiency has become a critical factor in product development and market competitiveness.

The renewable energy sector has also contributed to the growing demand for LFP batteries, particularly in grid-scale energy storage applications. The ability of these batteries to handle high charge-discharge rates efficiently is essential for managing peak loads, integrating intermittent renewable sources, and ensuring grid stability. This has led to increased interest in optimizing LFP battery performance under various charging and discharging conditions.

Consumer electronics and portable devices represent another significant market segment where LFP battery efficiency is gaining importance. As users demand faster charging times and longer battery life, manufacturers are exploring ways to improve the charge-discharge efficiency of LFP batteries in these applications.

The industrial and commercial sectors are also driving demand for LFP batteries with enhanced charge-discharge efficiency. Applications such as material handling equipment, backup power systems, and telecommunications infrastructure require batteries that can deliver high power output and withstand frequent cycling without significant degradation.

Market trends indicate a growing preference for fast-charging capabilities across all sectors. This has intensified research and development efforts focused on improving LFP battery efficiency at higher charge-discharge rates. Manufacturers are investing in advanced electrode materials, electrolyte formulations, and battery management systems to enhance performance and meet market demands.

The global push for sustainability and reduced carbon emissions has further amplified the market demand for efficient energy storage solutions. LFP batteries, with their potential for improved charge-discharge efficiency, are well-positioned to address these environmental concerns and support the transition to cleaner energy systems.

As the market continues to evolve, there is an increasing emphasis on developing LFP batteries that can maintain high efficiency across a wide range of charge-discharge rates. This versatility is crucial for addressing the diverse needs of different applications and ensuring optimal performance in various operating conditions.

Technical Challenges

The development of lithium iron phosphate (LiFePO4) batteries has been marked by significant advancements, yet several technical challenges persist, particularly concerning the impact of charge-discharge rates on battery efficiency. One of the primary obstacles is the relatively low electronic conductivity of LiFePO4, which can lead to decreased performance at high charge-discharge rates. This inherent limitation affects the battery's ability to quickly transfer electrons during rapid charging or discharging processes, potentially reducing overall efficiency and power output.

Another critical challenge lies in the structural stability of LiFePO4 cathodes during high-rate cycling. While these batteries are known for their excellent thermal stability, repeated rapid charge-discharge cycles can induce mechanical stress on the cathode material. This stress may lead to microstructural changes, particle fracturing, or degradation of the crystal structure, ultimately impacting the battery's long-term performance and cycle life.

The formation and growth of a solid electrolyte interphase (SEI) layer at high charge-discharge rates present additional complications. Rapid cycling can accelerate SEI formation, potentially leading to increased internal resistance and reduced lithium-ion diffusion. This phenomenon not only affects the battery's efficiency but also contributes to capacity fade over time, particularly when subjected to frequent fast charging.

Temperature management during high-rate operations poses another significant challenge. Rapid charge-discharge cycles generate more heat within the battery, which can lead to thermal runaway if not properly managed. Elevated temperatures can accelerate side reactions, degrade the electrolyte, and compromise the structural integrity of battery components, all of which negatively impact efficiency and safety.

The optimization of electrode design for high-rate performance while maintaining energy density remains a complex task. Increasing the surface area of active materials or reducing particle size to enhance reaction kinetics often comes at the cost of lower volumetric energy density. Striking the right balance between power capability and energy storage capacity continues to be a key challenge in LiFePO4 battery development.

Lastly, the development of advanced battery management systems (BMS) capable of effectively monitoring and controlling high-rate charge-discharge processes is crucial. Current BMS technologies face challenges in accurately predicting state-of-charge and state-of-health under dynamic, high-rate conditions, which is essential for optimizing battery performance and longevity.

Addressing these technical challenges requires interdisciplinary research efforts, combining materials science, electrochemistry, and advanced manufacturing techniques. Innovations in cathode material doping, nanostructured electrodes, electrolyte formulations, and thermal management systems are among the areas being explored to enhance the efficiency and performance of LiFePO4 batteries under varying charge-discharge rates.

Another critical challenge lies in the structural stability of LiFePO4 cathodes during high-rate cycling. While these batteries are known for their excellent thermal stability, repeated rapid charge-discharge cycles can induce mechanical stress on the cathode material. This stress may lead to microstructural changes, particle fracturing, or degradation of the crystal structure, ultimately impacting the battery's long-term performance and cycle life.

The formation and growth of a solid electrolyte interphase (SEI) layer at high charge-discharge rates present additional complications. Rapid cycling can accelerate SEI formation, potentially leading to increased internal resistance and reduced lithium-ion diffusion. This phenomenon not only affects the battery's efficiency but also contributes to capacity fade over time, particularly when subjected to frequent fast charging.

Temperature management during high-rate operations poses another significant challenge. Rapid charge-discharge cycles generate more heat within the battery, which can lead to thermal runaway if not properly managed. Elevated temperatures can accelerate side reactions, degrade the electrolyte, and compromise the structural integrity of battery components, all of which negatively impact efficiency and safety.

The optimization of electrode design for high-rate performance while maintaining energy density remains a complex task. Increasing the surface area of active materials or reducing particle size to enhance reaction kinetics often comes at the cost of lower volumetric energy density. Striking the right balance between power capability and energy storage capacity continues to be a key challenge in LiFePO4 battery development.

Lastly, the development of advanced battery management systems (BMS) capable of effectively monitoring and controlling high-rate charge-discharge processes is crucial. Current BMS technologies face challenges in accurately predicting state-of-charge and state-of-health under dynamic, high-rate conditions, which is essential for optimizing battery performance and longevity.

Addressing these technical challenges requires interdisciplinary research efforts, combining materials science, electrochemistry, and advanced manufacturing techniques. Innovations in cathode material doping, nanostructured electrodes, electrolyte formulations, and thermal management systems are among the areas being explored to enhance the efficiency and performance of LiFePO4 batteries under varying charge-discharge rates.

Current Solutions

01 Electrode material optimization

Improving the efficiency of Lithium Iron Phosphate (LiFePO4) batteries through optimization of electrode materials. This includes enhancing the conductivity and stability of the cathode material, as well as developing novel composite materials to increase energy density and power output.- Electrode material optimization: Improving the efficiency of lithium iron phosphate batteries through optimization of electrode materials. This includes enhancing the conductivity and stability of cathode materials, as well as developing novel anode materials to increase energy density and charge/discharge rates.

- Electrolyte composition enhancements: Developing advanced electrolyte formulations to improve the ionic conductivity and electrochemical stability of lithium iron phosphate batteries. This involves incorporating additives and modifying the electrolyte composition to enhance battery performance and longevity.

- Battery management system optimization: Implementing sophisticated battery management systems to optimize charging and discharging processes, monitor cell health, and balance voltage across cells. This approach aims to maximize battery efficiency and extend overall lifespan.

- Thermal management techniques: Developing advanced thermal management solutions to maintain optimal operating temperatures for lithium iron phosphate batteries. This includes innovative cooling systems and heat dissipation methods to enhance battery efficiency and prevent performance degradation.

- Nanostructured materials integration: Incorporating nanostructured materials into lithium iron phosphate battery components to improve energy density, power output, and cycling stability. This approach focuses on enhancing the surface area and reactivity of electrode materials to boost overall battery efficiency.

02 Electrolyte composition enhancement

Developing advanced electrolyte formulations to improve the ionic conductivity and electrochemical stability of LiFePO4 batteries. This involves the use of additives, solvents, and salts to enhance the overall battery performance and cycle life.Expand Specific Solutions03 Battery management system optimization

Implementing sophisticated battery management systems to maximize the efficiency of LiFePO4 batteries. This includes advanced algorithms for charge-discharge control, thermal management, and state-of-charge estimation to improve overall battery performance and longevity.Expand Specific Solutions04 Nanostructured materials integration

Incorporating nanostructured materials in LiFePO4 battery components to enhance efficiency. This approach focuses on increasing the surface area and reducing diffusion distances, leading to improved charge-discharge rates and overall battery performance.Expand Specific Solutions05 Manufacturing process improvements

Enhancing LiFePO4 battery efficiency through advancements in manufacturing processes. This includes optimizing synthesis methods, developing novel coating techniques, and improving assembly processes to reduce internal resistance and increase energy density.Expand Specific Solutions

Key Industry Players

The impact of charge-discharge rates on lithium iron phosphate battery efficiency is a critical area of research in the evolving energy storage landscape. The market for this technology is in a growth phase, with increasing demand driven by electric vehicles and renewable energy storage applications. The global market size for lithium iron phosphate batteries is projected to expand significantly in the coming years. Technologically, while the core principles are well-established, ongoing research by companies like LG Energy Solution, BYD, and Murata Manufacturing focuses on improving efficiency, cycle life, and charge-discharge performance. Emerging players such as Guangdong Bangpu and Sion Power are also contributing to advancements in this field, indicating a competitive and innovation-driven market.

LG Energy Solution Ltd.

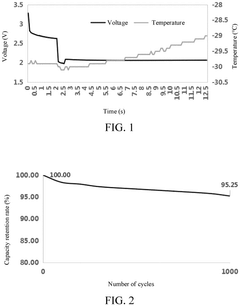

Technical Solution: LG Energy Solution has developed advanced lithium iron phosphate (LFP) batteries with improved charge-discharge rates. Their technology utilizes nano-sized LFP particles and a unique carbon coating process to enhance electron and ion transport[1]. This results in batteries that can maintain high efficiency even at elevated charge-discharge rates. The company has also implemented a sophisticated battery management system (BMS) that optimizes charging and discharging profiles based on real-time battery conditions and usage patterns[2]. This adaptive approach helps to minimize capacity loss and extend battery life, even under high-rate cycling conditions. Additionally, LG has introduced a novel electrolyte formulation that enhances ionic conductivity and reduces internal resistance, further improving the battery's performance at high charge-discharge rates[3].

Strengths: High-rate capability, long cycle life, and advanced BMS for optimized performance. Weaknesses: Potentially higher production costs due to advanced materials and manufacturing processes.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery, an innovative LFP battery design optimized for high charge-discharge rates. The Blade Battery utilizes a unique cell-to-pack technology that increases energy density while maintaining excellent thermal management[4]. This design allows for faster charging and discharging without compromising safety or longevity. BYD's approach includes a proprietary electrolyte additive that forms a stable solid electrolyte interphase (SEI) layer, reducing capacity fade during high-rate cycling[5]. The company has also developed an advanced cooling system that ensures uniform temperature distribution across the battery pack, even during rapid charge and discharge cycles. This thermal management strategy significantly contributes to maintaining high efficiency and prolonging battery life under demanding conditions[6].

Strengths: Innovative cell-to-pack design, excellent thermal management, and high safety standards. Weaknesses: Potentially limited to specific form factors due to the unique blade design.

Efficiency Innovations

Battery core, battery core preparation method, starting battery for fuel engine, and vehicle

PatentPendingEP4567913A2

Innovation

- A battery core is developed using composite lithium iron phosphate particles with different D50 particle diameters for the positive electrode and composite graphite particles with different D50 particle diameters for the negative electrode, along with an optimized electrolyte solution, to enhance lithium ion transmission and reduce impedance.

Patent

Innovation

- Development of advanced battery management systems to optimize charge-discharge rates based on real-time battery conditions.

- Implementation of novel electrode materials or coatings to improve the stability and efficiency of lithium iron phosphate batteries at high charge-discharge rates.

- Design of innovative thermal management systems to mitigate the negative effects of high charge-discharge rates on battery efficiency and lifespan.

Safety Considerations

Safety considerations are paramount when discussing the impact of charge-discharge rates on Lithium Iron Phosphate (LFP) battery efficiency. LFP batteries are known for their inherent safety advantages compared to other lithium-ion chemistries, but proper management of charge-discharge rates remains crucial for maintaining this safety profile.

At high charge rates, the primary safety concern is lithium plating, which can occur when lithium ions accumulate on the anode surface faster than they can intercalate into the graphite structure. This phenomenon is exacerbated at low temperatures and high states of charge. Lithium plating can lead to capacity loss, internal short circuits, and in extreme cases, thermal runaway. To mitigate this risk, charge rates are typically limited, especially as the battery approaches full charge.

Conversely, high discharge rates can lead to excessive heat generation within the battery. While LFP batteries have a higher thermal stability than other lithium-ion chemistries, prolonged exposure to high temperatures can still degrade the battery materials and potentially compromise safety. Thermal management systems are essential for dissipating heat and maintaining safe operating temperatures, particularly in high-power applications.

The battery management system (BMS) plays a critical role in ensuring safe operation across various charge-discharge rates. It monitors cell voltages, temperatures, and current flow, adjusting charge-discharge rates as necessary to prevent unsafe conditions. Advanced BMS algorithms can adapt to battery aging and environmental conditions, further enhancing safety over the battery's lifetime.

Mechanical stress is another safety consideration related to charge-discharge rates. Rapid charging or discharging can cause expansion and contraction of electrode materials, potentially leading to mechanical degradation over time. This can manifest as particle cracking, electrode delamination, or separator damage, all of which can compromise battery safety and performance.

To address these safety concerns, manufacturers often implement multi-layer protection strategies. These include careful cell design to minimize internal resistance and improve heat dissipation, robust packaging to withstand mechanical stress, and the use of safety devices such as current interrupt devices (CIDs) and positive temperature coefficient (PTC) elements. Additionally, rigorous testing protocols are employed to validate battery safety under various charge-discharge scenarios and abuse conditions.

In conclusion, while LFP batteries offer inherent safety advantages, the management of charge-discharge rates remains critical for maintaining this safety profile throughout the battery's operational life. Balancing performance requirements with safety considerations is an ongoing challenge that drives continuous innovation in battery design, materials, and management systems.

At high charge rates, the primary safety concern is lithium plating, which can occur when lithium ions accumulate on the anode surface faster than they can intercalate into the graphite structure. This phenomenon is exacerbated at low temperatures and high states of charge. Lithium plating can lead to capacity loss, internal short circuits, and in extreme cases, thermal runaway. To mitigate this risk, charge rates are typically limited, especially as the battery approaches full charge.

Conversely, high discharge rates can lead to excessive heat generation within the battery. While LFP batteries have a higher thermal stability than other lithium-ion chemistries, prolonged exposure to high temperatures can still degrade the battery materials and potentially compromise safety. Thermal management systems are essential for dissipating heat and maintaining safe operating temperatures, particularly in high-power applications.

The battery management system (BMS) plays a critical role in ensuring safe operation across various charge-discharge rates. It monitors cell voltages, temperatures, and current flow, adjusting charge-discharge rates as necessary to prevent unsafe conditions. Advanced BMS algorithms can adapt to battery aging and environmental conditions, further enhancing safety over the battery's lifetime.

Mechanical stress is another safety consideration related to charge-discharge rates. Rapid charging or discharging can cause expansion and contraction of electrode materials, potentially leading to mechanical degradation over time. This can manifest as particle cracking, electrode delamination, or separator damage, all of which can compromise battery safety and performance.

To address these safety concerns, manufacturers often implement multi-layer protection strategies. These include careful cell design to minimize internal resistance and improve heat dissipation, robust packaging to withstand mechanical stress, and the use of safety devices such as current interrupt devices (CIDs) and positive temperature coefficient (PTC) elements. Additionally, rigorous testing protocols are employed to validate battery safety under various charge-discharge scenarios and abuse conditions.

In conclusion, while LFP batteries offer inherent safety advantages, the management of charge-discharge rates remains critical for maintaining this safety profile throughout the battery's operational life. Balancing performance requirements with safety considerations is an ongoing challenge that drives continuous innovation in battery design, materials, and management systems.

Environmental Impact

The environmental impact of lithium iron phosphate (LFP) batteries, particularly in relation to charge-discharge rates, is a critical consideration in the broader context of sustainable energy storage solutions. LFP batteries have gained significant attention due to their relatively lower environmental footprint compared to other lithium-ion battery chemistries. However, the efficiency of these batteries, influenced by charge-discharge rates, plays a crucial role in determining their overall environmental impact.

One of the primary environmental benefits of LFP batteries is their longer cycle life, which is directly affected by charge-discharge rates. When operated within optimal charge-discharge rate ranges, LFP batteries can maintain their efficiency over a greater number of cycles, reducing the frequency of battery replacements and, consequently, the associated environmental costs of manufacturing and disposal.

The energy efficiency of LFP batteries during charge and discharge cycles is another key factor in their environmental impact. Higher charge-discharge rates can lead to increased energy losses due to internal resistance and heat generation. This reduced efficiency translates to higher energy consumption during the battery's operational life, indirectly contributing to increased carbon emissions if the charging energy is sourced from non-renewable sources.

Moreover, the thermal management requirements for LFP batteries under varying charge-discharge rates have environmental implications. Higher rates typically generate more heat, necessitating more robust cooling systems. The production and operation of these cooling systems contribute to the overall environmental footprint of the battery system.

The raw material extraction and processing for LFP batteries also have environmental consequences, which are indirectly influenced by charge-discharge rates. Batteries designed to withstand higher rates may require more robust materials or different manufacturing processes, potentially increasing the environmental impact of production.

End-of-life considerations for LFP batteries are also affected by their operational efficiency. Batteries that maintain high efficiency over their lifespan due to optimal charge-discharge rates are more likely to be suitable for second-life applications, such as stationary energy storage, before final recycling. This extended useful life helps to offset the initial environmental costs of production.

In the context of grid-scale energy storage, the efficiency of LFP batteries at various charge-discharge rates has broader environmental implications. Higher efficiency at rapid charge-discharge rates can enable better integration of renewable energy sources, potentially reducing reliance on fossil fuel-based peaker plants and contributing to overall grid decarbonization.

As research continues to optimize the performance of LFP batteries across different charge-discharge rates, the environmental impact of these energy storage solutions is expected to improve further. Advances in battery management systems, electrode materials, and cell design are all contributing to enhancing the efficiency and, by extension, the environmental sustainability of LFP battery technology.

One of the primary environmental benefits of LFP batteries is their longer cycle life, which is directly affected by charge-discharge rates. When operated within optimal charge-discharge rate ranges, LFP batteries can maintain their efficiency over a greater number of cycles, reducing the frequency of battery replacements and, consequently, the associated environmental costs of manufacturing and disposal.

The energy efficiency of LFP batteries during charge and discharge cycles is another key factor in their environmental impact. Higher charge-discharge rates can lead to increased energy losses due to internal resistance and heat generation. This reduced efficiency translates to higher energy consumption during the battery's operational life, indirectly contributing to increased carbon emissions if the charging energy is sourced from non-renewable sources.

Moreover, the thermal management requirements for LFP batteries under varying charge-discharge rates have environmental implications. Higher rates typically generate more heat, necessitating more robust cooling systems. The production and operation of these cooling systems contribute to the overall environmental footprint of the battery system.

The raw material extraction and processing for LFP batteries also have environmental consequences, which are indirectly influenced by charge-discharge rates. Batteries designed to withstand higher rates may require more robust materials or different manufacturing processes, potentially increasing the environmental impact of production.

End-of-life considerations for LFP batteries are also affected by their operational efficiency. Batteries that maintain high efficiency over their lifespan due to optimal charge-discharge rates are more likely to be suitable for second-life applications, such as stationary energy storage, before final recycling. This extended useful life helps to offset the initial environmental costs of production.

In the context of grid-scale energy storage, the efficiency of LFP batteries at various charge-discharge rates has broader environmental implications. Higher efficiency at rapid charge-discharge rates can enable better integration of renewable energy sources, potentially reducing reliance on fossil fuel-based peaker plants and contributing to overall grid decarbonization.

As research continues to optimize the performance of LFP batteries across different charge-discharge rates, the environmental impact of these energy storage solutions is expected to improve further. Advances in battery management systems, electrode materials, and cell design are all contributing to enhancing the efficiency and, by extension, the environmental sustainability of LFP battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!