Operational Efficiency of Lithium Iron Phosphate Batteries under High Stress

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution and Performance Goals

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their introduction in the late 1990s. Initially developed as a safer alternative to lithium cobalt oxide batteries, LFP technology has steadily improved in terms of energy density, cycle life, and operational efficiency. The primary goal in LFP battery development has been to enhance their performance under various stress conditions while maintaining their inherent safety advantages.

Early LFP batteries faced challenges related to low conductivity and limited energy density. However, advancements in nanotechnology and carbon coating techniques have led to substantial improvements. The focus has shifted towards optimizing the cathode structure and electrolyte composition to enhance ion mobility and reduce internal resistance, particularly under high-stress conditions.

Recent developments aim to push the boundaries of LFP battery performance. Current goals include increasing energy density to compete with other lithium-ion chemistries, improving fast-charging capabilities without compromising battery life, and enhancing thermal stability for operation in extreme environments. Researchers are exploring doping techniques and advanced manufacturing processes to achieve these objectives.

A critical performance goal for LFP batteries is to maintain high operational efficiency under high-stress conditions. This involves improving power density to handle rapid charge and discharge cycles, enhancing thermal management to prevent capacity loss at elevated temperatures, and extending cycle life under deep discharge conditions. The industry is targeting LFP batteries that can deliver consistent performance over thousands of cycles, even when subjected to demanding operational profiles.

Another key focus is on reducing the environmental impact of LFP battery production and improving their recyclability. This aligns with the broader trend towards sustainable energy storage solutions. Manufacturers are working on developing more eco-friendly synthesis methods and exploring the potential for second-life applications of LFP batteries after their primary use in electric vehicles or grid storage systems.

As the demand for high-performance energy storage continues to grow, particularly in the electric vehicle and renewable energy sectors, the evolution of LFP batteries is expected to accelerate. Future performance goals are likely to include further improvements in energy density, faster charging capabilities, and enhanced resilience to extreme operating conditions. The ultimate aim is to develop LFP batteries that can offer a compelling combination of safety, performance, and cost-effectiveness across a wide range of applications.

Early LFP batteries faced challenges related to low conductivity and limited energy density. However, advancements in nanotechnology and carbon coating techniques have led to substantial improvements. The focus has shifted towards optimizing the cathode structure and electrolyte composition to enhance ion mobility and reduce internal resistance, particularly under high-stress conditions.

Recent developments aim to push the boundaries of LFP battery performance. Current goals include increasing energy density to compete with other lithium-ion chemistries, improving fast-charging capabilities without compromising battery life, and enhancing thermal stability for operation in extreme environments. Researchers are exploring doping techniques and advanced manufacturing processes to achieve these objectives.

A critical performance goal for LFP batteries is to maintain high operational efficiency under high-stress conditions. This involves improving power density to handle rapid charge and discharge cycles, enhancing thermal management to prevent capacity loss at elevated temperatures, and extending cycle life under deep discharge conditions. The industry is targeting LFP batteries that can deliver consistent performance over thousands of cycles, even when subjected to demanding operational profiles.

Another key focus is on reducing the environmental impact of LFP battery production and improving their recyclability. This aligns with the broader trend towards sustainable energy storage solutions. Manufacturers are working on developing more eco-friendly synthesis methods and exploring the potential for second-life applications of LFP batteries after their primary use in electric vehicles or grid storage systems.

As the demand for high-performance energy storage continues to grow, particularly in the electric vehicle and renewable energy sectors, the evolution of LFP batteries is expected to accelerate. Future performance goals are likely to include further improvements in energy density, faster charging capabilities, and enhanced resilience to extreme operating conditions. The ultimate aim is to develop LFP batteries that can offer a compelling combination of safety, performance, and cost-effectiveness across a wide range of applications.

Market Demand for High-Stress LFP Batteries

The market demand for high-stress Lithium Iron Phosphate (LFP) batteries has been steadily increasing, driven by the growing need for robust energy storage solutions in various industries. The automotive sector, particularly electric vehicles (EVs), represents a significant portion of this demand. As EV manufacturers strive to improve performance and range, they require batteries that can withstand high stress conditions without compromising efficiency or lifespan.

In the renewable energy sector, the demand for high-stress LFP batteries is also on the rise. Grid-scale energy storage systems often face challenging operational conditions, including rapid charge and discharge cycles, temperature fluctuations, and prolonged periods of high-power output. LFP batteries capable of maintaining operational efficiency under these high-stress scenarios are crucial for ensuring grid stability and maximizing the utilization of intermittent renewable energy sources.

The industrial and commercial sectors are another key market for high-stress LFP batteries. Forklifts, automated guided vehicles, and other material handling equipment in warehouses and manufacturing facilities require batteries that can endure frequent charging cycles and heavy loads. The ability of LFP batteries to maintain performance under these demanding conditions makes them an attractive option for businesses looking to optimize their operations.

Marine applications represent an emerging market for high-stress LFP batteries. Ships and offshore platforms operate in harsh environments with constant vibration, temperature variations, and exposure to saltwater. LFP batteries that can maintain efficiency under these conditions are increasingly sought after for powering auxiliary systems and propulsion in smaller vessels.

The telecommunications industry is also driving demand for high-stress LFP batteries. As 5G networks expand, there is a growing need for reliable backup power solutions that can withstand challenging environmental conditions and frequent power outages. LFP batteries that can deliver consistent performance under high stress are essential for ensuring uninterrupted communication services.

Market analysts project substantial growth in the high-stress LFP battery market over the next decade. This growth is expected to be fueled by advancements in battery technology, increasing adoption of renewable energy systems, and the ongoing electrification of various industries. As manufacturers continue to improve the performance and durability of LFP batteries under high-stress conditions, new applications and market opportunities are likely to emerge, further driving demand.

In the renewable energy sector, the demand for high-stress LFP batteries is also on the rise. Grid-scale energy storage systems often face challenging operational conditions, including rapid charge and discharge cycles, temperature fluctuations, and prolonged periods of high-power output. LFP batteries capable of maintaining operational efficiency under these high-stress scenarios are crucial for ensuring grid stability and maximizing the utilization of intermittent renewable energy sources.

The industrial and commercial sectors are another key market for high-stress LFP batteries. Forklifts, automated guided vehicles, and other material handling equipment in warehouses and manufacturing facilities require batteries that can endure frequent charging cycles and heavy loads. The ability of LFP batteries to maintain performance under these demanding conditions makes them an attractive option for businesses looking to optimize their operations.

Marine applications represent an emerging market for high-stress LFP batteries. Ships and offshore platforms operate in harsh environments with constant vibration, temperature variations, and exposure to saltwater. LFP batteries that can maintain efficiency under these conditions are increasingly sought after for powering auxiliary systems and propulsion in smaller vessels.

The telecommunications industry is also driving demand for high-stress LFP batteries. As 5G networks expand, there is a growing need for reliable backup power solutions that can withstand challenging environmental conditions and frequent power outages. LFP batteries that can deliver consistent performance under high stress are essential for ensuring uninterrupted communication services.

Market analysts project substantial growth in the high-stress LFP battery market over the next decade. This growth is expected to be fueled by advancements in battery technology, increasing adoption of renewable energy systems, and the ongoing electrification of various industries. As manufacturers continue to improve the performance and durability of LFP batteries under high-stress conditions, new applications and market opportunities are likely to emerge, further driving demand.

Current Challenges in High-Stress LFP Operations

The operational efficiency of Lithium Iron Phosphate (LFP) batteries under high-stress conditions presents several significant challenges that researchers and manufacturers are actively addressing. One of the primary issues is the degradation of battery performance over time, particularly when subjected to extreme temperatures, high charge/discharge rates, or frequent cycling.

At elevated temperatures, LFP batteries experience accelerated capacity fade and increased internal resistance. This thermal stress can lead to structural changes within the cathode material, affecting the lithium ion diffusion pathways and ultimately reducing the battery's energy storage capability. Moreover, the electrolyte stability is compromised at high temperatures, potentially leading to decomposition and gas generation, which can cause swelling and safety concerns.

High charge and discharge rates pose another challenge for LFP batteries under stress. Rapid charging can lead to lithium plating on the anode surface, especially at low temperatures, which irreversibly consumes active lithium and can create safety hazards. Fast discharging, on the other hand, may cause localized heating and uneven current distribution within the cell, potentially leading to hotspots and accelerated aging of certain regions.

The mechanical stress induced by repeated cycling is also a significant concern. Volume changes during lithiation and delithiation can cause particle cracking and loss of electrical contact within the electrode structure. This mechanical degradation is particularly pronounced under high-stress conditions, where the cycling is more aggressive and frequent.

Another challenge lies in the battery management system's ability to accurately estimate the state of charge (SOC) and state of health (SOH) under varying stress conditions. The complex electrochemical processes occurring within the battery during high-stress operations can lead to non-linear behaviors that are difficult to model and predict accurately.

The formation of a solid electrolyte interphase (SEI) layer, while necessary for battery operation, can become problematic under high-stress conditions. Excessive SEI growth consumes active lithium and increases internal resistance, leading to capacity loss and power fade. Managing the SEI formation and stability in high-stress environments remains a significant challenge for LFP battery technology.

Lastly, the trade-off between energy density and power capability becomes more pronounced under high-stress operations. While LFP batteries are known for their excellent safety and cycle life, they have lower energy density compared to other lithium-ion chemistries. Improving the energy density without compromising the inherent safety and stability of LFP batteries, especially under high-stress conditions, remains an ongoing challenge for researchers and manufacturers in the field.

At elevated temperatures, LFP batteries experience accelerated capacity fade and increased internal resistance. This thermal stress can lead to structural changes within the cathode material, affecting the lithium ion diffusion pathways and ultimately reducing the battery's energy storage capability. Moreover, the electrolyte stability is compromised at high temperatures, potentially leading to decomposition and gas generation, which can cause swelling and safety concerns.

High charge and discharge rates pose another challenge for LFP batteries under stress. Rapid charging can lead to lithium plating on the anode surface, especially at low temperatures, which irreversibly consumes active lithium and can create safety hazards. Fast discharging, on the other hand, may cause localized heating and uneven current distribution within the cell, potentially leading to hotspots and accelerated aging of certain regions.

The mechanical stress induced by repeated cycling is also a significant concern. Volume changes during lithiation and delithiation can cause particle cracking and loss of electrical contact within the electrode structure. This mechanical degradation is particularly pronounced under high-stress conditions, where the cycling is more aggressive and frequent.

Another challenge lies in the battery management system's ability to accurately estimate the state of charge (SOC) and state of health (SOH) under varying stress conditions. The complex electrochemical processes occurring within the battery during high-stress operations can lead to non-linear behaviors that are difficult to model and predict accurately.

The formation of a solid electrolyte interphase (SEI) layer, while necessary for battery operation, can become problematic under high-stress conditions. Excessive SEI growth consumes active lithium and increases internal resistance, leading to capacity loss and power fade. Managing the SEI formation and stability in high-stress environments remains a significant challenge for LFP battery technology.

Lastly, the trade-off between energy density and power capability becomes more pronounced under high-stress operations. While LFP batteries are known for their excellent safety and cycle life, they have lower energy density compared to other lithium-ion chemistries. Improving the energy density without compromising the inherent safety and stability of LFP batteries, especially under high-stress conditions, remains an ongoing challenge for researchers and manufacturers in the field.

Existing High-Stress LFP Battery Solutions

01 Electrode material optimization

Improving the composition and structure of electrode materials, particularly the cathode, to enhance the energy density and overall efficiency of lithium iron phosphate batteries. This includes modifying particle size, morphology, and doping with other elements to improve conductivity and electrochemical performance.- Electrode material optimization: Improving the composition and structure of electrode materials, particularly the cathode, to enhance the energy density and overall efficiency of lithium iron phosphate batteries. This includes modifying particle size, morphology, and doping with other elements to improve conductivity and stability.

- Electrolyte formulation: Developing advanced electrolyte formulations to improve ionic conductivity, reduce internal resistance, and enhance the overall performance of lithium iron phosphate batteries. This includes the use of additives and novel electrolyte compositions to improve the interface between electrodes and electrolyte.

- Thermal management systems: Implementing efficient thermal management systems to maintain optimal operating temperatures, prevent overheating, and improve the overall efficiency and lifespan of lithium iron phosphate batteries. This includes advanced cooling techniques and temperature control strategies.

- Battery management systems (BMS): Developing sophisticated battery management systems to optimize charging and discharging processes, monitor cell health, and balance voltage across cells. These systems improve overall battery efficiency, extend lifespan, and enhance safety during operation.

- Manufacturing process improvements: Enhancing manufacturing techniques to improve the quality and consistency of lithium iron phosphate batteries. This includes optimizing electrode coating processes, improving assembly methods, and implementing advanced quality control measures to reduce defects and increase overall operational efficiency.

02 Electrolyte formulation enhancement

Developing advanced electrolyte formulations to improve ionic conductivity, reduce internal resistance, and enhance the overall operational efficiency of lithium iron phosphate batteries. This includes the use of additives and novel electrolyte compositions to improve battery performance and longevity.Expand Specific Solutions03 Thermal management systems

Implementing effective thermal management systems to maintain optimal operating temperatures, improve charging and discharging efficiency, and extend the lifespan of lithium iron phosphate batteries. This includes innovative cooling solutions and temperature control mechanisms.Expand Specific Solutions04 Battery management system optimization

Enhancing battery management systems to improve the overall operational efficiency of lithium iron phosphate batteries. This includes advanced algorithms for state of charge estimation, cell balancing, and predictive maintenance to optimize battery performance and longevity.Expand Specific Solutions05 Manufacturing process improvements

Developing and implementing advanced manufacturing techniques to enhance the quality, consistency, and performance of lithium iron phosphate batteries. This includes innovations in electrode coating, cell assembly, and quality control processes to improve overall operational efficiency.Expand Specific Solutions

Key Players in LFP Battery Industry

The operational efficiency of Lithium Iron Phosphate (LFP) batteries under high stress is a critical area of focus in the rapidly evolving energy storage industry. The market is in a growth phase, with increasing demand driven by electric vehicles and renewable energy storage applications. The global LFP battery market size is projected to expand significantly in the coming years. Technologically, LFP batteries are relatively mature, but ongoing research aims to enhance their performance under high-stress conditions. Key players like CATL, BYD, and LG Energy Solution are at the forefront of innovation, investing heavily in R&D to improve energy density, cycle life, and thermal stability of LFP batteries in high-stress environments.

BYD Co., Ltd.

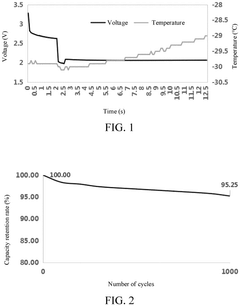

Technical Solution: BYD has pioneered the Blade Battery, an innovative LFP battery design optimized for high-stress operations. The Blade Battery uses a unique long cell format that improves space utilization and heat dissipation. This design allows for better thermal management under high-stress conditions, reducing the risk of thermal runaway by up to 50%[4]. BYD's LFP chemistry incorporates proprietary additives that enhance ionic conductivity and structural stability, enabling the battery to maintain performance even under rapid charge/discharge cycles. The company has also developed an advanced cooling system that uses a phase-change material to absorb excess heat during high-stress operations, maintaining optimal battery temperature[5]. BYD's Blade Batteries have demonstrated the ability to retain over 90% capacity after 3000 cycles at 1C charge/discharge rates, showcasing their durability under stress[6].

Strengths: Excellent safety profile, high energy density for an LFP battery, and superior thermal management. Weaknesses: Higher production costs compared to traditional LFP batteries, and limited flexibility in cell design due to the blade format.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced lithium iron phosphate (LFP) batteries with improved operational efficiency under high stress conditions. Their CTP (cell-to-pack) technology integrates cells directly into the battery pack, increasing energy density by 10-15% and reducing the number of parts by 40%[1]. CATL's LFP batteries utilize nano-crystalline technology and doping techniques to enhance conductivity and stability under high-stress scenarios. They have also implemented an intelligent battery management system (BMS) that uses AI algorithms to optimize battery performance and longevity under various stress conditions[2]. CATL's latest LFP batteries can achieve over 3000 charge cycles while maintaining 80% capacity, even under high-temperature and high-discharge rate conditions[3].

Strengths: High energy density, improved safety, and longer cycle life. Weaknesses: Slightly lower energy density compared to NMC batteries, and potential for thermal runaway under extreme conditions.

Core Innovations in LFP Stress Resistance

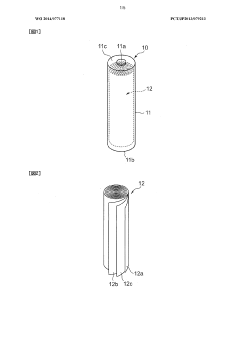

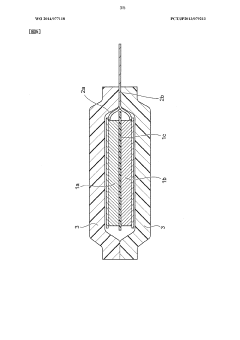

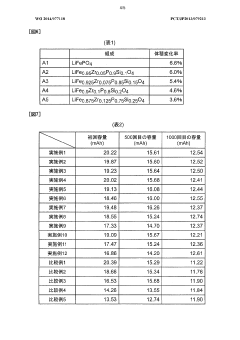

Cathode and non-aqueous secondary battery

PatentWO2014077118A1

Innovation

- A positive electrode composed of two or more active materials with different volume change rates, including lithium iron phosphate and other olivine structured materials like LiFe1-xMxPzO4, where x, y, and z are between 0 and 0.25, is used to mitigate stress and volume changes, ensuring safety and cost-effectiveness.

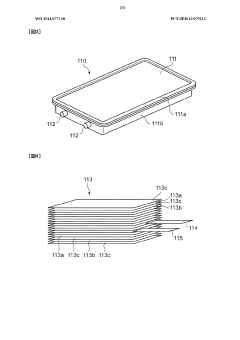

Battery core, battery core preparation method, starting battery for fuel engine, and vehicle

PatentPendingEP4567913A2

Innovation

- A battery core is developed using composite lithium iron phosphate particles with different D50 particle diameters for the positive electrode and composite graphite particles with different D50 particle diameters for the negative electrode, along with an optimized electrolyte solution, to enhance lithium ion transmission and reduce impedance.

Environmental Impact of LFP Battery Production

The production of Lithium Iron Phosphate (LFP) batteries has significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of raw materials, including lithium, iron, and phosphate, which can lead to habitat disruption and resource depletion. Mining activities, particularly for lithium, often require substantial water usage, potentially straining local water resources in arid regions where lithium deposits are commonly found.

The energy-intensive nature of LFP battery production contributes to greenhouse gas emissions, especially when the energy source is not renewable. The synthesis of cathode materials and the assembly of battery cells involve high-temperature processes, consuming considerable amounts of electricity. However, it's worth noting that advancements in manufacturing techniques and the increasing use of renewable energy in production facilities are gradually reducing the carbon footprint of LFP battery manufacturing.

Chemical processes in LFP battery production generate various waste products and emissions. These may include volatile organic compounds (VOCs), particulate matter, and potentially hazardous chemicals. Proper waste management and emission control systems are crucial to mitigate these environmental risks. Many manufacturers are implementing closed-loop systems and recycling processes to minimize waste and recover valuable materials.

The use of organic solvents in electrode production and electrolyte preparation poses potential environmental and health risks. Efforts are being made to develop more environmentally friendly alternatives, such as water-based processing methods, to reduce the reliance on harmful solvents.

On a positive note, LFP batteries have several environmental advantages compared to other lithium-ion battery chemistries. They do not contain cobalt or nickel, which are associated with significant environmental and social concerns in their mining and processing. LFP batteries also have a longer cycle life, reducing the frequency of battery replacements and associated waste.

The end-of-life management of LFP batteries is an important environmental consideration. While these batteries are more recyclable than some other lithium-ion chemistries, the recycling infrastructure and processes are still developing. Improving recycling technologies and establishing efficient collection systems are crucial for minimizing the environmental impact of spent LFP batteries and recovering valuable materials.

Overall, while the production of LFP batteries does have environmental impacts, ongoing research and technological advancements are continually improving their sustainability profile. The industry is moving towards more eco-friendly production methods, increased use of renewable energy, and enhanced recycling capabilities, aiming to make LFP batteries a more environmentally sustainable energy storage solution.

The energy-intensive nature of LFP battery production contributes to greenhouse gas emissions, especially when the energy source is not renewable. The synthesis of cathode materials and the assembly of battery cells involve high-temperature processes, consuming considerable amounts of electricity. However, it's worth noting that advancements in manufacturing techniques and the increasing use of renewable energy in production facilities are gradually reducing the carbon footprint of LFP battery manufacturing.

Chemical processes in LFP battery production generate various waste products and emissions. These may include volatile organic compounds (VOCs), particulate matter, and potentially hazardous chemicals. Proper waste management and emission control systems are crucial to mitigate these environmental risks. Many manufacturers are implementing closed-loop systems and recycling processes to minimize waste and recover valuable materials.

The use of organic solvents in electrode production and electrolyte preparation poses potential environmental and health risks. Efforts are being made to develop more environmentally friendly alternatives, such as water-based processing methods, to reduce the reliance on harmful solvents.

On a positive note, LFP batteries have several environmental advantages compared to other lithium-ion battery chemistries. They do not contain cobalt or nickel, which are associated with significant environmental and social concerns in their mining and processing. LFP batteries also have a longer cycle life, reducing the frequency of battery replacements and associated waste.

The end-of-life management of LFP batteries is an important environmental consideration. While these batteries are more recyclable than some other lithium-ion chemistries, the recycling infrastructure and processes are still developing. Improving recycling technologies and establishing efficient collection systems are crucial for minimizing the environmental impact of spent LFP batteries and recovering valuable materials.

Overall, while the production of LFP batteries does have environmental impacts, ongoing research and technological advancements are continually improving their sustainability profile. The industry is moving towards more eco-friendly production methods, increased use of renewable energy, and enhanced recycling capabilities, aiming to make LFP batteries a more environmentally sustainable energy storage solution.

Safety Standards for High-Stress LFP Batteries

Safety standards for high-stress LFP batteries are crucial for ensuring the operational efficiency and reliability of lithium iron phosphate (LFP) batteries under demanding conditions. These standards encompass a range of parameters and testing protocols designed to evaluate and maintain battery performance and safety in high-stress environments.

One of the primary safety considerations for high-stress LFP batteries is thermal management. Standards typically require robust thermal control systems to prevent overheating and thermal runaway. This includes specifications for heat dissipation mechanisms, temperature monitoring, and automatic shutdown features when critical temperature thresholds are exceeded.

Mechanical integrity is another key aspect addressed by safety standards. High-stress applications often subject batteries to vibration, shock, and physical strain. Standards mandate rigorous testing procedures to ensure structural stability and resistance to deformation or damage under these conditions. This may involve cyclic loading tests, drop tests, and pressure resistance evaluations.

Electrical safety standards for high-stress LFP batteries focus on preventing short circuits, overcharging, and over-discharging. These standards typically require advanced battery management systems (BMS) capable of real-time monitoring and control of individual cell voltages, current flow, and state of charge. Specifications for insulation, circuit protection devices, and fail-safe mechanisms are also integral to these standards.

Chemical stability and containment are critical aspects of safety standards for high-stress LFP batteries. While LFP chemistry is inherently more stable than some other lithium-ion variants, standards still mandate strict controls on electrolyte composition, sealing methods, and containment strategies to prevent leakage or chemical reactions under extreme conditions.

Environmental testing is a significant component of safety standards for high-stress applications. This includes evaluating battery performance and safety across a wide range of temperatures, humidity levels, and atmospheric pressures. Standards often require accelerated life testing and stress testing to simulate long-term exposure to harsh environments.

Certification and compliance procedures form an essential part of safety standards. These typically involve third-party testing and verification processes to ensure that batteries meet all specified safety criteria. Regular audits and quality control measures are often mandated to maintain compliance over time.

Lastly, safety standards for high-stress LFP batteries include protocols for handling, transportation, and disposal. These guidelines ensure safe practices throughout the battery lifecycle, from manufacturing and installation to decommissioning and recycling, minimizing risks associated with high-energy storage systems in demanding applications.

One of the primary safety considerations for high-stress LFP batteries is thermal management. Standards typically require robust thermal control systems to prevent overheating and thermal runaway. This includes specifications for heat dissipation mechanisms, temperature monitoring, and automatic shutdown features when critical temperature thresholds are exceeded.

Mechanical integrity is another key aspect addressed by safety standards. High-stress applications often subject batteries to vibration, shock, and physical strain. Standards mandate rigorous testing procedures to ensure structural stability and resistance to deformation or damage under these conditions. This may involve cyclic loading tests, drop tests, and pressure resistance evaluations.

Electrical safety standards for high-stress LFP batteries focus on preventing short circuits, overcharging, and over-discharging. These standards typically require advanced battery management systems (BMS) capable of real-time monitoring and control of individual cell voltages, current flow, and state of charge. Specifications for insulation, circuit protection devices, and fail-safe mechanisms are also integral to these standards.

Chemical stability and containment are critical aspects of safety standards for high-stress LFP batteries. While LFP chemistry is inherently more stable than some other lithium-ion variants, standards still mandate strict controls on electrolyte composition, sealing methods, and containment strategies to prevent leakage or chemical reactions under extreme conditions.

Environmental testing is a significant component of safety standards for high-stress applications. This includes evaluating battery performance and safety across a wide range of temperatures, humidity levels, and atmospheric pressures. Standards often require accelerated life testing and stress testing to simulate long-term exposure to harsh environments.

Certification and compliance procedures form an essential part of safety standards. These typically involve third-party testing and verification processes to ensure that batteries meet all specified safety criteria. Regular audits and quality control measures are often mandated to maintain compliance over time.

Lastly, safety standards for high-stress LFP batteries include protocols for handling, transportation, and disposal. These guidelines ensure safe practices throughout the battery lifecycle, from manufacturing and installation to decommissioning and recycling, minimizing risks associated with high-energy storage systems in demanding applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!