Real-Time Monitoring Systems for Lithium Iron Phosphate Battery Health

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Monitoring Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent energy storage solution in recent years, particularly in electric vehicles and renewable energy systems. The development of real-time monitoring systems for LFP battery health is crucial for ensuring optimal performance, longevity, and safety of these energy storage devices. This technological advancement aims to address the growing demand for reliable and efficient battery management in various applications.

The evolution of LFP battery monitoring technology can be traced back to the early 2000s when LFP batteries were first commercialized. Initially, monitoring systems were rudimentary, focusing primarily on basic parameters such as voltage and temperature. As the adoption of LFP batteries increased, so did the need for more sophisticated monitoring solutions. This led to the development of advanced Battery Management Systems (BMS) that could track a wider range of parameters and provide more accurate health assessments.

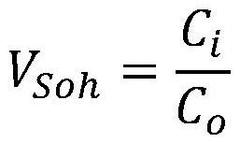

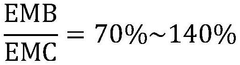

The primary objective of real-time monitoring systems for LFP battery health is to provide continuous, accurate, and comprehensive data on the battery's state of health (SOH), state of charge (SOC), and overall performance. These systems aim to detect potential issues before they escalate, optimize charging and discharging processes, and extend the battery's lifespan. Additionally, they play a crucial role in enhancing safety by identifying abnormal conditions that could lead to thermal runaway or other hazardous situations.

Current technological trends in LFP battery monitoring include the integration of artificial intelligence and machine learning algorithms to improve predictive capabilities. These advanced systems can analyze historical data and current operating conditions to forecast battery degradation and optimize performance. Another emerging trend is the development of non-invasive monitoring techniques, such as ultrasonic and electromagnetic methods, which can provide insights into the battery's internal state without compromising its integrity.

The future direction of LFP battery monitoring technology is expected to focus on increasing the accuracy and reliability of health assessments, reducing the cost and complexity of monitoring systems, and improving the integration with broader energy management platforms. As LFP batteries continue to play a significant role in the transition to sustainable energy, the importance of robust and efficient monitoring systems will only grow, driving further innovation in this field.

The evolution of LFP battery monitoring technology can be traced back to the early 2000s when LFP batteries were first commercialized. Initially, monitoring systems were rudimentary, focusing primarily on basic parameters such as voltage and temperature. As the adoption of LFP batteries increased, so did the need for more sophisticated monitoring solutions. This led to the development of advanced Battery Management Systems (BMS) that could track a wider range of parameters and provide more accurate health assessments.

The primary objective of real-time monitoring systems for LFP battery health is to provide continuous, accurate, and comprehensive data on the battery's state of health (SOH), state of charge (SOC), and overall performance. These systems aim to detect potential issues before they escalate, optimize charging and discharging processes, and extend the battery's lifespan. Additionally, they play a crucial role in enhancing safety by identifying abnormal conditions that could lead to thermal runaway or other hazardous situations.

Current technological trends in LFP battery monitoring include the integration of artificial intelligence and machine learning algorithms to improve predictive capabilities. These advanced systems can analyze historical data and current operating conditions to forecast battery degradation and optimize performance. Another emerging trend is the development of non-invasive monitoring techniques, such as ultrasonic and electromagnetic methods, which can provide insights into the battery's internal state without compromising its integrity.

The future direction of LFP battery monitoring technology is expected to focus on increasing the accuracy and reliability of health assessments, reducing the cost and complexity of monitoring systems, and improving the integration with broader energy management platforms. As LFP batteries continue to play a significant role in the transition to sustainable energy, the importance of robust and efficient monitoring systems will only grow, driving further innovation in this field.

Market Demand Analysis for LFP Battery Health Systems

The market demand for real-time monitoring systems for Lithium Iron Phosphate (LFP) battery health is experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) and energy storage sectors. As LFP batteries gain popularity due to their safety, long cycle life, and cost-effectiveness, the need for sophisticated health monitoring solutions has become paramount.

In the automotive industry, the shift towards electrification has created a substantial market for LFP battery health monitoring systems. Major automakers are increasingly adopting LFP batteries in their EV models, particularly in the entry-level and mid-range segments. This trend is especially pronounced in China, the world's largest EV market, where LFP batteries account for a significant portion of EV battery installations.

The energy storage sector represents another key driver of demand for LFP battery health monitoring systems. Grid-scale energy storage projects, as well as residential and commercial applications, are increasingly utilizing LFP batteries due to their stability and long lifespan. Real-time monitoring of these batteries is crucial for optimizing performance, predicting maintenance needs, and ensuring safety in large-scale installations.

The industrial and marine sectors are also contributing to the growing demand for LFP battery health monitoring systems. Forklifts, automated guided vehicles, and other industrial equipment are transitioning to electric power, with LFP batteries often being the preferred choice. Similarly, the marine industry is exploring LFP batteries for various applications, from small pleasure craft to large commercial vessels, all requiring robust health monitoring solutions.

Market analysts project that the global LFP battery market will continue its upward trajectory, with a corresponding increase in demand for health monitoring systems. This growth is fueled by ongoing improvements in LFP battery technology, increasing energy density, and expanding applications across various industries.

The demand for real-time monitoring systems is further intensified by the need for predictive maintenance and performance optimization. As battery systems become more complex and integral to operations, the ability to detect potential issues before they escalate and maximize battery lifespan becomes increasingly valuable. This has led to a surge in interest for advanced monitoring solutions that incorporate artificial intelligence and machine learning capabilities.

Regulatory pressures and safety concerns are also driving the adoption of sophisticated battery health monitoring systems. With the growing deployment of large-scale battery installations, authorities are implementing stricter safety standards, necessitating more comprehensive monitoring and management solutions.

As the market for LFP batteries continues to expand, the demand for real-time health monitoring systems is expected to grow in tandem. This presents significant opportunities for technology providers and system integrators to develop innovative solutions that address the specific needs of various industries and applications utilizing LFP batteries.

In the automotive industry, the shift towards electrification has created a substantial market for LFP battery health monitoring systems. Major automakers are increasingly adopting LFP batteries in their EV models, particularly in the entry-level and mid-range segments. This trend is especially pronounced in China, the world's largest EV market, where LFP batteries account for a significant portion of EV battery installations.

The energy storage sector represents another key driver of demand for LFP battery health monitoring systems. Grid-scale energy storage projects, as well as residential and commercial applications, are increasingly utilizing LFP batteries due to their stability and long lifespan. Real-time monitoring of these batteries is crucial for optimizing performance, predicting maintenance needs, and ensuring safety in large-scale installations.

The industrial and marine sectors are also contributing to the growing demand for LFP battery health monitoring systems. Forklifts, automated guided vehicles, and other industrial equipment are transitioning to electric power, with LFP batteries often being the preferred choice. Similarly, the marine industry is exploring LFP batteries for various applications, from small pleasure craft to large commercial vessels, all requiring robust health monitoring solutions.

Market analysts project that the global LFP battery market will continue its upward trajectory, with a corresponding increase in demand for health monitoring systems. This growth is fueled by ongoing improvements in LFP battery technology, increasing energy density, and expanding applications across various industries.

The demand for real-time monitoring systems is further intensified by the need for predictive maintenance and performance optimization. As battery systems become more complex and integral to operations, the ability to detect potential issues before they escalate and maximize battery lifespan becomes increasingly valuable. This has led to a surge in interest for advanced monitoring solutions that incorporate artificial intelligence and machine learning capabilities.

Regulatory pressures and safety concerns are also driving the adoption of sophisticated battery health monitoring systems. With the growing deployment of large-scale battery installations, authorities are implementing stricter safety standards, necessitating more comprehensive monitoring and management solutions.

As the market for LFP batteries continues to expand, the demand for real-time health monitoring systems is expected to grow in tandem. This presents significant opportunities for technology providers and system integrators to develop innovative solutions that address the specific needs of various industries and applications utilizing LFP batteries.

Current Challenges in Real-Time LFP Battery Monitoring

Real-time monitoring of Lithium Iron Phosphate (LFP) battery health presents several significant challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the inherent difficulty in accurately measuring the State of Charge (SoC) and State of Health (SoH) of LFP batteries due to their flat voltage profile during most of the discharge cycle. This characteristic makes it challenging to correlate voltage measurements with the actual charge state, requiring more sophisticated estimation techniques.

Another major challenge lies in the development of reliable and cost-effective sensors capable of providing accurate real-time data on various battery parameters. Current sensing technologies often struggle to maintain precision across the wide range of operating conditions experienced by LFP batteries, including varying temperatures, charge/discharge rates, and aging effects. The integration of these sensors into battery management systems without significantly increasing costs or compromising the battery's energy density remains a complex task.

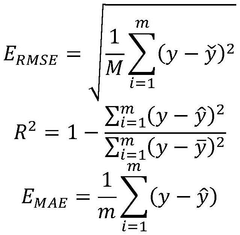

Data processing and interpretation pose additional challenges in real-time monitoring systems. The vast amount of data generated by multiple sensors needs to be processed quickly and efficiently to provide meaningful insights into battery health. This requires advanced algorithms and computational power, which must be balanced against the energy consumption of the monitoring system itself to avoid excessive drain on the battery.

The dynamic nature of battery behavior under different operating conditions further complicates real-time monitoring efforts. Factors such as temperature fluctuations, varying load profiles, and degradation over time can significantly affect battery performance and health indicators. Developing models and algorithms that can accurately account for these variables in real-time remains an ongoing challenge.

Standardization and interoperability issues also present hurdles in the widespread adoption of real-time monitoring systems for LFP batteries. The lack of unified protocols and data formats across different manufacturers and applications makes it difficult to develop universal monitoring solutions, leading to fragmented approaches and increased development costs.

Lastly, the long-term reliability and durability of monitoring systems themselves are critical challenges. These systems must operate consistently over the entire lifespan of the battery, which can span several years, while maintaining accuracy and reliability under harsh environmental conditions. Ensuring the longevity of sensors and associated electronics without compromising the overall battery system performance or safety is a complex engineering task that requires ongoing research and development efforts.

Another major challenge lies in the development of reliable and cost-effective sensors capable of providing accurate real-time data on various battery parameters. Current sensing technologies often struggle to maintain precision across the wide range of operating conditions experienced by LFP batteries, including varying temperatures, charge/discharge rates, and aging effects. The integration of these sensors into battery management systems without significantly increasing costs or compromising the battery's energy density remains a complex task.

Data processing and interpretation pose additional challenges in real-time monitoring systems. The vast amount of data generated by multiple sensors needs to be processed quickly and efficiently to provide meaningful insights into battery health. This requires advanced algorithms and computational power, which must be balanced against the energy consumption of the monitoring system itself to avoid excessive drain on the battery.

The dynamic nature of battery behavior under different operating conditions further complicates real-time monitoring efforts. Factors such as temperature fluctuations, varying load profiles, and degradation over time can significantly affect battery performance and health indicators. Developing models and algorithms that can accurately account for these variables in real-time remains an ongoing challenge.

Standardization and interoperability issues also present hurdles in the widespread adoption of real-time monitoring systems for LFP batteries. The lack of unified protocols and data formats across different manufacturers and applications makes it difficult to develop universal monitoring solutions, leading to fragmented approaches and increased development costs.

Lastly, the long-term reliability and durability of monitoring systems themselves are critical challenges. These systems must operate consistently over the entire lifespan of the battery, which can span several years, while maintaining accuracy and reliability under harsh environmental conditions. Ensuring the longevity of sensors and associated electronics without compromising the overall battery system performance or safety is a complex engineering task that requires ongoing research and development efforts.

Existing Real-Time LFP Battery Health Solutions

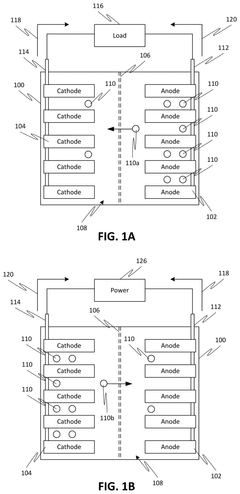

01 Battery management systems for LFP batteries

Advanced battery management systems are crucial for maintaining the health of Lithium Iron Phosphate (LFP) batteries. These systems monitor various parameters such as temperature, voltage, and current to optimize battery performance and longevity. They can also implement adaptive charging strategies and provide real-time diagnostics to prevent overcharging, over-discharging, and other potential issues that could degrade battery health.- Battery management systems for LiFePO4 batteries: Advanced battery management systems are crucial for maintaining the health of Lithium Iron Phosphate (LiFePO4) batteries. These systems monitor various parameters such as voltage, current, and temperature to optimize battery performance and longevity. They can also implement protective measures against overcharging, over-discharging, and thermal runaway, which are critical for preserving battery health.

- Electrolyte composition for improved LiFePO4 battery health: The composition of the electrolyte plays a significant role in the health and performance of LiFePO4 batteries. Researchers are developing novel electrolyte formulations that can enhance the ionic conductivity, reduce unwanted side reactions, and improve the overall stability of the battery. These advanced electrolytes can lead to better capacity retention and longer cycle life.

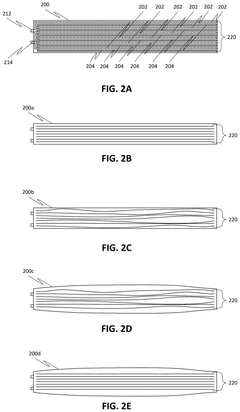

- Electrode material modifications for LiFePO4 batteries: Modifications to the electrode materials, particularly the cathode, can significantly impact the health and performance of LiFePO4 batteries. Techniques such as doping, surface coating, and nanostructuring of the active materials can improve the battery's capacity, rate capability, and cycling stability. These enhancements contribute to better overall battery health and longevity.

- Thermal management strategies for LiFePO4 batteries: Effective thermal management is crucial for maintaining the health of LiFePO4 batteries, especially in high-power applications. Advanced cooling systems and heat dissipation techniques can prevent thermal runaway and extend battery life. Strategies may include active cooling, phase change materials, or innovative cell designs that facilitate better heat distribution.

- State of health estimation and predictive maintenance: Accurate estimation of the state of health (SOH) of LiFePO4 batteries is essential for predictive maintenance and optimal utilization. Advanced algorithms and machine learning techniques are being developed to analyze battery data and predict degradation patterns. This enables proactive maintenance strategies and helps extend the overall lifespan of the battery systems.

02 Thermal management techniques

Effective thermal management is essential for preserving LFP battery health. This includes cooling systems to prevent overheating during charging and discharging, as well as heating mechanisms for cold environments. Proper thermal control helps maintain optimal operating temperatures, which can significantly extend battery life and improve overall performance.Expand Specific Solutions03 Electrode and electrolyte improvements

Advancements in electrode materials and electrolyte compositions can enhance LFP battery health. This includes developing more stable cathode materials, improving the conductivity of electrodes, and formulating electrolytes that reduce side reactions and prevent dendrite formation. These improvements can lead to increased capacity retention and longer cycle life.Expand Specific Solutions04 State of health estimation methods

Accurate estimation of the state of health (SOH) is crucial for managing LFP batteries. Advanced algorithms and machine learning techniques are being developed to assess battery health based on various parameters such as capacity fade, internal resistance changes, and voltage characteristics. These methods enable better prediction of remaining useful life and optimization of battery usage patterns.Expand Specific Solutions05 Charging protocols for extended battery life

Optimized charging protocols play a significant role in maintaining LFP battery health. This includes developing smart charging algorithms that adjust charging rates based on battery condition and usage patterns. Techniques such as pulse charging, multi-stage charging, and temperature-compensated charging can help minimize stress on the battery and extend its overall lifespan.Expand Specific Solutions

Key Players in LFP Battery Monitoring Industry

The real-time monitoring systems for lithium iron phosphate battery health market is in a growth phase, driven by increasing adoption of electric vehicles and energy storage systems. The market size is expanding rapidly, with projections indicating significant growth over the next decade. Technologically, the field is advancing quickly but still maturing, with companies like LG Energy Solution, Robert Bosch, and ACCURE Battery Intelligence leading innovation. These firms are developing sophisticated battery management systems, leveraging AI and big data analytics to enhance monitoring capabilities. Emerging players like Dukosi and Limatech are also contributing novel solutions, indicating a competitive and dynamic landscape with opportunities for further technological breakthroughs in battery health monitoring and optimization.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced real-time monitoring system for lithium iron phosphate (LFP) batteries, utilizing a combination of hardware sensors and sophisticated software algorithms. The system employs a network of embedded sensors to continuously measure key parameters such as voltage, current, temperature, and internal resistance across individual cells and modules[1]. This data is processed in real-time using machine learning algorithms to assess the battery's state of charge (SOC), state of health (SOH), and predict potential failure modes[3]. The system also incorporates a cloud-based analytics platform that allows for remote monitoring and predictive maintenance, enabling proactive interventions to optimize battery performance and longevity[5].

Strengths: Comprehensive real-time data collection, advanced analytics for accurate SOH estimation, and predictive maintenance capabilities. Weaknesses: Potential for increased cost due to extensive sensor network and computational requirements.

Robert Bosch GmbH

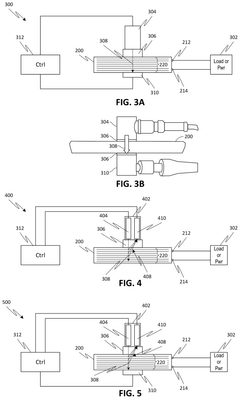

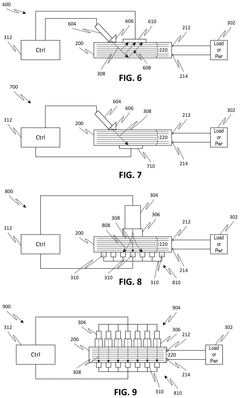

Technical Solution: Bosch has engineered a comprehensive real-time monitoring solution for lithium iron phosphate batteries, focusing on automotive and industrial applications. Their system integrates advanced sensor technology with intelligent data processing algorithms to provide continuous health monitoring[7]. The solution utilizes a distributed sensor network that captures voltage, current, and temperature data at both cell and module levels. A key innovation is the incorporation of ultrasonic sensors to detect physical changes within the battery, such as swelling or internal structural alterations[9]. The data is processed using a proprietary AI-driven analytics engine that can identify subtle patterns indicative of potential issues before they become critical[11]. Additionally, Bosch's system includes a wireless communication module for seamless integration with vehicle telematics or industrial control systems.

Strengths: Comprehensive monitoring with innovative ultrasonic sensing, AI-driven analytics for early problem detection, and seamless integration capabilities. Weaknesses: Potentially higher implementation costs and complexity in retrofitting existing battery systems.

Core Innovations in LFP Battery Health Monitoring

Battery health state real-time monitoring and intelligent management method and system

PatentPendingCN118849783A

Innovation

- Use deep learning network models, especially the Bi-LSTM_GRU model combined with the multi-head attention mechanism, to build a battery health state prediction model, monitor and diagnose potential faults and abnormal states of the battery system in real time, and implement intelligent management strategies to optimize the battery usage and recycling stages. of carbon emissions.

Systems, methods, and devices for health monitoring of an energy storage device

PatentPendingUS20250093305A1

Innovation

- The use of ultrasonic acoustic sources and sensors to non-destructively assess the internal condition of lithium-ion battery cells by detecting changes in acoustic impedance, allowing for real-time monitoring of state of health and potential degradation.

Safety Standards and Regulations for LFP Battery Systems

The safety standards and regulations for Lithium Iron Phosphate (LFP) battery systems are crucial for ensuring the safe operation and widespread adoption of these energy storage solutions. As the demand for LFP batteries continues to grow, particularly in electric vehicles and renewable energy applications, regulatory bodies worldwide have developed comprehensive guidelines to address potential risks associated with their use.

One of the primary safety standards for LFP battery systems is the UN38.3 certification, which is mandatory for the transportation of lithium batteries. This standard includes a series of tests designed to evaluate the safety of batteries under various conditions, such as altitude simulation, thermal cycling, vibration, shock, and external short circuit. Compliance with UN38.3 is essential for manufacturers to ship their LFP batteries internationally.

In the automotive sector, the ISO 26262 standard plays a significant role in ensuring the functional safety of electrical and electronic systems in vehicles. This standard is particularly relevant for LFP battery management systems (BMS) used in electric vehicles. It provides a framework for developing safety-critical systems and helps manufacturers identify and mitigate potential hazards associated with battery operation.

The IEC 62619 standard specifically addresses the safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard covers aspects such as electrical safety, thermal management, and mechanical integrity. It also outlines requirements for battery management systems, including protection against overcharge, over-discharge, and short circuits.

For stationary energy storage applications, the UL 9540A test method has become increasingly important. This standard evaluates the fire safety of battery energy storage systems and helps determine the potential for thermal runaway propagation. While not specific to LFP batteries, this test method is crucial for assessing the overall safety of large-scale battery installations.

In addition to these international standards, many countries have implemented their own regulations for LFP battery systems. For instance, China's GB/T 36276-2018 standard provides specific requirements for the safety of lithium-ion traction battery packs and systems for electric vehicles. Similarly, the European Union has established the ECE R100 regulation, which outlines safety specifications for the electric power train of road vehicles, including battery electric vehicles.

As real-time monitoring systems for LFP battery health become more sophisticated, they must also comply with these safety standards and regulations. These monitoring systems play a crucial role in ensuring that batteries operate within safe parameters and can detect potential issues before they escalate into safety hazards. Manufacturers and developers of such systems must consider these regulatory requirements throughout the design and implementation process to ensure compliance and enhance overall battery safety.

One of the primary safety standards for LFP battery systems is the UN38.3 certification, which is mandatory for the transportation of lithium batteries. This standard includes a series of tests designed to evaluate the safety of batteries under various conditions, such as altitude simulation, thermal cycling, vibration, shock, and external short circuit. Compliance with UN38.3 is essential for manufacturers to ship their LFP batteries internationally.

In the automotive sector, the ISO 26262 standard plays a significant role in ensuring the functional safety of electrical and electronic systems in vehicles. This standard is particularly relevant for LFP battery management systems (BMS) used in electric vehicles. It provides a framework for developing safety-critical systems and helps manufacturers identify and mitigate potential hazards associated with battery operation.

The IEC 62619 standard specifically addresses the safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard covers aspects such as electrical safety, thermal management, and mechanical integrity. It also outlines requirements for battery management systems, including protection against overcharge, over-discharge, and short circuits.

For stationary energy storage applications, the UL 9540A test method has become increasingly important. This standard evaluates the fire safety of battery energy storage systems and helps determine the potential for thermal runaway propagation. While not specific to LFP batteries, this test method is crucial for assessing the overall safety of large-scale battery installations.

In addition to these international standards, many countries have implemented their own regulations for LFP battery systems. For instance, China's GB/T 36276-2018 standard provides specific requirements for the safety of lithium-ion traction battery packs and systems for electric vehicles. Similarly, the European Union has established the ECE R100 regulation, which outlines safety specifications for the electric power train of road vehicles, including battery electric vehicles.

As real-time monitoring systems for LFP battery health become more sophisticated, they must also comply with these safety standards and regulations. These monitoring systems play a crucial role in ensuring that batteries operate within safe parameters and can detect potential issues before they escalate into safety hazards. Manufacturers and developers of such systems must consider these regulatory requirements throughout the design and implementation process to ensure compliance and enhance overall battery safety.

Environmental Impact of LFP Battery Monitoring Technologies

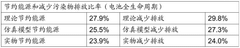

The environmental impact of LFP battery monitoring technologies is a crucial consideration in the development and implementation of real-time monitoring systems for lithium iron phosphate (LFP) battery health. These technologies play a significant role in optimizing battery performance and longevity, which indirectly contributes to environmental sustainability.

One of the primary environmental benefits of advanced monitoring systems is their ability to extend the lifespan of LFP batteries. By providing accurate, real-time data on battery health and performance, these systems enable more efficient battery management, reducing premature degradation and the need for frequent replacements. This, in turn, decreases the overall demand for raw materials and energy required for battery production, thereby minimizing the associated environmental footprint.

Moreover, real-time monitoring technologies contribute to the optimization of charging and discharging cycles, which can significantly reduce energy waste. By ensuring that batteries operate within their optimal parameters, these systems help maximize energy efficiency, leading to reduced power consumption and lower greenhouse gas emissions associated with electricity generation.

The implementation of advanced monitoring systems also enhances the safety of LFP batteries, reducing the risk of thermal runaway and other potential hazards. This increased safety not only protects users but also minimizes the environmental risks associated with battery failures, such as chemical leaks or fires that could release harmful substances into the environment.

However, it is important to consider the environmental impact of the monitoring technologies themselves. The production of sensors, data processing units, and communication modules required for these systems involves the use of various materials, including rare earth elements and precious metals. The extraction and processing of these materials can have significant environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions.

Additionally, the energy consumption of monitoring systems, while relatively low compared to the batteries they monitor, should not be overlooked. The continuous operation of sensors and data transmission systems contributes to the overall energy demand, which may have indirect environmental impacts depending on the source of electricity used.

As the adoption of LFP batteries and their monitoring technologies continues to grow, particularly in electric vehicles and renewable energy storage systems, the importance of considering their full lifecycle environmental impact becomes increasingly critical. This includes not only the operational phase but also the production and end-of-life stages of both the batteries and monitoring systems.

In conclusion, while LFP battery monitoring technologies offer significant environmental benefits through improved battery efficiency and longevity, it is essential to balance these advantages against the potential environmental costs associated with their production and operation. Future developments in this field should focus on minimizing the environmental footprint of monitoring systems while maximizing their positive impact on battery performance and sustainability.

One of the primary environmental benefits of advanced monitoring systems is their ability to extend the lifespan of LFP batteries. By providing accurate, real-time data on battery health and performance, these systems enable more efficient battery management, reducing premature degradation and the need for frequent replacements. This, in turn, decreases the overall demand for raw materials and energy required for battery production, thereby minimizing the associated environmental footprint.

Moreover, real-time monitoring technologies contribute to the optimization of charging and discharging cycles, which can significantly reduce energy waste. By ensuring that batteries operate within their optimal parameters, these systems help maximize energy efficiency, leading to reduced power consumption and lower greenhouse gas emissions associated with electricity generation.

The implementation of advanced monitoring systems also enhances the safety of LFP batteries, reducing the risk of thermal runaway and other potential hazards. This increased safety not only protects users but also minimizes the environmental risks associated with battery failures, such as chemical leaks or fires that could release harmful substances into the environment.

However, it is important to consider the environmental impact of the monitoring technologies themselves. The production of sensors, data processing units, and communication modules required for these systems involves the use of various materials, including rare earth elements and precious metals. The extraction and processing of these materials can have significant environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions.

Additionally, the energy consumption of monitoring systems, while relatively low compared to the batteries they monitor, should not be overlooked. The continuous operation of sensors and data transmission systems contributes to the overall energy demand, which may have indirect environmental impacts depending on the source of electricity used.

As the adoption of LFP batteries and their monitoring technologies continues to grow, particularly in electric vehicles and renewable energy storage systems, the importance of considering their full lifecycle environmental impact becomes increasingly critical. This includes not only the operational phase but also the production and end-of-life stages of both the batteries and monitoring systems.

In conclusion, while LFP battery monitoring technologies offer significant environmental benefits through improved battery efficiency and longevity, it is essential to balance these advantages against the potential environmental costs associated with their production and operation. Future developments in this field should focus on minimizing the environmental footprint of monitoring systems while maximizing their positive impact on battery performance and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!