Heat Dissipation Solutions for Large-Scale Lithium Iron Phosphate Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

The evolution of battery thermal management systems for large-scale lithium iron phosphate batteries has been driven by the increasing demand for high-performance energy storage solutions in various applications, including electric vehicles and grid-scale energy storage. The primary objective of these systems is to maintain optimal operating temperatures for the batteries, ensuring safety, longevity, and performance.

In the early stages of development, passive cooling methods were predominantly used, relying on natural convection and conduction to dissipate heat. However, as battery capacities and energy densities increased, more sophisticated active cooling techniques became necessary. This led to the introduction of forced air cooling systems, which utilized fans to circulate air around the battery cells, enhancing heat removal.

As the industry progressed, liquid cooling systems emerged as a more efficient solution for managing thermal issues in large-scale battery packs. These systems employed coolant fluids circulating through channels or plates in direct contact with the battery cells, offering superior heat transfer capabilities compared to air-based methods. The evolution continued with the development of advanced phase-change materials and heat pipes, which provided more uniform temperature distribution and improved thermal management efficiency.

Recent advancements in battery thermal management have focused on intelligent control systems and predictive modeling. These technologies enable real-time monitoring of battery temperatures and proactive adjustment of cooling parameters to optimize performance and prevent thermal runaway events. Additionally, the integration of artificial intelligence and machine learning algorithms has enhanced the ability to predict and mitigate potential thermal issues before they occur.

The current objectives of battery thermal management systems for large-scale lithium iron phosphate batteries include further improving energy efficiency, reducing system complexity, and minimizing the overall weight and volume of cooling components. Researchers and engineers are exploring novel materials with enhanced thermal conductivity and developing innovative cooling architectures to achieve these goals.

Another key objective is to address the challenges associated with fast charging and high-power applications, which generate significant heat and require rapid dissipation to maintain battery health. This has led to the exploration of hybrid cooling systems that combine multiple heat dissipation methods to handle diverse operating conditions effectively.

Looking ahead, the field aims to develop more sustainable and environmentally friendly cooling solutions, reducing the reliance on energy-intensive active cooling systems. This includes the investigation of bio-inspired cooling mechanisms and the use of renewable energy sources to power thermal management systems, aligning with global efforts to reduce carbon footprints in energy storage technologies.

In the early stages of development, passive cooling methods were predominantly used, relying on natural convection and conduction to dissipate heat. However, as battery capacities and energy densities increased, more sophisticated active cooling techniques became necessary. This led to the introduction of forced air cooling systems, which utilized fans to circulate air around the battery cells, enhancing heat removal.

As the industry progressed, liquid cooling systems emerged as a more efficient solution for managing thermal issues in large-scale battery packs. These systems employed coolant fluids circulating through channels or plates in direct contact with the battery cells, offering superior heat transfer capabilities compared to air-based methods. The evolution continued with the development of advanced phase-change materials and heat pipes, which provided more uniform temperature distribution and improved thermal management efficiency.

Recent advancements in battery thermal management have focused on intelligent control systems and predictive modeling. These technologies enable real-time monitoring of battery temperatures and proactive adjustment of cooling parameters to optimize performance and prevent thermal runaway events. Additionally, the integration of artificial intelligence and machine learning algorithms has enhanced the ability to predict and mitigate potential thermal issues before they occur.

The current objectives of battery thermal management systems for large-scale lithium iron phosphate batteries include further improving energy efficiency, reducing system complexity, and minimizing the overall weight and volume of cooling components. Researchers and engineers are exploring novel materials with enhanced thermal conductivity and developing innovative cooling architectures to achieve these goals.

Another key objective is to address the challenges associated with fast charging and high-power applications, which generate significant heat and require rapid dissipation to maintain battery health. This has led to the exploration of hybrid cooling systems that combine multiple heat dissipation methods to handle diverse operating conditions effectively.

Looking ahead, the field aims to develop more sustainable and environmentally friendly cooling solutions, reducing the reliance on energy-intensive active cooling systems. This includes the investigation of bio-inspired cooling mechanisms and the use of renewable energy sources to power thermal management systems, aligning with global efforts to reduce carbon footprints in energy storage technologies.

Market Demand for Advanced Battery Cooling Systems

The market demand for advanced battery cooling systems in large-scale lithium iron phosphate (LFP) batteries has been experiencing significant growth in recent years. This surge is primarily driven by the rapid expansion of electric vehicle (EV) production and the increasing adoption of renewable energy storage solutions. As LFP batteries continue to gain popularity due to their safety, long cycle life, and cost-effectiveness, the need for efficient heat dissipation solutions has become paramount.

In the automotive sector, the demand for advanced cooling systems is particularly strong. As EV manufacturers strive to improve charging speeds and extend driving ranges, the thermal management of battery packs has become a critical factor. Efficient cooling systems not only enhance battery performance but also contribute to the overall safety and longevity of the vehicles. This has led to a growing market for innovative cooling technologies that can effectively manage the heat generated during high-power charging and discharging cycles.

The stationary energy storage market is another key driver for advanced battery cooling systems. With the increasing integration of renewable energy sources into power grids, large-scale LFP battery installations are becoming more common for grid stabilization and peak shaving applications. These installations require robust cooling solutions to maintain optimal operating temperatures, especially in harsh environmental conditions or during periods of high energy demand.

Industrial and commercial sectors are also contributing to the market demand for advanced cooling systems. As businesses seek to reduce their carbon footprint and energy costs, many are turning to LFP battery-based energy storage systems. These applications often require high-capacity batteries that can operate reliably in various environments, further driving the need for sophisticated thermal management solutions.

The market is witnessing a shift towards more advanced and efficient cooling technologies. Traditional air cooling systems are being replaced by liquid cooling solutions, which offer superior heat dissipation capabilities. There is also growing interest in phase change materials and advanced thermal interface materials that can enhance the overall efficiency of battery cooling systems.

Geographically, the demand for advanced battery cooling systems is particularly strong in regions with well-established EV markets and ambitious renewable energy targets. Countries like China, the United States, and several European nations are at the forefront of this trend, with their automotive and energy sectors driving significant investments in battery technology and related thermal management solutions.

As the market for large-scale LFP batteries continues to expand, the demand for advanced cooling systems is expected to grow in tandem. This presents significant opportunities for companies specializing in thermal management technologies, as well as for battery manufacturers looking to differentiate their products through improved performance and safety features.

In the automotive sector, the demand for advanced cooling systems is particularly strong. As EV manufacturers strive to improve charging speeds and extend driving ranges, the thermal management of battery packs has become a critical factor. Efficient cooling systems not only enhance battery performance but also contribute to the overall safety and longevity of the vehicles. This has led to a growing market for innovative cooling technologies that can effectively manage the heat generated during high-power charging and discharging cycles.

The stationary energy storage market is another key driver for advanced battery cooling systems. With the increasing integration of renewable energy sources into power grids, large-scale LFP battery installations are becoming more common for grid stabilization and peak shaving applications. These installations require robust cooling solutions to maintain optimal operating temperatures, especially in harsh environmental conditions or during periods of high energy demand.

Industrial and commercial sectors are also contributing to the market demand for advanced cooling systems. As businesses seek to reduce their carbon footprint and energy costs, many are turning to LFP battery-based energy storage systems. These applications often require high-capacity batteries that can operate reliably in various environments, further driving the need for sophisticated thermal management solutions.

The market is witnessing a shift towards more advanced and efficient cooling technologies. Traditional air cooling systems are being replaced by liquid cooling solutions, which offer superior heat dissipation capabilities. There is also growing interest in phase change materials and advanced thermal interface materials that can enhance the overall efficiency of battery cooling systems.

Geographically, the demand for advanced battery cooling systems is particularly strong in regions with well-established EV markets and ambitious renewable energy targets. Countries like China, the United States, and several European nations are at the forefront of this trend, with their automotive and energy sectors driving significant investments in battery technology and related thermal management solutions.

As the market for large-scale LFP batteries continues to expand, the demand for advanced cooling systems is expected to grow in tandem. This presents significant opportunities for companies specializing in thermal management technologies, as well as for battery manufacturers looking to differentiate their products through improved performance and safety features.

Current Challenges in LFP Battery Heat Dissipation

Large-scale lithium iron phosphate (LFP) batteries face significant heat dissipation challenges that impact their performance, safety, and longevity. One of the primary issues is the uneven temperature distribution within battery packs. During charging and discharging cycles, certain areas of the battery tend to heat up more than others, creating hot spots that can lead to accelerated degradation and potential safety hazards.

The high energy density of LFP batteries, while advantageous for energy storage, exacerbates the heat generation problem. As these batteries scale up for industrial and grid-scale applications, the heat produced during operation increases exponentially, making efficient thermal management crucial. Traditional cooling methods often struggle to keep pace with the heat generated in large-scale systems, particularly during rapid charging or high-power output scenarios.

Another significant challenge is the limited thermal conductivity of battery components. The materials used in LFP batteries, including the electrodes and separators, typically have low thermal conductivity. This characteristic hinders the efficient transfer of heat from the internal components to the exterior of the battery, where it can be dissipated. As a result, heat tends to accumulate within the battery, potentially leading to thermal runaway if not properly managed.

The compact design of large-scale battery systems further complicates heat dissipation efforts. The close packing of cells within modules and modules within packs leaves little room for traditional cooling systems. This spatial constraint limits the effectiveness of air cooling methods and makes it challenging to implement liquid cooling solutions without significantly increasing the overall size and weight of the battery system.

Environmental factors also play a role in the heat dissipation challenges faced by LFP batteries. Extreme ambient temperatures, both hot and cold, can significantly impact the battery's thermal management needs. In hot climates, the cooling system must work harder to maintain optimal operating temperatures, while in cold environments, the battery may require heating to function efficiently, adding another layer of complexity to thermal management strategies.

The dynamic nature of battery usage patterns in large-scale applications presents additional challenges. Fluctuating charge and discharge rates, as well as varying depths of discharge, create constantly changing thermal profiles within the battery system. This variability makes it difficult to design a one-size-fits-all cooling solution, necessitating adaptive thermal management systems that can respond to real-time changes in heat generation.

The high energy density of LFP batteries, while advantageous for energy storage, exacerbates the heat generation problem. As these batteries scale up for industrial and grid-scale applications, the heat produced during operation increases exponentially, making efficient thermal management crucial. Traditional cooling methods often struggle to keep pace with the heat generated in large-scale systems, particularly during rapid charging or high-power output scenarios.

Another significant challenge is the limited thermal conductivity of battery components. The materials used in LFP batteries, including the electrodes and separators, typically have low thermal conductivity. This characteristic hinders the efficient transfer of heat from the internal components to the exterior of the battery, where it can be dissipated. As a result, heat tends to accumulate within the battery, potentially leading to thermal runaway if not properly managed.

The compact design of large-scale battery systems further complicates heat dissipation efforts. The close packing of cells within modules and modules within packs leaves little room for traditional cooling systems. This spatial constraint limits the effectiveness of air cooling methods and makes it challenging to implement liquid cooling solutions without significantly increasing the overall size and weight of the battery system.

Environmental factors also play a role in the heat dissipation challenges faced by LFP batteries. Extreme ambient temperatures, both hot and cold, can significantly impact the battery's thermal management needs. In hot climates, the cooling system must work harder to maintain optimal operating temperatures, while in cold environments, the battery may require heating to function efficiently, adding another layer of complexity to thermal management strategies.

The dynamic nature of battery usage patterns in large-scale applications presents additional challenges. Fluctuating charge and discharge rates, as well as varying depths of discharge, create constantly changing thermal profiles within the battery system. This variability makes it difficult to design a one-size-fits-all cooling solution, necessitating adaptive thermal management systems that can respond to real-time changes in heat generation.

Existing Heat Dissipation Techniques for LFP Batteries

01 Liquid cooling systems for battery packs

Implementing liquid cooling systems in large-scale lithium iron phosphate battery packs to efficiently dissipate heat. These systems typically involve coolant channels or plates integrated within the battery module structure, allowing for direct contact with cell surfaces and improved thermal management.- Liquid cooling systems for battery packs: Implementing liquid cooling systems in large-scale lithium iron phosphate battery packs to enhance heat dissipation. These systems typically involve circulating coolant through channels or plates in direct contact with battery cells or modules, efficiently removing heat and maintaining optimal operating temperatures.

- Phase change materials for thermal management: Utilizing phase change materials (PCMs) in battery thermal management systems to absorb and release heat during phase transitions. PCMs can be integrated into battery modules or surrounding structures to provide passive cooling and temperature stabilization, particularly effective for large-scale applications.

- Air cooling and ventilation designs: Developing advanced air cooling and ventilation systems for large-scale lithium iron phosphate batteries. These designs may include forced air circulation, strategically placed heat sinks, and optimized airflow channels to enhance convective heat transfer and maintain uniform temperature distribution across battery packs.

- Heat pipe and thermosiphon technologies: Incorporating heat pipes or thermosiphon systems into battery pack designs to facilitate efficient heat transfer from hot spots to cooling surfaces. These passive heat transfer devices can significantly improve thermal management in large-scale battery installations without requiring additional energy input.

- Thermal interface materials and cell spacing optimization: Improving heat dissipation through the use of advanced thermal interface materials between cells and cooling structures, as well as optimizing cell spacing and arrangement within battery modules. These approaches enhance thermal conductivity and promote more uniform heat distribution in large-scale battery systems.

02 Heat dissipation through structural design

Optimizing the structural design of battery modules and packs to enhance heat dissipation. This includes the use of heat-conductive materials, strategic placement of cooling elements, and the incorporation of air flow channels to facilitate natural or forced convection cooling.Expand Specific Solutions03 Phase change materials for thermal management

Utilizing phase change materials (PCMs) within the battery pack design to absorb and regulate excess heat. PCMs can help maintain optimal operating temperatures by absorbing heat during high-load conditions and releasing it during cooler periods, effectively stabilizing the thermal environment of the battery system.Expand Specific Solutions04 Smart thermal management systems

Implementing intelligent thermal management systems that use sensors, controllers, and algorithms to actively monitor and regulate battery temperature. These systems can adjust cooling mechanisms in real-time based on operating conditions, load demands, and environmental factors to optimize heat dissipation efficiency.Expand Specific Solutions05 Heat pipe and fin-based cooling solutions

Incorporating heat pipes and fin structures into battery pack designs to enhance heat transfer and dissipation. Heat pipes can efficiently move heat from high-temperature areas to cooler regions, while fins increase the surface area for heat exchange with the surrounding environment, improving overall cooling performance.Expand Specific Solutions

Key Players in Battery Cooling Solutions

The heat dissipation solutions market for large-scale lithium iron phosphate batteries is in a growth phase, driven by increasing demand for energy storage systems. The market size is expanding rapidly, with major players like BYD, LG Chem, and CATL investing heavily in research and development. Technologically, the field is advancing quickly, with companies like Samsung SDI and Panasonic developing innovative cooling systems. Emerging players such as AESC Japan and Gogoro are also contributing to technological progress. The competition is intensifying as both established battery manufacturers and new entrants seek to improve thermal management efficiency and safety in large-scale battery applications.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced heat dissipation solutions for large-scale lithium iron phosphate (LFP) batteries, focusing on innovative thermal management systems. Their approach includes the use of phase change materials (PCMs) integrated into the battery pack design. These PCMs absorb excess heat during charging and discharging cycles, maintaining optimal operating temperatures. LG Chem has also implemented a sophisticated liquid cooling system that circulates a coolant through channels between battery cells, ensuring uniform temperature distribution[1]. Additionally, they have developed smart thermal management algorithms that predict and preemptively adjust cooling based on battery usage patterns and environmental conditions[3].

Strengths: Efficient heat absorption and distribution, uniform temperature control, and predictive thermal management. Weaknesses: Potential complexity in manufacturing and higher initial costs compared to simpler cooling methods.

BYD Co., Ltd.

Technical Solution: BYD's heat dissipation solution for large-scale LFP batteries centers around their proprietary Blade Battery technology. This design features long, thin cells arranged in a parallel configuration, maximizing surface area for heat dissipation. The Blade Battery incorporates a highly conductive aluminum cooling plate between each cell, which efficiently transfers heat away from the battery core[2]. BYD has also implemented an advanced liquid cooling system that circulates a low-conductivity coolant through these plates, ensuring rapid and uniform heat removal. Furthermore, BYD's battery management system (BMS) includes thermal runaway prevention algorithms and real-time temperature monitoring at the cell level[4].

Strengths: Excellent heat dissipation due to increased surface area, enhanced safety features, and efficient cooling system integration. Weaknesses: Potentially higher production costs and complexity in battery pack assembly.

Innovative Thermal Management Patents and Research

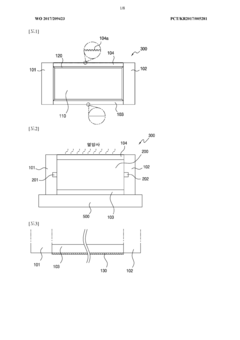

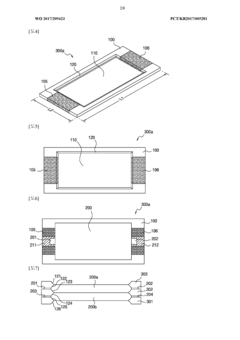

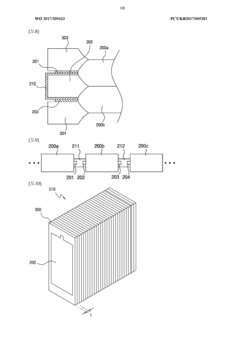

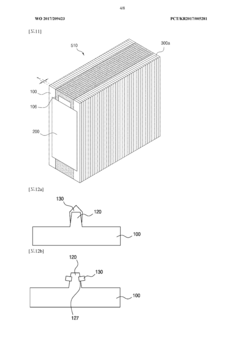

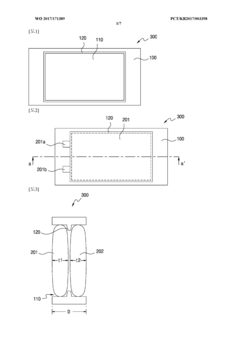

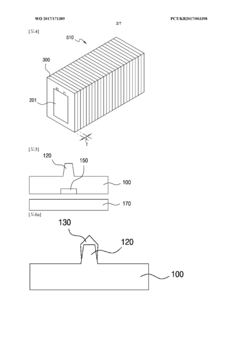

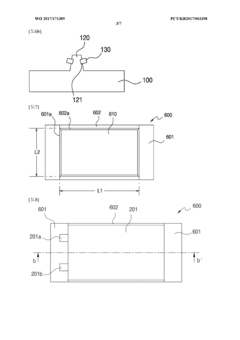

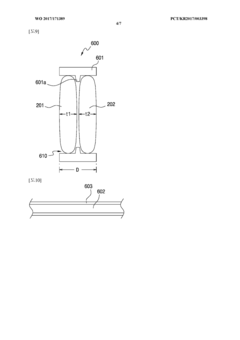

Heat-radiating cartridge and electric car battery pack using same

PatentWO2017209423A1

Innovation

- A heat dissipation cartridge with guide members made of thermally conductive materials, including metal and thermally conductive plastics, that supports batteries and incorporates a thermal interface material and radiation coating for enhanced heat dissipation, while maintaining rigidity and preventing deformation, allowing for the stacking of multiple batteries in a compact form.

Heat-radiating cartridge, and battery pack for electric vehicle using same

PatentWO2017171389A2

Innovation

- A heat dissipation cartridge with a frame structure made from heat dissipation plastic and integrated aluminum frames, incorporating a seating portion for batteries and a heat dissipation metal plate for efficient heat transfer, along with Thermal Interface Material (TIM) to reduce thermal resistance, allowing for uniform and effective heat dissipation while maintaining rigidity and preventing deformation.

Safety Standards for Large-Scale Battery Systems

Safety standards for large-scale battery systems are crucial for ensuring the safe operation and deployment of lithium iron phosphate (LFP) batteries in various applications. These standards encompass a wide range of safety considerations, including thermal management, electrical safety, and fire prevention measures.

One of the primary safety concerns for large-scale LFP battery systems is thermal runaway, which can lead to catastrophic failures. To address this, safety standards typically require robust thermal management systems that can effectively dissipate heat and maintain optimal operating temperatures. These systems often include active cooling mechanisms, such as liquid cooling or forced air circulation, as well as passive heat dissipation techniques like phase change materials or heat spreaders.

Electrical safety is another critical aspect covered by these standards. They mandate the implementation of proper insulation, grounding, and protection against short circuits and overcharging. Battery management systems (BMS) play a vital role in monitoring and controlling the electrical parameters of individual cells and the overall battery pack, ensuring safe operation within specified voltage and current limits.

Fire prevention and suppression measures are also integral to safety standards for large-scale battery systems. These may include the use of fire-resistant materials in battery enclosures, installation of fire detection and suppression systems, and the implementation of proper ventilation to prevent the accumulation of potentially flammable gases.

Standards often specify requirements for battery enclosure design, including structural integrity, impact resistance, and environmental protection. These measures help safeguard the battery system against external factors that could compromise its safety or performance.

Testing and certification procedures are typically outlined in safety standards to ensure compliance and verify the effectiveness of safety measures. These may include abuse tests, such as overcharging, short-circuit, and thermal shock tests, to evaluate the battery system's response under extreme conditions.

Safety standards also address the importance of proper installation, maintenance, and decommissioning procedures for large-scale battery systems. This includes guidelines for handling, transportation, and disposal of batteries to minimize environmental and safety risks throughout their lifecycle.

As the technology and applications of large-scale LFP battery systems continue to evolve, safety standards are regularly updated to address new challenges and incorporate lessons learned from real-world deployments. Compliance with these standards is essential for manufacturers, integrators, and operators to ensure the safe and reliable operation of large-scale battery systems across various industries and applications.

One of the primary safety concerns for large-scale LFP battery systems is thermal runaway, which can lead to catastrophic failures. To address this, safety standards typically require robust thermal management systems that can effectively dissipate heat and maintain optimal operating temperatures. These systems often include active cooling mechanisms, such as liquid cooling or forced air circulation, as well as passive heat dissipation techniques like phase change materials or heat spreaders.

Electrical safety is another critical aspect covered by these standards. They mandate the implementation of proper insulation, grounding, and protection against short circuits and overcharging. Battery management systems (BMS) play a vital role in monitoring and controlling the electrical parameters of individual cells and the overall battery pack, ensuring safe operation within specified voltage and current limits.

Fire prevention and suppression measures are also integral to safety standards for large-scale battery systems. These may include the use of fire-resistant materials in battery enclosures, installation of fire detection and suppression systems, and the implementation of proper ventilation to prevent the accumulation of potentially flammable gases.

Standards often specify requirements for battery enclosure design, including structural integrity, impact resistance, and environmental protection. These measures help safeguard the battery system against external factors that could compromise its safety or performance.

Testing and certification procedures are typically outlined in safety standards to ensure compliance and verify the effectiveness of safety measures. These may include abuse tests, such as overcharging, short-circuit, and thermal shock tests, to evaluate the battery system's response under extreme conditions.

Safety standards also address the importance of proper installation, maintenance, and decommissioning procedures for large-scale battery systems. This includes guidelines for handling, transportation, and disposal of batteries to minimize environmental and safety risks throughout their lifecycle.

As the technology and applications of large-scale LFP battery systems continue to evolve, safety standards are regularly updated to address new challenges and incorporate lessons learned from real-world deployments. Compliance with these standards is essential for manufacturers, integrators, and operators to ensure the safe and reliable operation of large-scale battery systems across various industries and applications.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies for large-scale lithium iron phosphate batteries is a critical consideration in the development and implementation of heat dissipation solutions. As the demand for energy storage systems grows, the need for efficient and environmentally friendly cooling methods becomes increasingly important.

Traditional cooling technologies, such as air conditioning and liquid cooling systems, often rely on refrigerants and energy-intensive processes that can contribute to greenhouse gas emissions and increased carbon footprints. These systems may also consume significant amounts of water, particularly in regions where water scarcity is a concern.

However, advancements in cooling technologies are addressing these environmental challenges. Passive cooling methods, such as phase change materials and heat pipes, offer promising alternatives with reduced energy consumption and minimal environmental impact. These solutions harness natural heat transfer mechanisms, reducing the reliance on active cooling systems and their associated energy requirements.

The use of natural cooling resources, such as geothermal energy or ambient air, can further minimize the environmental footprint of battery cooling systems. By leveraging these renewable sources, the overall sustainability of large-scale battery installations can be significantly improved.

Recycling and waste management considerations are also crucial when evaluating the environmental impact of cooling technologies. The materials used in cooling systems, such as heat transfer fluids and thermal interface materials, must be carefully selected to ensure they are recyclable or biodegradable at the end of their lifecycle.

Furthermore, the integration of smart cooling management systems can optimize energy usage and reduce unnecessary cooling, thereby minimizing the overall environmental impact. These systems can adapt to changing environmental conditions and battery usage patterns, ensuring efficient cooling while conserving resources.

The development of more efficient battery chemistries and designs that generate less heat during operation can also indirectly reduce the environmental impact of cooling technologies. By addressing the root cause of heat generation, the demand for intensive cooling solutions can be decreased, leading to a more sustainable approach to battery thermal management.

As regulations and environmental standards become more stringent, the adoption of eco-friendly cooling technologies for large-scale lithium iron phosphate batteries will likely accelerate. This shift towards sustainable cooling solutions will play a crucial role in mitigating the environmental impact of energy storage systems and supporting the transition to cleaner energy sources.

Traditional cooling technologies, such as air conditioning and liquid cooling systems, often rely on refrigerants and energy-intensive processes that can contribute to greenhouse gas emissions and increased carbon footprints. These systems may also consume significant amounts of water, particularly in regions where water scarcity is a concern.

However, advancements in cooling technologies are addressing these environmental challenges. Passive cooling methods, such as phase change materials and heat pipes, offer promising alternatives with reduced energy consumption and minimal environmental impact. These solutions harness natural heat transfer mechanisms, reducing the reliance on active cooling systems and their associated energy requirements.

The use of natural cooling resources, such as geothermal energy or ambient air, can further minimize the environmental footprint of battery cooling systems. By leveraging these renewable sources, the overall sustainability of large-scale battery installations can be significantly improved.

Recycling and waste management considerations are also crucial when evaluating the environmental impact of cooling technologies. The materials used in cooling systems, such as heat transfer fluids and thermal interface materials, must be carefully selected to ensure they are recyclable or biodegradable at the end of their lifecycle.

Furthermore, the integration of smart cooling management systems can optimize energy usage and reduce unnecessary cooling, thereby minimizing the overall environmental impact. These systems can adapt to changing environmental conditions and battery usage patterns, ensuring efficient cooling while conserving resources.

The development of more efficient battery chemistries and designs that generate less heat during operation can also indirectly reduce the environmental impact of cooling technologies. By addressing the root cause of heat generation, the demand for intensive cooling solutions can be decreased, leading to a more sustainable approach to battery thermal management.

As regulations and environmental standards become more stringent, the adoption of eco-friendly cooling technologies for large-scale lithium iron phosphate batteries will likely accelerate. This shift towards sustainable cooling solutions will play a crucial role in mitigating the environmental impact of energy storage systems and supporting the transition to cleaner energy sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!