Lithium Iron Phosphate Battery Performance in Cold Environments

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Cold Performance Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a promising energy storage solution, particularly in electric vehicles and renewable energy systems. However, their performance in cold environments has been a significant concern for researchers and industry professionals. This technical pre-research report aims to provide a comprehensive overview of the background and objectives related to LFP battery cold performance.

The development of LFP batteries can be traced back to the late 1990s when John Goodenough and his team at the University of Texas discovered the material's potential as a cathode for lithium-ion batteries. Since then, LFP technology has undergone substantial improvements in terms of energy density, cycle life, and safety features. Despite these advancements, the challenge of maintaining optimal performance in low-temperature conditions has persisted.

Cold weather significantly impacts the electrochemical processes within LFP batteries, leading to reduced capacity, decreased power output, and slower charging rates. These issues are primarily attributed to the increased internal resistance and slower lithium-ion diffusion at low temperatures. As the demand for electric vehicles and grid-scale energy storage continues to grow in regions with cold climates, addressing these performance limitations has become a critical focus for battery manufacturers and researchers.

The primary objective of research into LFP battery cold performance is to develop solutions that maintain high efficiency and reliability across a wide temperature range, particularly in sub-zero conditions. This goal encompasses several key areas of improvement, including enhancing the electrolyte composition to reduce viscosity at low temperatures, modifying electrode materials to facilitate better ion transport, and optimizing battery management systems to adapt to changing environmental conditions.

Another crucial objective is to minimize the capacity loss and power fade experienced by LFP batteries in cold environments. This involves investigating novel approaches to battery thermal management, such as advanced insulation techniques, integrated heating systems, and innovative cell designs that promote uniform temperature distribution. Additionally, researchers aim to improve the fast-charging capabilities of LFP batteries in cold conditions, as this is a significant factor in the widespread adoption of electric vehicles in colder regions.

The evolution of LFP battery technology is closely tied to broader trends in the energy sector, including the push for sustainable transportation and the integration of renewable energy sources into the power grid. As such, the objectives for improving cold performance align with overarching goals of increasing energy density, extending battery lifespan, and reducing production costs. These efforts are driven by the need to meet stringent performance requirements across diverse climatic conditions and to compete effectively with other battery chemistries in the global market.

The development of LFP batteries can be traced back to the late 1990s when John Goodenough and his team at the University of Texas discovered the material's potential as a cathode for lithium-ion batteries. Since then, LFP technology has undergone substantial improvements in terms of energy density, cycle life, and safety features. Despite these advancements, the challenge of maintaining optimal performance in low-temperature conditions has persisted.

Cold weather significantly impacts the electrochemical processes within LFP batteries, leading to reduced capacity, decreased power output, and slower charging rates. These issues are primarily attributed to the increased internal resistance and slower lithium-ion diffusion at low temperatures. As the demand for electric vehicles and grid-scale energy storage continues to grow in regions with cold climates, addressing these performance limitations has become a critical focus for battery manufacturers and researchers.

The primary objective of research into LFP battery cold performance is to develop solutions that maintain high efficiency and reliability across a wide temperature range, particularly in sub-zero conditions. This goal encompasses several key areas of improvement, including enhancing the electrolyte composition to reduce viscosity at low temperatures, modifying electrode materials to facilitate better ion transport, and optimizing battery management systems to adapt to changing environmental conditions.

Another crucial objective is to minimize the capacity loss and power fade experienced by LFP batteries in cold environments. This involves investigating novel approaches to battery thermal management, such as advanced insulation techniques, integrated heating systems, and innovative cell designs that promote uniform temperature distribution. Additionally, researchers aim to improve the fast-charging capabilities of LFP batteries in cold conditions, as this is a significant factor in the widespread adoption of electric vehicles in colder regions.

The evolution of LFP battery technology is closely tied to broader trends in the energy sector, including the push for sustainable transportation and the integration of renewable energy sources into the power grid. As such, the objectives for improving cold performance align with overarching goals of increasing energy density, extending battery lifespan, and reducing production costs. These efforts are driven by the need to meet stringent performance requirements across diverse climatic conditions and to compete effectively with other battery chemistries in the global market.

Market Demand for Cold-Resistant Energy Storage

The market demand for cold-resistant energy storage solutions has been steadily increasing, driven by the growing need for reliable power sources in extreme environments. Lithium Iron Phosphate (LFP) batteries have emerged as a promising technology in this sector, particularly due to their inherent safety features and long cycle life. However, their performance in cold environments has been a significant concern for potential adopters.

In regions with harsh winter conditions, such as Northern Europe, Canada, and parts of the United States, there is a pressing need for energy storage systems that can maintain efficiency and reliability in sub-zero temperatures. This demand extends beyond consumer electronics to critical infrastructure, including renewable energy systems, electric vehicles, and emergency power supplies. The automotive industry, in particular, has shown keen interest in cold-resistant LFP batteries to improve the range and performance of electric vehicles in winter conditions.

The renewable energy sector is another key driver of this market demand. As wind and solar installations expand into colder climates, the need for robust energy storage solutions that can operate efficiently in low temperatures becomes crucial. Grid operators and utility companies are increasingly looking for battery systems that can provide consistent performance year-round, including during cold snaps when energy demand often peaks.

Telecommunications companies and data centers operating in cold regions also contribute significantly to the market demand. These facilities require uninterrupted power supply, and the ability of energy storage systems to function reliably in cold environments is critical to their operations. The military and aerospace sectors have likewise shown interest in cold-resistant energy storage for applications in extreme environments.

Market research indicates that the global demand for cold-resistant energy storage is expected to grow substantially in the coming years. This growth is fueled by the increasing electrification of various industries and the push towards renewable energy sources. Manufacturers of LFP batteries are responding to this demand by investing in research and development to enhance the low-temperature performance of their products.

The market is also seeing a trend towards integrated solutions that combine cold-resistant batteries with advanced thermal management systems. These solutions aim to mitigate the impact of low temperatures on battery performance, thereby expanding the potential applications and market reach of LFP batteries in cold climates.

In regions with harsh winter conditions, such as Northern Europe, Canada, and parts of the United States, there is a pressing need for energy storage systems that can maintain efficiency and reliability in sub-zero temperatures. This demand extends beyond consumer electronics to critical infrastructure, including renewable energy systems, electric vehicles, and emergency power supplies. The automotive industry, in particular, has shown keen interest in cold-resistant LFP batteries to improve the range and performance of electric vehicles in winter conditions.

The renewable energy sector is another key driver of this market demand. As wind and solar installations expand into colder climates, the need for robust energy storage solutions that can operate efficiently in low temperatures becomes crucial. Grid operators and utility companies are increasingly looking for battery systems that can provide consistent performance year-round, including during cold snaps when energy demand often peaks.

Telecommunications companies and data centers operating in cold regions also contribute significantly to the market demand. These facilities require uninterrupted power supply, and the ability of energy storage systems to function reliably in cold environments is critical to their operations. The military and aerospace sectors have likewise shown interest in cold-resistant energy storage for applications in extreme environments.

Market research indicates that the global demand for cold-resistant energy storage is expected to grow substantially in the coming years. This growth is fueled by the increasing electrification of various industries and the push towards renewable energy sources. Manufacturers of LFP batteries are responding to this demand by investing in research and development to enhance the low-temperature performance of their products.

The market is also seeing a trend towards integrated solutions that combine cold-resistant batteries with advanced thermal management systems. These solutions aim to mitigate the impact of low temperatures on battery performance, thereby expanding the potential applications and market reach of LFP batteries in cold climates.

LFP Battery Low-Temperature Challenges

Lithium Iron Phosphate (LFP) batteries have gained significant attention in the energy storage industry due to their safety, long cycle life, and cost-effectiveness. However, their performance in cold environments remains a critical challenge that limits their widespread adoption in certain applications. The primary issue stems from the inherent characteristics of lithium-ion batteries, where low temperatures significantly affect the electrochemical reactions and ion mobility within the cell.

At temperatures below 0°C, the electrolyte's viscosity increases, leading to reduced ion conductivity. This results in higher internal resistance and slower charge transfer kinetics. Consequently, LFP batteries experience a substantial decrease in capacity, power output, and charging efficiency in cold conditions. The severity of performance degradation is directly correlated with the drop in temperature, with some studies reporting capacity losses of up to 50% at -20°C compared to room temperature performance.

Another significant challenge is the risk of lithium plating during charging at low temperatures. The reduced kinetics of lithium intercalation into the graphite anode can cause lithium ions to accumulate on the electrode surface, forming metallic lithium. This not only reduces the battery's capacity but also poses safety risks, as lithium plating can lead to internal short circuits and thermal runaway.

The cold temperature performance issue is particularly problematic for electric vehicles (EVs) operating in regions with harsh winters. Reduced driving range, longer charging times, and decreased acceleration capabilities are common complaints among EV users in cold climates. This challenge extends to grid energy storage systems in cold regions, where maintaining consistent performance across varying temperature conditions is crucial for grid stability and reliability.

Addressing the low-temperature challenges of LFP batteries requires a multifaceted approach. Research efforts are focused on several key areas: electrolyte optimization to improve low-temperature conductivity, electrode material modifications to enhance charge transfer kinetics, and advanced battery management systems that can adapt charging and discharging strategies based on temperature conditions. Some promising approaches include the use of electrolyte additives, development of nano-structured electrode materials, and implementation of pre-heating systems for critical applications.

As the demand for high-performance energy storage solutions continues to grow, overcoming the low-temperature limitations of LFP batteries remains a priority for researchers and manufacturers alike. Success in this area could significantly expand the applicability of LFP technology, particularly in automotive and grid storage applications in colder climates, further solidifying its position as a leading energy storage solution.

At temperatures below 0°C, the electrolyte's viscosity increases, leading to reduced ion conductivity. This results in higher internal resistance and slower charge transfer kinetics. Consequently, LFP batteries experience a substantial decrease in capacity, power output, and charging efficiency in cold conditions. The severity of performance degradation is directly correlated with the drop in temperature, with some studies reporting capacity losses of up to 50% at -20°C compared to room temperature performance.

Another significant challenge is the risk of lithium plating during charging at low temperatures. The reduced kinetics of lithium intercalation into the graphite anode can cause lithium ions to accumulate on the electrode surface, forming metallic lithium. This not only reduces the battery's capacity but also poses safety risks, as lithium plating can lead to internal short circuits and thermal runaway.

The cold temperature performance issue is particularly problematic for electric vehicles (EVs) operating in regions with harsh winters. Reduced driving range, longer charging times, and decreased acceleration capabilities are common complaints among EV users in cold climates. This challenge extends to grid energy storage systems in cold regions, where maintaining consistent performance across varying temperature conditions is crucial for grid stability and reliability.

Addressing the low-temperature challenges of LFP batteries requires a multifaceted approach. Research efforts are focused on several key areas: electrolyte optimization to improve low-temperature conductivity, electrode material modifications to enhance charge transfer kinetics, and advanced battery management systems that can adapt charging and discharging strategies based on temperature conditions. Some promising approaches include the use of electrolyte additives, development of nano-structured electrode materials, and implementation of pre-heating systems for critical applications.

As the demand for high-performance energy storage solutions continues to grow, overcoming the low-temperature limitations of LFP batteries remains a priority for researchers and manufacturers alike. Success in this area could significantly expand the applicability of LFP technology, particularly in automotive and grid storage applications in colder climates, further solidifying its position as a leading energy storage solution.

Current Cold-Resistant LFP Solutions

01 Electrode material composition and structure

The performance of lithium iron phosphate batteries can be improved by optimizing the composition and structure of electrode materials. This includes modifying the cathode material with dopants, controlling particle size and morphology, and developing novel synthesis methods to enhance the electrochemical properties of the active material.- Electrode material composition and structure: Improving the composition and structure of electrode materials, particularly the cathode, can enhance the performance of lithium iron phosphate batteries. This includes optimizing particle size, morphology, and doping with other elements to increase conductivity and stability.

- Electrolyte formulation and additives: Developing advanced electrolyte formulations and incorporating performance-enhancing additives can improve the ionic conductivity, stability, and overall efficiency of lithium iron phosphate batteries. This includes the use of novel solvents and salts to enhance battery performance.

- Battery management and thermal control: Implementing sophisticated battery management systems and thermal control strategies can optimize the performance and longevity of lithium iron phosphate batteries. This includes advanced charging algorithms, temperature regulation, and state-of-charge monitoring.

- Nanostructured materials and coatings: Utilizing nanostructured materials and applying specialized coatings to battery components can enhance the electrochemical properties and stability of lithium iron phosphate batteries. This approach can improve charge/discharge rates and cycle life.

- Manufacturing process optimization: Refining the manufacturing processes for lithium iron phosphate batteries, including synthesis methods, electrode preparation, and cell assembly techniques, can lead to improved performance and consistency. This includes innovations in scalable production methods and quality control measures.

02 Electrolyte formulation and additives

Enhancing the electrolyte composition through the use of additives and novel formulations can significantly impact battery performance. This includes developing electrolytes with improved ionic conductivity, better stability at high voltages, and reduced side reactions at the electrode-electrolyte interface.Expand Specific Solutions03 Battery management and control systems

Advanced battery management systems and control algorithms play a crucial role in optimizing lithium iron phosphate battery performance. These systems can improve charge-discharge efficiency, extend battery life, and enhance safety through accurate state-of-charge estimation and thermal management.Expand Specific Solutions04 Cell design and packaging

Innovations in cell design and packaging can lead to improved energy density, better thermal management, and enhanced overall performance of lithium iron phosphate batteries. This includes developing new cell formats, optimizing electrode stacking or winding techniques, and improving current collector designs.Expand Specific Solutions05 Manufacturing processes and quality control

Advancements in manufacturing processes and quality control measures can significantly impact the performance and consistency of lithium iron phosphate batteries. This includes developing precise coating techniques, implementing advanced in-line inspection methods, and optimizing the formation and aging processes of cells.Expand Specific Solutions

Key LFP Battery Manufacturers

The lithium iron phosphate (LFP) battery market for cold environment applications is in a growth phase, driven by increasing demand for electric vehicles and energy storage systems. The market size is expanding rapidly, with major players like BYD, CATL, and SK Innovation investing heavily in research and development. Technological maturity varies among companies, with established firms like Toyota and emerging players such as Sionic Energy competing to improve LFP battery performance in low temperatures. Key areas of focus include electrolyte optimization, cell design, and thermal management systems to enhance cold weather operation. As the technology evolves, collaborations between industry leaders and research institutions like Caltech and CNRS are accelerating advancements in this field.

BYD Co., Ltd.

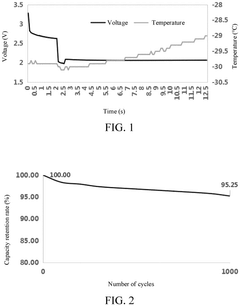

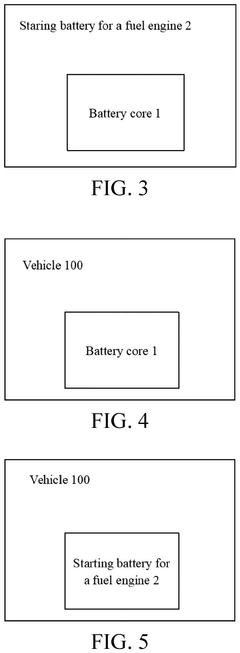

Technical Solution: BYD has developed a revolutionary Blade Battery technology, specifically designed to address the performance challenges of lithium iron phosphate (LFP) batteries in cold environments. The Blade Battery utilizes a unique cell-to-pack design that increases energy density and improves thermal management. In cold conditions, BYD's battery management system employs advanced algorithms to optimize charging and discharging processes, maintaining efficiency even at temperatures as low as -30°C [1]. The company has also implemented a rapid heating technology that can warm up the battery to optimal operating temperatures within minutes, significantly reducing performance loss in cold weather [2]. Additionally, BYD has incorporated a phase-change material into their battery packs, which helps regulate temperature and extends the operating range in extreme conditions [3].

Strengths: Excellent cold weather performance, high energy density, rapid heating capability, and advanced thermal management. Weaknesses: Higher production costs compared to traditional LFP batteries, and potential complexity in manufacturing and maintenance.

Ningde Amperex Technology Ltd.

Technical Solution: CATL, known as Ningde Amperex Technology, has developed an innovative solution for improving LFP battery performance in cold environments. Their approach involves a multi-layered electrolyte system that maintains ionic conductivity at low temperatures. This technology, combined with their cell-to-pack (CTP) design, allows for improved energy density and cold weather performance. CATL's batteries incorporate a self-heating mechanism that utilizes the battery's own power to rapidly increase cell temperature, enabling normal operation in as little as 5-10 minutes in sub-zero conditions [4]. The company has also implemented advanced thermal insulation materials and intelligent temperature control algorithms to minimize heat loss and optimize battery performance across a wide temperature range [5].

Strengths: Rapid self-heating capability, high energy density, and advanced thermal management. Weaknesses: Potentially higher costs due to complex electrolyte system and thermal management components.

Core Innovations in LFP Cold Performance

Battery core, battery core preparation method, starting battery for fuel engine, and vehicle

PatentPendingEP4567913A2

Innovation

- A battery core is developed using composite lithium iron phosphate particles with different D50 particle diameters for the positive electrode and composite graphite particles with different D50 particle diameters for the negative electrode, along with an optimized electrolyte solution, to enhance lithium ion transmission and reduce impedance.

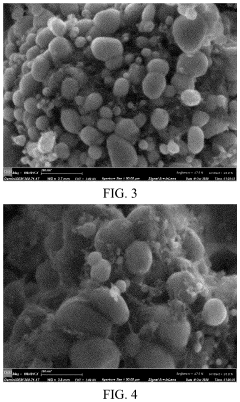

Lithium iron phosphate positive electrode material, preparation method thereof, and lithium ion battery

PatentPendingUS20240079573A1

Innovation

- A lithium iron phosphate positive electrode material with a formula of LiFe1-xMxPO4/C, where 0<x≤0.05, and M is selected from elements like Mg, Al, Zr, Ti, Co, V, Mn, W, Sn, Nb, and Mo, is synthesized using a method involving hydrothermal reaction, sand milling, and sintering, with the addition of a dispersant and grain growth inhibitor to control particle size and conductivity.

Environmental Impact of LFP Batteries

The environmental impact of Lithium Iron Phosphate (LFP) batteries, particularly in the context of their performance in cold environments, is a crucial consideration for their widespread adoption. LFP batteries have gained popularity due to their safety, long cycle life, and lower cost compared to other lithium-ion chemistries. However, their environmental footprint throughout their lifecycle must be carefully examined.

In the production phase, LFP batteries generally have a lower environmental impact compared to other lithium-ion technologies. The use of iron and phosphate, which are abundant and less environmentally sensitive materials, contributes to reduced mining-related impacts. Additionally, the manufacturing process for LFP batteries typically requires less energy and produces fewer emissions than the production of nickel-based lithium-ion batteries.

The performance of LFP batteries in cold environments has implications for their environmental impact during use. While LFP batteries generally exhibit reduced performance in low temperatures, advancements in electrolyte formulations and battery management systems have improved their cold weather capabilities. This enhanced performance in cold conditions can lead to more efficient energy utilization and potentially reduce the need for energy-intensive heating systems in electric vehicles, thereby lowering overall emissions.

End-of-life considerations for LFP batteries are also favorable from an environmental perspective. The absence of cobalt and nickel in LFP chemistry simplifies the recycling process and reduces the environmental burden associated with these materials. Moreover, the long cycle life of LFP batteries means they need to be replaced less frequently, reducing waste generation and the demand for new battery production.

However, the environmental impact of LFP batteries in cold environments is not without challenges. The need for battery heating systems to maintain optimal performance in extreme cold can increase energy consumption and potentially offset some of the environmental benefits. Additionally, the production of phosphorus for LFP batteries can have localized environmental impacts, including water pollution and ecosystem disruption if not properly managed.

When considering the broader environmental implications, the use of LFP batteries in cold climates can contribute to the reduction of greenhouse gas emissions by enabling the electrification of transportation and energy storage in regions previously challenging for battery technologies. This can lead to decreased reliance on fossil fuels and support the integration of renewable energy sources, even in harsh climatic conditions.

In conclusion, while LFP batteries present several environmental advantages, particularly in their production and end-of-life stages, their performance in cold environments introduces both opportunities and challenges from an environmental perspective. Ongoing research and development efforts aimed at improving cold weather performance without compromising environmental benefits will be crucial in maximizing the positive environmental impact of LFP batteries across diverse climatic conditions.

In the production phase, LFP batteries generally have a lower environmental impact compared to other lithium-ion technologies. The use of iron and phosphate, which are abundant and less environmentally sensitive materials, contributes to reduced mining-related impacts. Additionally, the manufacturing process for LFP batteries typically requires less energy and produces fewer emissions than the production of nickel-based lithium-ion batteries.

The performance of LFP batteries in cold environments has implications for their environmental impact during use. While LFP batteries generally exhibit reduced performance in low temperatures, advancements in electrolyte formulations and battery management systems have improved their cold weather capabilities. This enhanced performance in cold conditions can lead to more efficient energy utilization and potentially reduce the need for energy-intensive heating systems in electric vehicles, thereby lowering overall emissions.

End-of-life considerations for LFP batteries are also favorable from an environmental perspective. The absence of cobalt and nickel in LFP chemistry simplifies the recycling process and reduces the environmental burden associated with these materials. Moreover, the long cycle life of LFP batteries means they need to be replaced less frequently, reducing waste generation and the demand for new battery production.

However, the environmental impact of LFP batteries in cold environments is not without challenges. The need for battery heating systems to maintain optimal performance in extreme cold can increase energy consumption and potentially offset some of the environmental benefits. Additionally, the production of phosphorus for LFP batteries can have localized environmental impacts, including water pollution and ecosystem disruption if not properly managed.

When considering the broader environmental implications, the use of LFP batteries in cold climates can contribute to the reduction of greenhouse gas emissions by enabling the electrification of transportation and energy storage in regions previously challenging for battery technologies. This can lead to decreased reliance on fossil fuels and support the integration of renewable energy sources, even in harsh climatic conditions.

In conclusion, while LFP batteries present several environmental advantages, particularly in their production and end-of-life stages, their performance in cold environments introduces both opportunities and challenges from an environmental perspective. Ongoing research and development efforts aimed at improving cold weather performance without compromising environmental benefits will be crucial in maximizing the positive environmental impact of LFP batteries across diverse climatic conditions.

Safety Considerations for Cold LFP Operation

Operating Lithium Iron Phosphate (LFP) batteries in cold environments presents unique safety challenges that require careful consideration and mitigation strategies. The primary concern stems from the reduced electrochemical activity and increased internal resistance at low temperatures, which can lead to performance degradation and potential safety hazards.

One of the most critical safety issues in cold environments is the risk of lithium plating. As the temperature drops, the lithium ions' mobility decreases, making it harder for them to intercalate into the graphite anode. This can result in lithium metal deposition on the anode surface, potentially leading to dendrite formation. Lithium dendrites can grow and penetrate the separator, causing internal short circuits and thermal runaway.

To address this risk, battery management systems (BMS) must be optimized for cold weather operation. Advanced BMS algorithms can monitor cell temperatures and adjust charging rates accordingly, preventing lithium plating by limiting charge current at low temperatures. Additionally, implementing pre-heating systems can help maintain the battery pack within a safe operating temperature range, reducing the risk of lithium plating and improving overall safety.

Another safety consideration is the potential for electrolyte freezing. While LFP batteries generally have good low-temperature performance, extreme cold can cause the electrolyte to freeze, leading to mechanical stress on the cell components and possible damage to the internal structure. To mitigate this risk, electrolyte formulations with lower freezing points and improved low-temperature conductivity are being developed.

The mechanical integrity of the battery pack is also crucial in cold environments. Thermal expansion and contraction of materials can lead to stress on cell connections and seals. Proper design of the battery pack, including the use of flexible interconnects and robust sealing materials, can help maintain structural integrity and prevent leaks or short circuits caused by temperature fluctuations.

Furthermore, the reduced performance of LFP batteries in cold conditions can indirectly impact safety. Lower power output may lead to unexpected system shutdowns or reduced functionality of critical safety systems in electric vehicles or other applications. To address this, redundant power systems or auxiliary heating elements may be necessary to ensure consistent performance and maintain safety features.

Lastly, proper handling and storage procedures are essential for LFP batteries in cold climates. Rapid temperature changes, such as moving a cold battery into a warm environment, can cause condensation and potential short circuits. Gradual warming procedures and moisture-resistant packaging can help mitigate these risks during transportation and storage.

One of the most critical safety issues in cold environments is the risk of lithium plating. As the temperature drops, the lithium ions' mobility decreases, making it harder for them to intercalate into the graphite anode. This can result in lithium metal deposition on the anode surface, potentially leading to dendrite formation. Lithium dendrites can grow and penetrate the separator, causing internal short circuits and thermal runaway.

To address this risk, battery management systems (BMS) must be optimized for cold weather operation. Advanced BMS algorithms can monitor cell temperatures and adjust charging rates accordingly, preventing lithium plating by limiting charge current at low temperatures. Additionally, implementing pre-heating systems can help maintain the battery pack within a safe operating temperature range, reducing the risk of lithium plating and improving overall safety.

Another safety consideration is the potential for electrolyte freezing. While LFP batteries generally have good low-temperature performance, extreme cold can cause the electrolyte to freeze, leading to mechanical stress on the cell components and possible damage to the internal structure. To mitigate this risk, electrolyte formulations with lower freezing points and improved low-temperature conductivity are being developed.

The mechanical integrity of the battery pack is also crucial in cold environments. Thermal expansion and contraction of materials can lead to stress on cell connections and seals. Proper design of the battery pack, including the use of flexible interconnects and robust sealing materials, can help maintain structural integrity and prevent leaks or short circuits caused by temperature fluctuations.

Furthermore, the reduced performance of LFP batteries in cold conditions can indirectly impact safety. Lower power output may lead to unexpected system shutdowns or reduced functionality of critical safety systems in electric vehicles or other applications. To address this, redundant power systems or auxiliary heating elements may be necessary to ensure consistent performance and maintain safety features.

Lastly, proper handling and storage procedures are essential for LFP batteries in cold climates. Rapid temperature changes, such as moving a cold battery into a warm environment, can cause condensation and potential short circuits. Gradual warming procedures and moisture-resistant packaging can help mitigate these risks during transportation and storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!