Fast-Charging Techniques for Lithium Iron Phosphate Batteries

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Fast-Charging Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent energy storage solution, particularly in electric vehicles and renewable energy systems. The development of fast-charging techniques for LFP batteries represents a critical advancement in battery technology, addressing the growing demand for rapid energy replenishment in various applications.

The evolution of LFP battery technology can be traced back to the late 1990s when researchers at the University of Texas discovered the potential of lithium iron phosphate as a cathode material. Since then, LFP batteries have gained significant attention due to their inherent safety, long cycle life, and environmental friendliness. However, their relatively lower energy density compared to other lithium-ion chemistries has been a limiting factor in certain applications.

Fast-charging capabilities have become increasingly important as the adoption of electric vehicles and portable electronic devices continues to grow. The ability to quickly recharge LFP batteries without compromising their longevity or safety is a key focus area for researchers and industry professionals alike. This technological pursuit aims to overcome the traditional trade-off between charging speed and battery life, potentially revolutionizing the way we interact with energy storage systems.

The primary objective of developing fast-charging techniques for LFP batteries is to significantly reduce charging times while maintaining or even improving battery performance and lifespan. This goal encompasses several key aspects, including enhancing charge transfer kinetics, optimizing electrode structures, and developing advanced battery management systems. By achieving these objectives, fast-charging LFP batteries could potentially match or exceed the charging speeds of conventional lithium-ion batteries, while retaining their inherent advantages in safety and durability.

Another crucial aim is to address the thermal management challenges associated with rapid charging. Fast-charging processes generate substantial heat, which can lead to accelerated degradation of battery components and, in extreme cases, safety hazards. Developing efficient cooling systems and thermal management strategies is therefore an integral part of the fast-charging research agenda.

Furthermore, the pursuit of fast-charging techniques for LFP batteries is closely aligned with broader technological trends in the energy sector. As the world transitions towards renewable energy sources and electrified transportation, the demand for high-performance, rapidly chargeable energy storage solutions continues to grow. The successful development of fast-charging LFP batteries could play a pivotal role in accelerating this global shift towards sustainable energy systems.

In conclusion, the background and objectives of fast-charging techniques for LFP batteries reflect a convergence of technological innovation, market demands, and environmental considerations. By pushing the boundaries of charging speed and efficiency, researchers and industry leaders aim to unlock new possibilities for energy storage and utilization, potentially reshaping various sectors and contributing to a more sustainable future.

The evolution of LFP battery technology can be traced back to the late 1990s when researchers at the University of Texas discovered the potential of lithium iron phosphate as a cathode material. Since then, LFP batteries have gained significant attention due to their inherent safety, long cycle life, and environmental friendliness. However, their relatively lower energy density compared to other lithium-ion chemistries has been a limiting factor in certain applications.

Fast-charging capabilities have become increasingly important as the adoption of electric vehicles and portable electronic devices continues to grow. The ability to quickly recharge LFP batteries without compromising their longevity or safety is a key focus area for researchers and industry professionals alike. This technological pursuit aims to overcome the traditional trade-off between charging speed and battery life, potentially revolutionizing the way we interact with energy storage systems.

The primary objective of developing fast-charging techniques for LFP batteries is to significantly reduce charging times while maintaining or even improving battery performance and lifespan. This goal encompasses several key aspects, including enhancing charge transfer kinetics, optimizing electrode structures, and developing advanced battery management systems. By achieving these objectives, fast-charging LFP batteries could potentially match or exceed the charging speeds of conventional lithium-ion batteries, while retaining their inherent advantages in safety and durability.

Another crucial aim is to address the thermal management challenges associated with rapid charging. Fast-charging processes generate substantial heat, which can lead to accelerated degradation of battery components and, in extreme cases, safety hazards. Developing efficient cooling systems and thermal management strategies is therefore an integral part of the fast-charging research agenda.

Furthermore, the pursuit of fast-charging techniques for LFP batteries is closely aligned with broader technological trends in the energy sector. As the world transitions towards renewable energy sources and electrified transportation, the demand for high-performance, rapidly chargeable energy storage solutions continues to grow. The successful development of fast-charging LFP batteries could play a pivotal role in accelerating this global shift towards sustainable energy systems.

In conclusion, the background and objectives of fast-charging techniques for LFP batteries reflect a convergence of technological innovation, market demands, and environmental considerations. By pushing the boundaries of charging speed and efficiency, researchers and industry leaders aim to unlock new possibilities for energy storage and utilization, potentially reshaping various sectors and contributing to a more sustainable future.

Market Analysis for Fast-Charging LFP Batteries

The market for fast-charging Lithium Iron Phosphate (LFP) batteries is experiencing rapid growth, driven by increasing demand for electric vehicles (EVs) and renewable energy storage solutions. LFP batteries have gained significant traction due to their safety, long cycle life, and cost-effectiveness compared to other lithium-ion chemistries. The fast-charging capability further enhances their appeal, addressing one of the primary concerns of EV adoption - charging time.

In the automotive sector, fast-charging LFP batteries are becoming increasingly popular among EV manufacturers. Major automakers are incorporating these batteries into their vehicle lineups, particularly in the mid-range and economy segments. This trend is expected to continue as consumers seek more affordable EVs with reduced charging times. The market for fast-charging LFP batteries in EVs is projected to grow substantially over the next decade, with Asia-Pacific leading in terms of production and adoption.

The stationary energy storage market also presents significant opportunities for fast-charging LFP batteries. Grid-scale energy storage systems and residential battery installations are adopting these batteries due to their improved charging capabilities, which allow for more efficient integration of renewable energy sources. This market segment is expected to see robust growth, particularly in regions with high renewable energy penetration.

Consumer electronics represent another potential growth area for fast-charging LFP batteries. While currently dominated by other lithium-ion chemistries, there is increasing interest in LFP for applications requiring longer lifespan and enhanced safety, such as power tools and portable electronics.

Market challenges include competition from other battery technologies, such as high-nickel NMC (Nickel Manganese Cobalt) batteries, which offer higher energy density. However, the cost advantages and improving performance of LFP batteries are expected to maintain their competitiveness.

Geographically, China leads in LFP battery production and adoption, with significant investments in manufacturing capacity. Other Asian countries, notably South Korea and Japan, are also key players. North America and Europe are seeing increased interest in fast-charging LFP batteries, driven by EV market growth and energy storage demands.

The supply chain for fast-charging LFP batteries is evolving, with efforts to diversify raw material sources and reduce dependence on specific regions. This is likely to impact market dynamics and potentially lead to more localized production in key consumption markets.

Overall, the market for fast-charging LFP batteries shows strong growth potential, supported by technological advancements, increasing demand across multiple sectors, and favorable policy environments promoting electrification and renewable energy adoption. As research and development efforts continue to improve charging speeds and overall performance, the market is expected to expand further, potentially reshaping the broader energy storage landscape.

In the automotive sector, fast-charging LFP batteries are becoming increasingly popular among EV manufacturers. Major automakers are incorporating these batteries into their vehicle lineups, particularly in the mid-range and economy segments. This trend is expected to continue as consumers seek more affordable EVs with reduced charging times. The market for fast-charging LFP batteries in EVs is projected to grow substantially over the next decade, with Asia-Pacific leading in terms of production and adoption.

The stationary energy storage market also presents significant opportunities for fast-charging LFP batteries. Grid-scale energy storage systems and residential battery installations are adopting these batteries due to their improved charging capabilities, which allow for more efficient integration of renewable energy sources. This market segment is expected to see robust growth, particularly in regions with high renewable energy penetration.

Consumer electronics represent another potential growth area for fast-charging LFP batteries. While currently dominated by other lithium-ion chemistries, there is increasing interest in LFP for applications requiring longer lifespan and enhanced safety, such as power tools and portable electronics.

Market challenges include competition from other battery technologies, such as high-nickel NMC (Nickel Manganese Cobalt) batteries, which offer higher energy density. However, the cost advantages and improving performance of LFP batteries are expected to maintain their competitiveness.

Geographically, China leads in LFP battery production and adoption, with significant investments in manufacturing capacity. Other Asian countries, notably South Korea and Japan, are also key players. North America and Europe are seeing increased interest in fast-charging LFP batteries, driven by EV market growth and energy storage demands.

The supply chain for fast-charging LFP batteries is evolving, with efforts to diversify raw material sources and reduce dependence on specific regions. This is likely to impact market dynamics and potentially lead to more localized production in key consumption markets.

Overall, the market for fast-charging LFP batteries shows strong growth potential, supported by technological advancements, increasing demand across multiple sectors, and favorable policy environments promoting electrification and renewable energy adoption. As research and development efforts continue to improve charging speeds and overall performance, the market is expected to expand further, potentially reshaping the broader energy storage landscape.

Current Challenges in LFP Fast-Charging Technology

Despite the numerous advantages of Lithium Iron Phosphate (LFP) batteries, including high safety, long cycle life, and low cost, their widespread adoption in electric vehicles (EVs) faces a significant hurdle: slow charging rates. This limitation stems from several interconnected challenges that researchers and engineers are actively working to overcome.

One of the primary obstacles is the inherent low ionic conductivity of LFP materials. This characteristic restricts the speed at which lithium ions can move through the cathode during the charging process, leading to extended charging times. The challenge is further compounded by the fact that increasing the charging rate often results in capacity loss and accelerated degradation of the battery, shortening its overall lifespan.

Another critical issue is the formation of lithium plating on the anode surface during fast charging. This phenomenon occurs when lithium ions accumulate on the anode faster than they can be intercalated into the graphite structure. Lithium plating not only reduces the battery's capacity but also poses significant safety risks, including the potential for short circuits and thermal runaway.

The solid-electrolyte interphase (SEI) layer, while crucial for battery stability, presents its own set of challenges in fast-charging scenarios. Rapid charging can lead to the breakdown and reformation of this layer, consuming active lithium and contributing to capacity fade. Developing electrolyte formulations that can maintain a stable SEI under high-rate charging conditions remains a significant research focus.

Thermal management during fast charging is another major hurdle. The increased current flow generates substantial heat, which, if not properly dissipated, can lead to accelerated degradation of battery components and, in extreme cases, safety hazards. Designing effective cooling systems that can handle the heat generation during rapid charging without adding excessive weight or complexity to the battery pack is a complex engineering challenge.

Furthermore, the current battery management systems (BMS) struggle to accurately monitor and control the charging process at high rates. Improving the precision and responsiveness of BMS to optimize charging protocols in real-time, while ensuring safety and longevity, is crucial for enabling faster charging capabilities.

Lastly, the infrastructure required to support widespread fast charging of LFP batteries presents logistical and economic challenges. The power grid must be capable of delivering high power levels consistently, and charging stations need to be equipped with advanced cooling systems and high-power electronics, all of which require significant investment and planning.

Addressing these multifaceted challenges requires a holistic approach, combining advancements in materials science, electrochemistry, thermal engineering, and control systems. As research progresses, overcoming these hurdles will be crucial in realizing the full potential of LFP batteries in the rapidly evolving electric vehicle market.

One of the primary obstacles is the inherent low ionic conductivity of LFP materials. This characteristic restricts the speed at which lithium ions can move through the cathode during the charging process, leading to extended charging times. The challenge is further compounded by the fact that increasing the charging rate often results in capacity loss and accelerated degradation of the battery, shortening its overall lifespan.

Another critical issue is the formation of lithium plating on the anode surface during fast charging. This phenomenon occurs when lithium ions accumulate on the anode faster than they can be intercalated into the graphite structure. Lithium plating not only reduces the battery's capacity but also poses significant safety risks, including the potential for short circuits and thermal runaway.

The solid-electrolyte interphase (SEI) layer, while crucial for battery stability, presents its own set of challenges in fast-charging scenarios. Rapid charging can lead to the breakdown and reformation of this layer, consuming active lithium and contributing to capacity fade. Developing electrolyte formulations that can maintain a stable SEI under high-rate charging conditions remains a significant research focus.

Thermal management during fast charging is another major hurdle. The increased current flow generates substantial heat, which, if not properly dissipated, can lead to accelerated degradation of battery components and, in extreme cases, safety hazards. Designing effective cooling systems that can handle the heat generation during rapid charging without adding excessive weight or complexity to the battery pack is a complex engineering challenge.

Furthermore, the current battery management systems (BMS) struggle to accurately monitor and control the charging process at high rates. Improving the precision and responsiveness of BMS to optimize charging protocols in real-time, while ensuring safety and longevity, is crucial for enabling faster charging capabilities.

Lastly, the infrastructure required to support widespread fast charging of LFP batteries presents logistical and economic challenges. The power grid must be capable of delivering high power levels consistently, and charging stations need to be equipped with advanced cooling systems and high-power electronics, all of which require significant investment and planning.

Addressing these multifaceted challenges requires a holistic approach, combining advancements in materials science, electrochemistry, thermal engineering, and control systems. As research progresses, overcoming these hurdles will be crucial in realizing the full potential of LFP batteries in the rapidly evolving electric vehicle market.

Existing Fast-Charging Solutions for LFP Batteries

01 Advanced electrode materials for faster charging

Developing new electrode materials or modifying existing ones can significantly improve the charging speed of Lithium Iron Phosphate (LFP) batteries. This includes using nanostructured materials, doping with other elements, or creating composite electrodes to enhance ion diffusion and electron transfer rates.- Advanced electrode materials for faster charging: Developing new electrode materials or modifying existing ones can significantly improve the charging speed of Lithium Iron Phosphate (LFP) batteries. This includes using nanostructured materials, doping with other elements, or creating composite electrodes to enhance ion diffusion and electron transfer rates.

- Optimized electrolyte formulations: Improving electrolyte compositions can enhance the ionic conductivity and stability of LFP batteries, leading to faster charging capabilities. This may involve using novel electrolyte additives, adjusting electrolyte concentrations, or developing new electrolyte systems that are more compatible with high-rate charging.

- Advanced charging algorithms and protocols: Implementing sophisticated charging algorithms and protocols can optimize the charging process for LFP batteries. This includes pulse charging techniques, multi-stage charging methods, and adaptive charging strategies that adjust based on battery state and temperature to maximize charging speed while maintaining safety and longevity.

- Thermal management systems: Developing efficient thermal management systems can help maintain optimal temperature ranges during fast charging, preventing degradation and ensuring safety. This may involve advanced cooling techniques, heat dissipation materials, or intelligent temperature control systems integrated into the battery pack or charging infrastructure.

- Battery structure and design optimization: Improving the overall structure and design of LFP batteries can enhance charging speed. This includes optimizing electrode thickness, porosity, and surface area, as well as developing novel cell architectures that facilitate faster ion transport and reduce internal resistance during charging.

02 Optimized electrolyte formulations

Improving electrolyte compositions can enhance the ionic conductivity and stability of LFP batteries, leading to faster charging capabilities. This may involve using novel electrolyte additives, adjusting electrolyte concentrations, or developing new electrolyte systems that are more compatible with high-rate charging.Expand Specific Solutions03 Advanced charging protocols and algorithms

Implementing sophisticated charging protocols and algorithms can optimize the charging process for LFP batteries. This includes techniques such as pulse charging, multi-stage charging, or adaptive charging methods that adjust based on the battery's state of charge and temperature.Expand Specific Solutions04 Thermal management systems

Developing efficient thermal management systems can help maintain optimal temperature ranges during fast charging, preventing degradation and ensuring safety. This may involve advanced cooling techniques, heat dissipation materials, or intelligent temperature control systems integrated into the battery pack or charging infrastructure.Expand Specific Solutions05 Battery structure and design optimization

Improving the overall structure and design of LFP batteries can enhance charging speed. This includes optimizing electrode thickness, porosity, and surface area, as well as developing novel cell architectures that facilitate faster ion transport and reduce internal resistance.Expand Specific Solutions

Key Players in LFP Fast-Charging Industry

The fast-charging techniques for Lithium Iron Phosphate (LFP) batteries market is in a growth phase, driven by increasing demand for electric vehicles and energy storage systems. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Contemporary Amperex Technology Co., Ltd. (CATL), StoreDot Ltd., and LG Energy Solution Ltd. leading innovation. These companies are developing cutting-edge fast-charging solutions, pushing the boundaries of charging speeds and efficiency. The competition is intense, with both established battery manufacturers and emerging startups vying for market share and technological breakthroughs in this critical area of energy technology.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative fast-charging technique for LFP batteries called "cell-to-pack" (CTP) technology. This approach integrates cells directly into the battery pack, eliminating the need for modules. The CTP design increases energy density by 15-20% and reduces the number of parts by 40% [1]. CATL's LFP batteries can achieve an 80% charge in just 15 minutes using their advanced charging algorithm and thermal management system. The company has also introduced a new LFP chemistry with higher nickel content, improving energy density while maintaining the fast-charging capabilities [2][3].

Strengths: Higher energy density, reduced production costs, and faster charging times. Weaknesses: Potential thermal management challenges in extreme conditions and higher initial investment for manufacturing setup.

StoreDot Ltd.

Technical Solution: StoreDot has developed a revolutionary "extreme fast charging" (XFC) technology for LFP batteries. Their approach uses specially designed nanoparticles called "nanodots" to enable ultra-fast ion transport within the battery. This technology allows for charging rates of up to 4C (15 minutes for a full charge) without significant degradation to the battery life [4]. StoreDot's LFP batteries incorporate a unique electrode design that reduces internal resistance and heat generation during fast charging. The company has also developed advanced electrolyte formulations that enhance ion mobility and stability at high charging rates [5][6].

Strengths: Extremely fast charging capabilities, potential for high cycle life, and compatibility with existing manufacturing processes. Weaknesses: Higher production costs due to specialized materials and potential scalability challenges.

Core Innovations in LFP Fast-Charging Techniques

Charging method

PatentWO2011096469A1

Innovation

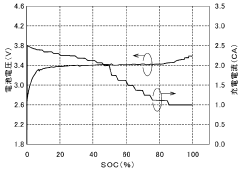

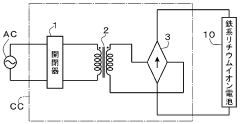

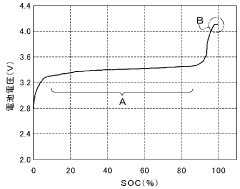

- Implementing a quasi-constant voltage charging method with a drooping characteristic, combined with a specific lithium compound that enhances the voltage plateau, allows for safe and efficient charging without the need for complex balancing circuits, using a lithium compound containing an iron component and a specific lithium compound mixed in the positive electrode active material, and employing a charging circuit with a switch, transformer, and diode bridge to manage charging current.

Charging method for battery made of mixed system material of lithium iron phosphate and ternary

PatentWO2024098271A1

Innovation

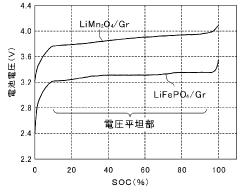

- The charging method uses lithium iron phosphate mixed with ternary mixed system materials. By setting the charging limit voltage to 4.2-4.4V, it ensures that the lithium-ion battery is fully charged with sufficient power and has both excellent cycle performance and safety performance. At the same time, the design is adapted charging circuits and chargers to reduce equipment R&D and design costs.

Safety Considerations in LFP Fast-Charging

Safety considerations are paramount in the development and implementation of fast-charging techniques for Lithium Iron Phosphate (LFP) batteries. As the demand for rapid charging capabilities increases, it is crucial to address potential risks and ensure the safety of both the battery systems and end-users.

One of the primary safety concerns in LFP fast-charging is thermal management. Rapid charging can lead to significant heat generation within the battery cells, potentially causing thermal runaway if not properly managed. To mitigate this risk, advanced cooling systems and thermal management strategies must be implemented. These may include active liquid cooling, phase change materials, or innovative heat dissipation designs to maintain optimal operating temperatures during fast-charging cycles.

Another critical safety aspect is the prevention of lithium plating. Fast-charging at high current rates can lead to the deposition of metallic lithium on the anode surface, particularly at low temperatures or when charging rates exceed the lithium-ion diffusion rate in the electrode materials. This phenomenon can result in capacity loss, increased internal resistance, and potential safety hazards. To address this, sophisticated battery management systems (BMS) must be developed to monitor and control charging parameters in real-time, adjusting the charging profile based on battery state and environmental conditions.

Mechanical stress on battery components during fast-charging is also a significant safety consideration. Rapid lithium-ion insertion and extraction can cause volume changes in electrode materials, leading to mechanical degradation over time. This may result in particle cracking, electrode delamination, or separator damage, potentially compromising the battery's structural integrity. To enhance safety, advanced electrode and separator materials with improved mechanical stability must be developed and incorporated into LFP battery designs for fast-charging applications.

Electrical safety is another crucial aspect of LFP fast-charging. High charging currents necessitate robust electrical connections, insulation, and protection mechanisms to prevent short circuits, arcing, or other electrical failures. This includes the development of advanced connectors, high-current capable busbars, and intelligent fault detection systems within both the battery pack and charging infrastructure.

Lastly, the long-term impact of fast-charging on battery life and safety must be carefully evaluated. Accelerated aging and degradation mechanisms induced by repeated fast-charging cycles could potentially lead to unforeseen safety issues over the battery's lifetime. Comprehensive long-term testing protocols and predictive modeling techniques are essential to understand and mitigate these risks, ensuring that LFP batteries maintain their safety characteristics throughout their operational life, even when subjected to frequent fast-charging events.

One of the primary safety concerns in LFP fast-charging is thermal management. Rapid charging can lead to significant heat generation within the battery cells, potentially causing thermal runaway if not properly managed. To mitigate this risk, advanced cooling systems and thermal management strategies must be implemented. These may include active liquid cooling, phase change materials, or innovative heat dissipation designs to maintain optimal operating temperatures during fast-charging cycles.

Another critical safety aspect is the prevention of lithium plating. Fast-charging at high current rates can lead to the deposition of metallic lithium on the anode surface, particularly at low temperatures or when charging rates exceed the lithium-ion diffusion rate in the electrode materials. This phenomenon can result in capacity loss, increased internal resistance, and potential safety hazards. To address this, sophisticated battery management systems (BMS) must be developed to monitor and control charging parameters in real-time, adjusting the charging profile based on battery state and environmental conditions.

Mechanical stress on battery components during fast-charging is also a significant safety consideration. Rapid lithium-ion insertion and extraction can cause volume changes in electrode materials, leading to mechanical degradation over time. This may result in particle cracking, electrode delamination, or separator damage, potentially compromising the battery's structural integrity. To enhance safety, advanced electrode and separator materials with improved mechanical stability must be developed and incorporated into LFP battery designs for fast-charging applications.

Electrical safety is another crucial aspect of LFP fast-charging. High charging currents necessitate robust electrical connections, insulation, and protection mechanisms to prevent short circuits, arcing, or other electrical failures. This includes the development of advanced connectors, high-current capable busbars, and intelligent fault detection systems within both the battery pack and charging infrastructure.

Lastly, the long-term impact of fast-charging on battery life and safety must be carefully evaluated. Accelerated aging and degradation mechanisms induced by repeated fast-charging cycles could potentially lead to unforeseen safety issues over the battery's lifetime. Comprehensive long-term testing protocols and predictive modeling techniques are essential to understand and mitigate these risks, ensuring that LFP batteries maintain their safety characteristics throughout their operational life, even when subjected to frequent fast-charging events.

Environmental Impact of LFP Fast-Charging Technologies

The environmental impact of fast-charging technologies for Lithium Iron Phosphate (LFP) batteries is a critical consideration in the development and adoption of these advanced energy storage solutions. As the demand for rapid charging capabilities increases, it is essential to evaluate the potential ecological consequences associated with these technologies.

One of the primary environmental concerns related to LFP fast-charging is the increased energy consumption during the charging process. Rapid charging typically requires higher power inputs, which can lead to greater electricity demand from the grid. This increased energy consumption may result in higher greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

The accelerated charging rates can also lead to increased heat generation within the battery cells. This thermal stress may contribute to faster degradation of battery components, potentially shortening the overall lifespan of the battery. Consequently, this could lead to more frequent battery replacements and increased electronic waste, posing challenges for recycling and disposal processes.

Fast-charging technologies may also impact the raw material requirements for LFP battery production. The need for more robust electrode materials and advanced cooling systems to withstand rapid charging could potentially increase the demand for certain minerals and metals. This heightened resource extraction could have implications for mining activities and associated environmental impacts.

However, it is important to note that fast-charging LFP batteries also offer potential environmental benefits. By enabling quicker charging times, these technologies can facilitate the wider adoption of electric vehicles and renewable energy storage systems. This transition away from fossil fuel-dependent technologies can contribute to overall reductions in carbon emissions and air pollution.

The manufacturing processes for fast-charging LFP batteries may require additional energy and resources compared to standard LFP batteries. This could result in a higher initial carbon footprint for the production phase. However, the extended cycle life and improved performance of these batteries may offset this initial impact over their operational lifetime.

Water usage is another environmental factor to consider in LFP fast-charging technologies. Advanced cooling systems required to manage the heat generated during rapid charging may increase water consumption in battery production and charging infrastructure. This could potentially strain local water resources, particularly in water-scarce regions.

In conclusion, while fast-charging technologies for LFP batteries offer significant advantages in terms of user convenience and potential for accelerating the transition to cleaner energy systems, their environmental impact must be carefully managed. Ongoing research and development efforts should focus on optimizing energy efficiency, minimizing resource intensity, and improving the recyclability of these advanced battery systems to ensure a sustainable path forward.

One of the primary environmental concerns related to LFP fast-charging is the increased energy consumption during the charging process. Rapid charging typically requires higher power inputs, which can lead to greater electricity demand from the grid. This increased energy consumption may result in higher greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

The accelerated charging rates can also lead to increased heat generation within the battery cells. This thermal stress may contribute to faster degradation of battery components, potentially shortening the overall lifespan of the battery. Consequently, this could lead to more frequent battery replacements and increased electronic waste, posing challenges for recycling and disposal processes.

Fast-charging technologies may also impact the raw material requirements for LFP battery production. The need for more robust electrode materials and advanced cooling systems to withstand rapid charging could potentially increase the demand for certain minerals and metals. This heightened resource extraction could have implications for mining activities and associated environmental impacts.

However, it is important to note that fast-charging LFP batteries also offer potential environmental benefits. By enabling quicker charging times, these technologies can facilitate the wider adoption of electric vehicles and renewable energy storage systems. This transition away from fossil fuel-dependent technologies can contribute to overall reductions in carbon emissions and air pollution.

The manufacturing processes for fast-charging LFP batteries may require additional energy and resources compared to standard LFP batteries. This could result in a higher initial carbon footprint for the production phase. However, the extended cycle life and improved performance of these batteries may offset this initial impact over their operational lifetime.

Water usage is another environmental factor to consider in LFP fast-charging technologies. Advanced cooling systems required to manage the heat generated during rapid charging may increase water consumption in battery production and charging infrastructure. This could potentially strain local water resources, particularly in water-scarce regions.

In conclusion, while fast-charging technologies for LFP batteries offer significant advantages in terms of user convenience and potential for accelerating the transition to cleaner energy systems, their environmental impact must be carefully managed. Ongoing research and development efforts should focus on optimizing energy efficiency, minimizing resource intensity, and improving the recyclability of these advanced battery systems to ensure a sustainable path forward.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!