Durability and Lifespan of Lithium Iron Phosphate Batteries in EV Applications

AUG 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery EV Evolution

The evolution of lithium iron phosphate (LFP) batteries in electric vehicle (EV) applications has been marked by significant technological advancements and market adoption. Initially developed in the 1990s, LFP batteries gained traction in the EV industry due to their inherent safety, long cycle life, and cost-effectiveness compared to other lithium-ion chemistries.

In the early 2000s, LFP batteries began to see commercial use in electric vehicles, primarily in China. The technology's early adoption was driven by its thermal stability and resistance to thermal runaway, addressing safety concerns that had plagued other battery types. However, these early iterations faced challenges in energy density and cold weather performance, limiting their widespread adoption in global markets.

The mid-2010s marked a turning point for LFP batteries in EVs. Improvements in manufacturing processes and cell design led to increased energy density and better overall performance. This period saw the introduction of cell-to-pack (CTP) technology, which significantly boosted the energy density of LFP battery packs by reducing structural components and optimizing space utilization.

From 2018 onwards, LFP batteries experienced a renaissance in the EV market. Major automakers, including Tesla, began incorporating LFP cells into their mass-market vehicles. This shift was driven by advancements in LFP chemistry that addressed previous limitations, coupled with the growing demand for more affordable electric vehicles.

Recent years have seen further innovations in LFP technology for EV applications. The development of high-nickel cathodes and silicon-based anodes has pushed the energy density of LFP batteries closer to that of nickel-based chemistries. Additionally, improvements in electrolyte formulations have enhanced low-temperature performance, addressing one of the key historical drawbacks of LFP batteries.

Looking ahead, the evolution of LFP batteries in EVs is expected to continue along several trajectories. Research is ongoing into nano-scale cathode materials and advanced doping techniques to further increase energy density. Efforts are also being made to improve fast-charging capabilities and extend cycle life beyond current limits, potentially enabling LFP batteries to last the entire lifetime of an electric vehicle without replacement.

In the early 2000s, LFP batteries began to see commercial use in electric vehicles, primarily in China. The technology's early adoption was driven by its thermal stability and resistance to thermal runaway, addressing safety concerns that had plagued other battery types. However, these early iterations faced challenges in energy density and cold weather performance, limiting their widespread adoption in global markets.

The mid-2010s marked a turning point for LFP batteries in EVs. Improvements in manufacturing processes and cell design led to increased energy density and better overall performance. This period saw the introduction of cell-to-pack (CTP) technology, which significantly boosted the energy density of LFP battery packs by reducing structural components and optimizing space utilization.

From 2018 onwards, LFP batteries experienced a renaissance in the EV market. Major automakers, including Tesla, began incorporating LFP cells into their mass-market vehicles. This shift was driven by advancements in LFP chemistry that addressed previous limitations, coupled with the growing demand for more affordable electric vehicles.

Recent years have seen further innovations in LFP technology for EV applications. The development of high-nickel cathodes and silicon-based anodes has pushed the energy density of LFP batteries closer to that of nickel-based chemistries. Additionally, improvements in electrolyte formulations have enhanced low-temperature performance, addressing one of the key historical drawbacks of LFP batteries.

Looking ahead, the evolution of LFP batteries in EVs is expected to continue along several trajectories. Research is ongoing into nano-scale cathode materials and advanced doping techniques to further increase energy density. Efforts are also being made to improve fast-charging capabilities and extend cycle life beyond current limits, potentially enabling LFP batteries to last the entire lifetime of an electric vehicle without replacement.

EV Market LFP Demand

The electric vehicle (EV) market has witnessed a significant surge in demand for lithium iron phosphate (LFP) batteries in recent years. This growing interest is primarily driven by the unique advantages that LFP batteries offer in EV applications, particularly their enhanced safety profile, longer cycle life, and lower production costs compared to other lithium-ion battery chemistries.

The global EV market has been expanding rapidly, with annual sales growth rates consistently exceeding 40% over the past few years. This growth trajectory has created a substantial demand for high-performance, cost-effective battery solutions. LFP batteries have emerged as a compelling option for many EV manufacturers, especially in the mid-range and economy vehicle segments.

China, the world's largest EV market, has been at the forefront of LFP battery adoption. Major Chinese automakers have increasingly shifted towards LFP batteries for their electric vehicle models, citing improved cost-effectiveness and performance characteristics. This trend has begun to influence global markets, with several international automotive giants announcing plans to incorporate LFP batteries into their EV lineups.

The demand for LFP batteries in the EV sector is further bolstered by ongoing improvements in energy density and charging capabilities. While traditionally lagging behind nickel-based chemistries in these aspects, recent advancements have narrowed the gap, making LFP batteries increasingly competitive across a broader range of vehicle types and performance requirements.

Environmental considerations also play a crucial role in driving LFP demand. The absence of cobalt and nickel in LFP batteries addresses ethical sourcing concerns and reduces the environmental impact associated with battery production. This aligns well with the growing emphasis on sustainability in the automotive industry and appeals to environmentally conscious consumers.

The commercial vehicle sector, including electric buses and trucks, represents another significant growth area for LFP batteries. The chemistry's inherent safety characteristics and long cycle life make it particularly well-suited for these applications, where reliability and operational longevity are paramount.

As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for LFP batteries is expected to continue its upward trajectory. Market analysts project that LFP chemistry could account for a substantial portion of the EV battery market in the coming years, potentially reaching 30-40% market share by 2025.

The global EV market has been expanding rapidly, with annual sales growth rates consistently exceeding 40% over the past few years. This growth trajectory has created a substantial demand for high-performance, cost-effective battery solutions. LFP batteries have emerged as a compelling option for many EV manufacturers, especially in the mid-range and economy vehicle segments.

China, the world's largest EV market, has been at the forefront of LFP battery adoption. Major Chinese automakers have increasingly shifted towards LFP batteries for their electric vehicle models, citing improved cost-effectiveness and performance characteristics. This trend has begun to influence global markets, with several international automotive giants announcing plans to incorporate LFP batteries into their EV lineups.

The demand for LFP batteries in the EV sector is further bolstered by ongoing improvements in energy density and charging capabilities. While traditionally lagging behind nickel-based chemistries in these aspects, recent advancements have narrowed the gap, making LFP batteries increasingly competitive across a broader range of vehicle types and performance requirements.

Environmental considerations also play a crucial role in driving LFP demand. The absence of cobalt and nickel in LFP batteries addresses ethical sourcing concerns and reduces the environmental impact associated with battery production. This aligns well with the growing emphasis on sustainability in the automotive industry and appeals to environmentally conscious consumers.

The commercial vehicle sector, including electric buses and trucks, represents another significant growth area for LFP batteries. The chemistry's inherent safety characteristics and long cycle life make it particularly well-suited for these applications, where reliability and operational longevity are paramount.

As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for LFP batteries is expected to continue its upward trajectory. Market analysts project that LFP chemistry could account for a substantial portion of the EV battery market in the coming years, potentially reaching 30-40% market share by 2025.

LFP Battery Challenges

Lithium iron phosphate (LFP) batteries have gained significant traction in electric vehicle applications due to their safety, long cycle life, and cost-effectiveness. However, several challenges persist in maximizing their durability and lifespan in the demanding environment of electric vehicles.

One of the primary challenges is the impact of temperature fluctuations on LFP battery performance. Extreme temperatures, both hot and cold, can significantly affect the battery's capacity and longevity. In cold conditions, LFP batteries experience reduced power output and slower charging rates, while high temperatures can accelerate capacity fade and potentially lead to thermal runaway.

Depth of discharge (DoD) management presents another critical challenge. While LFP batteries generally have a higher tolerance for deep discharge compared to other lithium-ion chemistries, repeated deep discharges can still accelerate capacity loss over time. Balancing the need for maximum range with optimal battery life requires sophisticated battery management systems and user education.

Charging protocols also play a crucial role in LFP battery durability. Fast charging, while convenient for users, can induce mechanical stress on the battery structure and lead to accelerated degradation if not carefully managed. Developing charging strategies that balance speed with long-term battery health remains an ongoing challenge for manufacturers and researchers.

Cycle life optimization is another area of focus. Although LFP batteries are known for their long cycle life, achieving the theoretical maximum in real-world conditions is challenging. Factors such as charge/discharge rates, environmental conditions, and usage patterns all contribute to the actual cycle life achieved in electric vehicles.

The cathode material stability of LFP batteries, while generally good, can still be improved. Over time, structural changes in the cathode can lead to capacity fade and increased internal resistance. Research into cathode material modifications and protective coatings is ongoing to enhance long-term stability.

Finally, the integration of LFP batteries into electric vehicle designs presents its own set of challenges. Optimizing the battery pack configuration, thermal management systems, and overall vehicle architecture to maximize the benefits of LFP chemistry while mitigating its limitations requires careful engineering and continuous innovation.

One of the primary challenges is the impact of temperature fluctuations on LFP battery performance. Extreme temperatures, both hot and cold, can significantly affect the battery's capacity and longevity. In cold conditions, LFP batteries experience reduced power output and slower charging rates, while high temperatures can accelerate capacity fade and potentially lead to thermal runaway.

Depth of discharge (DoD) management presents another critical challenge. While LFP batteries generally have a higher tolerance for deep discharge compared to other lithium-ion chemistries, repeated deep discharges can still accelerate capacity loss over time. Balancing the need for maximum range with optimal battery life requires sophisticated battery management systems and user education.

Charging protocols also play a crucial role in LFP battery durability. Fast charging, while convenient for users, can induce mechanical stress on the battery structure and lead to accelerated degradation if not carefully managed. Developing charging strategies that balance speed with long-term battery health remains an ongoing challenge for manufacturers and researchers.

Cycle life optimization is another area of focus. Although LFP batteries are known for their long cycle life, achieving the theoretical maximum in real-world conditions is challenging. Factors such as charge/discharge rates, environmental conditions, and usage patterns all contribute to the actual cycle life achieved in electric vehicles.

The cathode material stability of LFP batteries, while generally good, can still be improved. Over time, structural changes in the cathode can lead to capacity fade and increased internal resistance. Research into cathode material modifications and protective coatings is ongoing to enhance long-term stability.

Finally, the integration of LFP batteries into electric vehicle designs presents its own set of challenges. Optimizing the battery pack configuration, thermal management systems, and overall vehicle architecture to maximize the benefits of LFP chemistry while mitigating its limitations requires careful engineering and continuous innovation.

LFP Durability Solutions

01 Electrode material composition and structure

The durability and lifespan of lithium iron phosphate batteries can be improved by optimizing the composition and structure of electrode materials. This includes using nanostructured materials, doping with various elements, and creating composite structures to enhance stability and conductivity.- Electrode material composition and structure: The durability and lifespan of lithium iron phosphate batteries can be improved by optimizing the composition and structure of electrode materials. This includes using nanostructured materials, doping with various elements, and creating composite structures to enhance stability and conductivity.

- Electrolyte formulation and additives: Developing advanced electrolyte formulations and incorporating specific additives can significantly enhance the durability and lifespan of lithium iron phosphate batteries. These improvements can reduce side reactions, prevent electrode degradation, and maintain stable performance over extended cycles.

- Battery management systems and charging protocols: Implementing sophisticated battery management systems and optimized charging protocols can extend the durability and lifespan of lithium iron phosphate batteries. These systems can monitor and control various parameters to prevent overcharging, deep discharging, and thermal runaway.

- Thermal management and safety features: Incorporating effective thermal management systems and safety features can significantly improve the durability and lifespan of lithium iron phosphate batteries. These enhancements can include advanced cooling systems, thermal insulation, and protective mechanisms to prevent thermal runaway and maintain optimal operating conditions.

- Manufacturing processes and quality control: Optimizing manufacturing processes and implementing stringent quality control measures can enhance the durability and lifespan of lithium iron phosphate batteries. This includes refining electrode coating techniques, improving cell assembly methods, and implementing advanced testing protocols to ensure consistent performance and reliability.

02 Electrolyte formulation and additives

Developing advanced electrolyte formulations and incorporating specific additives can significantly enhance the durability and lifespan of lithium iron phosphate batteries. These improvements can reduce side reactions, prevent electrode degradation, and maintain stable performance over extended cycles.Expand Specific Solutions03 Battery management systems and charging protocols

Implementing sophisticated battery management systems and optimized charging protocols can extend the durability and lifespan of lithium iron phosphate batteries. These systems can monitor and control various parameters to prevent overcharging, overheating, and other detrimental conditions.Expand Specific Solutions04 Thermal management and safety features

Incorporating effective thermal management systems and safety features can significantly improve the durability and lifespan of lithium iron phosphate batteries. These enhancements can prevent thermal runaway, maintain optimal operating temperatures, and protect against external factors that may compromise battery performance.Expand Specific Solutions05 Manufacturing processes and quality control

Optimizing manufacturing processes and implementing stringent quality control measures can enhance the durability and lifespan of lithium iron phosphate batteries. This includes improving electrode coating techniques, reducing impurities, and ensuring consistent production standards to minimize defects and variations in battery performance.Expand Specific Solutions

Key LFP Manufacturers

The research on lithium iron phosphate (LFP) batteries for electric vehicles is in a mature stage, with significant market growth and technological advancements. The global market for LFP batteries is expanding rapidly, driven by increasing demand for electric vehicles and energy storage systems. Major players like LG Energy Solution, BYD, and CATL are leading the industry with continuous innovations in battery technology. Companies such as Guangdong Bangpu Recycling Technology and Hunan Bangpu Recycling Technology are focusing on sustainable recycling solutions, addressing the full lifecycle of these batteries. The involvement of automotive giants like Toyota and GM further indicates the technology's importance in the electric vehicle market. Research institutions like Chongqing University and North China Electric Power University are contributing to advancements in LFP battery technology, enhancing durability and lifespan for electric vehicle applications.

Ningde Amperex Technology Ltd.

Technical Solution: CATL has developed advanced lithium iron phosphate (LFP) batteries for electric vehicles, focusing on improving durability and lifespan. Their CTP (cell-to-pack) technology integrates cells directly into the battery pack, increasing energy density by 10-15% and reducing the number of parts by 40%[1]. CATL's LFP batteries utilize nano-crystalline technology and doping techniques to enhance conductivity and stability. They have also implemented advanced battery management systems (BMS) that use AI algorithms to optimize charging and discharging cycles, potentially extending battery life by up to 20%[2]. CATL's research includes the development of novel electrolyte additives that form a more stable solid electrolyte interphase (SEI), reducing capacity fade over time[3].

Strengths: High energy density, improved safety, and longer cycle life. Weaknesses: Lower energy density compared to NMC batteries, potential for thermal runaway at high temperatures.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery, an innovative LFP battery design specifically engineered for enhanced durability and lifespan in electric vehicles. The Blade Battery utilizes a unique cell-to-pack structure, eliminating the need for module housing and improving space utilization by over 50%[4]. BYD's LFP chemistry incorporates proprietary additives and coatings to enhance electrode stability and reduce side reactions. Their advanced manufacturing process includes precision control of particle size distribution and electrode thickness, contributing to improved cycle life. BYD has also developed an intelligent battery management system that employs machine learning algorithms to predict and mitigate degradation factors, potentially extending battery lifespan by up to 30%[5].

Strengths: Excellent thermal stability, high safety standards, and long cycle life. Weaknesses: Slightly lower energy density compared to some competitors, higher initial production costs.

LFP Lifespan Research

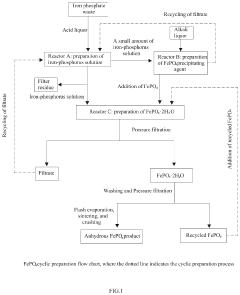

Method for recycling iron phosphate waste and use thereof

PatentPendingUS20240021903A1

Innovation

- A method involving the mixing of iron phosphate waste with an acid liquid for dissolution, followed by pH adjustment with an alkali liquid, filtration, and subsequent heating to produce an iron phosphate dihydrate precipitate, which is then dried to obtain anhydrous iron phosphate, allowing for a cyclic process with reduced alkali consumption and energy usage, suitable for large-scale industrial production.

RECOVERY METHOD FOR A LITHIUM-IRON PHOSPHATE BATTERY

PatentPendingFR3140212A1

Innovation

- A recovery process involving discharging, crushing, and screening used lithium iron phosphate batteries to separate copper and aluminum foils, followed by primary and secondary leaching reactions to obtain lithium leaching liquor, then using alkali to precipitate lithium carbonate, and finally enriching lithium through electrolysis with the precipitate waste liquor as an electrolyte.

LFP Battery Recycling

Lithium iron phosphate (LFP) battery recycling is becoming increasingly important as the adoption of electric vehicles (EVs) continues to grow. The recycling process for LFP batteries differs from that of other lithium-ion batteries due to their unique chemical composition and structure. As these batteries reach the end of their useful life in EVs, efficient recycling methods are crucial for recovering valuable materials and minimizing environmental impact.

Current LFP battery recycling processes typically involve several stages. First, the batteries are discharged and disassembled to separate the different components. The cathode material, which contains lithium, iron, and phosphate, is then processed using hydrometallurgical or pyrometallurgical methods. Hydrometallurgical processes use chemical leaching to extract the valuable metals, while pyrometallurgical processes involve high-temperature smelting.

One of the challenges in LFP battery recycling is the lower economic value of the recovered materials compared to other lithium-ion chemistries. The absence of cobalt, a high-value metal found in other battery types, makes the recycling process less profitable. However, the increasing scale of LFP battery production and use in EVs is driving the development of more efficient and cost-effective recycling technologies.

Recent advancements in recycling techniques have focused on improving material recovery rates and reducing energy consumption. For example, some companies are developing direct recycling methods that aim to recover cathode materials in a form that can be directly reused in new batteries, minimizing the need for extensive reprocessing.

The environmental benefits of LFP battery recycling are significant. By recovering materials such as lithium, iron, and phosphorus, the demand for primary raw materials is reduced, leading to lower mining impacts and energy consumption. Additionally, proper recycling prevents the release of potentially harmful substances into the environment and reduces the volume of waste sent to landfills.

As the EV industry continues to expand, the importance of establishing a robust LFP battery recycling infrastructure becomes more apparent. Governments and industry stakeholders are increasingly recognizing the need for regulations and incentives to promote battery recycling. This includes extended producer responsibility programs and the development of standardized recycling processes.

The future of LFP battery recycling is likely to see further innovations in recycling technologies, increased automation in the recycling process, and the establishment of more localized recycling facilities to reduce transportation costs and environmental impact. As the industry matures, it is expected that the economics of LFP battery recycling will improve, driven by technological advancements and economies of scale.

Current LFP battery recycling processes typically involve several stages. First, the batteries are discharged and disassembled to separate the different components. The cathode material, which contains lithium, iron, and phosphate, is then processed using hydrometallurgical or pyrometallurgical methods. Hydrometallurgical processes use chemical leaching to extract the valuable metals, while pyrometallurgical processes involve high-temperature smelting.

One of the challenges in LFP battery recycling is the lower economic value of the recovered materials compared to other lithium-ion chemistries. The absence of cobalt, a high-value metal found in other battery types, makes the recycling process less profitable. However, the increasing scale of LFP battery production and use in EVs is driving the development of more efficient and cost-effective recycling technologies.

Recent advancements in recycling techniques have focused on improving material recovery rates and reducing energy consumption. For example, some companies are developing direct recycling methods that aim to recover cathode materials in a form that can be directly reused in new batteries, minimizing the need for extensive reprocessing.

The environmental benefits of LFP battery recycling are significant. By recovering materials such as lithium, iron, and phosphorus, the demand for primary raw materials is reduced, leading to lower mining impacts and energy consumption. Additionally, proper recycling prevents the release of potentially harmful substances into the environment and reduces the volume of waste sent to landfills.

As the EV industry continues to expand, the importance of establishing a robust LFP battery recycling infrastructure becomes more apparent. Governments and industry stakeholders are increasingly recognizing the need for regulations and incentives to promote battery recycling. This includes extended producer responsibility programs and the development of standardized recycling processes.

The future of LFP battery recycling is likely to see further innovations in recycling technologies, increased automation in the recycling process, and the establishment of more localized recycling facilities to reduce transportation costs and environmental impact. As the industry matures, it is expected that the economics of LFP battery recycling will improve, driven by technological advancements and economies of scale.

LFP Environmental Impact

The environmental impact of lithium iron phosphate (LFP) batteries in electric vehicle applications is a crucial consideration in the broader context of sustainable transportation. LFP batteries have gained significant attention due to their potential to offer a more environmentally friendly alternative to other lithium-ion battery chemistries.

One of the primary environmental advantages of LFP batteries is their lower reliance on critical raw materials. Unlike nickel-based lithium-ion batteries, LFP cells do not require cobalt or nickel, which are associated with significant environmental and social concerns in their extraction processes. This reduction in the use of these materials helps mitigate the environmental impact of battery production and alleviates supply chain pressures.

The production of LFP batteries also tends to have a lower carbon footprint compared to other lithium-ion chemistries. The manufacturing process for LFP cathodes is generally less energy-intensive, resulting in reduced greenhouse gas emissions during production. This aspect contributes to the overall reduction of the carbon footprint associated with electric vehicle manufacturing.

In terms of longevity, LFP batteries demonstrate excellent cycle life, which has positive implications for their environmental impact. The extended lifespan of these batteries means they need to be replaced less frequently, reducing the demand for new battery production and the associated environmental costs of manufacturing and disposal.

The safety profile of LFP batteries is another factor that indirectly contributes to their environmental benefits. These batteries are inherently more stable and less prone to thermal runaway, reducing the risk of fires or explosions. This enhanced safety not only protects users but also minimizes the potential for environmental contamination that could result from battery-related accidents.

End-of-life considerations are also favorable for LFP batteries. The materials used in these batteries are more easily recyclable compared to some other lithium-ion chemistries. The absence of cobalt and nickel simplifies the recycling process and makes it more economically viable. This recyclability helps to close the loop in the battery lifecycle, reducing the need for virgin material extraction and minimizing waste.

However, it is important to note that the environmental impact of LFP batteries is not entirely benign. The extraction of lithium and phosphate still has environmental implications, including water usage in lithium mining and potential ecosystem disruption. Additionally, the energy-intensive nature of battery manufacturing, regardless of chemistry, remains a concern that requires ongoing efforts to improve efficiency and increase the use of renewable energy in production processes.

One of the primary environmental advantages of LFP batteries is their lower reliance on critical raw materials. Unlike nickel-based lithium-ion batteries, LFP cells do not require cobalt or nickel, which are associated with significant environmental and social concerns in their extraction processes. This reduction in the use of these materials helps mitigate the environmental impact of battery production and alleviates supply chain pressures.

The production of LFP batteries also tends to have a lower carbon footprint compared to other lithium-ion chemistries. The manufacturing process for LFP cathodes is generally less energy-intensive, resulting in reduced greenhouse gas emissions during production. This aspect contributes to the overall reduction of the carbon footprint associated with electric vehicle manufacturing.

In terms of longevity, LFP batteries demonstrate excellent cycle life, which has positive implications for their environmental impact. The extended lifespan of these batteries means they need to be replaced less frequently, reducing the demand for new battery production and the associated environmental costs of manufacturing and disposal.

The safety profile of LFP batteries is another factor that indirectly contributes to their environmental benefits. These batteries are inherently more stable and less prone to thermal runaway, reducing the risk of fires or explosions. This enhanced safety not only protects users but also minimizes the potential for environmental contamination that could result from battery-related accidents.

End-of-life considerations are also favorable for LFP batteries. The materials used in these batteries are more easily recyclable compared to some other lithium-ion chemistries. The absence of cobalt and nickel simplifies the recycling process and makes it more economically viable. This recyclability helps to close the loop in the battery lifecycle, reducing the need for virgin material extraction and minimizing waste.

However, it is important to note that the environmental impact of LFP batteries is not entirely benign. The extraction of lithium and phosphate still has environmental implications, including water usage in lithium mining and potential ecosystem disruption. Additionally, the energy-intensive nature of battery manufacturing, regardless of chemistry, remains a concern that requires ongoing efforts to improve efficiency and increase the use of renewable energy in production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!