The Role of 3D Printing in Lithium Iron Phosphate Battery Development

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing in LFP Batteries: Background and Objectives

The integration of 3D printing technology into lithium iron phosphate (LFP) battery development represents a significant advancement in energy storage solutions. This convergence of additive manufacturing and battery technology has emerged as a promising approach to address the growing demand for more efficient, customizable, and sustainable energy storage systems.

3D printing, also known as additive manufacturing, has evolved rapidly over the past decade, transitioning from a prototyping tool to a viable manufacturing process for various industries. In the context of LFP batteries, 3D printing offers unique opportunities to enhance battery performance, reduce production costs, and enable novel designs that were previously unattainable through traditional manufacturing methods.

The primary objective of incorporating 3D printing in LFP battery development is to overcome the limitations of conventional battery production techniques. These limitations include constraints on electrode architecture, electrolyte distribution, and overall battery geometry. By leveraging 3D printing, researchers and manufacturers aim to create batteries with improved energy density, faster charging capabilities, and longer cycle life.

One of the key advantages of 3D printing in LFP battery production is the ability to precisely control the internal structure of battery components. This level of control allows for the creation of complex electrode geometries that can significantly increase the surface area for electrochemical reactions, potentially leading to higher power output and faster charging times.

Furthermore, 3D printing enables the development of custom-shaped batteries that can be tailored to fit specific device requirements. This flexibility is particularly valuable in applications where space is at a premium, such as in electric vehicles, portable electronics, and aerospace systems.

The technology also holds promise for reducing the environmental impact of battery production. 3D printing can potentially minimize material waste and energy consumption during the manufacturing process, aligning with the growing emphasis on sustainable production methods in the energy storage sector.

As research in this field progresses, the goals extend beyond merely improving existing battery designs. Scientists and engineers are exploring the possibility of creating entirely new battery architectures that could revolutionize energy storage. These innovations may include gradient materials, multi-material structures, and even batteries with integrated cooling systems or self-healing properties.

3D printing, also known as additive manufacturing, has evolved rapidly over the past decade, transitioning from a prototyping tool to a viable manufacturing process for various industries. In the context of LFP batteries, 3D printing offers unique opportunities to enhance battery performance, reduce production costs, and enable novel designs that were previously unattainable through traditional manufacturing methods.

The primary objective of incorporating 3D printing in LFP battery development is to overcome the limitations of conventional battery production techniques. These limitations include constraints on electrode architecture, electrolyte distribution, and overall battery geometry. By leveraging 3D printing, researchers and manufacturers aim to create batteries with improved energy density, faster charging capabilities, and longer cycle life.

One of the key advantages of 3D printing in LFP battery production is the ability to precisely control the internal structure of battery components. This level of control allows for the creation of complex electrode geometries that can significantly increase the surface area for electrochemical reactions, potentially leading to higher power output and faster charging times.

Furthermore, 3D printing enables the development of custom-shaped batteries that can be tailored to fit specific device requirements. This flexibility is particularly valuable in applications where space is at a premium, such as in electric vehicles, portable electronics, and aerospace systems.

The technology also holds promise for reducing the environmental impact of battery production. 3D printing can potentially minimize material waste and energy consumption during the manufacturing process, aligning with the growing emphasis on sustainable production methods in the energy storage sector.

As research in this field progresses, the goals extend beyond merely improving existing battery designs. Scientists and engineers are exploring the possibility of creating entirely new battery architectures that could revolutionize energy storage. These innovations may include gradient materials, multi-material structures, and even batteries with integrated cooling systems or self-healing properties.

Market Analysis for 3D Printed LFP Batteries

The market for 3D printed Lithium Iron Phosphate (LFP) batteries is experiencing significant growth, driven by the increasing demand for sustainable energy storage solutions across various industries. The global LFP battery market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years, with 3D printing technology playing a crucial role in this growth.

The automotive sector represents the largest market segment for 3D printed LFP batteries, as electric vehicle (EV) manufacturers seek to improve battery performance, reduce costs, and enhance sustainability. The ability of 3D printing to create complex geometries and optimize battery designs is particularly attractive to EV producers looking to maximize energy density and reduce vehicle weight.

Energy storage systems for renewable energy applications form another significant market segment. As the adoption of solar and wind power increases, the demand for efficient and cost-effective energy storage solutions grows in parallel. 3D printed LFP batteries offer advantages in terms of customization and scalability, making them well-suited for both residential and utility-scale energy storage projects.

The consumer electronics industry is also showing interest in 3D printed LFP batteries, particularly for applications requiring high power density and long cycle life. Wearable devices, smartphones, and laptops are potential areas where 3D printed LFP batteries could gain traction, offering improved performance and potentially longer device lifespans.

Industrial and aerospace sectors are emerging markets for 3D printed LFP batteries, with applications in robotics, drones, and satellite systems. The ability to create lightweight, high-performance batteries with complex shapes is particularly valuable in these fields, where weight and space constraints are critical factors.

Market trends indicate a growing preference for sustainable and recyclable battery technologies. 3D printed LFP batteries align well with this trend, as they can be designed for easier disassembly and recycling, potentially reducing environmental impact and improving the circular economy of battery production.

Geographically, Asia-Pacific is expected to dominate the market for 3D printed LFP batteries, driven by strong demand in China, Japan, and South Korea. North America and Europe are also significant markets, with increasing investments in electric vehicle production and renewable energy infrastructure.

Challenges in the market include the need for further technological advancements to improve printing speed and reduce production costs. Additionally, ensuring consistent quality and performance of 3D printed batteries at scale remains a key focus area for manufacturers and researchers in this field.

The automotive sector represents the largest market segment for 3D printed LFP batteries, as electric vehicle (EV) manufacturers seek to improve battery performance, reduce costs, and enhance sustainability. The ability of 3D printing to create complex geometries and optimize battery designs is particularly attractive to EV producers looking to maximize energy density and reduce vehicle weight.

Energy storage systems for renewable energy applications form another significant market segment. As the adoption of solar and wind power increases, the demand for efficient and cost-effective energy storage solutions grows in parallel. 3D printed LFP batteries offer advantages in terms of customization and scalability, making them well-suited for both residential and utility-scale energy storage projects.

The consumer electronics industry is also showing interest in 3D printed LFP batteries, particularly for applications requiring high power density and long cycle life. Wearable devices, smartphones, and laptops are potential areas where 3D printed LFP batteries could gain traction, offering improved performance and potentially longer device lifespans.

Industrial and aerospace sectors are emerging markets for 3D printed LFP batteries, with applications in robotics, drones, and satellite systems. The ability to create lightweight, high-performance batteries with complex shapes is particularly valuable in these fields, where weight and space constraints are critical factors.

Market trends indicate a growing preference for sustainable and recyclable battery technologies. 3D printed LFP batteries align well with this trend, as they can be designed for easier disassembly and recycling, potentially reducing environmental impact and improving the circular economy of battery production.

Geographically, Asia-Pacific is expected to dominate the market for 3D printed LFP batteries, driven by strong demand in China, Japan, and South Korea. North America and Europe are also significant markets, with increasing investments in electric vehicle production and renewable energy infrastructure.

Challenges in the market include the need for further technological advancements to improve printing speed and reduce production costs. Additionally, ensuring consistent quality and performance of 3D printed batteries at scale remains a key focus area for manufacturers and researchers in this field.

Current State and Challenges in 3D Printing LFP Batteries

The integration of 3D printing technology into lithium iron phosphate (LFP) battery development has shown promising advancements, yet it faces several significant challenges. Currently, 3D printing is being explored for various components of LFP batteries, including electrodes, separators, and even entire cell structures. This approach offers potential benefits such as improved energy density, customized designs, and more efficient manufacturing processes.

One of the primary challenges in 3D printing LFP batteries is achieving the necessary material properties and performance characteristics. The printed structures must maintain high electrical conductivity, mechanical stability, and electrochemical performance comparable to traditionally manufactured batteries. Researchers are working on developing specialized inks and printing techniques to address these issues, but consistent quality and scalability remain hurdles.

Another significant challenge is the precision and resolution of 3D printing technologies when applied to battery components. LFP battery electrodes require intricate microstructures to optimize ion transport and electron conduction. While some advanced 3D printing techniques can achieve micro-scale resolution, maintaining this precision over larger areas and in mass production settings is still problematic.

The current state of 3D printed LFP batteries also faces limitations in terms of printing speed and production volume. Traditional battery manufacturing methods are highly optimized for mass production, whereas 3D printing processes are generally slower and more suited to customized, small-batch production. Bridging this gap to make 3D printing competitive for large-scale battery production is a key area of ongoing research and development.

Material compatibility is another challenge in the 3D printing of LFP batteries. The printing process must be compatible with the active materials, conductive additives, and binders used in LFP batteries without degrading their performance. Additionally, ensuring the long-term stability and safety of 3D printed battery components under various operating conditions is crucial and requires extensive testing and validation.

Regulatory and standardization issues also present challenges. As 3D printing of batteries is a relatively new field, there is a lack of established standards and regulations specific to this manufacturing method. This can create uncertainties in quality control, safety assessments, and market acceptance of 3D printed LFP batteries.

Despite these challenges, the potential benefits of 3D printing in LFP battery development continue to drive research and innovation in this field. Overcoming these obstacles could lead to significant advancements in battery technology, enabling more efficient energy storage solutions for a wide range of applications.

One of the primary challenges in 3D printing LFP batteries is achieving the necessary material properties and performance characteristics. The printed structures must maintain high electrical conductivity, mechanical stability, and electrochemical performance comparable to traditionally manufactured batteries. Researchers are working on developing specialized inks and printing techniques to address these issues, but consistent quality and scalability remain hurdles.

Another significant challenge is the precision and resolution of 3D printing technologies when applied to battery components. LFP battery electrodes require intricate microstructures to optimize ion transport and electron conduction. While some advanced 3D printing techniques can achieve micro-scale resolution, maintaining this precision over larger areas and in mass production settings is still problematic.

The current state of 3D printed LFP batteries also faces limitations in terms of printing speed and production volume. Traditional battery manufacturing methods are highly optimized for mass production, whereas 3D printing processes are generally slower and more suited to customized, small-batch production. Bridging this gap to make 3D printing competitive for large-scale battery production is a key area of ongoing research and development.

Material compatibility is another challenge in the 3D printing of LFP batteries. The printing process must be compatible with the active materials, conductive additives, and binders used in LFP batteries without degrading their performance. Additionally, ensuring the long-term stability and safety of 3D printed battery components under various operating conditions is crucial and requires extensive testing and validation.

Regulatory and standardization issues also present challenges. As 3D printing of batteries is a relatively new field, there is a lack of established standards and regulations specific to this manufacturing method. This can create uncertainties in quality control, safety assessments, and market acceptance of 3D printed LFP batteries.

Despite these challenges, the potential benefits of 3D printing in LFP battery development continue to drive research and innovation in this field. Overcoming these obstacles could lead to significant advancements in battery technology, enabling more efficient energy storage solutions for a wide range of applications.

Existing 3D Printing Solutions for LFP Batteries

01 Electrode material composition and preparation

Lithium iron phosphate (LiFePO4) is a key cathode material for lithium-ion batteries. The composition and preparation methods of this material significantly impact battery performance. Techniques include doping with other elements, controlling particle size and morphology, and optimizing synthesis conditions to enhance conductivity and capacity.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

- Battery structure and assembly: Advancements in the design and assembly of lithium iron phosphate batteries. This encompasses innovations in cell architecture, electrode stacking or winding techniques, and the integration of safety features such as pressure relief mechanisms or thermal management systems.

- Electrolyte formulations: Development of novel electrolyte formulations for lithium iron phosphate batteries. This includes the use of additives to improve ionic conductivity, enhance cycling stability, and mitigate side reactions at the electrode-electrolyte interface.

- Battery management and control systems: Innovations in battery management systems (BMS) and control algorithms for lithium iron phosphate batteries. This includes methods for accurate state-of-charge estimation, thermal management, and balancing of cells within battery packs to optimize performance and longevity.

- Manufacturing processes and quality control: Advancements in manufacturing processes and quality control techniques for lithium iron phosphate batteries. This encompasses innovations in electrode coating, cell assembly automation, and in-line inspection methods to improve production efficiency and ensure consistent battery performance.

02 Battery structure and assembly

The design and assembly of lithium iron phosphate batteries play a crucial role in their performance and safety. This includes innovations in electrode stacking, separator materials, electrolyte formulations, and overall cell construction to improve energy density, cycle life, and thermal management.Expand Specific Solutions03 Charging and discharging control systems

Advanced control systems for charging and discharging lithium iron phosphate batteries are essential for optimizing performance and longevity. These systems may include smart charging algorithms, battery management systems (BMS), and techniques for balancing individual cells within a battery pack.Expand Specific Solutions04 Safety and thermal management

Enhancing the safety and thermal management of lithium iron phosphate batteries is crucial for their widespread adoption. This includes developing improved cooling systems, fire-resistant materials, and safety mechanisms to prevent thermal runaway and other potential hazards associated with high-energy battery systems.Expand Specific Solutions05 Application-specific battery designs

Tailoring lithium iron phosphate batteries for specific applications such as electric vehicles, grid energy storage, and portable electronics involves optimizing various parameters. This includes adjusting energy density, power output, cycle life, and form factor to meet the unique requirements of each application.Expand Specific Solutions

Key Players in 3D Printed LFP Battery Industry

The development of 3D printing in lithium iron phosphate battery production is in its early stages, with the market showing significant growth potential. The technology's maturity varies across different applications, ranging from prototype development to small-scale production. Key players like Fuzhou University, NXP Semiconductors, and Koninklijke Philips NV are actively researching and developing 3D printing techniques for battery components. Universities such as Harvard, University College Cork, and Southeast University are contributing to fundamental research, while companies like Microvast and Toyota are exploring practical applications. The involvement of government institutions like the Naval Research Laboratory and Centre National de la Recherche Scientifique indicates growing interest in this technology's strategic importance for energy storage solutions.

International Business Machines Corp.

Technical Solution: IBM has leveraged its expertise in materials science and 3D printing to develop innovative approaches for LFP battery manufacturing. The company has created a 3D-printable LFP nanocomposite material that can be directly printed into complex electrode structures[7]. This method allows for the creation of high-surface-area electrodes with optimized porosity, leading to improved energy density and power output. IBM has also developed AI-driven algorithms to design and optimize 3D-printed LFP battery structures, enabling rapid prototyping and iterative improvements[8]. Furthermore, the company has explored the use of 3D-printed graphene-based current collectors to enhance the overall performance of LFP batteries[9].

Strengths: Advanced materials expertise, AI-driven optimization, potential for rapid prototyping. Weaknesses: Limited experience in large-scale battery production, potential intellectual property challenges.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has made significant contributions to 3D printing in LFP battery development. Their research focuses on developing novel 3D-printable LFP composite materials with enhanced electrochemical properties[13]. IPE has pioneered a technique for 3D printing LFP cathodes with controlled microstructures, enabling improved lithium-ion diffusion and electron conductivity[14]. The institute has also explored the integration of graphene and carbon nanotubes into 3D-printed LFP electrodes, resulting in batteries with higher capacity and rate capability[15]. Furthermore, IPE has developed a scalable 3D printing process for LFP batteries, addressing challenges in mass production and commercialization.

Strengths: Advanced material development, focus on scalability, integration of nanomaterials. Weaknesses: Potential challenges in technology transfer and industrial adoption.

Core Innovations in 3D Printed LFP Battery Technology

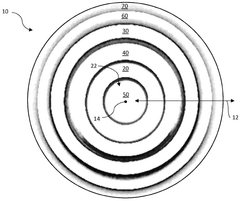

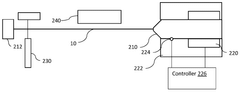

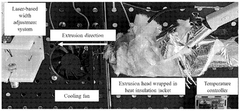

Printed batteries, and systems and methods of making and using same

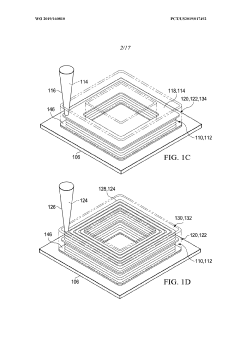

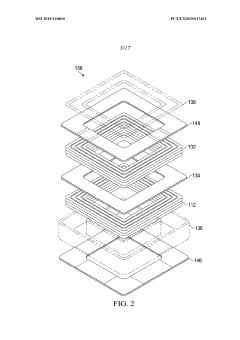

PatentWO2025015021A1

Innovation

- A printed battery filament comprising a first electrode, a second electrode, a solid electrolyte, and collectors, manufactured using a cored-filament manufacturing process that allows for simultaneous extrusion of multiple layers, enhancing energy efficiency and enabling custom-built, lightweight energy storage systems.

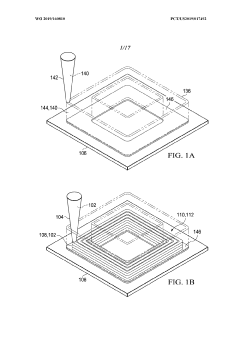

3D printed battery and method of 3D printing a battery

PatentWO2019160810A1

Innovation

- The method involves 3D printing of batteries using rheologically-tailored electrode ink formulations with dispersed electroactive and conductive particles, along with curable polymer composite packaging and separator ink formulations, allowing for the creation of thick, biphasic semi-solid electrodes with enhanced ionic and electronic transport, and arbitrary form factors without the need for drying, electrolyte-infilling, calendering, or heat-sealing processes.

Environmental Impact of 3D Printed LFP Batteries

The integration of 3D printing technology in the development of Lithium Iron Phosphate (LFP) batteries presents both opportunities and challenges from an environmental perspective. This innovative manufacturing approach offers potential benefits in terms of resource efficiency and waste reduction, but also raises concerns about energy consumption and material sustainability.

One of the primary environmental advantages of 3D printed LFP batteries is the potential for significant waste reduction. Traditional battery manufacturing processes often involve subtractive techniques that generate substantial material waste. In contrast, 3D printing employs additive manufacturing, allowing for precise material deposition and minimizing excess material usage. This approach can lead to a more efficient use of raw materials, potentially reducing the environmental impact associated with resource extraction and processing.

Furthermore, 3D printing enables the creation of complex geometries and customized designs that may be difficult or impossible to achieve through conventional manufacturing methods. This capability allows for the optimization of battery structures, potentially improving energy density and overall performance. Enhanced battery efficiency could lead to longer-lasting batteries, reducing the frequency of replacements and associated environmental impacts.

However, the environmental impact of 3D printed LFP batteries is not without concerns. The energy consumption associated with 3D printing processes can be significant, particularly for large-scale production. The high temperatures required for some 3D printing techniques may result in increased energy demands compared to traditional manufacturing methods. This energy intensity could potentially offset some of the environmental benefits gained through material efficiency.

Another consideration is the sustainability of the materials used in 3D printed LFP batteries. While the technology allows for precise material usage, the environmental impact of the raw materials themselves must be carefully evaluated. The production and disposal of specialized 3D printing materials, such as polymer binders or conductive additives, may introduce new environmental challenges that need to be addressed.

The lifecycle assessment of 3D printed LFP batteries is crucial for understanding their overall environmental impact. This includes evaluating the energy and resource requirements during production, the performance and longevity of the batteries in use, and the potential for recycling or disposal at the end of their life. Comparative studies between 3D printed and conventionally manufactured LFP batteries are necessary to quantify the net environmental benefits or drawbacks.

As the technology continues to evolve, there is potential for further environmental improvements in 3D printed LFP batteries. Advancements in printing materials, process efficiency, and recycling techniques could enhance the sustainability profile of these batteries. Additionally, the localization of production enabled by 3D printing may reduce transportation-related emissions in the battery supply chain.

One of the primary environmental advantages of 3D printed LFP batteries is the potential for significant waste reduction. Traditional battery manufacturing processes often involve subtractive techniques that generate substantial material waste. In contrast, 3D printing employs additive manufacturing, allowing for precise material deposition and minimizing excess material usage. This approach can lead to a more efficient use of raw materials, potentially reducing the environmental impact associated with resource extraction and processing.

Furthermore, 3D printing enables the creation of complex geometries and customized designs that may be difficult or impossible to achieve through conventional manufacturing methods. This capability allows for the optimization of battery structures, potentially improving energy density and overall performance. Enhanced battery efficiency could lead to longer-lasting batteries, reducing the frequency of replacements and associated environmental impacts.

However, the environmental impact of 3D printed LFP batteries is not without concerns. The energy consumption associated with 3D printing processes can be significant, particularly for large-scale production. The high temperatures required for some 3D printing techniques may result in increased energy demands compared to traditional manufacturing methods. This energy intensity could potentially offset some of the environmental benefits gained through material efficiency.

Another consideration is the sustainability of the materials used in 3D printed LFP batteries. While the technology allows for precise material usage, the environmental impact of the raw materials themselves must be carefully evaluated. The production and disposal of specialized 3D printing materials, such as polymer binders or conductive additives, may introduce new environmental challenges that need to be addressed.

The lifecycle assessment of 3D printed LFP batteries is crucial for understanding their overall environmental impact. This includes evaluating the energy and resource requirements during production, the performance and longevity of the batteries in use, and the potential for recycling or disposal at the end of their life. Comparative studies between 3D printed and conventionally manufactured LFP batteries are necessary to quantify the net environmental benefits or drawbacks.

As the technology continues to evolve, there is potential for further environmental improvements in 3D printed LFP batteries. Advancements in printing materials, process efficiency, and recycling techniques could enhance the sustainability profile of these batteries. Additionally, the localization of production enabled by 3D printing may reduce transportation-related emissions in the battery supply chain.

Cost-Benefit Analysis of 3D Printing in LFP Battery Production

The implementation of 3D printing technology in Lithium Iron Phosphate (LFP) battery production presents a complex cost-benefit scenario that warrants careful analysis. On the cost side, the initial investment in 3D printing equipment and materials can be substantial. High-quality 3D printers capable of producing battery components with the necessary precision and material compatibility often come with a significant price tag. Additionally, specialized materials for 3D printing LFP battery components may be more expensive than traditional manufacturing materials, at least in the short term.

However, these upfront costs must be weighed against the potential long-term benefits and cost savings. 3D printing can significantly reduce material waste compared to traditional subtractive manufacturing methods, potentially lowering overall material costs over time. The technology also offers greater design flexibility, allowing for the creation of complex geometries that can enhance battery performance and efficiency. This could lead to improved energy density and longer battery life, increasing the value proposition of LFP batteries produced using 3D printing techniques.

Labor costs represent another important consideration. While 3D printing may reduce the need for certain manual assembly processes, it requires skilled operators and technicians to manage the printing systems and post-processing operations. The balance between reduced assembly labor and increased technical expertise must be carefully evaluated in the context of specific production environments and local labor markets.

One of the most significant potential benefits of 3D printing in LFP battery production is the ability to rapidly prototype and iterate designs. This agility can dramatically reduce development cycles and time-to-market for new battery configurations, potentially offering a competitive advantage in the fast-evolving energy storage market. The cost savings associated with faster product development and reduced tooling requirements for new designs could offset a substantial portion of the initial investment in 3D printing technology.

Scalability and production volume are critical factors in the cost-benefit analysis. While 3D printing excels in low-volume, customized production scenarios, its cost-effectiveness in high-volume manufacturing compared to traditional methods remains a point of debate. As 3D printing technology continues to advance, improvements in printing speed and material properties may shift this balance, making it more competitive for larger-scale production.

Lastly, the environmental impact and sustainability aspects of 3D printing in LFP battery production should not be overlooked. The potential for reduced material waste, localized production, and the ability to more easily recycle and reuse materials could lead to significant environmental benefits. These factors may not have an immediate financial impact but could become increasingly important as environmental regulations tighten and consumers demand more sustainable products.

In conclusion, the cost-benefit analysis of integrating 3D printing into LFP battery production is multifaceted and dynamic. While the technology offers promising advantages in terms of design flexibility, rapid prototyping, and potential long-term cost savings, it also presents challenges in terms of initial investment and scaling to high-volume production. As the technology matures and costs potentially decrease, the balance may shift further in favor of 3D printing, making it an increasingly attractive option for LFP battery manufacturers.

However, these upfront costs must be weighed against the potential long-term benefits and cost savings. 3D printing can significantly reduce material waste compared to traditional subtractive manufacturing methods, potentially lowering overall material costs over time. The technology also offers greater design flexibility, allowing for the creation of complex geometries that can enhance battery performance and efficiency. This could lead to improved energy density and longer battery life, increasing the value proposition of LFP batteries produced using 3D printing techniques.

Labor costs represent another important consideration. While 3D printing may reduce the need for certain manual assembly processes, it requires skilled operators and technicians to manage the printing systems and post-processing operations. The balance between reduced assembly labor and increased technical expertise must be carefully evaluated in the context of specific production environments and local labor markets.

One of the most significant potential benefits of 3D printing in LFP battery production is the ability to rapidly prototype and iterate designs. This agility can dramatically reduce development cycles and time-to-market for new battery configurations, potentially offering a competitive advantage in the fast-evolving energy storage market. The cost savings associated with faster product development and reduced tooling requirements for new designs could offset a substantial portion of the initial investment in 3D printing technology.

Scalability and production volume are critical factors in the cost-benefit analysis. While 3D printing excels in low-volume, customized production scenarios, its cost-effectiveness in high-volume manufacturing compared to traditional methods remains a point of debate. As 3D printing technology continues to advance, improvements in printing speed and material properties may shift this balance, making it more competitive for larger-scale production.

Lastly, the environmental impact and sustainability aspects of 3D printing in LFP battery production should not be overlooked. The potential for reduced material waste, localized production, and the ability to more easily recycle and reuse materials could lead to significant environmental benefits. These factors may not have an immediate financial impact but could become increasingly important as environmental regulations tighten and consumers demand more sustainable products.

In conclusion, the cost-benefit analysis of integrating 3D printing into LFP battery production is multifaceted and dynamic. While the technology offers promising advantages in terms of design flexibility, rapid prototyping, and potential long-term cost savings, it also presents challenges in terms of initial investment and scaling to high-volume production. As the technology matures and costs potentially decrease, the balance may shift further in favor of 3D printing, making it an increasingly attractive option for LFP battery manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!