Recycling Processes for Critical Materials in Lithium Iron Phosphate Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Recycling Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a crucial component in the global shift towards sustainable energy solutions. As the demand for these batteries continues to grow, particularly in electric vehicles and renewable energy storage systems, the need for efficient recycling processes has become increasingly apparent. The recycling of LFP batteries is not only essential for environmental sustainability but also for securing a stable supply of critical materials.

The evolution of LFP battery technology can be traced back to the late 1990s when researchers first developed this cathode material. Since then, LFP batteries have gained popularity due to their safety, long cycle life, and relatively low cost. However, as the first generation of these batteries reaches the end of their lifespan, the industry faces the challenge of developing effective recycling methods to recover valuable materials and minimize environmental impact.

The primary objective of LFP battery recycling is to recover critical materials such as lithium, iron, and phosphorus, which are essential for the production of new batteries. This recycling process aims to create a closed-loop system, reducing the reliance on raw material extraction and mitigating the environmental impact of battery production. Additionally, recycling helps address concerns about the future availability of these materials, particularly lithium, which is a finite resource.

Current recycling technologies for LFP batteries are still in their early stages compared to those for other lithium-ion battery chemistries. The unique chemical composition of LFP batteries presents specific challenges in material separation and recovery. As a result, there is a pressing need for innovative recycling processes that can efficiently extract and purify the critical materials while being economically viable and environmentally friendly.

The development of effective recycling processes for LFP batteries is driven by several factors, including regulatory pressures, environmental concerns, and economic incentives. Many countries and regions have implemented or are considering regulations that mandate the recycling of lithium-ion batteries, including LFP batteries. These regulations aim to reduce waste, conserve resources, and promote a circular economy in the battery industry.

As the technology evolves, researchers and industry players are exploring various approaches to LFP battery recycling, including hydrometallurgical, pyrometallurgical, and direct recycling methods. Each of these approaches has its advantages and challenges, and ongoing research aims to optimize these processes for large-scale implementation. The ultimate goal is to develop recycling technologies that can recover a high percentage of critical materials while minimizing energy consumption and waste generation.

The evolution of LFP battery technology can be traced back to the late 1990s when researchers first developed this cathode material. Since then, LFP batteries have gained popularity due to their safety, long cycle life, and relatively low cost. However, as the first generation of these batteries reaches the end of their lifespan, the industry faces the challenge of developing effective recycling methods to recover valuable materials and minimize environmental impact.

The primary objective of LFP battery recycling is to recover critical materials such as lithium, iron, and phosphorus, which are essential for the production of new batteries. This recycling process aims to create a closed-loop system, reducing the reliance on raw material extraction and mitigating the environmental impact of battery production. Additionally, recycling helps address concerns about the future availability of these materials, particularly lithium, which is a finite resource.

Current recycling technologies for LFP batteries are still in their early stages compared to those for other lithium-ion battery chemistries. The unique chemical composition of LFP batteries presents specific challenges in material separation and recovery. As a result, there is a pressing need for innovative recycling processes that can efficiently extract and purify the critical materials while being economically viable and environmentally friendly.

The development of effective recycling processes for LFP batteries is driven by several factors, including regulatory pressures, environmental concerns, and economic incentives. Many countries and regions have implemented or are considering regulations that mandate the recycling of lithium-ion batteries, including LFP batteries. These regulations aim to reduce waste, conserve resources, and promote a circular economy in the battery industry.

As the technology evolves, researchers and industry players are exploring various approaches to LFP battery recycling, including hydrometallurgical, pyrometallurgical, and direct recycling methods. Each of these approaches has its advantages and challenges, and ongoing research aims to optimize these processes for large-scale implementation. The ultimate goal is to develop recycling technologies that can recover a high percentage of critical materials while minimizing energy consumption and waste generation.

Market Analysis for LFP Battery Recycling

The market for LFP battery recycling is experiencing significant growth, driven by the increasing adoption of lithium iron phosphate (LFP) batteries in electric vehicles and energy storage systems. As the demand for these batteries rises, so does the need for efficient and sustainable recycling processes to recover critical materials.

The global LFP battery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the automotive sector, where LFP batteries are gaining popularity due to their lower cost, improved safety, and longer lifespan compared to other lithium-ion battery chemistries.

China currently dominates the LFP battery market, accounting for over 70% of global production. However, other regions, including Europe and North America, are ramping up their manufacturing capabilities to reduce dependence on Chinese suppliers. This geographical diversification is expected to create new opportunities for recycling facilities in various locations.

The recycling market for LFP batteries is still in its early stages but is poised for substantial growth. As the first generation of LFP-powered electric vehicles reaches end-of-life, the volume of batteries available for recycling will increase dramatically. Industry experts anticipate that the LFP battery recycling market could reach several billion dollars by 2030.

Key drivers for the recycling market include regulatory pressures, environmental concerns, and the strategic importance of recovering critical materials. Many countries are implementing or considering regulations that mandate battery recycling, creating a favorable environment for market growth. Additionally, the recycling of LFP batteries aligns with sustainability goals and circular economy principles, attracting investment and support from both public and private sectors.

The recycling of LFP batteries presents unique challenges and opportunities. While these batteries contain less cobalt compared to other lithium-ion chemistries, they still hold valuable materials such as lithium, iron, and phosphorus. The recovery of these elements, particularly lithium, is crucial for reducing reliance on primary mining and ensuring a stable supply chain for battery production.

Market analysts predict that as recycling technologies improve and economies of scale are achieved, the cost of recycling LFP batteries will decrease. This cost reduction is essential for making recycling economically viable and competitive with primary material sourcing. Innovations in recycling processes, such as direct recycling methods that preserve the cathode structure, are expected to play a significant role in shaping the market landscape.

The LFP battery recycling market is attracting interest from various stakeholders, including battery manufacturers, automakers, recycling companies, and materials suppliers. Partnerships and joint ventures are emerging as key strategies for companies looking to establish a strong position in this growing market. These collaborations often aim to create closed-loop systems that integrate battery production, use, and recycling.

The global LFP battery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the automotive sector, where LFP batteries are gaining popularity due to their lower cost, improved safety, and longer lifespan compared to other lithium-ion battery chemistries.

China currently dominates the LFP battery market, accounting for over 70% of global production. However, other regions, including Europe and North America, are ramping up their manufacturing capabilities to reduce dependence on Chinese suppliers. This geographical diversification is expected to create new opportunities for recycling facilities in various locations.

The recycling market for LFP batteries is still in its early stages but is poised for substantial growth. As the first generation of LFP-powered electric vehicles reaches end-of-life, the volume of batteries available for recycling will increase dramatically. Industry experts anticipate that the LFP battery recycling market could reach several billion dollars by 2030.

Key drivers for the recycling market include regulatory pressures, environmental concerns, and the strategic importance of recovering critical materials. Many countries are implementing or considering regulations that mandate battery recycling, creating a favorable environment for market growth. Additionally, the recycling of LFP batteries aligns with sustainability goals and circular economy principles, attracting investment and support from both public and private sectors.

The recycling of LFP batteries presents unique challenges and opportunities. While these batteries contain less cobalt compared to other lithium-ion chemistries, they still hold valuable materials such as lithium, iron, and phosphorus. The recovery of these elements, particularly lithium, is crucial for reducing reliance on primary mining and ensuring a stable supply chain for battery production.

Market analysts predict that as recycling technologies improve and economies of scale are achieved, the cost of recycling LFP batteries will decrease. This cost reduction is essential for making recycling economically viable and competitive with primary material sourcing. Innovations in recycling processes, such as direct recycling methods that preserve the cathode structure, are expected to play a significant role in shaping the market landscape.

The LFP battery recycling market is attracting interest from various stakeholders, including battery manufacturers, automakers, recycling companies, and materials suppliers. Partnerships and joint ventures are emerging as key strategies for companies looking to establish a strong position in this growing market. These collaborations often aim to create closed-loop systems that integrate battery production, use, and recycling.

Technical Challenges in LFP Battery Recycling

Recycling lithium iron phosphate (LFP) batteries presents several significant technical challenges that hinder the widespread adoption of efficient and cost-effective recycling processes. One of the primary obstacles is the complex composition of LFP batteries, which makes it difficult to separate and recover individual components efficiently. The cathode material, lithium iron phosphate, is particularly challenging to recycle due to its stable chemical structure and low economic value compared to other lithium-ion battery chemistries.

The presence of a phosphate group in LFP batteries adds another layer of complexity to the recycling process. Traditional hydrometallurgical methods used for other lithium-ion batteries are less effective for LFP batteries, as the phosphate bonds are resistant to acid leaching. This necessitates the development of new, specialized techniques for breaking down the cathode material and recovering its constituent elements.

Another significant challenge is the low lithium content in LFP batteries compared to other lithium-ion chemistries. This lower concentration makes the extraction and recovery of lithium less economically viable, potentially discouraging recycling efforts. The iron content, while abundant, has relatively low market value, further complicating the economic feasibility of recycling processes.

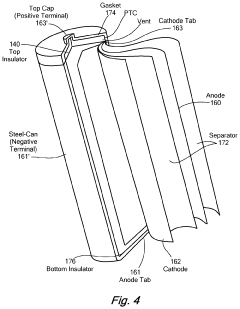

The physical structure of LFP batteries also poses challenges for recycling. The tight integration of components and the use of binders make it difficult to separate materials mechanically. This necessitates the development of advanced sorting and separation technologies to effectively isolate different battery components for recycling.

Energy consumption during the recycling process is another critical challenge. Current methods for breaking down LFP batteries and recovering materials often require high temperatures and energy-intensive processes, which can offset the environmental benefits of recycling. Developing more energy-efficient recycling techniques is crucial for improving the overall sustainability of LFP battery recycling.

Safety concerns also present significant challenges in LFP battery recycling. The potential for thermal runaway and the release of toxic substances during the recycling process necessitates stringent safety protocols and specialized equipment. This adds complexity and cost to recycling operations, potentially limiting the number of facilities capable of handling LFP battery recycling.

Lastly, the lack of standardization in LFP battery design and composition across different manufacturers complicates the development of universal recycling processes. This variability requires recycling facilities to be adaptable and capable of handling a wide range of battery designs, which can increase operational complexity and costs.

The presence of a phosphate group in LFP batteries adds another layer of complexity to the recycling process. Traditional hydrometallurgical methods used for other lithium-ion batteries are less effective for LFP batteries, as the phosphate bonds are resistant to acid leaching. This necessitates the development of new, specialized techniques for breaking down the cathode material and recovering its constituent elements.

Another significant challenge is the low lithium content in LFP batteries compared to other lithium-ion chemistries. This lower concentration makes the extraction and recovery of lithium less economically viable, potentially discouraging recycling efforts. The iron content, while abundant, has relatively low market value, further complicating the economic feasibility of recycling processes.

The physical structure of LFP batteries also poses challenges for recycling. The tight integration of components and the use of binders make it difficult to separate materials mechanically. This necessitates the development of advanced sorting and separation technologies to effectively isolate different battery components for recycling.

Energy consumption during the recycling process is another critical challenge. Current methods for breaking down LFP batteries and recovering materials often require high temperatures and energy-intensive processes, which can offset the environmental benefits of recycling. Developing more energy-efficient recycling techniques is crucial for improving the overall sustainability of LFP battery recycling.

Safety concerns also present significant challenges in LFP battery recycling. The potential for thermal runaway and the release of toxic substances during the recycling process necessitates stringent safety protocols and specialized equipment. This adds complexity and cost to recycling operations, potentially limiting the number of facilities capable of handling LFP battery recycling.

Lastly, the lack of standardization in LFP battery design and composition across different manufacturers complicates the development of universal recycling processes. This variability requires recycling facilities to be adaptable and capable of handling a wide range of battery designs, which can increase operational complexity and costs.

Current LFP Battery Recycling Processes

01 Composition and synthesis of lithium iron phosphate cathode materials

This point focuses on the development and optimization of lithium iron phosphate (LiFePO4) cathode materials for batteries. It includes methods for synthesizing high-performance LiFePO4 with improved electrochemical properties, such as enhanced conductivity and capacity. The synthesis processes may involve various techniques like solid-state reactions, hydrothermal methods, or sol-gel processes to achieve desired particle sizes and morphologies.- Composition and synthesis of lithium iron phosphate cathode materials: This point focuses on the development and optimization of lithium iron phosphate (LiFePO4) cathode materials for batteries. It includes methods for synthesizing high-performance LiFePO4 with improved electrochemical properties, such as enhanced capacity and cycling stability. The synthesis processes may involve various techniques like solid-state reactions, hydrothermal methods, or sol-gel processes to achieve desired particle morphology and crystal structure.

- Doping and surface modification of lithium iron phosphate: This aspect involves the modification of lithium iron phosphate materials through doping with various elements or surface coating to enhance their performance. Doping can improve the electronic conductivity and ionic diffusion of LiFePO4, while surface modifications can enhance the material's stability and rate capability. These techniques aim to overcome the inherent limitations of LiFePO4, such as low electronic conductivity.

- Nanostructured lithium iron phosphate materials: This point addresses the development of nanostructured LiFePO4 materials for improved battery performance. Nanostructuring can significantly enhance the electrochemical properties of LiFePO4 by increasing the surface area and shortening the diffusion paths for lithium ions. Various nanostructures, such as nanoparticles, nanowires, or nanocomposites, are explored to optimize the material's performance in lithium-ion batteries.

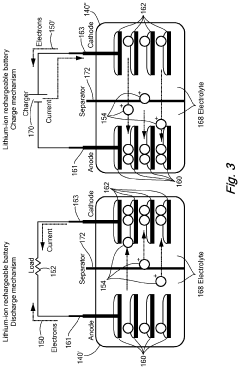

- Electrolyte formulations for lithium iron phosphate batteries: This aspect focuses on developing and optimizing electrolyte formulations specifically tailored for lithium iron phosphate batteries. The electrolyte plays a crucial role in battery performance, affecting factors such as ionic conductivity, electrode-electrolyte interface stability, and overall battery safety. Research in this area aims to enhance the compatibility between the electrolyte and LiFePO4 cathode materials to improve battery efficiency and longevity.

- Manufacturing processes for lithium iron phosphate batteries: This point encompasses the development of efficient and cost-effective manufacturing processes for lithium iron phosphate batteries. It includes innovations in electrode preparation, cell assembly, and quality control techniques. The focus is on scaling up production while maintaining consistent performance and reducing manufacturing costs. This may involve advancements in coating technologies, electrode calendering, or novel cell designs optimized for LiFePO4 chemistry.

02 Doping and surface modification of LiFePO4 materials

This category covers techniques for improving the performance of LiFePO4 through doping with various elements or surface modification. These methods aim to enhance the electronic conductivity, ionic diffusion, and structural stability of the cathode material. Doping agents may include metals like manganese, cobalt, or nickel, while surface modifications can involve carbon coating or other conductive materials.Expand Specific Solutions03 Electrolyte formulations for lithium iron phosphate batteries

This point addresses the development of specialized electrolyte formulations tailored for lithium iron phosphate batteries. It includes research on electrolyte additives, solvents, and lithium salts that can improve the battery's performance, safety, and longevity. The focus is on enhancing the ionic conductivity, reducing side reactions, and improving the solid electrolyte interphase (SEI) formation.Expand Specific Solutions04 Anode materials and designs for LiFePO4 batteries

This category explores innovative anode materials and designs that complement lithium iron phosphate cathodes. It includes research on high-capacity anode materials, such as silicon-based composites or advanced graphite formulations, as well as novel anode structures that can improve the overall battery performance. The focus is on enhancing capacity, cycle life, and rate capability of the full battery system.Expand Specific Solutions05 Manufacturing processes and scale-up techniques for LiFePO4 batteries

This point covers advancements in manufacturing processes and scale-up techniques for lithium iron phosphate batteries. It includes innovations in electrode preparation, cell assembly, and quality control methods to improve production efficiency and reduce costs. The focus is on developing scalable and sustainable manufacturing processes that maintain the high performance and safety standards of LiFePO4 batteries.Expand Specific Solutions

Key Players in LFP Battery Recycling Industry

The recycling processes for critical materials in Lithium Iron Phosphate (LFP) batteries are in a rapidly evolving phase, with the market showing significant growth potential. The industry is transitioning from early-stage development to commercial scaling, driven by increasing demand for sustainable battery solutions. Key players like Guangdong Bangpu, GEM Co., and Li-Cycle Corp. are advancing innovative recycling technologies, focusing on high-efficiency material recovery and environmental sustainability. The market is characterized by a mix of established companies and emerging startups, indicating a competitive landscape with diverse technological approaches. While the technology is maturing, ongoing research and development efforts by companies and institutions like the Institute of Process Engineering, CAS, suggest that further advancements are expected in improving recycling efficiency and reducing costs.

BASF Corp.

Technical Solution: BASF Corp. has developed a comprehensive recycling process for lithium-ion batteries, including those with LFP chemistry. Their approach combines mechanical and hydrometallurgical techniques to recover critical materials efficiently. For LFP batteries, BASF's process begins with a controlled discharge and disassembly step, followed by crushing and sorting to separate cathode materials. The company employs a proprietary leaching process optimized for LFP, using mild acids and reducing agents to selectively dissolve lithium, iron, and phosphorus[13]. BASF's innovative purification steps include solvent extraction and ion exchange technologies to produce high-purity individual elements. The recovered materials can be directly used in the synthesis of new LFP cathode materials or other applications. BASF's process achieves recovery rates of over 95% for lithium and 97% for iron and phosphorus, with the ability to handle mixed battery chemistries in a single recycling stream[15].

Strengths: High recovery rates, ability to handle mixed battery chemistries, integration with BASF's cathode material production. Weaknesses: Complex purification steps may increase processing costs, potential challenges in scaling up the technology.

GEM Co., Ltd.

Technical Solution: GEM Co., Ltd. has developed an advanced recycling process for lithium iron phosphate (LFP) batteries, focusing on the recovery of critical materials. Their method involves a combination of mechanical and hydrometallurgical processes. First, the batteries are dismantled and crushed, followed by a separation process to isolate the cathode materials. The cathode powder then undergoes a leaching process using environmentally friendly reagents to extract lithium, iron, and phosphorus. GEM's innovative approach includes a selective precipitation step to recover high-purity lithium phosphate and iron phosphate separately[1]. The company has also implemented a closed-loop system that recycles the leaching solution, reducing waste and improving overall efficiency[3]. GEM's process achieves a recovery rate of over 95% for lithium and 98% for iron, significantly higher than traditional methods[5].

Strengths: High recovery rates for critical materials, environmentally friendly process, closed-loop system for reagent recycling. Weaknesses: Potentially high initial investment costs, process complexity may require specialized equipment and expertise.

Innovative Techniques for Critical Material Recovery

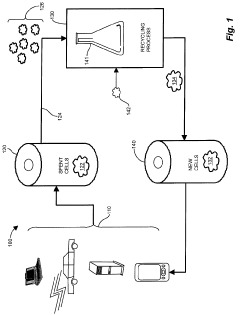

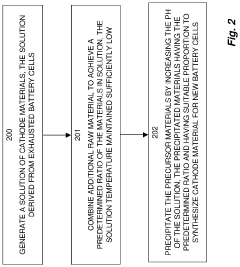

Method and apparatus for recycling lithium iron phosphate batteries

PatentActiveUS10741890B2

Innovation

- A low-temperature solution that maintains cobalt, manganese, and nickel in a commingled state during precipitation, using sodium hydroxide to adjust pH and add pure materials to achieve the desired ratio for recycled cathode materials, avoiding the need for high-temperature separation and recombination.

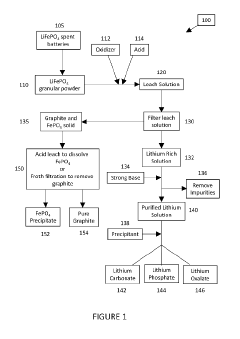

Lithium iron phosphate (LFP) battery recycling

PatentPendingIN202437012179A

Innovation

- A method involving the addition of an oxidizing agent and acid to a recycling stream of lithium iron phosphate batteries to form a leach solution, followed by filtration and pH modification to obtain a purified lithium solution, which is then precipitated into a lithium compound using a precipitant, enhancing the recovery of lithium and graphite.

Environmental Impact of LFP Battery Recycling

The environmental impact of LFP battery recycling is a critical consideration in the sustainable development of lithium-ion battery technologies. As the demand for lithium iron phosphate (LFP) batteries continues to grow, particularly in electric vehicles and energy storage systems, the need for efficient and environmentally friendly recycling processes becomes increasingly important.

One of the primary environmental benefits of LFP battery recycling is the reduction of raw material extraction. By recovering critical materials such as lithium, iron, and phosphorus, recycling processes can significantly decrease the need for mining activities. This, in turn, helps to minimize habitat destruction, soil erosion, and water pollution associated with traditional mining operations.

However, the recycling processes themselves can have environmental implications. Many current recycling methods involve energy-intensive processes, such as pyrometallurgy, which can contribute to greenhouse gas emissions. The use of chemicals in hydrometallurgical processes may also pose risks to water quality and ecosystems if not properly managed. It is crucial to develop and implement recycling technologies that minimize these negative impacts while maximizing material recovery.

The disposal of non-recyclable components and waste products from LFP battery recycling is another environmental concern. Proper handling and treatment of these materials are essential to prevent soil and groundwater contamination. Additionally, the transportation of end-of-life batteries to recycling facilities can contribute to carbon emissions, highlighting the need for localized recycling infrastructure.

On the positive side, LFP batteries have some inherent advantages in terms of environmental impact compared to other lithium-ion chemistries. They typically contain less toxic materials and have a lower risk of thermal runaway, which can reduce the environmental hazards associated with battery disposal and recycling processes.

Advancements in recycling technologies are focusing on improving the environmental performance of LFP battery recycling. Direct recycling methods, which aim to recover cathode materials with minimal processing, show promise in reducing energy consumption and chemical usage. Additionally, the development of closed-loop recycling systems can help minimize waste and maximize resource efficiency.

The overall environmental impact of LFP battery recycling is influenced by factors such as the efficiency of the recycling process, the energy sources used, and the scale of operations. As the industry matures, it is expected that improvements in technology and best practices will lead to more environmentally friendly recycling solutions, contributing to the circular economy and sustainable energy transition.

One of the primary environmental benefits of LFP battery recycling is the reduction of raw material extraction. By recovering critical materials such as lithium, iron, and phosphorus, recycling processes can significantly decrease the need for mining activities. This, in turn, helps to minimize habitat destruction, soil erosion, and water pollution associated with traditional mining operations.

However, the recycling processes themselves can have environmental implications. Many current recycling methods involve energy-intensive processes, such as pyrometallurgy, which can contribute to greenhouse gas emissions. The use of chemicals in hydrometallurgical processes may also pose risks to water quality and ecosystems if not properly managed. It is crucial to develop and implement recycling technologies that minimize these negative impacts while maximizing material recovery.

The disposal of non-recyclable components and waste products from LFP battery recycling is another environmental concern. Proper handling and treatment of these materials are essential to prevent soil and groundwater contamination. Additionally, the transportation of end-of-life batteries to recycling facilities can contribute to carbon emissions, highlighting the need for localized recycling infrastructure.

On the positive side, LFP batteries have some inherent advantages in terms of environmental impact compared to other lithium-ion chemistries. They typically contain less toxic materials and have a lower risk of thermal runaway, which can reduce the environmental hazards associated with battery disposal and recycling processes.

Advancements in recycling technologies are focusing on improving the environmental performance of LFP battery recycling. Direct recycling methods, which aim to recover cathode materials with minimal processing, show promise in reducing energy consumption and chemical usage. Additionally, the development of closed-loop recycling systems can help minimize waste and maximize resource efficiency.

The overall environmental impact of LFP battery recycling is influenced by factors such as the efficiency of the recycling process, the energy sources used, and the scale of operations. As the industry matures, it is expected that improvements in technology and best practices will lead to more environmentally friendly recycling solutions, contributing to the circular economy and sustainable energy transition.

Economic Viability of LFP Battery Recycling

The economic viability of recycling Lithium Iron Phosphate (LFP) batteries is a complex issue that requires careful analysis of multiple factors. The increasing adoption of LFP batteries in electric vehicles and energy storage systems has led to a growing need for efficient and cost-effective recycling processes.

One of the primary challenges in LFP battery recycling is the relatively low value of recovered materials compared to other lithium-ion battery chemistries. LFP batteries contain less cobalt and nickel, which are typically the most valuable components in battery recycling. This lower intrinsic value of materials can make the economic case for recycling more challenging.

However, the abundance of iron and phosphate in LFP batteries presents an opportunity for developing specialized recycling processes that focus on these materials. The recovery of lithium, which is common to all lithium-ion batteries, remains a key economic driver for recycling efforts.

The economic viability of LFP battery recycling is also influenced by the scale of operations. As the volume of end-of-life LFP batteries increases, economies of scale can be achieved, potentially improving the cost-effectiveness of recycling processes. This scaling effect is crucial for establishing a sustainable recycling industry for LFP batteries.

Technological advancements in recycling processes play a significant role in improving economic viability. Innovations in hydrometallurgical and pyrometallurgical techniques specific to LFP batteries can enhance material recovery rates and reduce processing costs. These advancements are essential for making LFP battery recycling more economically attractive.

Regulatory frameworks and government incentives also impact the economic landscape of LFP battery recycling. Policies that mandate recycling or provide financial incentives can significantly influence the profitability of recycling operations. Extended producer responsibility schemes, where manufacturers are responsible for the end-of-life management of their products, can create a more stable economic environment for recyclers.

The market demand for recycled materials is another critical factor. As sustainability becomes increasingly important in battery manufacturing, the value of recycled materials may increase, improving the economic case for LFP battery recycling. This trend could be further reinforced by regulations requiring the use of recycled content in new batteries.

In conclusion, while LFP battery recycling faces economic challenges due to the lower value of recovered materials, several factors can contribute to its viability. These include technological innovations, economies of scale, supportive policies, and growing market demand for sustainable battery materials. As the industry evolves, it is likely that the economic case for LFP battery recycling will strengthen, driven by both technological progress and environmental imperatives.

One of the primary challenges in LFP battery recycling is the relatively low value of recovered materials compared to other lithium-ion battery chemistries. LFP batteries contain less cobalt and nickel, which are typically the most valuable components in battery recycling. This lower intrinsic value of materials can make the economic case for recycling more challenging.

However, the abundance of iron and phosphate in LFP batteries presents an opportunity for developing specialized recycling processes that focus on these materials. The recovery of lithium, which is common to all lithium-ion batteries, remains a key economic driver for recycling efforts.

The economic viability of LFP battery recycling is also influenced by the scale of operations. As the volume of end-of-life LFP batteries increases, economies of scale can be achieved, potentially improving the cost-effectiveness of recycling processes. This scaling effect is crucial for establishing a sustainable recycling industry for LFP batteries.

Technological advancements in recycling processes play a significant role in improving economic viability. Innovations in hydrometallurgical and pyrometallurgical techniques specific to LFP batteries can enhance material recovery rates and reduce processing costs. These advancements are essential for making LFP battery recycling more economically attractive.

Regulatory frameworks and government incentives also impact the economic landscape of LFP battery recycling. Policies that mandate recycling or provide financial incentives can significantly influence the profitability of recycling operations. Extended producer responsibility schemes, where manufacturers are responsible for the end-of-life management of their products, can create a more stable economic environment for recyclers.

The market demand for recycled materials is another critical factor. As sustainability becomes increasingly important in battery manufacturing, the value of recycled materials may increase, improving the economic case for LFP battery recycling. This trend could be further reinforced by regulations requiring the use of recycled content in new batteries.

In conclusion, while LFP battery recycling faces economic challenges due to the lower value of recovered materials, several factors can contribute to its viability. These include technological innovations, economies of scale, supportive policies, and growing market demand for sustainable battery materials. As the industry evolves, it is likely that the economic case for LFP battery recycling will strengthen, driven by both technological progress and environmental imperatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!