Lithium Iron Phosphate Battery Potential in Off-Grid Energy Solutions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their inception in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has seen remarkable advancements in performance, cost-effectiveness, and applicability, particularly in off-grid energy solutions.

The early 2000s marked the beginning of commercial production for LFP batteries, with a focus on improving energy density and cycle life. During this period, researchers concentrated on optimizing the cathode material's structure and composition to enhance its electrochemical properties. By the mid-2000s, LFP batteries had already demonstrated superior thermal stability and longer cycle life compared to other lithium-ion chemistries.

A major breakthrough came in the late 2000s with the development of nano-scale LFP particles. This innovation significantly improved the battery's power density and rate capability, making it more suitable for high-power applications. Concurrently, advancements in manufacturing processes led to reduced production costs, paving the way for wider adoption in various sectors, including off-grid energy storage.

The 2010s saw a surge in LFP battery implementation for stationary energy storage systems. Improvements in cell design and battery management systems enhanced the overall efficiency and reliability of LFP-based solutions. This period also witnessed the integration of LFP batteries with renewable energy sources, particularly in off-grid and microgrid applications, showcasing their potential in sustainable energy solutions.

Recent years have brought about further refinements in LFP technology. The introduction of silicon-doped LFP cathodes has pushed the boundaries of energy density, addressing one of the primary limitations of earlier LFP batteries. Additionally, advancements in electrolyte formulations have led to improved low-temperature performance, expanding the operational range of LFP batteries in diverse environmental conditions.

The evolution of LFP batteries has also been marked by significant improvements in charging speeds. Fast-charging capabilities have been enhanced through optimized electrode designs and advanced charging algorithms, making LFP batteries increasingly attractive for off-grid applications where rapid energy replenishment is crucial.

Looking ahead, the trajectory of LFP battery evolution points towards even greater energy density, longer cycle life, and enhanced sustainability. Research is ongoing to develop solid-state LFP batteries, which promise higher energy density and improved safety. Moreover, efforts to reduce the environmental impact of LFP battery production and improve recycling processes are gaining momentum, aligning with the growing emphasis on sustainable energy solutions.

The early 2000s marked the beginning of commercial production for LFP batteries, with a focus on improving energy density and cycle life. During this period, researchers concentrated on optimizing the cathode material's structure and composition to enhance its electrochemical properties. By the mid-2000s, LFP batteries had already demonstrated superior thermal stability and longer cycle life compared to other lithium-ion chemistries.

A major breakthrough came in the late 2000s with the development of nano-scale LFP particles. This innovation significantly improved the battery's power density and rate capability, making it more suitable for high-power applications. Concurrently, advancements in manufacturing processes led to reduced production costs, paving the way for wider adoption in various sectors, including off-grid energy storage.

The 2010s saw a surge in LFP battery implementation for stationary energy storage systems. Improvements in cell design and battery management systems enhanced the overall efficiency and reliability of LFP-based solutions. This period also witnessed the integration of LFP batteries with renewable energy sources, particularly in off-grid and microgrid applications, showcasing their potential in sustainable energy solutions.

Recent years have brought about further refinements in LFP technology. The introduction of silicon-doped LFP cathodes has pushed the boundaries of energy density, addressing one of the primary limitations of earlier LFP batteries. Additionally, advancements in electrolyte formulations have led to improved low-temperature performance, expanding the operational range of LFP batteries in diverse environmental conditions.

The evolution of LFP batteries has also been marked by significant improvements in charging speeds. Fast-charging capabilities have been enhanced through optimized electrode designs and advanced charging algorithms, making LFP batteries increasingly attractive for off-grid applications where rapid energy replenishment is crucial.

Looking ahead, the trajectory of LFP battery evolution points towards even greater energy density, longer cycle life, and enhanced sustainability. Research is ongoing to develop solid-state LFP batteries, which promise higher energy density and improved safety. Moreover, efforts to reduce the environmental impact of LFP battery production and improve recycling processes are gaining momentum, aligning with the growing emphasis on sustainable energy solutions.

Off-Grid Energy Demand

The demand for off-grid energy solutions has been steadily increasing globally, driven by various factors including the need for electrification in remote areas, the desire for energy independence, and the growing focus on sustainable and renewable energy sources. In developing countries, off-grid energy solutions are crucial for providing electricity to rural and remote communities that are not connected to the main power grid. These solutions often rely on renewable energy sources such as solar, wind, and small-scale hydropower, with energy storage systems playing a vital role in ensuring a consistent power supply.

The market for off-grid energy solutions is expected to grow significantly in the coming years. According to recent market research, the global off-grid solar market alone is projected to reach $1.8 billion by 2022, with a compound annual growth rate of 14%. This growth is particularly pronounced in regions such as Sub-Saharan Africa and South Asia, where large portions of the population still lack access to reliable electricity.

In developed countries, the demand for off-grid energy solutions is driven by different factors. These include the desire for energy independence, resilience against power outages, and the integration of renewable energy sources into existing power systems. The increasing frequency of natural disasters and extreme weather events has also highlighted the importance of off-grid energy solutions as backup power sources.

The industrial sector is another significant driver of off-grid energy demand. Remote industrial sites, such as mining operations, oil and gas facilities, and telecommunications infrastructure, often require reliable power sources independent of the main grid. These applications demand high-performance energy storage solutions that can withstand harsh environments and provide consistent power output.

As the world transitions towards cleaner energy sources, the role of energy storage in off-grid solutions becomes increasingly critical. Lithium Iron Phosphate (LiFePO4) batteries are emerging as a promising technology for these applications due to their favorable characteristics such as long cycle life, high safety, and improved thermal stability compared to other lithium-ion chemistries.

The demand for off-grid energy solutions is also being shaped by policy initiatives and international development goals. The United Nations' Sustainable Development Goal 7 aims to ensure access to affordable, reliable, sustainable, and modern energy for all by 2030. This goal has spurred investments and initiatives in off-grid energy solutions, particularly in developing countries.

The market for off-grid energy solutions is expected to grow significantly in the coming years. According to recent market research, the global off-grid solar market alone is projected to reach $1.8 billion by 2022, with a compound annual growth rate of 14%. This growth is particularly pronounced in regions such as Sub-Saharan Africa and South Asia, where large portions of the population still lack access to reliable electricity.

In developed countries, the demand for off-grid energy solutions is driven by different factors. These include the desire for energy independence, resilience against power outages, and the integration of renewable energy sources into existing power systems. The increasing frequency of natural disasters and extreme weather events has also highlighted the importance of off-grid energy solutions as backup power sources.

The industrial sector is another significant driver of off-grid energy demand. Remote industrial sites, such as mining operations, oil and gas facilities, and telecommunications infrastructure, often require reliable power sources independent of the main grid. These applications demand high-performance energy storage solutions that can withstand harsh environments and provide consistent power output.

As the world transitions towards cleaner energy sources, the role of energy storage in off-grid solutions becomes increasingly critical. Lithium Iron Phosphate (LiFePO4) batteries are emerging as a promising technology for these applications due to their favorable characteristics such as long cycle life, high safety, and improved thermal stability compared to other lithium-ion chemistries.

The demand for off-grid energy solutions is also being shaped by policy initiatives and international development goals. The United Nations' Sustainable Development Goal 7 aims to ensure access to affordable, reliable, sustainable, and modern energy for all by 2030. This goal has spurred investments and initiatives in off-grid energy solutions, particularly in developing countries.

LFP Tech Challenges

Despite the numerous advantages of Lithium Iron Phosphate (LFP) batteries in off-grid energy solutions, several technical challenges persist that hinder their widespread adoption and optimal performance. One of the primary obstacles is the relatively low energy density of LFP batteries compared to other lithium-ion chemistries. This limitation necessitates larger battery packs to achieve the same energy storage capacity, potentially increasing system size and cost for off-grid applications.

Another significant challenge lies in the temperature sensitivity of LFP batteries. While they generally perform well in moderate climates, extreme temperatures can impact their efficiency and lifespan. In cold environments, LFP batteries may experience reduced capacity and power output, while high temperatures can accelerate degradation processes. This temperature dependence poses difficulties for off-grid systems in diverse geographical locations with varying climate conditions.

The charging efficiency of LFP batteries at low states of charge presents another technical hurdle. These batteries tend to exhibit lower charging acceptance rates when deeply discharged, which can prolong charging times and reduce overall system efficiency in off-grid scenarios where rapid recharging may be crucial during limited periods of energy generation.

Manufacturing consistency and quality control remain ongoing challenges in LFP battery production. Variations in cell performance and capacity within a battery pack can lead to imbalances, potentially reducing overall system performance and lifespan. Ensuring uniformity across large-scale production is essential for reliable off-grid energy storage solutions.

The integration of LFP batteries with renewable energy sources in off-grid systems presents its own set of challenges. Optimizing charge and discharge cycles to align with intermittent energy generation from solar or wind sources requires sophisticated battery management systems (BMS). Developing robust and adaptive BMS algorithms that can handle the unique characteristics of LFP batteries in variable off-grid environments is an ongoing area of research and development.

Long-term cycling stability and capacity retention of LFP batteries in off-grid applications also require further improvement. While LFP chemistry offers good cycle life compared to some other lithium-ion technologies, extending this performance over many years of continuous use in demanding off-grid conditions remains a challenge. Enhancing the structural stability of LFP cathodes and mitigating degradation mechanisms are key areas of focus for researchers and manufacturers.

Lastly, the cost of LFP batteries, although decreasing, still presents a barrier to widespread adoption in off-grid energy solutions, particularly in developing regions. Balancing the trade-offs between performance, longevity, and cost-effectiveness is an ongoing challenge that requires continued innovation in materials science, manufacturing processes, and system design to make LFP-based off-grid solutions more accessible and economically viable.

Another significant challenge lies in the temperature sensitivity of LFP batteries. While they generally perform well in moderate climates, extreme temperatures can impact their efficiency and lifespan. In cold environments, LFP batteries may experience reduced capacity and power output, while high temperatures can accelerate degradation processes. This temperature dependence poses difficulties for off-grid systems in diverse geographical locations with varying climate conditions.

The charging efficiency of LFP batteries at low states of charge presents another technical hurdle. These batteries tend to exhibit lower charging acceptance rates when deeply discharged, which can prolong charging times and reduce overall system efficiency in off-grid scenarios where rapid recharging may be crucial during limited periods of energy generation.

Manufacturing consistency and quality control remain ongoing challenges in LFP battery production. Variations in cell performance and capacity within a battery pack can lead to imbalances, potentially reducing overall system performance and lifespan. Ensuring uniformity across large-scale production is essential for reliable off-grid energy storage solutions.

The integration of LFP batteries with renewable energy sources in off-grid systems presents its own set of challenges. Optimizing charge and discharge cycles to align with intermittent energy generation from solar or wind sources requires sophisticated battery management systems (BMS). Developing robust and adaptive BMS algorithms that can handle the unique characteristics of LFP batteries in variable off-grid environments is an ongoing area of research and development.

Long-term cycling stability and capacity retention of LFP batteries in off-grid applications also require further improvement. While LFP chemistry offers good cycle life compared to some other lithium-ion technologies, extending this performance over many years of continuous use in demanding off-grid conditions remains a challenge. Enhancing the structural stability of LFP cathodes and mitigating degradation mechanisms are key areas of focus for researchers and manufacturers.

Lastly, the cost of LFP batteries, although decreasing, still presents a barrier to widespread adoption in off-grid energy solutions, particularly in developing regions. Balancing the trade-offs between performance, longevity, and cost-effectiveness is an ongoing challenge that requires continued innovation in materials science, manufacturing processes, and system design to make LFP-based off-grid solutions more accessible and economically viable.

Current LFP Solutions

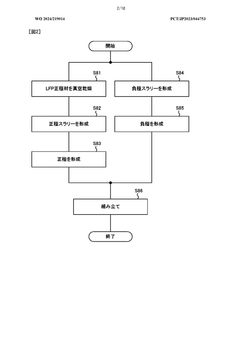

01 Electrode material composition and preparation

Innovations in electrode material composition and preparation methods for lithium iron phosphate batteries. This includes novel synthesis techniques, doping strategies, and particle size control to enhance the electrochemical performance and energy density of the cathode material.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

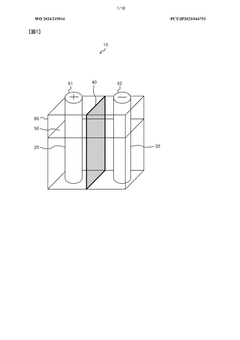

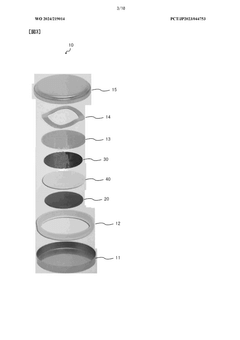

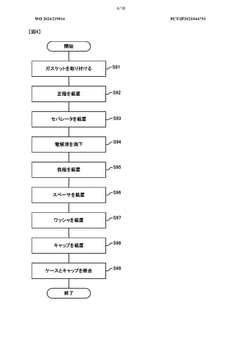

- Battery structure and assembly: Advancements in the design and assembly of lithium iron phosphate batteries. This encompasses innovations in cell architecture, electrode stacking or winding techniques, and the integration of safety features such as pressure relief mechanisms or thermal management systems.

- Electrolyte formulations: Development of novel electrolyte formulations for lithium iron phosphate batteries. This includes the use of additives to improve ionic conductivity, enhance cycling stability, and mitigate side reactions at the electrode-electrolyte interface.

- Battery management and control systems: Innovations in battery management systems (BMS) and control algorithms for lithium iron phosphate batteries. This covers techniques for monitoring cell voltage, temperature, and state of charge, as well as strategies for balancing cells and optimizing battery performance and longevity.

- Manufacturing processes and quality control: Advancements in manufacturing processes and quality control techniques for lithium iron phosphate batteries. This includes innovations in electrode coating, cell assembly automation, and in-line inspection methods to ensure consistent product quality and performance.

02 Battery cell design and assembly

Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses improvements in electrode stacking, electrolyte formulation, and separator technology to optimize cell performance, safety, and longevity.Expand Specific Solutions03 Thermal management and safety features

Development of thermal management systems and safety features specific to lithium iron phosphate batteries. This includes innovative cooling mechanisms, fire-retardant materials, and protective circuits to enhance battery safety and prevent thermal runaway.Expand Specific Solutions04 Battery management systems

Advanced battery management systems tailored for lithium iron phosphate batteries. These systems focus on optimizing charging/discharging protocols, state-of-charge estimation, and cell balancing to maximize battery life and performance.Expand Specific Solutions05 Large-scale energy storage applications

Innovations in scaling up lithium iron phosphate battery technology for large-scale energy storage applications. This includes modular designs, grid integration strategies, and power management solutions for renewable energy systems and electric vehicle charging infrastructure.Expand Specific Solutions

Key LFP Manufacturers

The Lithium Iron Phosphate (LFP) battery market for off-grid energy solutions is in a growth phase, driven by increasing demand for renewable energy storage. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, LFP batteries are relatively mature, offering advantages in safety, longevity, and cost-effectiveness. Key players like BYD, CATL (through subsidiaries like Guangdong Bangpu), and Panasonic Energy are leading innovation and production. Research institutions such as Zhejiang University and IIT Bombay are contributing to advancements. The competitive landscape is intensifying as more companies, including traditional automotive manufacturers like Toyota and emerging specialists like SK On, enter the market, driving further technological improvements and cost reductions.

BYD Co., Ltd.

Technical Solution: BYD has developed advanced Lithium Iron Phosphate (LFP) batteries specifically designed for off-grid energy solutions. Their Blade Battery technology utilizes LFP chemistry in a unique cell-to-pack design, increasing energy density by up to 50% compared to traditional LFP batteries[1]. This innovation allows for more compact and efficient energy storage systems suitable for remote and off-grid applications. BYD's LFP batteries feature a long cycle life of over 3000 cycles, maintaining 80% capacity after 3000 full charge-discharge cycles[2]. The company has also implemented advanced battery management systems to optimize performance and extend battery life in varying environmental conditions, crucial for off-grid installations[3].

Strengths: High energy density, long cycle life, improved safety, and advanced management systems. Weaknesses: Higher initial cost compared to some competitors, potential supply chain dependencies for raw materials.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has developed a range of LFP batteries tailored for off-grid energy solutions. Their technology focuses on enhancing the power output and energy density of LFP cells while maintaining the inherent safety and longevity benefits of the chemistry. Panasonic's LFP batteries feature advanced electrode designs and electrolyte formulations that improve ionic conductivity, resulting in faster charging capabilities and higher power density[4]. For off-grid applications, Panasonic has integrated their LFP cells into modular energy storage systems that can be easily scaled to meet varying power requirements. These systems incorporate smart energy management software that optimizes battery performance based on usage patterns and environmental conditions, extending the overall system lifespan[5].

Strengths: High power density, scalable modular design, advanced energy management software. Weaknesses: Slightly lower energy density compared to some newer LFP technologies, potentially higher cost for large-scale installations.

LFP Patent Landscape

Lithium iron phosphate battery and hybrid vehicle

PatentPendingUS20250233125A1

Innovation

- A lithium iron phosphate battery design incorporating both large-particle and small-particle cathode and anode active materials, which addresses poor rate performance and polarization issues when using only large particles, and excessive side reactions when using only small particles.

Lithium iron phosphate ion battery and method for manufacturing lithium iron phosphate ion battery

PatentWO2024219014A1

Innovation

- Incorporating amorphous carbon with 10% or less of fullerene or carbon nanotubes into the positive and negative electrodes of lithium iron phosphate batteries to enhance discharge energy, reducing electrical resistance and improving conductive additives.

Environmental Impact

The environmental impact of Lithium Iron Phosphate (LFP) batteries in off-grid energy solutions is a critical consideration for sustainable development. These batteries offer several advantages over traditional lead-acid batteries and other lithium-ion chemistries in terms of their environmental footprint.

LFP batteries have a significantly longer lifespan compared to lead-acid batteries, typically lasting 3-4 times longer. This extended lifecycle reduces the frequency of battery replacements, thereby minimizing waste generation and the environmental impact associated with battery production and disposal. The longevity of LFP batteries also contributes to a lower overall carbon footprint when considering the entire life cycle of off-grid energy systems.

In terms of raw materials, LFP batteries utilize more abundant and less controversial elements compared to other lithium-ion chemistries. The absence of cobalt, a material often associated with ethical and environmental concerns in mining practices, makes LFP batteries a more sustainable choice. Additionally, the iron and phosphate used in these batteries are widely available and have a lower environmental impact during extraction and processing.

The safety profile of LFP batteries is another factor contributing to their positive environmental impact. These batteries are inherently more stable and less prone to thermal runaway, reducing the risk of fires or explosions. This enhanced safety not only protects the environment from potential hazards but also extends the usable life of the batteries, further reducing waste and resource consumption.

Recycling and end-of-life management of LFP batteries present both challenges and opportunities. While the recycling process for LFP batteries is less developed compared to other battery types, ongoing research and development are improving recycling efficiencies. The relatively simple chemistry of LFP batteries makes them potentially easier to recycle, with valuable materials such as lithium and iron being recoverable for reuse.

In off-grid applications, LFP batteries enable more efficient integration of renewable energy sources like solar and wind power. This integration reduces reliance on fossil fuel-based energy generation, leading to lower greenhouse gas emissions and air pollution. The high cycle life and deep discharge capabilities of LFP batteries allow for more effective energy storage and utilization in off-grid systems, maximizing the environmental benefits of renewable energy sources.

The temperature tolerance of LFP batteries is another environmental advantage, particularly in off-grid applications. These batteries perform well in a wide range of temperatures, reducing the need for energy-intensive cooling or heating systems in battery storage facilities. This characteristic not only improves overall system efficiency but also decreases the environmental impact associated with temperature management in battery installations.

LFP batteries have a significantly longer lifespan compared to lead-acid batteries, typically lasting 3-4 times longer. This extended lifecycle reduces the frequency of battery replacements, thereby minimizing waste generation and the environmental impact associated with battery production and disposal. The longevity of LFP batteries also contributes to a lower overall carbon footprint when considering the entire life cycle of off-grid energy systems.

In terms of raw materials, LFP batteries utilize more abundant and less controversial elements compared to other lithium-ion chemistries. The absence of cobalt, a material often associated with ethical and environmental concerns in mining practices, makes LFP batteries a more sustainable choice. Additionally, the iron and phosphate used in these batteries are widely available and have a lower environmental impact during extraction and processing.

The safety profile of LFP batteries is another factor contributing to their positive environmental impact. These batteries are inherently more stable and less prone to thermal runaway, reducing the risk of fires or explosions. This enhanced safety not only protects the environment from potential hazards but also extends the usable life of the batteries, further reducing waste and resource consumption.

Recycling and end-of-life management of LFP batteries present both challenges and opportunities. While the recycling process for LFP batteries is less developed compared to other battery types, ongoing research and development are improving recycling efficiencies. The relatively simple chemistry of LFP batteries makes them potentially easier to recycle, with valuable materials such as lithium and iron being recoverable for reuse.

In off-grid applications, LFP batteries enable more efficient integration of renewable energy sources like solar and wind power. This integration reduces reliance on fossil fuel-based energy generation, leading to lower greenhouse gas emissions and air pollution. The high cycle life and deep discharge capabilities of LFP batteries allow for more effective energy storage and utilization in off-grid systems, maximizing the environmental benefits of renewable energy sources.

The temperature tolerance of LFP batteries is another environmental advantage, particularly in off-grid applications. These batteries perform well in a wide range of temperatures, reducing the need for energy-intensive cooling or heating systems in battery storage facilities. This characteristic not only improves overall system efficiency but also decreases the environmental impact associated with temperature management in battery installations.

Grid Integration

The integration of Lithium Iron Phosphate (LiFePO4) batteries into off-grid energy solutions presents both opportunities and challenges for grid integration. These batteries offer several advantages that make them particularly suitable for off-grid applications, including their long cycle life, high safety profile, and stable discharge characteristics.

One of the key benefits of LiFePO4 batteries in off-grid systems is their ability to provide reliable power storage and distribution. Their flat discharge curve allows for consistent voltage output throughout the discharge cycle, which is crucial for maintaining stable power supply in off-grid scenarios. This characteristic makes them ideal for integration with renewable energy sources such as solar and wind, which are often intermittent in nature.

The scalability of LiFePO4 battery systems is another factor that facilitates their integration into off-grid solutions. These batteries can be easily connected in parallel to increase capacity, allowing for flexible system design that can be tailored to specific energy requirements. This scalability also enables the gradual expansion of off-grid systems as energy demands grow over time.

However, the integration of LiFePO4 batteries into off-grid energy solutions also presents certain challenges. One of the primary concerns is the need for sophisticated battery management systems (BMS) to ensure optimal performance and longevity. The BMS must be capable of monitoring individual cell voltages, managing charge and discharge rates, and implementing safety protocols to prevent overcharging or deep discharging.

Another consideration for grid integration is the need for efficient power conversion systems. Off-grid solutions typically require inverters to convert the DC power stored in the batteries to AC power for use in standard appliances and equipment. The selection of appropriate inverters that are compatible with LiFePO4 battery characteristics is crucial for maximizing system efficiency and reliability.

The integration of LiFePO4 batteries also necessitates careful system design to ensure proper thermal management. While these batteries are known for their thermal stability, prolonged exposure to extreme temperatures can still impact their performance and lifespan. Implementing effective cooling or heating systems, depending on the environmental conditions, is essential for maintaining optimal battery operation in off-grid installations.

Furthermore, the integration of LiFePO4 batteries into off-grid energy solutions requires consideration of the overall system architecture. This includes the design of charge controllers, load management systems, and monitoring interfaces that can effectively coordinate the operation of the batteries with other components of the off-grid system, such as solar panels or wind turbines.

One of the key benefits of LiFePO4 batteries in off-grid systems is their ability to provide reliable power storage and distribution. Their flat discharge curve allows for consistent voltage output throughout the discharge cycle, which is crucial for maintaining stable power supply in off-grid scenarios. This characteristic makes them ideal for integration with renewable energy sources such as solar and wind, which are often intermittent in nature.

The scalability of LiFePO4 battery systems is another factor that facilitates their integration into off-grid solutions. These batteries can be easily connected in parallel to increase capacity, allowing for flexible system design that can be tailored to specific energy requirements. This scalability also enables the gradual expansion of off-grid systems as energy demands grow over time.

However, the integration of LiFePO4 batteries into off-grid energy solutions also presents certain challenges. One of the primary concerns is the need for sophisticated battery management systems (BMS) to ensure optimal performance and longevity. The BMS must be capable of monitoring individual cell voltages, managing charge and discharge rates, and implementing safety protocols to prevent overcharging or deep discharging.

Another consideration for grid integration is the need for efficient power conversion systems. Off-grid solutions typically require inverters to convert the DC power stored in the batteries to AC power for use in standard appliances and equipment. The selection of appropriate inverters that are compatible with LiFePO4 battery characteristics is crucial for maximizing system efficiency and reliability.

The integration of LiFePO4 batteries also necessitates careful system design to ensure proper thermal management. While these batteries are known for their thermal stability, prolonged exposure to extreme temperatures can still impact their performance and lifespan. Implementing effective cooling or heating systems, depending on the environmental conditions, is essential for maintaining optimal battery operation in off-grid installations.

Furthermore, the integration of LiFePO4 batteries into off-grid energy solutions requires consideration of the overall system architecture. This includes the design of charge controllers, load management systems, and monitoring interfaces that can effectively coordinate the operation of the batteries with other components of the off-grid system, such as solar panels or wind turbines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!