Lithium Iron Phosphate Battery Applications in Smart Transportation Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution in Transportation

The evolution of Lithium Iron Phosphate (LFP) batteries in transportation has been marked by significant technological advancements and increasing adoption across various modes of transport. Initially developed in the late 1990s, LFP batteries have undergone substantial improvements in energy density, cycle life, and safety features, making them increasingly attractive for transportation applications.

In the early 2000s, LFP batteries began to gain traction in the electric vehicle (EV) market, primarily due to their enhanced safety characteristics and lower production costs compared to other lithium-ion chemistries. The first commercial applications were seen in electric buses and other heavy-duty vehicles, where the batteries' durability and thermal stability were particularly advantageous.

As research and development efforts intensified, LFP battery technology saw rapid improvements in energy density and power output. By the mid-2010s, these advancements led to broader adoption in passenger EVs, with several major automakers incorporating LFP batteries into their vehicle lineups. This shift was driven by the batteries' improved performance, longer lifespan, and cost-effectiveness.

The integration of LFP batteries into smart transportation systems has been a key driver of their evolution. In recent years, there has been a growing focus on developing battery management systems (BMS) specifically optimized for LFP chemistry. These advanced BMS have enabled more accurate state-of-charge estimation and enhanced overall battery performance in real-world driving conditions.

Another significant development has been the application of LFP batteries in electric trains and trams. The batteries' ability to withstand frequent charge-discharge cycles and their excellent thermal management properties have made them well-suited for these high-demand transportation applications. This has led to increased electrification of rail systems in urban areas, contributing to reduced emissions and improved energy efficiency in public transportation.

The marine sector has also seen growing adoption of LFP batteries, particularly in electric ferries and hybrid vessels. The batteries' safety features and ability to deliver high power output have made them an attractive option for maritime applications, where reliability and performance under challenging conditions are crucial.

Looking ahead, the evolution of LFP batteries in transportation is expected to continue, with ongoing research focused on further improving energy density, fast-charging capabilities, and integration with smart grid systems. As smart transportation networks become more prevalent, LFP batteries are likely to play an increasingly important role in enabling efficient, sustainable, and interconnected mobility solutions across various modes of transport.

In the early 2000s, LFP batteries began to gain traction in the electric vehicle (EV) market, primarily due to their enhanced safety characteristics and lower production costs compared to other lithium-ion chemistries. The first commercial applications were seen in electric buses and other heavy-duty vehicles, where the batteries' durability and thermal stability were particularly advantageous.

As research and development efforts intensified, LFP battery technology saw rapid improvements in energy density and power output. By the mid-2010s, these advancements led to broader adoption in passenger EVs, with several major automakers incorporating LFP batteries into their vehicle lineups. This shift was driven by the batteries' improved performance, longer lifespan, and cost-effectiveness.

The integration of LFP batteries into smart transportation systems has been a key driver of their evolution. In recent years, there has been a growing focus on developing battery management systems (BMS) specifically optimized for LFP chemistry. These advanced BMS have enabled more accurate state-of-charge estimation and enhanced overall battery performance in real-world driving conditions.

Another significant development has been the application of LFP batteries in electric trains and trams. The batteries' ability to withstand frequent charge-discharge cycles and their excellent thermal management properties have made them well-suited for these high-demand transportation applications. This has led to increased electrification of rail systems in urban areas, contributing to reduced emissions and improved energy efficiency in public transportation.

The marine sector has also seen growing adoption of LFP batteries, particularly in electric ferries and hybrid vessels. The batteries' safety features and ability to deliver high power output have made them an attractive option for maritime applications, where reliability and performance under challenging conditions are crucial.

Looking ahead, the evolution of LFP batteries in transportation is expected to continue, with ongoing research focused on further improving energy density, fast-charging capabilities, and integration with smart grid systems. As smart transportation networks become more prevalent, LFP batteries are likely to play an increasingly important role in enabling efficient, sustainable, and interconnected mobility solutions across various modes of transport.

Smart Transport Market Demand

The smart transportation market is experiencing rapid growth, driven by increasing urbanization, environmental concerns, and the need for efficient mobility solutions. Lithium Iron Phosphate (LiFePO4) batteries are emerging as a key enabler in this sector, offering numerous advantages for various applications within smart transportation systems.

The demand for LiFePO4 batteries in smart transportation is primarily fueled by the electric vehicle (EV) market. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, safe, and long-lasting batteries continues to rise. LiFePO4 batteries are particularly well-suited for electric buses, trucks, and other commercial vehicles due to their excellent thermal stability, long cycle life, and high power density.

In addition to EVs, the smart transportation ecosystem encompasses a wide range of applications that can benefit from LiFePO4 battery technology. These include electric scooters, e-bikes, and other micromobility solutions that are gaining popularity in urban areas. The growing trend of shared mobility services further amplifies the demand for reliable and durable battery solutions in these applications.

Smart infrastructure is another key driver of LiFePO4 battery demand in transportation. Intelligent traffic management systems, smart streetlights, and roadside sensors all require reliable power sources that can withstand harsh outdoor conditions. LiFePO4 batteries, with their wide operating temperature range and long service life, are ideal for powering these critical infrastructure components.

The market for energy storage systems in transportation hubs, such as railway stations and airports, is also expanding. These facilities require robust and safe battery solutions to manage peak energy demands, integrate renewable energy sources, and provide backup power. LiFePO4 batteries are well-positioned to meet these requirements, offering a balance of performance, safety, and cost-effectiveness.

As smart cities continue to evolve, the integration of transportation systems with other urban services creates new opportunities for LiFePO4 battery applications. For instance, vehicle-to-grid (V2G) technology, which allows EVs to feed energy back into the grid, relies on advanced battery systems that can handle frequent charging and discharging cycles – a characteristic where LiFePO4 batteries excel.

The maritime sector is another area where LiFePO4 batteries are gaining traction. Electric and hybrid vessels for short-sea shipping, ferries, and port operations are increasingly adopting these batteries due to their safety profile and ability to deliver high power output.

While the market demand for LiFePO4 batteries in smart transportation is strong, it is important to note that the technology faces competition from other battery chemistries, such as nickel-manganese-cobalt (NMC) and solid-state batteries. However, the unique combination of safety, longevity, and cost-effectiveness positions LiFePO4 batteries as a compelling choice for many smart transportation applications.

The demand for LiFePO4 batteries in smart transportation is primarily fueled by the electric vehicle (EV) market. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, safe, and long-lasting batteries continues to rise. LiFePO4 batteries are particularly well-suited for electric buses, trucks, and other commercial vehicles due to their excellent thermal stability, long cycle life, and high power density.

In addition to EVs, the smart transportation ecosystem encompasses a wide range of applications that can benefit from LiFePO4 battery technology. These include electric scooters, e-bikes, and other micromobility solutions that are gaining popularity in urban areas. The growing trend of shared mobility services further amplifies the demand for reliable and durable battery solutions in these applications.

Smart infrastructure is another key driver of LiFePO4 battery demand in transportation. Intelligent traffic management systems, smart streetlights, and roadside sensors all require reliable power sources that can withstand harsh outdoor conditions. LiFePO4 batteries, with their wide operating temperature range and long service life, are ideal for powering these critical infrastructure components.

The market for energy storage systems in transportation hubs, such as railway stations and airports, is also expanding. These facilities require robust and safe battery solutions to manage peak energy demands, integrate renewable energy sources, and provide backup power. LiFePO4 batteries are well-positioned to meet these requirements, offering a balance of performance, safety, and cost-effectiveness.

As smart cities continue to evolve, the integration of transportation systems with other urban services creates new opportunities for LiFePO4 battery applications. For instance, vehicle-to-grid (V2G) technology, which allows EVs to feed energy back into the grid, relies on advanced battery systems that can handle frequent charging and discharging cycles – a characteristic where LiFePO4 batteries excel.

The maritime sector is another area where LiFePO4 batteries are gaining traction. Electric and hybrid vessels for short-sea shipping, ferries, and port operations are increasingly adopting these batteries due to their safety profile and ability to deliver high power output.

While the market demand for LiFePO4 batteries in smart transportation is strong, it is important to note that the technology faces competition from other battery chemistries, such as nickel-manganese-cobalt (NMC) and solid-state batteries. However, the unique combination of safety, longevity, and cost-effectiveness positions LiFePO4 batteries as a compelling choice for many smart transportation applications.

LFP Battery Tech Challenges

Despite the widespread adoption of Lithium Iron Phosphate (LFP) batteries in smart transportation systems, several technical challenges persist that hinder their full potential. One of the primary issues is the relatively low energy density of LFP batteries compared to other lithium-ion chemistries. This limitation impacts the driving range of electric vehicles, necessitating larger battery packs and potentially increasing vehicle weight and cost.

Another significant challenge is the temperature sensitivity of LFP batteries. While they perform well at room temperature, their performance can degrade significantly in extreme cold or hot conditions. This poses difficulties for smart transportation applications in regions with harsh climates, affecting both charging speeds and overall battery life.

The charging rate of LFP batteries also presents a challenge, particularly for fast-charging applications in smart transportation. Although LFP batteries are generally considered safer and more stable than other lithium-ion chemistries, their charging speed is still limited to maintain battery health and longevity. This constraint can lead to longer charging times, which may be problematic for commercial fleet operations and long-distance travel scenarios.

Cycle life and capacity fade remain areas of concern, especially in high-utilization scenarios common in smart transportation systems. While LFP batteries generally offer good cycle life, continuous rapid charging and discharging can accelerate capacity loss over time. This degradation affects the long-term reliability and cost-effectiveness of LFP-powered vehicles and infrastructure.

Manufacturing scalability and cost reduction present ongoing challenges for the LFP battery industry. As demand for electric vehicles and smart transportation solutions grows, there is a pressing need to increase production capacity while simultaneously reducing costs. This requires advancements in manufacturing processes, material sourcing, and supply chain optimization.

Lastly, the integration of LFP batteries with smart grid systems and vehicle-to-grid (V2G) technologies poses technical hurdles. Developing efficient bidirectional charging systems, optimizing battery management for grid support functions, and ensuring seamless communication between vehicles and the power grid are complex tasks that require further innovation and standardization efforts.

Addressing these technical challenges is crucial for the continued advancement of LFP battery applications in smart transportation systems. Overcoming these hurdles will pave the way for more efficient, reliable, and cost-effective electric mobility solutions, ultimately accelerating the transition to sustainable transportation infrastructure.

Another significant challenge is the temperature sensitivity of LFP batteries. While they perform well at room temperature, their performance can degrade significantly in extreme cold or hot conditions. This poses difficulties for smart transportation applications in regions with harsh climates, affecting both charging speeds and overall battery life.

The charging rate of LFP batteries also presents a challenge, particularly for fast-charging applications in smart transportation. Although LFP batteries are generally considered safer and more stable than other lithium-ion chemistries, their charging speed is still limited to maintain battery health and longevity. This constraint can lead to longer charging times, which may be problematic for commercial fleet operations and long-distance travel scenarios.

Cycle life and capacity fade remain areas of concern, especially in high-utilization scenarios common in smart transportation systems. While LFP batteries generally offer good cycle life, continuous rapid charging and discharging can accelerate capacity loss over time. This degradation affects the long-term reliability and cost-effectiveness of LFP-powered vehicles and infrastructure.

Manufacturing scalability and cost reduction present ongoing challenges for the LFP battery industry. As demand for electric vehicles and smart transportation solutions grows, there is a pressing need to increase production capacity while simultaneously reducing costs. This requires advancements in manufacturing processes, material sourcing, and supply chain optimization.

Lastly, the integration of LFP batteries with smart grid systems and vehicle-to-grid (V2G) technologies poses technical hurdles. Developing efficient bidirectional charging systems, optimizing battery management for grid support functions, and ensuring seamless communication between vehicles and the power grid are complex tasks that require further innovation and standardization efforts.

Addressing these technical challenges is crucial for the continued advancement of LFP battery applications in smart transportation systems. Overcoming these hurdles will pave the way for more efficient, reliable, and cost-effective electric mobility solutions, ultimately accelerating the transition to sustainable transportation infrastructure.

Current LFP Solutions

01 Electrode material composition and preparation

Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

- Battery structure and assembly: Advancements in the design and assembly of lithium iron phosphate batteries. This encompasses innovations in cell architecture, electrode stacking or winding techniques, and the integration of components such as separators and current collectors to improve energy density and overall battery performance.

- Electrolyte formulations: Development of novel electrolyte formulations for lithium iron phosphate batteries. This includes the use of additives, ionic liquids, or solid-state electrolytes to enhance battery safety, cycling stability, and performance across a wide temperature range.

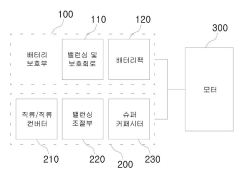

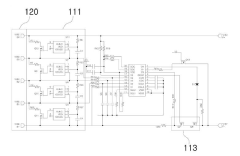

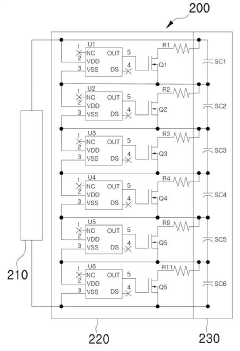

- Battery management and control systems: Innovations in battery management systems (BMS) and control algorithms specifically designed for lithium iron phosphate batteries. This includes advanced state-of-charge estimation, thermal management, and balancing techniques to optimize battery life and performance.

- Manufacturing processes and quality control: Advancements in manufacturing processes and quality control techniques for lithium iron phosphate batteries. This includes innovations in electrode coating, cell assembly automation, and in-line inspection methods to improve production efficiency and ensure consistent battery quality.

02 Battery cell design and assembly

Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.Expand Specific Solutions03 Battery management and control systems

Development of sophisticated battery management and control systems for lithium iron phosphate batteries. This includes algorithms for state-of-charge estimation, thermal management, balancing techniques, and safety monitoring to optimize battery performance and longevity.Expand Specific Solutions04 Manufacturing processes and scalability

Innovations in manufacturing processes and scalability of lithium iron phosphate batteries. This covers advancements in production techniques, automation, quality control measures, and cost-effective scaling strategies to meet growing demand for these batteries.Expand Specific Solutions05 Application-specific battery designs

Development of lithium iron phosphate batteries tailored for specific applications. This includes customized designs for electric vehicles, renewable energy storage, and portable electronics, focusing on optimizing performance characteristics such as power density, fast charging capabilities, and cycle life for each use case.Expand Specific Solutions

Key LFP Battery Manufacturers

The Lithium Iron Phosphate (LFP) battery market for smart transportation systems is in a growth phase, driven by increasing demand for electric vehicles and sustainable energy solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, LFP batteries are relatively mature, offering advantages in safety, cost, and longevity. Key players like CATL, BYD, and A123 Systems are leading innovation, while companies such as LG Energy Solution and Toyota are also making significant strides. The competitive landscape is intensifying as more automotive manufacturers and technology firms enter the market, driving further advancements in energy density, charging speed, and integration with smart transportation infrastructure.

A123 Systems LLC

Technical Solution: A123 Systems specializes in LFP battery technology for smart transportation applications. Their Nanophosphate® LFP chemistry offers high power density and exceptional thermal stability, making it ideal for demanding transportation environments[13]. A123's batteries feature a patented electrode design that enhances ion flow, resulting in improved charge acceptance and up to 25% higher power output compared to conventional LFP cells[14]. For smart transportation systems, A123 has developed an intelligent battery management platform that utilizes edge computing to process real-time data, enabling predictive maintenance and optimizing battery performance across vehicle fleets[15].

Strengths: High power density, excellent thermal stability, advanced electrode design, and intelligent fleet management capabilities. Weaknesses: Slightly lower energy density compared to some competitors, potentially higher production costs due to specialized materials.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed LFP batteries tailored for smart transportation systems, focusing on high power density and fast charging capabilities. Their LFP cells utilize a unique doping process that enhances conductivity, allowing for 0-80% charging in under 20 minutes[10]. LG's smart battery management system incorporates machine learning algorithms to adapt to individual driving patterns, optimizing performance and extending battery life by up to 20%[11]. For smart city applications, LG's LFP batteries are designed with vehicle-to-everything (V2X) compatibility, enabling seamless integration with smart grid infrastructure and supporting dynamic energy management in urban environments[12].

Strengths: Fast charging capability, adaptive BMS with ML, V2X compatibility for smart city integration. Weaknesses: Slightly lower energy density compared to their own NMC offerings, higher initial cost due to advanced features.

Core LFP Innovations

Smart battery system for two-wheeled vehicles

PatentActiveKR1020230105762A

Innovation

- An integrated battery system using supercapacitors and lithium-iron phosphate batteries, controlled by a single battery protection circuit, enhances startability and efficiency while incorporating a Bluetooth-enabled locking mechanism.

Lithium iron phosphate battery and hybrid vehicle

PatentPendingEP4567928A1

Innovation

- The lithium iron phosphate battery incorporates both large-particle and small-particle cathode and anode active materials, combining their advantages to improve rate performance, cycle performance, and energy efficiency.

LFP Battery Safety Standards

Safety standards for Lithium Iron Phosphate (LFP) batteries in smart transportation systems are crucial for ensuring the reliability and security of these energy storage solutions. The development of these standards has been driven by the increasing adoption of LFP batteries in electric vehicles, public transportation, and other smart mobility applications.

International organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established comprehensive safety standards for LFP batteries. These standards cover various aspects, including thermal management, electrical safety, mechanical integrity, and fire prevention.

One of the key safety standards for LFP batteries is IEC 62619, which specifies requirements for the safe operation of lithium-ion cells and batteries in industrial applications. This standard addresses issues such as overcharging, short circuits, and thermal runaway, providing guidelines for manufacturers to design and produce safer battery systems.

In the automotive sector, SAE J2464 is a widely recognized standard that outlines safety and abuse testing for electric vehicle batteries. This standard includes tests for mechanical shock, vibration, thermal cycling, and overcharge protection, ensuring that LFP batteries can withstand the rigors of vehicular use.

The United Nations has also developed regulations for the transportation of lithium batteries, including LFP batteries. UN 38.3 specifies a series of tests that batteries must pass to be considered safe for air, sea, and ground transportation. These tests evaluate the battery's performance under various environmental and physical stresses.

For smart transportation systems, additional safety considerations are necessary due to the integration of LFP batteries with intelligent control systems. Standards such as ISO 26262, which focuses on functional safety for road vehicles, are being adapted to address the unique challenges posed by battery-powered smart transportation.

Manufacturers and operators of smart transportation systems must also comply with regional safety regulations. In the United States, for example, the National Highway Traffic Safety Administration (NHTSA) has established guidelines for electric vehicle safety, which include provisions for battery safety and crash protection.

As the technology evolves, safety standards for LFP batteries in smart transportation systems continue to be refined. Emerging areas of focus include cybersecurity measures to protect battery management systems from potential hacking attempts and the development of advanced diagnostic tools for real-time monitoring of battery health and safety parameters.

The implementation of these safety standards has significantly improved the reliability and public perception of LFP batteries in smart transportation applications. However, ongoing research and development efforts are essential to address new challenges and ensure that safety standards keep pace with technological advancements in the field.

International organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established comprehensive safety standards for LFP batteries. These standards cover various aspects, including thermal management, electrical safety, mechanical integrity, and fire prevention.

One of the key safety standards for LFP batteries is IEC 62619, which specifies requirements for the safe operation of lithium-ion cells and batteries in industrial applications. This standard addresses issues such as overcharging, short circuits, and thermal runaway, providing guidelines for manufacturers to design and produce safer battery systems.

In the automotive sector, SAE J2464 is a widely recognized standard that outlines safety and abuse testing for electric vehicle batteries. This standard includes tests for mechanical shock, vibration, thermal cycling, and overcharge protection, ensuring that LFP batteries can withstand the rigors of vehicular use.

The United Nations has also developed regulations for the transportation of lithium batteries, including LFP batteries. UN 38.3 specifies a series of tests that batteries must pass to be considered safe for air, sea, and ground transportation. These tests evaluate the battery's performance under various environmental and physical stresses.

For smart transportation systems, additional safety considerations are necessary due to the integration of LFP batteries with intelligent control systems. Standards such as ISO 26262, which focuses on functional safety for road vehicles, are being adapted to address the unique challenges posed by battery-powered smart transportation.

Manufacturers and operators of smart transportation systems must also comply with regional safety regulations. In the United States, for example, the National Highway Traffic Safety Administration (NHTSA) has established guidelines for electric vehicle safety, which include provisions for battery safety and crash protection.

As the technology evolves, safety standards for LFP batteries in smart transportation systems continue to be refined. Emerging areas of focus include cybersecurity measures to protect battery management systems from potential hacking attempts and the development of advanced diagnostic tools for real-time monitoring of battery health and safety parameters.

The implementation of these safety standards has significantly improved the reliability and public perception of LFP batteries in smart transportation applications. However, ongoing research and development efforts are essential to address new challenges and ensure that safety standards keep pace with technological advancements in the field.

Environmental Impact of LFP

The environmental impact of Lithium Iron Phosphate (LFP) batteries in smart transportation systems is a critical consideration as these energy storage solutions become increasingly prevalent. LFP batteries offer several environmental advantages compared to traditional lead-acid batteries and other lithium-ion chemistries.

One of the primary environmental benefits of LFP batteries is their long cycle life, which can exceed 2000 cycles. This extended lifespan reduces the frequency of battery replacements, thereby minimizing waste generation and the need for raw material extraction. Additionally, LFP batteries do not contain toxic heavy metals like lead or cadmium, making them safer for the environment throughout their lifecycle.

The production of LFP batteries also has a lower environmental footprint compared to other lithium-ion chemistries. The cathode material, lithium iron phosphate, is abundant and can be synthesized using less energy-intensive processes. This results in reduced greenhouse gas emissions during manufacturing. Furthermore, the absence of cobalt in LFP batteries alleviates concerns related to unethical mining practices and environmental degradation associated with cobalt extraction.

In smart transportation systems, LFP batteries contribute to reduced emissions and improved air quality. Electric vehicles powered by LFP batteries produce zero direct emissions, helping to decrease urban pollution levels. The batteries' high thermal stability and safety characteristics also minimize the risk of thermal runaway and fire incidents, reducing potential environmental hazards during operation and accidents.

End-of-life management for LFP batteries presents both challenges and opportunities. While recycling processes for LFP batteries are less developed compared to other lithium-ion chemistries, ongoing research is improving recycling efficiencies. The batteries' composition allows for easier separation of materials, potentially enabling more effective recycling and recovery of valuable components.

The use of LFP batteries in smart transportation systems also supports the integration of renewable energy sources. Their ability to handle frequent charge-discharge cycles makes them suitable for grid energy storage applications, facilitating the increased adoption of intermittent renewable energy sources like solar and wind power. This indirect effect further contributes to reducing the overall carbon footprint of transportation systems.

However, it is important to note that the environmental impact of LFP batteries is not entirely benign. The extraction of lithium and other raw materials still has environmental consequences, including water consumption and potential ecosystem disruption in mining areas. Additionally, the energy-intensive battery production process continues to rely on fossil fuels in many regions, offsetting some of the environmental benefits.

One of the primary environmental benefits of LFP batteries is their long cycle life, which can exceed 2000 cycles. This extended lifespan reduces the frequency of battery replacements, thereby minimizing waste generation and the need for raw material extraction. Additionally, LFP batteries do not contain toxic heavy metals like lead or cadmium, making them safer for the environment throughout their lifecycle.

The production of LFP batteries also has a lower environmental footprint compared to other lithium-ion chemistries. The cathode material, lithium iron phosphate, is abundant and can be synthesized using less energy-intensive processes. This results in reduced greenhouse gas emissions during manufacturing. Furthermore, the absence of cobalt in LFP batteries alleviates concerns related to unethical mining practices and environmental degradation associated with cobalt extraction.

In smart transportation systems, LFP batteries contribute to reduced emissions and improved air quality. Electric vehicles powered by LFP batteries produce zero direct emissions, helping to decrease urban pollution levels. The batteries' high thermal stability and safety characteristics also minimize the risk of thermal runaway and fire incidents, reducing potential environmental hazards during operation and accidents.

End-of-life management for LFP batteries presents both challenges and opportunities. While recycling processes for LFP batteries are less developed compared to other lithium-ion chemistries, ongoing research is improving recycling efficiencies. The batteries' composition allows for easier separation of materials, potentially enabling more effective recycling and recovery of valuable components.

The use of LFP batteries in smart transportation systems also supports the integration of renewable energy sources. Their ability to handle frequent charge-discharge cycles makes them suitable for grid energy storage applications, facilitating the increased adoption of intermittent renewable energy sources like solar and wind power. This indirect effect further contributes to reducing the overall carbon footprint of transportation systems.

However, it is important to note that the environmental impact of LFP batteries is not entirely benign. The extraction of lithium and other raw materials still has environmental consequences, including water consumption and potential ecosystem disruption in mining areas. Additionally, the energy-intensive battery production process continues to rely on fossil fuels in many regions, offsetting some of the environmental benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!