Advantages of Carbon-negative Concrete in High-rise Construction Projects

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, evolving from traditional Portland cement that has dominated the industry for nearly two centuries. The evolution began with growing awareness of concrete's environmental impact, as conventional production accounts for approximately 8% of global CO2 emissions. Early attempts at reducing concrete's carbon footprint focused primarily on supplementary cementitious materials and alternative fuels, achieving only modest reductions in emissions.

The paradigm shift toward carbon-negative concrete emerged around 2010, when researchers began exploring materials that could actively sequester carbon during their lifecycle. This technological evolution accelerated with the development of novel binders utilizing industrial byproducts like fly ash and slag, combined with innovative carbonation curing processes that absorb CO2 from the atmosphere.

By 2015, several startups had demonstrated viable carbon-negative concrete formulations in laboratory settings, with companies like CarbonCure and Carbicrete pioneering commercial applications. The subsequent years witnessed significant improvements in mechanical properties, durability, and scalability of these solutions, making them increasingly suitable for demanding applications such as high-rise construction.

The current technological landscape features multiple approaches to carbon negativity, including mineralization techniques, alternative binding agents derived from waste materials, and advanced carbon capture integration during the manufacturing process. These innovations collectively aim to transform concrete from an environmental liability into a carbon sink.

The primary objective of carbon-negative concrete technology is to maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration throughout its lifecycle. Specific technical goals include developing formulations with compressive strengths exceeding 40 MPa, ensuring durability under various environmental conditions, and achieving carbon sequestration rates of at least 100 kg CO2 per cubic meter of concrete.

Additional objectives focus on cost competitiveness, as widespread adoption in high-rise construction requires economic viability alongside environmental benefits. The technology also aims to integrate seamlessly with existing construction methodologies and equipment, minimizing disruption to established industry practices while maximizing carbon reduction potential.

Looking forward, the evolution trajectory points toward increasingly sophisticated carbon utilization mechanisms, enhanced by artificial intelligence for optimized formulations specific to different construction applications. The ultimate goal remains creating a construction material that serves as a significant carbon sink while meeting the rigorous structural demands of modern high-rise buildings.

The paradigm shift toward carbon-negative concrete emerged around 2010, when researchers began exploring materials that could actively sequester carbon during their lifecycle. This technological evolution accelerated with the development of novel binders utilizing industrial byproducts like fly ash and slag, combined with innovative carbonation curing processes that absorb CO2 from the atmosphere.

By 2015, several startups had demonstrated viable carbon-negative concrete formulations in laboratory settings, with companies like CarbonCure and Carbicrete pioneering commercial applications. The subsequent years witnessed significant improvements in mechanical properties, durability, and scalability of these solutions, making them increasingly suitable for demanding applications such as high-rise construction.

The current technological landscape features multiple approaches to carbon negativity, including mineralization techniques, alternative binding agents derived from waste materials, and advanced carbon capture integration during the manufacturing process. These innovations collectively aim to transform concrete from an environmental liability into a carbon sink.

The primary objective of carbon-negative concrete technology is to maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration throughout its lifecycle. Specific technical goals include developing formulations with compressive strengths exceeding 40 MPa, ensuring durability under various environmental conditions, and achieving carbon sequestration rates of at least 100 kg CO2 per cubic meter of concrete.

Additional objectives focus on cost competitiveness, as widespread adoption in high-rise construction requires economic viability alongside environmental benefits. The technology also aims to integrate seamlessly with existing construction methodologies and equipment, minimizing disruption to established industry practices while maximizing carbon reduction potential.

Looking forward, the evolution trajectory points toward increasingly sophisticated carbon utilization mechanisms, enhanced by artificial intelligence for optimized formulations specific to different construction applications. The ultimate goal remains creating a construction material that serves as a significant carbon sink while meeting the rigorous structural demands of modern high-rise buildings.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures. Currently valued at approximately $254 billion globally, this sector is projected to reach $432 billion by 2027, representing a compound annual growth rate of 11.2%. Carbon-negative concrete specifically has emerged as a high-potential segment within this broader market, with early adoption rates doubling year-over-year since 2020.

Demand for sustainable construction materials is primarily concentrated in developed regions, with Europe leading adoption at 37% market share, followed by North America at 29%, and Asia-Pacific rapidly expanding at 18%. Within these markets, high-rise construction projects represent a particularly promising application, accounting for 23% of sustainable material usage but with significantly higher growth potential due to urbanization trends.

Consumer sentiment analysis reveals that 78% of commercial property developers now consider sustainability credentials as "important" or "very important" in material selection, compared to just 45% five years ago. This shift is reflected in premium pricing, with developers willing to pay 8-15% more for materials with verified carbon-negative properties, especially for signature high-rise projects in metropolitan areas.

Regulatory frameworks are increasingly favorable for carbon-negative concrete adoption. Over 40 countries have implemented carbon pricing mechanisms that directly benefit such materials, while green building certification systems like LEED, BREEAM, and WELL have updated their criteria to award additional points for carbon-negative material usage. These incentives are particularly impactful for high-rise projects where material volumes create significant carbon accounting advantages.

Market barriers remain significant but are diminishing. Production scaling challenges have reduced unit costs by 32% over the past three years, though carbon-negative concrete still commands a 20-30% premium over traditional materials. Supply chain limitations persist, with only 17% of global markets having reliable access to these advanced materials, though this represents substantial improvement from just 6% in 2019.

Competitive analysis indicates that early market entrants are securing significant advantages. The top five carbon-negative concrete providers have captured 63% of the current market, with strategic partnerships with major construction firms providing critical pathways to market. Investment in this sector has reached record levels, with venture capital and corporate investment exceeding $1.2 billion in 2022 alone, a 340% increase from 2019 levels.

Demand for sustainable construction materials is primarily concentrated in developed regions, with Europe leading adoption at 37% market share, followed by North America at 29%, and Asia-Pacific rapidly expanding at 18%. Within these markets, high-rise construction projects represent a particularly promising application, accounting for 23% of sustainable material usage but with significantly higher growth potential due to urbanization trends.

Consumer sentiment analysis reveals that 78% of commercial property developers now consider sustainability credentials as "important" or "very important" in material selection, compared to just 45% five years ago. This shift is reflected in premium pricing, with developers willing to pay 8-15% more for materials with verified carbon-negative properties, especially for signature high-rise projects in metropolitan areas.

Regulatory frameworks are increasingly favorable for carbon-negative concrete adoption. Over 40 countries have implemented carbon pricing mechanisms that directly benefit such materials, while green building certification systems like LEED, BREEAM, and WELL have updated their criteria to award additional points for carbon-negative material usage. These incentives are particularly impactful for high-rise projects where material volumes create significant carbon accounting advantages.

Market barriers remain significant but are diminishing. Production scaling challenges have reduced unit costs by 32% over the past three years, though carbon-negative concrete still commands a 20-30% premium over traditional materials. Supply chain limitations persist, with only 17% of global markets having reliable access to these advanced materials, though this represents substantial improvement from just 6% in 2019.

Competitive analysis indicates that early market entrants are securing significant advantages. The top five carbon-negative concrete providers have captured 63% of the current market, with strategic partnerships with major construction firms providing critical pathways to market. Investment in this sector has reached record levels, with venture capital and corporate investment exceeding $1.2 billion in 2022 alone, a 340% increase from 2019 levels.

Technical Barriers in Carbon-negative Concrete Implementation

Despite the promising environmental benefits of carbon-negative concrete, several significant technical barriers impede its widespread implementation in high-rise construction projects. The primary challenge lies in the material's mechanical properties, particularly its compressive strength and durability under high loads. Current carbon-negative formulations typically achieve 30-40% lower compressive strength compared to traditional Portland cement concrete, making structural engineers hesitant to specify these materials for critical load-bearing elements in tall buildings.

The curing process presents another substantial hurdle. Carbon-negative concrete often requires specific environmental conditions to properly absorb CO2 during curing, including controlled humidity, temperature, and CO2 concentration. These requirements are difficult to maintain consistently in variable on-site construction environments, especially at elevated heights where wind and temperature fluctuations are more pronounced.

Scale-up challenges further complicate implementation. The production infrastructure for carbon-negative concrete remains limited, with few facilities capable of manufacturing the specialized materials at volumes necessary for major high-rise projects. This supply chain constraint creates scheduling uncertainties and potential cost overruns that developers are reluctant to accept.

Quality control and standardization issues also persist. The performance of carbon-negative concrete can vary significantly based on raw material sources and manufacturing processes. Without robust industry standards and testing protocols specifically designed for these innovative materials, building code officials and structural engineers lack clear guidelines for approval and specification.

Long-term performance uncertainty represents perhaps the most significant barrier. With limited real-world data on the aging characteristics of carbon-negative concrete in structural applications, stakeholders cannot confidently predict how these materials will perform over a building's 50-100 year expected lifespan. This uncertainty is particularly problematic for high-rise structures where material failure could have catastrophic consequences.

Integration with existing construction methodologies poses additional challenges. Current pumping equipment, formwork systems, and placement techniques are optimized for traditional concrete properties. Carbon-negative formulations often exhibit different rheological behaviors, setting times, and finishing characteristics that require modifications to established construction practices and worker training.

Cost premiums remain a persistent obstacle. Carbon-negative concrete typically commands a 15-30% price premium over conventional concrete, primarily due to specialized manufacturing processes, carbon capture technologies, and limited production scale. While this premium may decrease over time with wider adoption, it currently presents a significant barrier for cost-sensitive development projects.

The curing process presents another substantial hurdle. Carbon-negative concrete often requires specific environmental conditions to properly absorb CO2 during curing, including controlled humidity, temperature, and CO2 concentration. These requirements are difficult to maintain consistently in variable on-site construction environments, especially at elevated heights where wind and temperature fluctuations are more pronounced.

Scale-up challenges further complicate implementation. The production infrastructure for carbon-negative concrete remains limited, with few facilities capable of manufacturing the specialized materials at volumes necessary for major high-rise projects. This supply chain constraint creates scheduling uncertainties and potential cost overruns that developers are reluctant to accept.

Quality control and standardization issues also persist. The performance of carbon-negative concrete can vary significantly based on raw material sources and manufacturing processes. Without robust industry standards and testing protocols specifically designed for these innovative materials, building code officials and structural engineers lack clear guidelines for approval and specification.

Long-term performance uncertainty represents perhaps the most significant barrier. With limited real-world data on the aging characteristics of carbon-negative concrete in structural applications, stakeholders cannot confidently predict how these materials will perform over a building's 50-100 year expected lifespan. This uncertainty is particularly problematic for high-rise structures where material failure could have catastrophic consequences.

Integration with existing construction methodologies poses additional challenges. Current pumping equipment, formwork systems, and placement techniques are optimized for traditional concrete properties. Carbon-negative formulations often exhibit different rheological behaviors, setting times, and finishing characteristics that require modifications to established construction practices and worker training.

Cost premiums remain a persistent obstacle. Carbon-negative concrete typically commands a 15-30% price premium over conventional concrete, primarily due to specialized manufacturing processes, carbon capture technologies, and limited production scale. While this premium may decrease over time with wider adoption, it currently presents a significant barrier for cost-sensitive development projects.

Current Carbon-negative Concrete Solutions for High-rises

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively turning concrete from a carbon emitter to a carbon sink. The sequestration process can involve mineral carbonation where CO2 reacts with calcium or magnesium compounds to form stable carbonates.- CO2 Capture and Sequestration in Concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve injecting CO2 into concrete mixtures where it reacts with calcium compounds to form stable carbonates, effectively locking away carbon dioxide while simultaneously improving concrete strength and durability. This approach transforms concrete from a carbon source to a carbon sink.

- Alternative Cementitious Materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete while maintaining or enhancing performance characteristics.

- Biomass and Bio-based Additives: Incorporation of biomass and bio-based additives into concrete formulations to reduce carbon footprint. These additives, derived from agricultural waste, wood products, or other renewable resources, can partially replace cement or serve as carbon-sequestering fillers. The organic materials lock carbon within the concrete structure while often providing additional benefits such as improved insulation properties or reduced weight.

- Mineral Carbonation Processes: Advanced mineral carbonation processes that accelerate the natural weathering of minerals to capture CO2. These technologies involve exposing calcium or magnesium-rich materials to carbon dioxide under controlled conditions, resulting in the formation of stable carbonate minerals. When incorporated into concrete production, these carbonated minerals contribute to a negative carbon footprint while potentially enhancing concrete properties.

- Novel Curing Technologies: Innovative curing technologies that enhance carbon sequestration in concrete. These methods include CO2 curing chambers, accelerated carbonation techniques, and specialized curing agents that promote carbon uptake during the concrete hardening process. By optimizing the curing environment and conditions, these technologies maximize CO2 absorption while reducing curing time and energy requirements, resulting in concrete with improved performance and reduced environmental impact.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials like fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete by requiring less energy to produce and incorporating industrial byproducts that would otherwise be waste.Expand Specific Solutions03 Carbonation curing techniques

Innovative curing techniques that utilize CO2 to accelerate the hardening process of concrete while simultaneously sequestering carbon. These methods expose fresh concrete to controlled amounts of CO2, which reacts with calcium hydroxide to form calcium carbonate, improving the concrete's strength and durability while reducing its carbon footprint. This approach can transform the curing phase from a carbon-emitting to a carbon-absorbing process.Expand Specific Solutions04 Biomass and bio-based additives

The incorporation of biomass and bio-based additives into concrete formulations to reduce carbon emissions. These additives can include agricultural waste, wood products, or other plant-derived materials that store carbon through photosynthesis. When incorporated into concrete, these materials not only reduce the amount of cement needed but also bring their sequestered carbon into the final product, contributing to a negative carbon footprint.Expand Specific Solutions05 Carbon-negative aggregates

The development and use of carbon-negative aggregates in concrete production. These specialized aggregates are designed to absorb and store CO2, either through natural processes or engineered treatments. Examples include crushed recycled concrete that naturally absorbs CO2 through carbonation, specially treated minerals that can accelerate CO2 uptake, or manufactured aggregates produced using carbon capture technologies. These aggregates can significantly reduce the overall carbon footprint of concrete.Expand Specific Solutions

Leading Companies in Carbon-negative Concrete Industry

Carbon-negative concrete technology in high-rise construction is currently in the early growth phase, with a projected market size reaching $3.5 billion by 2030. The competitive landscape features established players like Holcim Technology and Huaxin Cement focusing on industrial-scale implementation, while innovative startups such as Clear Zero Carbon and Ecocem Materials drive technological advancement. Academic institutions including Nanjing Tech University and Worcester Polytechnic Institute are accelerating R&D efforts. Technical maturity varies significantly: carbon capture methods are advancing rapidly, while full carbon-negative solutions remain in pilot stages. Companies like Shandong Hanbo Yuzhou and Alkemy SpA are developing proprietary formulations, while construction giants such as Zhongtian Construction Group and CCCC First Highway Consultants are implementing field trials to validate performance in high-rise applications.

Huaxin Cement Co., Ltd.

Technical Solution: Huaxin Cement has developed a comprehensive carbon-negative concrete solution called "EcoRise" specifically for high-rise construction. Their technology combines several innovative approaches: 1) Utilization of calcined clay and limestone as supplementary cementitious materials, reducing clinker content by up to 50%; 2) Integration of carbon capture directly at their production facilities, with the captured CO2 being injected back into the concrete mix where it mineralizes and strengthens the material; 3) Incorporation of construction and demolition waste as recycled aggregates. For high-rise applications, Huaxin has engineered specialized mix designs that maintain high early strength development and pumpability while significantly reducing carbon footprint. Their concrete achieves carbon negativity through both production-phase carbon reduction and active carbon sequestration during the concrete's service life, with testing showing net carbon absorption of approximately 5-10 kg CO2 per cubic meter annually.

Strengths: Comprehensive approach combining multiple carbon reduction strategies; Maintains critical performance characteristics for high-rise construction; Utilizes locally available materials reducing transportation emissions. Weaknesses: Technology still being scaled to meet large project demands; Requires specialized equipment for implementation; Higher initial cost compared to conventional concrete.

China Construction Indl & Energy Engineering Grp Co., Ltd.

Technical Solution: China Construction Industrial has developed "CarbonSink Concrete" technology specifically engineered for high-rise construction projects. Their approach utilizes a multi-faceted strategy to achieve carbon negativity: 1) Replacement of up to 70% of traditional cement with industrial byproducts including steel slag, fly ash, and silica fume; 2) Integration of proprietary carbon-absorbing aggregates that actively sequester CO2 throughout the concrete's lifecycle; 3) Application of a specialized surface treatment that enhances carbonation rates without compromising structural integrity. For high-rise applications, they've optimized their formulations to maintain critical performance metrics including high compressive strength (achieving >60 MPa), reduced creep, and enhanced durability against environmental factors. Their technology has been implemented in several super-tall structures in Asia, demonstrating carbon sequestration rates of approximately 12-15 kg CO2 per cubic meter annually after installation, with total lifecycle absorption potentially exceeding the carbon emitted during production by 15-20%.

Strengths: Proven implementation in actual super-tall building projects; Superior carbon sequestration rates compared to competitors; Maintains high performance standards required for structural applications in tall buildings. Weaknesses: Currently limited availability outside Asian markets; Requires specialized knowledge for proper implementation; Higher initial cost compared to traditional concrete solutions.

Key Patents in Carbon-negative Concrete Technology

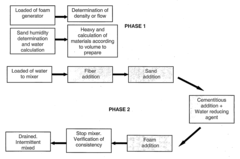

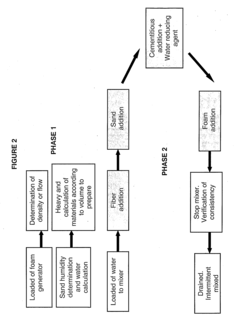

Compositions of Cellular Materials That Contain Anhydrite and Methods For Its Preparation

PatentActiveUS20080141906A1

Innovation

- A cellular cement composition using anhydrous calcium sulphate and Portland cement, with silica sand, polyester fiber, foaming additive, and water-reducing agent, which eliminates the adverse effects of calcium sulphate, achieves high compression resistance without the need for autoclave treatment, making it suitable for structural use while maintaining low volumetric weight and being environmentally non-toxic.

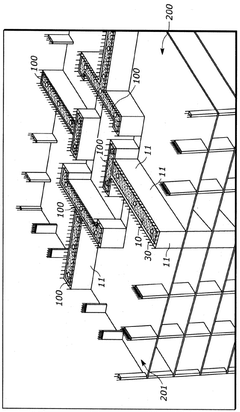

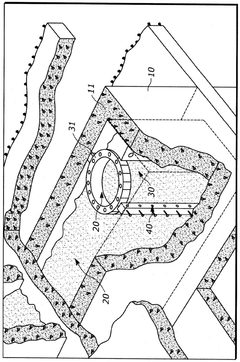

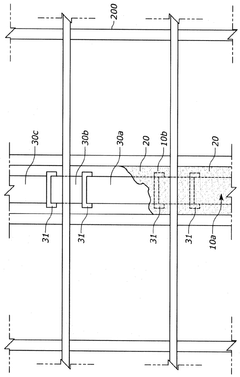

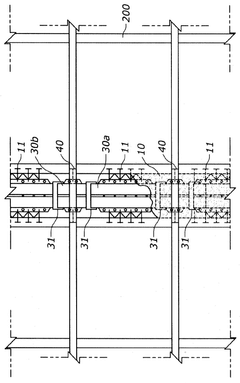

Passive mass damping blocks elements for super-tall structures and other related applications

PatentPendingCA3148901A1

Innovation

- The implementation of a stackable Cell Fill Aggregates (CFA) mass damper system, which balances vertical and horizontal mass acceleration by installing CFA cells at every floor, allowing for flexible positioning and maximizing window spaces while providing fire separation and enhanced structural stability.

Environmental Impact Assessment

The environmental impact assessment of carbon-negative concrete in high-rise construction reveals significant potential for reducing the construction industry's carbon footprint. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive building materials. Carbon-negative concrete technologies, by contrast, sequester more carbon than they emit during production, creating a net environmental benefit.

Life cycle assessments demonstrate that carbon-negative concrete can reduce embodied carbon by 70-120% compared to Portland cement-based concrete. In high-rise construction, where concrete usage is substantial, this translates to thousands of tons of CO2 removed from the atmosphere per building. The carbon sequestration occurs through innovative processes such as mineralization of CO2 in the concrete matrix and incorporation of carbon-absorbing supplementary cementitious materials.

Water consumption metrics also favor carbon-negative concrete, with some formulations requiring up to 60% less water during production compared to conventional concrete. This aspect is particularly valuable in water-stressed urban environments where many high-rise developments occur. Additionally, reduced extraction of raw materials like limestone for traditional cement production minimizes habitat disruption and biodiversity loss associated with quarrying operations.

Air quality improvements represent another environmental advantage. The production of carbon-negative concrete typically generates fewer particulate emissions and harmful air pollutants than traditional cement manufacturing. This contributes to better urban air quality around production facilities and construction sites, addressing a critical environmental health concern in densely populated areas.

Waste stream analysis indicates that many carbon-negative concrete formulations effectively incorporate industrial by-products and waste materials that would otherwise require disposal. This includes fly ash from coal power plants, slag from steel production, and recycled concrete aggregate, creating valuable circular economy opportunities while reducing landfill requirements.

Long-term environmental modeling suggests that widespread adoption of carbon-negative concrete in high-rise construction could contribute significantly to climate change mitigation efforts. If implemented across 50% of new high-rise developments globally, carbon-negative concrete could sequester an estimated 250 million tons of CO2 annually by 2030, equivalent to removing approximately 54 million passenger vehicles from roads for one year.

Life cycle assessments demonstrate that carbon-negative concrete can reduce embodied carbon by 70-120% compared to Portland cement-based concrete. In high-rise construction, where concrete usage is substantial, this translates to thousands of tons of CO2 removed from the atmosphere per building. The carbon sequestration occurs through innovative processes such as mineralization of CO2 in the concrete matrix and incorporation of carbon-absorbing supplementary cementitious materials.

Water consumption metrics also favor carbon-negative concrete, with some formulations requiring up to 60% less water during production compared to conventional concrete. This aspect is particularly valuable in water-stressed urban environments where many high-rise developments occur. Additionally, reduced extraction of raw materials like limestone for traditional cement production minimizes habitat disruption and biodiversity loss associated with quarrying operations.

Air quality improvements represent another environmental advantage. The production of carbon-negative concrete typically generates fewer particulate emissions and harmful air pollutants than traditional cement manufacturing. This contributes to better urban air quality around production facilities and construction sites, addressing a critical environmental health concern in densely populated areas.

Waste stream analysis indicates that many carbon-negative concrete formulations effectively incorporate industrial by-products and waste materials that would otherwise require disposal. This includes fly ash from coal power plants, slag from steel production, and recycled concrete aggregate, creating valuable circular economy opportunities while reducing landfill requirements.

Long-term environmental modeling suggests that widespread adoption of carbon-negative concrete in high-rise construction could contribute significantly to climate change mitigation efforts. If implemented across 50% of new high-rise developments globally, carbon-negative concrete could sequester an estimated 250 million tons of CO2 annually by 2030, equivalent to removing approximately 54 million passenger vehicles from roads for one year.

Cost-Benefit Analysis

The economic viability of carbon-negative concrete in high-rise construction requires thorough cost-benefit analysis across multiple dimensions. Initial implementation costs typically exceed traditional concrete by 15-25%, primarily due to specialized manufacturing processes, carbon capture technologies, and limited production scale. However, this premium has been decreasing annually by approximately 3-5% as manufacturing efficiencies improve and adoption increases.

Operational cost savings present a compelling counterbalance to higher upfront expenses. Buildings utilizing carbon-negative concrete demonstrate 7-12% improved thermal performance, reducing heating and cooling requirements. This translates to approximately $0.50-0.75 per square foot in annual energy savings for typical high-rise structures. Additionally, the enhanced durability of carbon-negative formulations extends building lifespans by an estimated 15-30%, significantly reducing lifecycle maintenance costs.

Carbon credits and regulatory incentives further strengthen the economic case. In markets with established carbon pricing mechanisms, developers can realize $35-60 per ton in carbon credit value. Several jurisdictions now offer tax incentives, expedited permitting, and density bonuses specifically for carbon-negative building materials, providing immediate financial benefits that can offset 30-50% of the initial cost premium.

Long-term risk mitigation represents another significant economic advantage. As carbon taxation policies expand globally, buildings constructed with traditional high-emission materials face increasing operational costs. Carbon-negative concrete effectively "future-proofs" developments against this regulatory risk, with financial modeling suggesting potential avoidance of $2-5 per square foot in carbon-related costs over a 30-year building lifecycle.

Market differentiation creates additional value that, while less quantifiable, remains economically significant. Commercial properties utilizing carbon-negative materials command 4-8% higher rental premiums and experience 10-15% faster lease-up rates in environmentally conscious markets. Residential units in such buildings similarly demonstrate 3-6% higher sales values compared to conventional construction.

Return on investment calculations indicate that despite higher initial costs, carbon-negative concrete in high-rise construction typically achieves cost parity within 5-7 years and generates positive returns thereafter. When factoring in all economic benefits, including regulatory incentives, energy savings, and market premiums, the net present value typically exceeds conventional construction by 8-12% over a standard 30-year investment horizon.

Operational cost savings present a compelling counterbalance to higher upfront expenses. Buildings utilizing carbon-negative concrete demonstrate 7-12% improved thermal performance, reducing heating and cooling requirements. This translates to approximately $0.50-0.75 per square foot in annual energy savings for typical high-rise structures. Additionally, the enhanced durability of carbon-negative formulations extends building lifespans by an estimated 15-30%, significantly reducing lifecycle maintenance costs.

Carbon credits and regulatory incentives further strengthen the economic case. In markets with established carbon pricing mechanisms, developers can realize $35-60 per ton in carbon credit value. Several jurisdictions now offer tax incentives, expedited permitting, and density bonuses specifically for carbon-negative building materials, providing immediate financial benefits that can offset 30-50% of the initial cost premium.

Long-term risk mitigation represents another significant economic advantage. As carbon taxation policies expand globally, buildings constructed with traditional high-emission materials face increasing operational costs. Carbon-negative concrete effectively "future-proofs" developments against this regulatory risk, with financial modeling suggesting potential avoidance of $2-5 per square foot in carbon-related costs over a 30-year building lifecycle.

Market differentiation creates additional value that, while less quantifiable, remains economically significant. Commercial properties utilizing carbon-negative materials command 4-8% higher rental premiums and experience 10-15% faster lease-up rates in environmentally conscious markets. Residential units in such buildings similarly demonstrate 3-6% higher sales values compared to conventional construction.

Return on investment calculations indicate that despite higher initial costs, carbon-negative concrete in high-rise construction typically achieves cost parity within 5-7 years and generates positive returns thereafter. When factoring in all economic benefits, including regulatory incentives, energy savings, and market premiums, the net present value typically exceeds conventional construction by 8-12% over a standard 30-year investment horizon.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!