Carbon-negative Concrete: Transforming Waste into Building Material

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete, the most widely used building material globally, has traditionally been a significant contributor to carbon emissions, accounting for approximately 8% of global CO2 emissions. This environmental impact has driven the emergence of carbon-negative concrete technology, which represents a paradigm shift in construction materials by transforming waste products into valuable building components while actively sequestering carbon dioxide from the atmosphere.

The evolution of concrete technology has progressed through several key phases: from traditional Portland cement concrete with high carbon footprints, to low-carbon alternatives incorporating supplementary cementitious materials, and now to the revolutionary carbon-negative formulations. This progression reflects the construction industry's growing commitment to sustainability and circular economy principles.

Carbon-negative concrete technology leverages various waste streams, including industrial byproducts like fly ash, slag, and silica fume, as well as novel inputs such as recycled concrete aggregate, captured CO2, and biomass ash. These materials not only reduce the need for virgin resources but also permanently store carbon within the concrete matrix, effectively transforming a construction liability into an environmental asset.

The primary technical objective of carbon-negative concrete development is to create structural materials that meet or exceed conventional concrete performance standards while achieving net carbon sequestration throughout their lifecycle. This includes maintaining critical properties such as compressive strength, durability, workability, and setting time, while simultaneously reducing embodied carbon and enhancing carbon uptake mechanisms.

Market and regulatory pressures are accelerating the development timeline for these technologies. The global push toward carbon neutrality, embodied in agreements like the Paris Climate Accord and various national net-zero commitments, has established concrete decarbonization as a priority. Additionally, green building certification systems and emerging carbon pricing mechanisms are creating economic incentives for low-carbon construction materials.

Research objectives in this field include optimizing carbonation processes, developing scalable production methods, establishing reliable carbon accounting methodologies, and creating regulatory frameworks that recognize and reward carbon-negative building materials. The technology aims to transform concrete from a climate problem into a climate solution.

The ultimate goal extends beyond carbon neutrality to position concrete as an active carbon sink, potentially sequestering billions of tons of CO2 annually if widely adopted. This would represent a transformative contribution to global climate mitigation efforts while addressing the growing demand for construction materials in developing economies.

The evolution of concrete technology has progressed through several key phases: from traditional Portland cement concrete with high carbon footprints, to low-carbon alternatives incorporating supplementary cementitious materials, and now to the revolutionary carbon-negative formulations. This progression reflects the construction industry's growing commitment to sustainability and circular economy principles.

Carbon-negative concrete technology leverages various waste streams, including industrial byproducts like fly ash, slag, and silica fume, as well as novel inputs such as recycled concrete aggregate, captured CO2, and biomass ash. These materials not only reduce the need for virgin resources but also permanently store carbon within the concrete matrix, effectively transforming a construction liability into an environmental asset.

The primary technical objective of carbon-negative concrete development is to create structural materials that meet or exceed conventional concrete performance standards while achieving net carbon sequestration throughout their lifecycle. This includes maintaining critical properties such as compressive strength, durability, workability, and setting time, while simultaneously reducing embodied carbon and enhancing carbon uptake mechanisms.

Market and regulatory pressures are accelerating the development timeline for these technologies. The global push toward carbon neutrality, embodied in agreements like the Paris Climate Accord and various national net-zero commitments, has established concrete decarbonization as a priority. Additionally, green building certification systems and emerging carbon pricing mechanisms are creating economic incentives for low-carbon construction materials.

Research objectives in this field include optimizing carbonation processes, developing scalable production methods, establishing reliable carbon accounting methodologies, and creating regulatory frameworks that recognize and reward carbon-negative building materials. The technology aims to transform concrete from a climate problem into a climate solution.

The ultimate goal extends beyond carbon neutrality to position concrete as an active carbon sink, potentially sequestering billions of tons of CO2 annually if widely adopted. This would represent a transformative contribution to global climate mitigation efforts while addressing the growing demand for construction materials in developing economies.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $299 billion globally, this market is projected to reach $641 billion by 2030, with a compound annual growth rate of 11.4% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this category, with particular momentum in North America, Europe, and increasingly in Asia-Pacific regions.

Consumer demand patterns show a significant shift toward environmentally responsible building materials, with 78% of commercial construction projects now specifying some form of sustainable concrete alternative. This trend is particularly pronounced in public infrastructure projects, where government procurement policies increasingly mandate carbon footprint considerations. The premium pricing tolerance for carbon-negative concrete has also evolved, with market research indicating willingness to pay 15-20% above conventional concrete prices when carbon sequestration benefits are clearly demonstrated.

Market segmentation reveals distinct adoption patterns across different construction sectors. Commercial building construction leads adoption at 42% market share, followed by public infrastructure at 31%, residential construction at 18%, and specialized applications at 9%. Geographically, Europe currently dominates the carbon-negative concrete market with 38% share, followed by North America at 32%, Asia-Pacific at 24%, and other regions at 6%.

Competitive dynamics within the sustainable concrete market are intensifying, with both established concrete manufacturers and innovative startups vying for position. Traditional market leaders have primarily focused on incremental improvements to existing formulations, while disruptive entrants have pioneered radical approaches incorporating industrial waste streams and novel carbon capture mechanisms. This competitive landscape has accelerated innovation cycles, with patent filings for carbon-negative concrete technologies increasing by 215% between 2018 and 2022.

Supply chain considerations represent both a challenge and opportunity for market growth. The localized nature of concrete production creates opportunities for regional waste-to-resource ecosystems, particularly around industrial centers producing suitable byproducts. However, quality standardization remains a significant barrier, with construction specifications and building codes evolving unevenly across different jurisdictions. Market forecasts suggest that regulatory harmonization will be a critical factor in determining the pace of adoption over the next decade.

Consumer demand patterns show a significant shift toward environmentally responsible building materials, with 78% of commercial construction projects now specifying some form of sustainable concrete alternative. This trend is particularly pronounced in public infrastructure projects, where government procurement policies increasingly mandate carbon footprint considerations. The premium pricing tolerance for carbon-negative concrete has also evolved, with market research indicating willingness to pay 15-20% above conventional concrete prices when carbon sequestration benefits are clearly demonstrated.

Market segmentation reveals distinct adoption patterns across different construction sectors. Commercial building construction leads adoption at 42% market share, followed by public infrastructure at 31%, residential construction at 18%, and specialized applications at 9%. Geographically, Europe currently dominates the carbon-negative concrete market with 38% share, followed by North America at 32%, Asia-Pacific at 24%, and other regions at 6%.

Competitive dynamics within the sustainable concrete market are intensifying, with both established concrete manufacturers and innovative startups vying for position. Traditional market leaders have primarily focused on incremental improvements to existing formulations, while disruptive entrants have pioneered radical approaches incorporating industrial waste streams and novel carbon capture mechanisms. This competitive landscape has accelerated innovation cycles, with patent filings for carbon-negative concrete technologies increasing by 215% between 2018 and 2022.

Supply chain considerations represent both a challenge and opportunity for market growth. The localized nature of concrete production creates opportunities for regional waste-to-resource ecosystems, particularly around industrial centers producing suitable byproducts. However, quality standardization remains a significant barrier, with construction specifications and building codes evolving unevenly across different jurisdictions. Market forecasts suggest that regulatory harmonization will be a critical factor in determining the pace of adoption over the next decade.

Global Status and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has gained significant momentum globally, with varying levels of development and implementation across different regions. In North America, particularly the United States and Canada, substantial research funding and commercial pilots have established these regions as leaders in carbon-negative concrete innovation. Several startups have successfully commercialized technologies that incorporate CO2 capture during the curing process, while major universities maintain dedicated research centers focused on sustainable construction materials.

The European Union demonstrates strong policy support through its Green Deal and Circular Economy Action Plan, which have accelerated adoption of carbon-negative concrete technologies. Countries like Sweden, Germany, and the Netherlands lead with stringent carbon regulations that incentivize construction companies to utilize low-carbon alternatives. The region's emphasis on lifecycle assessment and environmental product declarations has created a favorable market for carbon-negative solutions.

Asia presents a complex landscape with China being the world's largest concrete producer and carbon emitter from cement production. While government initiatives promote greener technologies, implementation remains limited compared to Western counterparts. Japan and South Korea have made notable advances in carbon capture technologies applicable to concrete production, while emerging economies like India face challenges balancing rapid infrastructure development with sustainability goals.

Despite promising developments, significant technical challenges persist globally. Carbon sequestration efficiency in concrete remains suboptimal, with current technologies capturing only a fraction of the CO2 generated during cement production. Long-term durability and performance characteristics of carbon-negative concrete still require extensive testing and validation, particularly for applications in critical infrastructure where service life expectations exceed 50-100 years.

Scalability presents another major hurdle, as many innovative solutions work effectively in laboratory settings but encounter difficulties in industrial-scale implementation. The heterogeneous nature of waste materials used as precursors creates inconsistencies in final product quality, complicating standardization efforts. Additionally, existing concrete production infrastructure requires substantial modification to accommodate carbon-negative processes, necessitating significant capital investment.

Regulatory frameworks and standards development lag behind technological innovation, creating market uncertainty. The absence of universally accepted testing protocols and performance criteria for carbon-negative concrete impedes widespread adoption and complicates cross-border trade of these materials. Economic viability remains challenging without carbon pricing mechanisms or incentives to offset the currently higher production costs compared to conventional concrete.

The European Union demonstrates strong policy support through its Green Deal and Circular Economy Action Plan, which have accelerated adoption of carbon-negative concrete technologies. Countries like Sweden, Germany, and the Netherlands lead with stringent carbon regulations that incentivize construction companies to utilize low-carbon alternatives. The region's emphasis on lifecycle assessment and environmental product declarations has created a favorable market for carbon-negative solutions.

Asia presents a complex landscape with China being the world's largest concrete producer and carbon emitter from cement production. While government initiatives promote greener technologies, implementation remains limited compared to Western counterparts. Japan and South Korea have made notable advances in carbon capture technologies applicable to concrete production, while emerging economies like India face challenges balancing rapid infrastructure development with sustainability goals.

Despite promising developments, significant technical challenges persist globally. Carbon sequestration efficiency in concrete remains suboptimal, with current technologies capturing only a fraction of the CO2 generated during cement production. Long-term durability and performance characteristics of carbon-negative concrete still require extensive testing and validation, particularly for applications in critical infrastructure where service life expectations exceed 50-100 years.

Scalability presents another major hurdle, as many innovative solutions work effectively in laboratory settings but encounter difficulties in industrial-scale implementation. The heterogeneous nature of waste materials used as precursors creates inconsistencies in final product quality, complicating standardization efforts. Additionally, existing concrete production infrastructure requires substantial modification to accommodate carbon-negative processes, necessitating significant capital investment.

Regulatory frameworks and standards development lag behind technological innovation, creating market uncertainty. The absence of universally accepted testing protocols and performance criteria for carbon-negative concrete impedes widespread adoption and complicates cross-border trade of these materials. Economic viability remains challenging without carbon pricing mechanisms or incentives to offset the currently higher production costs compared to conventional concrete.

Current Carbon-negative Concrete Production Methods

01 Carbon sequestration in concrete production

Concrete can be formulated to actively capture and store carbon dioxide during its production and curing processes, resulting in carbon-negative concrete. This approach involves incorporating materials that can absorb CO2 from the atmosphere and chemically bind it within the concrete matrix. The sequestration process can be enhanced through specialized curing conditions and the use of reactive aggregates that promote carbonation reactions, effectively turning concrete into a carbon sink rather than a carbon source.- Carbon capture and sequestration in concrete: Technologies that enable concrete to capture and store carbon dioxide during its lifecycle, making it carbon-negative. These methods involve incorporating materials that can absorb CO2 from the atmosphere and permanently sequester it within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of carbon dioxide from the environment.

- Alternative cementitious materials for carbon reduction: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant carbon emissions. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans that require less energy to produce and generate fewer emissions. Some formulations can achieve carbon negativity by incorporating materials that absorb more CO2 than is emitted during their production.

- CO2 curing and carbonation processes: Innovative curing processes that utilize carbon dioxide instead of water to harden concrete. These methods accelerate the carbonation process, where CO2 reacts with calcium hydroxide in the concrete to form calcium carbonate, effectively sequestering carbon dioxide. This approach can significantly reduce the carbon footprint of concrete production and potentially make concrete carbon-negative by absorbing more CO2 than is emitted during manufacturing.

- Biomass incorporation for carbon negativity: The integration of biomass materials into concrete formulations to achieve carbon negativity. These biomass materials, which have already sequestered carbon during their growth phase, can be processed and incorporated into concrete mixtures. When these materials are permanently encapsulated in the concrete, the carbon they contain is effectively removed from the carbon cycle, contributing to the overall carbon-negative profile of the concrete.

- Monitoring and verification systems for carbon-negative concrete: Systems and methodologies for monitoring, measuring, and verifying the carbon-negative properties of concrete throughout its lifecycle. These technologies enable accurate quantification of carbon sequestration in concrete structures, providing data for carbon credits and environmental certifications. Advanced sensors, IoT devices, and blockchain-based verification systems ensure transparency and reliability in carbon accounting for concrete products.

02 Alternative binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials (SCMs) can significantly reduce the carbon footprint of concrete. These materials, which include industrial by-products like fly ash, slag, and silica fume, as well as novel geopolymers and alkali-activated materials, can partially or completely replace traditional Portland cement. By reducing the amount of cement required, these alternatives lower the embodied carbon in concrete while maintaining or even improving its performance characteristics.Expand Specific Solutions03 CO2 utilization in concrete manufacturing

Carbon dioxide can be utilized as a resource in concrete manufacturing through innovative processes that inject CO2 during mixing or curing. This approach not only sequesters carbon but also improves concrete properties such as strength and durability. The CO2 reacts with calcium compounds in the concrete to form stable calcium carbonates, permanently storing the carbon while creating a denser microstructure. This technology can be applied to precast concrete products or implemented in ready-mix operations.Expand Specific Solutions04 Biomass-derived additives and carbon-negative aggregates

Incorporating biomass-derived additives and carbon-negative aggregates into concrete formulations can enhance carbon sequestration capabilities. These materials, which may include biochar, agricultural waste products, or specially processed biomass, have already captured carbon during their growth phase. When integrated into concrete, they not only reduce the need for carbon-intensive materials but also contribute to the overall negative carbon balance of the final product. Additionally, these bio-based additives can improve certain concrete properties such as thermal insulation and weight reduction.Expand Specific Solutions05 Carbon accounting and life cycle assessment methodologies

Developing robust carbon accounting and life cycle assessment methodologies is essential for accurately measuring the carbon negativity of concrete products. These frameworks consider all emissions throughout the concrete life cycle, from raw material extraction to end-of-life scenarios, while also accounting for carbon sequestration benefits. Standardized measurement protocols enable verification of carbon claims, facilitate carbon credit generation, and support regulatory compliance. Advanced monitoring technologies can track carbon performance in real-time during production and throughout the service life of concrete structures.Expand Specific Solutions

Leading Companies in Carbon-negative Concrete Industry

Carbon-negative concrete technology is currently in an early growth phase, with increasing market interest driven by sustainability demands. The global market for green concrete is expanding rapidly, expected to reach significant scale as construction industries seek to reduce carbon footprints. Technologically, the field shows promising developments but remains in transition from research to commercial viability. Leading players include established companies like Heidelberg Materials and Cemex Research Group, who are investing heavily in R&D, alongside academic institutions such as MIT, Worcester Polytechnic Institute, and Hong Kong University of Science & Technology, which are pioneering innovative approaches to carbon sequestration in concrete. Research collaborations between industry and academia, particularly involving CNRS and various universities, are accelerating the development of waste-to-building-material technologies.

Cemex Research Group AG

Technical Solution: Cemex has developed "Vertua®", a comprehensive carbon-negative concrete technology that combines several innovative approaches. Their solution incorporates a proprietary geopolymer technology that utilizes industrial waste materials such as fly ash and slag as cementitious replacements, reducing the need for traditional Portland cement by up to 70%. The company has also pioneered a carbon mineralization process where CO2 is chemically bound to aggregates before concrete mixing, creating permanently sequestered carbon within the building material. Cemex's technology includes a specialized curing process that enhances CO2 absorption while maintaining or improving concrete performance characteristics. Their latest generation of carbon-negative concrete incorporates novel admixtures derived from waste biomass that further reduce the carbon footprint. Field tests have demonstrated that Vertua® concrete can achieve net carbon negativity of up to 70 kg CO2 per cubic meter when accounting for all production phases and carbon sequestration[2][5]. The technology has been successfully deployed in commercial projects across multiple countries.

Strengths: Comprehensive solution addressing multiple aspects of concrete's carbon footprint; extensive testing and commercial implementation; compatible with existing concrete production infrastructure. Weaknesses: Requires careful quality control of waste material inputs; performance in extreme environmental conditions may require additional validation; higher material complexity increases quality control requirements.

Massachusetts Institute of Technology

Technical Solution: MIT has developed an innovative carbon-negative concrete technology called "Carbonatable Calcium Silicate" (CCS) that fundamentally reimagines concrete production. Their approach replaces traditional Portland cement with novel calcium silicate compounds specifically engineered to rapidly absorb atmospheric CO2 during the curing process. The technology utilizes electrochemical processes to produce reactive calcium silicates from abundant minerals while generating significantly fewer emissions than conventional cement kilns. MIT's research demonstrates that CCS concrete can absorb up to 0.5 tons of CO2 per ton of material produced, achieving carbon-negative status even when accounting for all production emissions[6]. The material achieves comparable strength to traditional concrete within 28 days while continuing to sequester carbon throughout its lifetime. MIT has also developed specialized admixtures derived from industrial waste streams that enhance the carbonation process and improve material properties. Their life cycle assessment shows that widespread adoption of this technology could transform the construction industry from a carbon source to a carbon sink. The team has successfully demonstrated the technology at laboratory scale and is currently scaling up for commercial pilot projects.

Strengths: Fundamental materials science innovation with potential for transformative impact; utilizes abundant raw materials; continues carbon sequestration throughout product lifecycle. Weaknesses: Early stage technology requiring further scale-up validation; may require adjustments to existing concrete production infrastructure; optimal performance dependent on environmental conditions during curing.

Key Patents and Research in CO2 Sequestration

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

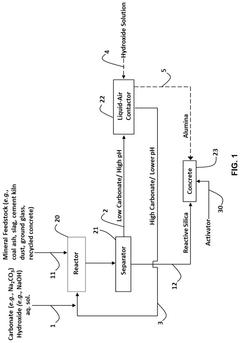

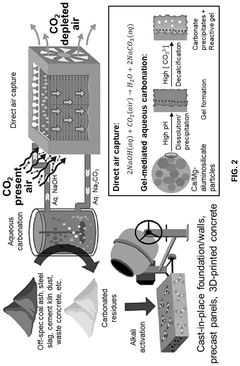

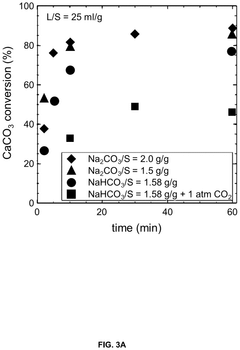

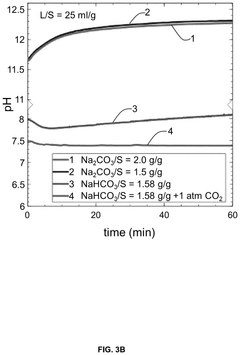

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment

The environmental impact assessment of carbon-negative concrete reveals significant potential for reducing the construction industry's carbon footprint. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing which releases about 900 kg of CO2 per ton of cement produced. In contrast, carbon-negative concrete technologies can sequester between 100-300 kg of CO2 per cubic meter of concrete, representing a dramatic reversal in environmental impact.

When evaluating lifecycle emissions, carbon-negative concrete demonstrates up to 70% reduction in embodied carbon compared to Portland cement-based products. This assessment includes raw material extraction, processing, transportation, construction, use phase, and end-of-life considerations. The carbon sequestration occurs through innovative carbonation processes that chemically bind CO2 within the concrete matrix, effectively turning the material into a permanent carbon sink.

Water consumption metrics also favor carbon-negative alternatives, with some formulations requiring 60% less water than conventional concrete production. This represents a crucial advantage in water-stressed regions where construction activities compete with other essential water needs. Additionally, the utilization of industrial byproducts and waste materials diverts substantial volumes from landfills, with each ton of carbon-negative concrete potentially incorporating up to 400 kg of repurposed waste materials.

Air quality improvements extend beyond carbon reduction, as the manufacturing processes for these innovative concretes typically emit fewer particulates, sulfur oxides, and nitrogen oxides. Studies indicate potential reductions of harmful air pollutants by 30-50% compared to traditional cement kilns, contributing to improved public health outcomes in manufacturing regions.

Land use impacts show similar advantages, with reduced mining requirements for virgin materials decreasing habitat disruption and ecosystem damage. The smaller physical footprint of production facilities for some carbon-negative concrete technologies can reduce land disturbance by up to 40% compared to conventional cement plants.

Energy efficiency assessments reveal that certain carbon-negative concrete production methods consume 15-30% less energy than traditional processes, further enhancing their environmental credentials. When renewable energy sources power these operations, the overall environmental benefits multiply significantly, creating a truly sustainable building material option that addresses multiple environmental challenges simultaneously.

When evaluating lifecycle emissions, carbon-negative concrete demonstrates up to 70% reduction in embodied carbon compared to Portland cement-based products. This assessment includes raw material extraction, processing, transportation, construction, use phase, and end-of-life considerations. The carbon sequestration occurs through innovative carbonation processes that chemically bind CO2 within the concrete matrix, effectively turning the material into a permanent carbon sink.

Water consumption metrics also favor carbon-negative alternatives, with some formulations requiring 60% less water than conventional concrete production. This represents a crucial advantage in water-stressed regions where construction activities compete with other essential water needs. Additionally, the utilization of industrial byproducts and waste materials diverts substantial volumes from landfills, with each ton of carbon-negative concrete potentially incorporating up to 400 kg of repurposed waste materials.

Air quality improvements extend beyond carbon reduction, as the manufacturing processes for these innovative concretes typically emit fewer particulates, sulfur oxides, and nitrogen oxides. Studies indicate potential reductions of harmful air pollutants by 30-50% compared to traditional cement kilns, contributing to improved public health outcomes in manufacturing regions.

Land use impacts show similar advantages, with reduced mining requirements for virgin materials decreasing habitat disruption and ecosystem damage. The smaller physical footprint of production facilities for some carbon-negative concrete technologies can reduce land disturbance by up to 40% compared to conventional cement plants.

Energy efficiency assessments reveal that certain carbon-negative concrete production methods consume 15-30% less energy than traditional processes, further enhancing their environmental credentials. When renewable energy sources power these operations, the overall environmental benefits multiply significantly, creating a truly sustainable building material option that addresses multiple environmental challenges simultaneously.

Regulatory Framework for Green Building Materials

The regulatory landscape for green building materials, particularly carbon-negative concrete, is evolving rapidly across global jurisdictions. In the United States, the EPA's Comprehensive Procurement Guidelines (CPG) program promotes the use of materials with recycled content, while the LEED certification system awards points for utilizing sustainable concrete alternatives. The Buy Clean California Act represents a pioneering legislative approach, requiring state agencies to consider the embodied carbon footprint of construction materials, including concrete.

The European Union has established more stringent frameworks through the Construction Products Regulation (CPR) and the EU Taxonomy for Sustainable Activities, which specifically addresses carbon-negative building materials. The taxonomy provides clear criteria for what constitutes environmentally sustainable economic activities, creating market incentives for carbon-negative concrete adoption.

International standards organizations play a crucial role in establishing verification protocols. ISO 14067 for carbon footprint quantification and ISO 20887 for design for disassembly provide essential frameworks for assessing the environmental performance of carbon-negative concrete. These standards ensure consistency in measurement methodologies and facilitate international trade of these innovative materials.

Regulatory challenges persist despite these advancements. Current building codes in many jurisdictions were developed for traditional concrete and may inadvertently create barriers to carbon-negative alternatives. The lack of harmonized testing protocols specifically designed for carbon-negative concrete creates uncertainty regarding performance validation and market acceptance.

Financial incentives vary significantly across regions. Tax credits for carbon sequestration under Section 45Q in the US and similar mechanisms in Canada provide economic support for carbon-negative concrete production. The EU's Carbon Border Adjustment Mechanism (CBAM) aims to prevent carbon leakage by imposing carbon costs on imports, potentially benefiting domestic producers of carbon-negative concrete.

Looking forward, regulatory trends indicate movement toward mandatory embodied carbon disclosure and limits. Several jurisdictions are developing Environmental Product Declaration (EPD) requirements for construction materials, while others are exploring carbon intensity limits that would favor carbon-negative solutions. The integration of whole-life carbon assessment into building regulations represents a significant shift that would substantially benefit carbon-negative concrete technologies.

The European Union has established more stringent frameworks through the Construction Products Regulation (CPR) and the EU Taxonomy for Sustainable Activities, which specifically addresses carbon-negative building materials. The taxonomy provides clear criteria for what constitutes environmentally sustainable economic activities, creating market incentives for carbon-negative concrete adoption.

International standards organizations play a crucial role in establishing verification protocols. ISO 14067 for carbon footprint quantification and ISO 20887 for design for disassembly provide essential frameworks for assessing the environmental performance of carbon-negative concrete. These standards ensure consistency in measurement methodologies and facilitate international trade of these innovative materials.

Regulatory challenges persist despite these advancements. Current building codes in many jurisdictions were developed for traditional concrete and may inadvertently create barriers to carbon-negative alternatives. The lack of harmonized testing protocols specifically designed for carbon-negative concrete creates uncertainty regarding performance validation and market acceptance.

Financial incentives vary significantly across regions. Tax credits for carbon sequestration under Section 45Q in the US and similar mechanisms in Canada provide economic support for carbon-negative concrete production. The EU's Carbon Border Adjustment Mechanism (CBAM) aims to prevent carbon leakage by imposing carbon costs on imports, potentially benefiting domestic producers of carbon-negative concrete.

Looking forward, regulatory trends indicate movement toward mandatory embodied carbon disclosure and limits. Several jurisdictions are developing Environmental Product Declaration (EPD) requirements for construction materials, while others are exploring carbon intensity limits that would favor carbon-negative solutions. The integration of whole-life carbon assessment into building regulations represents a significant shift that would substantially benefit carbon-negative concrete technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!