Carbon-negative Concrete: Enhancing Eco-efficient Urban Development

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete production has been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. This environmental impact has driven the evolution of concrete technology towards more sustainable alternatives, with carbon-negative concrete emerging as a revolutionary approach in construction materials science. Carbon-negative concrete represents a paradigm shift from traditional cement-based concrete that releases substantial amounts of carbon dioxide during production to innovative formulations that actively sequester more carbon than they emit throughout their lifecycle.

The development trajectory of carbon-negative concrete has accelerated significantly over the past decade, propelled by advances in material science, carbon capture technologies, and growing environmental imperatives. Early iterations focused primarily on reducing emissions through supplementary cementitious materials, while contemporary approaches incorporate novel binding agents and carbon sequestration mechanisms directly into the concrete matrix.

The technical objectives for carbon-negative concrete development are multifaceted and ambitious. Primary goals include achieving net carbon sequestration of at least 100kg CO2 per cubic meter of concrete, maintaining or exceeding the structural performance characteristics of traditional concrete, ensuring economic viability at scale, and establishing production processes compatible with existing concrete manufacturing infrastructure. These objectives align with broader sustainability targets including the Paris Agreement climate goals and various national carbon neutrality commitments.

Research indicates that the most promising pathways involve replacing traditional Portland cement with alternative binders such as alkali-activated materials, magnesium oxide-based cements, and calcium silicate hydrates that can incorporate and mineralize CO2. Additionally, integrating carbon capture during the curing process and incorporating carbon-sequestering aggregates presents significant potential for enhancing the carbon-negative properties of concrete.

The technical evolution trend points toward hybrid approaches that combine multiple carbon reduction strategies, optimized for specific applications and regional material availability. Recent breakthroughs in accelerated carbonation techniques and biologically-mediated cementation processes suggest that the carbon sequestration capacity of next-generation concrete could potentially increase by an order of magnitude within the coming decade.

As urban development intensifies globally, with projections indicating 68% of the world population will live in urban areas by 2050, the imperative for eco-efficient construction materials becomes increasingly critical. Carbon-negative concrete stands as a transformative technology that could fundamentally alter the environmental footprint of the built environment, transitioning urban infrastructure from a carbon source to a carbon sink.

The development trajectory of carbon-negative concrete has accelerated significantly over the past decade, propelled by advances in material science, carbon capture technologies, and growing environmental imperatives. Early iterations focused primarily on reducing emissions through supplementary cementitious materials, while contemporary approaches incorporate novel binding agents and carbon sequestration mechanisms directly into the concrete matrix.

The technical objectives for carbon-negative concrete development are multifaceted and ambitious. Primary goals include achieving net carbon sequestration of at least 100kg CO2 per cubic meter of concrete, maintaining or exceeding the structural performance characteristics of traditional concrete, ensuring economic viability at scale, and establishing production processes compatible with existing concrete manufacturing infrastructure. These objectives align with broader sustainability targets including the Paris Agreement climate goals and various national carbon neutrality commitments.

Research indicates that the most promising pathways involve replacing traditional Portland cement with alternative binders such as alkali-activated materials, magnesium oxide-based cements, and calcium silicate hydrates that can incorporate and mineralize CO2. Additionally, integrating carbon capture during the curing process and incorporating carbon-sequestering aggregates presents significant potential for enhancing the carbon-negative properties of concrete.

The technical evolution trend points toward hybrid approaches that combine multiple carbon reduction strategies, optimized for specific applications and regional material availability. Recent breakthroughs in accelerated carbonation techniques and biologically-mediated cementation processes suggest that the carbon sequestration capacity of next-generation concrete could potentially increase by an order of magnitude within the coming decade.

As urban development intensifies globally, with projections indicating 68% of the world population will live in urban areas by 2050, the imperative for eco-efficient construction materials becomes increasingly critical. Carbon-negative concrete stands as a transformative technology that could fundamentally alter the environmental footprint of the built environment, transitioning urban infrastructure from a carbon source to a carbon sink.

Market Analysis for Sustainable Construction Materials

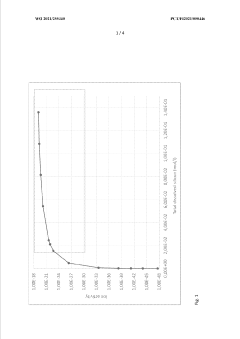

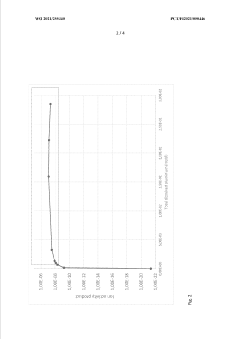

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations targeting carbon emissions reduction. Currently valued at approximately $299 billion globally, this sector is projected to reach $561 billion by 2030, with a compound annual growth rate of 11.2% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this market, with particular acceleration in developed economies across North America, Europe, and parts of Asia-Pacific.

Consumer demand patterns show a significant shift toward environmentally responsible building materials, with 78% of commercial construction projects now incorporating sustainability criteria in material selection processes. This trend is particularly pronounced in urban development projects, where municipal governments increasingly mandate low-carbon or carbon-neutral construction approaches. The premium pricing tolerance for sustainable alternatives has also expanded, with developers willing to pay 15-20% more for materials that demonstrably reduce carbon footprints.

Regulatory frameworks are creating powerful market incentives for carbon-negative concrete adoption. The European Union's Carbon Border Adjustment Mechanism, China's emissions trading scheme, and various carbon pricing initiatives across 45 countries have established economic advantages for low-carbon construction materials. Additionally, green building certification systems like LEED, BREEAM, and WELL are driving market demand by awarding higher ratings to projects utilizing carbon-negative materials.

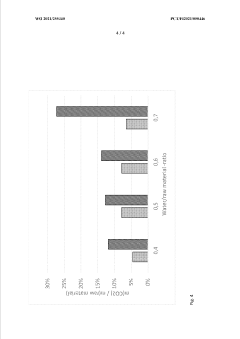

Market segmentation analysis reveals that commercial construction currently dominates carbon-negative concrete applications (42% of market share), followed by public infrastructure (31%), residential construction (18%), and industrial applications (9%). Geographically, Europe leads adoption with 38% market share, followed by North America (29%), Asia-Pacific (24%), and other regions (9%).

Supply chain dynamics present both challenges and opportunities. While traditional cement production remains heavily entrenched with significant sunk costs in existing infrastructure, emerging technologies for carbon capture and alternative binding agents are disrupting established production models. Material sourcing for carbon-negative concrete components shows regional variability, with local availability of supplementary cementitious materials like fly ash and slag significantly impacting adoption rates.

Competitive pricing remains a key market barrier, with carbon-negative concrete solutions currently averaging 30-45% higher costs than traditional Portland cement concrete. However, this gap is narrowing as production scales up and carbon pricing mechanisms increasingly internalize environmental externalities. Market forecasts indicate price parity could be achieved in leading markets by 2028, substantially accelerating adoption rates.

Consumer demand patterns show a significant shift toward environmentally responsible building materials, with 78% of commercial construction projects now incorporating sustainability criteria in material selection processes. This trend is particularly pronounced in urban development projects, where municipal governments increasingly mandate low-carbon or carbon-neutral construction approaches. The premium pricing tolerance for sustainable alternatives has also expanded, with developers willing to pay 15-20% more for materials that demonstrably reduce carbon footprints.

Regulatory frameworks are creating powerful market incentives for carbon-negative concrete adoption. The European Union's Carbon Border Adjustment Mechanism, China's emissions trading scheme, and various carbon pricing initiatives across 45 countries have established economic advantages for low-carbon construction materials. Additionally, green building certification systems like LEED, BREEAM, and WELL are driving market demand by awarding higher ratings to projects utilizing carbon-negative materials.

Market segmentation analysis reveals that commercial construction currently dominates carbon-negative concrete applications (42% of market share), followed by public infrastructure (31%), residential construction (18%), and industrial applications (9%). Geographically, Europe leads adoption with 38% market share, followed by North America (29%), Asia-Pacific (24%), and other regions (9%).

Supply chain dynamics present both challenges and opportunities. While traditional cement production remains heavily entrenched with significant sunk costs in existing infrastructure, emerging technologies for carbon capture and alternative binding agents are disrupting established production models. Material sourcing for carbon-negative concrete components shows regional variability, with local availability of supplementary cementitious materials like fly ash and slag significantly impacting adoption rates.

Competitive pricing remains a key market barrier, with carbon-negative concrete solutions currently averaging 30-45% higher costs than traditional Portland cement concrete. However, this gap is narrowing as production scales up and carbon pricing mechanisms increasingly internalize environmental externalities. Market forecasts indicate price parity could be achieved in leading markets by 2028, substantially accelerating adoption rates.

Current State and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has made significant strides globally, yet remains in early commercial deployment stages. Current implementations primarily exist as pilot projects and limited commercial applications, with major initiatives concentrated in North America, Europe, and parts of Asia. Companies like Carbicrete, CarbonCure, and Solidia Technologies have demonstrated viable carbon-capturing concrete production methods, though widespread adoption faces substantial barriers.

The fundamental technical challenge lies in balancing carbon sequestration with maintaining or enhancing concrete's structural integrity. Traditional Portland cement, responsible for approximately 8% of global CO2 emissions, remains difficult to replace entirely while preserving concrete's essential performance characteristics. Alternative binding materials such as geopolymers and alkali-activated materials show promise but face durability concerns under varied environmental conditions.

Scale presents another significant obstacle. Current carbon-negative concrete production facilities operate at limited capacity, making it difficult to meet the enormous demand of the global construction industry. The specialized equipment and modified production processes required for carbon-negative concrete manufacturing necessitate substantial capital investment, creating economic barriers to widespread implementation.

Regulatory frameworks and standardization remain underdeveloped across most regions. Building codes and construction standards have been slow to incorporate provisions for novel concrete formulations, creating uncertainty for potential adopters. The absence of universally accepted testing protocols and performance metrics for carbon-negative concrete further complicates market acceptance.

Supply chain constraints also impede progress. Many carbon-negative concrete technologies rely on industrial byproducts like fly ash and slag, which have variable availability depending on regional industrial activity. The geographical mismatch between waste material sources and concrete production facilities creates logistical challenges and increases costs.

Knowledge gaps persist regarding long-term performance. While laboratory tests show promising results, real-world data on decades-long durability remains limited. This uncertainty creates hesitation among engineers, architects, and building owners who prioritize structural longevity.

Cost competitiveness represents perhaps the most significant market barrier. Despite decreasing production costs, most carbon-negative concrete solutions still command a premium over conventional concrete. Without carbon pricing mechanisms or regulatory mandates, this price differential slows adoption, particularly in price-sensitive construction sectors.

The technology landscape is further complicated by regional variations in raw material availability, energy sources, and climate conditions, which affect both the carbon footprint calculations and the technical feasibility of different approaches to carbon-negative concrete production.

The fundamental technical challenge lies in balancing carbon sequestration with maintaining or enhancing concrete's structural integrity. Traditional Portland cement, responsible for approximately 8% of global CO2 emissions, remains difficult to replace entirely while preserving concrete's essential performance characteristics. Alternative binding materials such as geopolymers and alkali-activated materials show promise but face durability concerns under varied environmental conditions.

Scale presents another significant obstacle. Current carbon-negative concrete production facilities operate at limited capacity, making it difficult to meet the enormous demand of the global construction industry. The specialized equipment and modified production processes required for carbon-negative concrete manufacturing necessitate substantial capital investment, creating economic barriers to widespread implementation.

Regulatory frameworks and standardization remain underdeveloped across most regions. Building codes and construction standards have been slow to incorporate provisions for novel concrete formulations, creating uncertainty for potential adopters. The absence of universally accepted testing protocols and performance metrics for carbon-negative concrete further complicates market acceptance.

Supply chain constraints also impede progress. Many carbon-negative concrete technologies rely on industrial byproducts like fly ash and slag, which have variable availability depending on regional industrial activity. The geographical mismatch between waste material sources and concrete production facilities creates logistical challenges and increases costs.

Knowledge gaps persist regarding long-term performance. While laboratory tests show promising results, real-world data on decades-long durability remains limited. This uncertainty creates hesitation among engineers, architects, and building owners who prioritize structural longevity.

Cost competitiveness represents perhaps the most significant market barrier. Despite decreasing production costs, most carbon-negative concrete solutions still command a premium over conventional concrete. Without carbon pricing mechanisms or regulatory mandates, this price differential slows adoption, particularly in price-sensitive construction sectors.

The technology landscape is further complicated by regional variations in raw material availability, energy sources, and climate conditions, which affect both the carbon footprint calculations and the technical feasibility of different approaches to carbon-negative concrete production.

Existing Carbon-negative Concrete Solutions

01 CO2 capture and sequestration in concrete production

Technologies that capture and sequester carbon dioxide during the concrete manufacturing process, transforming traditional concrete production into a carbon sink. These methods involve injecting CO2 into concrete mixtures during curing, where it reacts with calcium compounds to form stable carbonates, effectively locking away carbon dioxide while simultaneously improving concrete strength and durability.- CO2 capture and sequestration in concrete production: Carbon-negative concrete can be achieved through processes that capture and sequester CO2 during concrete production. These methods involve injecting CO2 into concrete mixtures during curing, where it reacts with calcium compounds to form stable carbonates. This mineralization process not only sequesters carbon dioxide permanently but also improves concrete strength and durability, effectively turning concrete from a carbon source into a carbon sink.

- Alternative cementitious materials for carbon reduction: Using alternative cementitious materials can significantly reduce the carbon footprint of concrete. These include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans that partially replace traditional Portland cement. Additionally, novel binders such as geopolymers, alkali-activated materials, and magnesium-based cements can be used to create concrete with substantially lower carbon emissions or even negative carbon footprints when combined with carbon sequestration techniques.

- Biomass incorporation and carbonation techniques: Carbon-negative concrete can be produced by incorporating biomass materials and enhanced carbonation techniques. Biomass materials like agricultural waste, wood products, or biochar can be added to concrete mixtures, effectively storing biogenic carbon. Enhanced carbonation techniques accelerate the natural process of CO2 absorption in concrete through specialized curing conditions or the addition of catalysts, resulting in concrete that sequesters more carbon than is emitted during its production.

- Energy-efficient production methods and renewable energy integration: Carbon-negative concrete production can be achieved through energy-efficient manufacturing processes and renewable energy integration. This includes optimizing kiln operations, using alternative fuels, implementing waste heat recovery systems, and powering concrete production facilities with renewable energy sources. These approaches significantly reduce the carbon emissions associated with concrete manufacturing, which, when combined with carbon sequestration techniques, can result in a net negative carbon footprint.

- Carbon accounting and lifecycle assessment methodologies: Developing robust carbon accounting and lifecycle assessment methodologies is crucial for verifying carbon-negative concrete. These methodologies quantify the carbon emissions throughout the concrete lifecycle, from raw material extraction to end-of-life scenarios, and account for carbon sequestration. They include standardized measurement protocols, verification procedures, and certification systems that enable accurate assessment of the carbon footprint of concrete products and validate claims of carbon negativity.

02 Alternative cementitious materials with lower carbon footprint

Development of cement alternatives that require less energy to produce and generate fewer emissions than traditional Portland cement. These include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete while maintaining or enhancing performance characteristics.Expand Specific Solutions03 Biomass incorporation and biogenic carbon sequestration

Integration of biomass-derived materials into concrete formulations to sequester biogenic carbon. These approaches include incorporating agricultural waste, wood products, or other plant-based materials that have absorbed CO2 during their growth cycle. When these materials are incorporated into concrete, they lock away the captured carbon while potentially improving properties like thermal insulation and weight reduction.Expand Specific Solutions04 Enhanced carbonation curing techniques

Advanced curing methodologies that accelerate and maximize the natural carbonation process in concrete. These techniques involve controlling temperature, pressure, and CO2 concentration during curing to optimize carbon uptake. The process not only sequesters carbon but also reduces curing time and energy requirements while improving concrete properties such as compressive strength and reduced permeability.Expand Specific Solutions05 Carbon-negative concrete production systems

Integrated systems and processes designed to make the entire concrete production lifecycle carbon-negative. These approaches combine multiple carbon reduction strategies including renewable energy use in manufacturing, carbon capture technologies, alternative raw materials, and optimized mix designs. The systems often incorporate life cycle assessment methodologies to verify and quantify the net carbon reduction achieved throughout the concrete's production and service life.Expand Specific Solutions

Leading Companies in Eco-concrete Development

Carbon-negative concrete technology is currently in an early growth phase, with increasing market adoption driven by global sustainability initiatives. The market size is expanding rapidly, projected to reach significant scale as urban development embraces eco-efficient solutions. Technologically, companies are at varying maturity levels: established players like Holcim Technology and China National Building Material Group are advancing commercial applications, while innovative startups like Carbon Limit Co. and Ecocem Materials are developing breakthrough formulations. Research institutions including MIT, Colorado School of Mines, and Guangxi University are accelerating fundamental innovations. The competitive landscape features traditional concrete manufacturers (China West Construction, SUNGSHIN CEMENT) adapting their portfolios alongside specialized carbon-capture concrete developers, creating a dynamic ecosystem balancing established infrastructure with disruptive technologies.

Holcim Technology Ltd.

Technical Solution: Holcim has developed ECOPact, a carbon-negative concrete solution that incorporates carbon capture technology and alternative cementitious materials. Their process involves using supplementary cementitious materials (SCMs) like calcined clay and industrial by-products to replace traditional Portland cement. Additionally, Holcim has pioneered carbon capture utilization and storage (CCUS) technology at their cement plants, where captured CO2 is mineralized into the concrete, permanently sequestering carbon. Their ECOPlanet cement can reduce carbon footprint by up to 90% compared to standard cement[1]. Holcim also employs innovative 3D concrete printing technology that optimizes material usage and reduces waste in construction processes, further enhancing the sustainability profile of their concrete solutions[2].

Strengths: Global scale and extensive R&D capabilities allow for rapid commercialization; proprietary CCUS technology gives competitive advantage; comprehensive approach addressing both production and application phases. Weaknesses: High initial implementation costs; requires significant changes to existing production infrastructure; performance in extreme weather conditions still being validated.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group has developed an innovative carbon-negative concrete technology called "CO2NCRETE," which utilizes industrial waste materials and carbon capture processes. Their approach involves capturing CO2 emissions directly from cement kilns and incorporating them into concrete production through a carbonation curing process. This technology uses a specialized binder system that replaces up to 60% of traditional cement with industrial by-products such as fly ash and slag[3]. The company has also pioneered a low-temperature clinker production method that reduces energy consumption by approximately 30% compared to conventional processes. Their concrete formulation includes proprietary additives that enhance CO2 absorption during the concrete's lifetime, effectively turning structures into carbon sinks[4].

Strengths: Massive production scale enables significant carbon reduction impact; strong integration with China's industrial waste streams; government backing accelerates implementation. Weaknesses: Technology primarily optimized for Chinese market conditions; international standards compliance still in progress; higher water requirements compared to some competing technologies.

Key Patents and Research in CO2 Sequestration Concrete

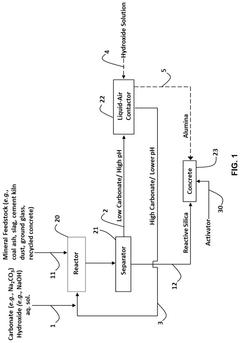

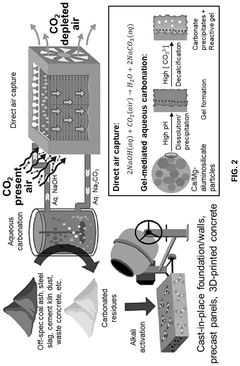

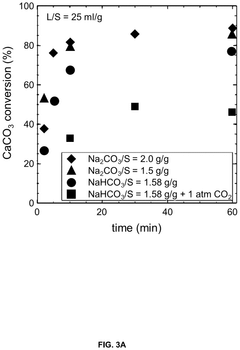

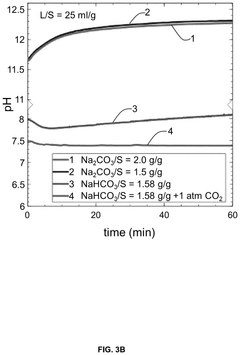

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Controlling carbonation

PatentWO2021255340A1

Innovation

- A method for controlling carbonation by adjusting the total concentration of dissolved silicon and/or aluminium in a mix, which is cured with carbon dioxide, using an alkaline substance to activate the raw material, thereby increasing carbon dioxide uptake and reducing the need for cement in concrete production.

Environmental Policy Frameworks for Green Building Materials

Environmental policy frameworks play a crucial role in accelerating the adoption of carbon-negative concrete and other green building materials in urban development. These frameworks establish the regulatory foundation that can either facilitate or hinder the transition toward more sustainable construction practices. Currently, several major economies have implemented policies that specifically target embodied carbon in construction materials, creating market incentives for carbon-negative alternatives.

The European Union leads with its ambitious European Green Deal, which includes the Construction Products Regulation (CPR) that mandates Environmental Product Declarations (EPDs) for building materials. This transparency requirement enables accurate carbon accounting throughout the supply chain. Additionally, the EU Taxonomy for Sustainable Activities provides clear criteria for identifying environmentally sustainable economic activities, including those related to construction materials.

In North America, policy approaches vary significantly by jurisdiction. Canada's Greening Government Strategy requires federal buildings to reduce embodied carbon by 30% by 2025, while several U.S. states have enacted procurement policies that favor low-carbon concrete. California's Buy Clean California Act (BCCA) stands out by requiring state agencies to consider the Global Warming Potential (GWP) of construction materials in procurement decisions.

The Asia-Pacific region demonstrates diverse policy approaches. Singapore's Green Mark certification system awards additional points for projects using sustainable concrete formulations, while Japan's Top Runner Program has expanded to include building materials with carbon reduction targets. China has incorporated green building materials into its national Five-Year Plans, emphasizing the importance of reducing carbon emissions in construction.

Financial mechanisms within these policy frameworks create powerful market signals. Carbon pricing schemes in over 40 countries now affect the construction sector, making carbon-intensive traditional concrete increasingly expensive compared to carbon-negative alternatives. Green public procurement policies, implemented in various forms across 26 OECD countries, leverage government purchasing power to create demand for sustainable building materials.

Looking forward, policy harmonization represents both a challenge and opportunity. The International Organization for Standardization (ISO) is developing standardized methodologies for measuring embodied carbon in building materials, which could facilitate international policy alignment. Meanwhile, emerging policy innovations include carbon border adjustment mechanisms that may prevent "carbon leakage" in the building materials sector and performance-based building codes that regulate embodied carbon alongside operational emissions.

The European Union leads with its ambitious European Green Deal, which includes the Construction Products Regulation (CPR) that mandates Environmental Product Declarations (EPDs) for building materials. This transparency requirement enables accurate carbon accounting throughout the supply chain. Additionally, the EU Taxonomy for Sustainable Activities provides clear criteria for identifying environmentally sustainable economic activities, including those related to construction materials.

In North America, policy approaches vary significantly by jurisdiction. Canada's Greening Government Strategy requires federal buildings to reduce embodied carbon by 30% by 2025, while several U.S. states have enacted procurement policies that favor low-carbon concrete. California's Buy Clean California Act (BCCA) stands out by requiring state agencies to consider the Global Warming Potential (GWP) of construction materials in procurement decisions.

The Asia-Pacific region demonstrates diverse policy approaches. Singapore's Green Mark certification system awards additional points for projects using sustainable concrete formulations, while Japan's Top Runner Program has expanded to include building materials with carbon reduction targets. China has incorporated green building materials into its national Five-Year Plans, emphasizing the importance of reducing carbon emissions in construction.

Financial mechanisms within these policy frameworks create powerful market signals. Carbon pricing schemes in over 40 countries now affect the construction sector, making carbon-intensive traditional concrete increasingly expensive compared to carbon-negative alternatives. Green public procurement policies, implemented in various forms across 26 OECD countries, leverage government purchasing power to create demand for sustainable building materials.

Looking forward, policy harmonization represents both a challenge and opportunity. The International Organization for Standardization (ISO) is developing standardized methodologies for measuring embodied carbon in building materials, which could facilitate international policy alignment. Meanwhile, emerging policy innovations include carbon border adjustment mechanisms that may prevent "carbon leakage" in the building materials sector and performance-based building codes that regulate embodied carbon alongside operational emissions.

Life Cycle Assessment of Carbon-negative Concrete Applications

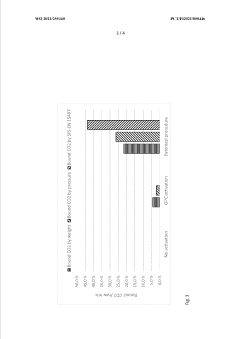

Life Cycle Assessment (LCA) of carbon-negative concrete applications provides a comprehensive framework for evaluating the environmental impacts throughout the entire lifecycle of concrete products. This assessment begins with raw material extraction and continues through manufacturing, transportation, installation, use phase, and end-of-life disposal or recycling. For carbon-negative concrete, the LCA reveals significant environmental advantages compared to traditional Portland cement concrete.

The extraction phase analysis demonstrates that carbon-negative concrete typically requires less energy-intensive mining operations due to its incorporation of industrial byproducts and waste materials such as fly ash, slag, and recycled aggregates. These alternative materials reduce the need for virgin limestone extraction, which is a major source of CO2 emissions in conventional concrete production.

During the manufacturing phase, carbon-negative concrete technologies employ various CO2 sequestration methods. Companies like CarbonCure and Solidia have developed processes that inject and permanently store CO2 within the concrete matrix, effectively transforming concrete from a carbon source to a carbon sink. LCA data indicates that these technologies can sequester between 5-30% of the carbon typically emitted during traditional concrete production.

Transportation impacts vary significantly based on the proximity of raw materials and manufacturing facilities to construction sites. LCA studies show that locally sourced materials for carbon-negative concrete can reduce transportation-related emissions by up to 40% compared to conventional concrete supply chains that often require long-distance shipping of Portland cement.

The installation and use phases demonstrate minimal differences in environmental impact between carbon-negative and conventional concrete. However, the durability advantages of many carbon-negative formulations translate to extended service life, reducing the frequency of replacement and associated environmental impacts over time.

End-of-life analysis reveals that carbon-negative concrete maintains its carbon sequestration benefits even after demolition. When crushed, the increased surface area can potentially accelerate further carbonation, enhancing the carbon sequestration capacity. Additionally, recycled carbon-negative concrete aggregate can be incorporated into new concrete mixes, creating a circular economy approach that further reduces environmental impacts.

Comprehensive LCA studies conducted by research institutions such as MIT and ETH Zurich confirm that carbon-negative concrete can achieve net carbon reductions of 10-70% compared to conventional concrete, depending on the specific technology employed. These assessments typically use Global Warming Potential (GWP) as a key metric, measured in kg CO2-equivalent per cubic meter of concrete, providing standardized comparisons across different concrete formulations and applications.

The extraction phase analysis demonstrates that carbon-negative concrete typically requires less energy-intensive mining operations due to its incorporation of industrial byproducts and waste materials such as fly ash, slag, and recycled aggregates. These alternative materials reduce the need for virgin limestone extraction, which is a major source of CO2 emissions in conventional concrete production.

During the manufacturing phase, carbon-negative concrete technologies employ various CO2 sequestration methods. Companies like CarbonCure and Solidia have developed processes that inject and permanently store CO2 within the concrete matrix, effectively transforming concrete from a carbon source to a carbon sink. LCA data indicates that these technologies can sequester between 5-30% of the carbon typically emitted during traditional concrete production.

Transportation impacts vary significantly based on the proximity of raw materials and manufacturing facilities to construction sites. LCA studies show that locally sourced materials for carbon-negative concrete can reduce transportation-related emissions by up to 40% compared to conventional concrete supply chains that often require long-distance shipping of Portland cement.

The installation and use phases demonstrate minimal differences in environmental impact between carbon-negative and conventional concrete. However, the durability advantages of many carbon-negative formulations translate to extended service life, reducing the frequency of replacement and associated environmental impacts over time.

End-of-life analysis reveals that carbon-negative concrete maintains its carbon sequestration benefits even after demolition. When crushed, the increased surface area can potentially accelerate further carbonation, enhancing the carbon sequestration capacity. Additionally, recycled carbon-negative concrete aggregate can be incorporated into new concrete mixes, creating a circular economy approach that further reduces environmental impacts.

Comprehensive LCA studies conducted by research institutions such as MIT and ETH Zurich confirm that carbon-negative concrete can achieve net carbon reductions of 10-70% compared to conventional concrete, depending on the specific technology employed. These assessments typically use Global Warming Potential (GWP) as a key metric, measured in kg CO2-equivalent per cubic meter of concrete, providing standardized comparisons across different concrete formulations and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!