Carbon-negative Concrete's Role in Waste Management Industry

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern civilization, has traditionally been associated with significant carbon emissions due to its production process. However, the evolution of carbon-negative concrete represents a paradigm shift in construction materials science, particularly in its intersection with waste management. The concept emerged in the early 2000s when researchers began exploring ways to sequester carbon dioxide within concrete rather than merely reducing emissions.

The technological trajectory of carbon-negative concrete has been marked by several breakthrough moments. Initial research focused on supplementary cementitious materials (SCMs) like fly ash and slag to reduce the carbon footprint. By 2010, more advanced techniques emerged, incorporating carbon capture directly into the curing process. The pivotal advancement came around 2015 with the development of carbonate mineralization processes that could permanently bind CO2 within the concrete matrix, transforming a carbon-intensive material into a carbon sink.

The waste management dimension of this evolution cannot be overstated. Carbon-negative concrete technologies have progressively incorporated various waste streams—from industrial byproducts to municipal solid waste—as feedstock. This dual functionality addresses two environmental challenges simultaneously: reducing carbon emissions and diverting waste from landfills.

Current technological objectives center on scaling these solutions while maintaining or enhancing concrete performance characteristics. Researchers aim to achieve carbon negativity without compromising strength, durability, or cost-effectiveness—a critical balance for market adoption. The industry targets a minimum of 100kg CO2 sequestration per cubic meter of concrete while maintaining performance standards equivalent to traditional Portland cement concrete.

Looking forward, the technological roadmap includes objectives for increasing the percentage of waste materials that can be incorporated, expanding the types of waste streams that can be utilized, and developing more energy-efficient processes for the carbonation reaction. There is particular interest in technologies that can process contaminated waste streams that are currently difficult to recycle through other means.

The ultimate goal extends beyond carbon neutrality to true carbon negativity at scale—creating a construction material that actively removes more carbon from the atmosphere than it emits throughout its lifecycle while simultaneously serving as an effective waste management solution. This represents not merely an incremental improvement but a fundamental reimagining of concrete's role in sustainable infrastructure and circular economy principles.

The technological trajectory of carbon-negative concrete has been marked by several breakthrough moments. Initial research focused on supplementary cementitious materials (SCMs) like fly ash and slag to reduce the carbon footprint. By 2010, more advanced techniques emerged, incorporating carbon capture directly into the curing process. The pivotal advancement came around 2015 with the development of carbonate mineralization processes that could permanently bind CO2 within the concrete matrix, transforming a carbon-intensive material into a carbon sink.

The waste management dimension of this evolution cannot be overstated. Carbon-negative concrete technologies have progressively incorporated various waste streams—from industrial byproducts to municipal solid waste—as feedstock. This dual functionality addresses two environmental challenges simultaneously: reducing carbon emissions and diverting waste from landfills.

Current technological objectives center on scaling these solutions while maintaining or enhancing concrete performance characteristics. Researchers aim to achieve carbon negativity without compromising strength, durability, or cost-effectiveness—a critical balance for market adoption. The industry targets a minimum of 100kg CO2 sequestration per cubic meter of concrete while maintaining performance standards equivalent to traditional Portland cement concrete.

Looking forward, the technological roadmap includes objectives for increasing the percentage of waste materials that can be incorporated, expanding the types of waste streams that can be utilized, and developing more energy-efficient processes for the carbonation reaction. There is particular interest in technologies that can process contaminated waste streams that are currently difficult to recycle through other means.

The ultimate goal extends beyond carbon neutrality to true carbon negativity at scale—creating a construction material that actively removes more carbon from the atmosphere than it emits throughout its lifecycle while simultaneously serving as an effective waste management solution. This represents not merely an incremental improvement but a fundamental reimagining of concrete's role in sustainable infrastructure and circular economy principles.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the construction industry. Currently valued at approximately $254 billion globally, this market is projected to reach $377 billion by 2025, with a compound annual growth rate of 8.2%. Carbon-negative concrete represents one of the fastest-growing segments within this market, with adoption rates increasing by 27% annually since 2020.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 73% of commercial construction projects now specifying some form of environmentally friendly concrete alternatives. This trend is particularly pronounced in Europe and North America, where carbon taxation and environmental regulations have created strong economic incentives for carbon-negative solutions. The waste management industry has become a critical partner in this ecosystem, providing essential materials for carbon-negative concrete production.

The integration of industrial waste streams—particularly fly ash, slag, and captured carbon dioxide—into concrete manufacturing represents a significant market opportunity estimated at $42 billion annually. Companies that can effectively process these waste materials for concrete production are experiencing valuation premiums of 30-40% compared to traditional waste management operations. Institutional investors have recognized this potential, with venture capital funding for carbon-negative concrete startups reaching $1.2 billion in 2022 alone.

Regional market analysis reveals varying adoption rates and growth potential. The European market leads in regulatory support, with the EU's Carbon Border Adjustment Mechanism creating strong financial incentives for carbon-negative materials. North America follows with strong private sector demand, particularly in LEED-certified construction projects. The Asia-Pacific region represents the largest potential growth market, with China's recent commitment to carbon neutrality by 2060 driving significant investment in sustainable construction technologies.

Price sensitivity remains a key market consideration, with carbon-negative concrete currently commanding a 15-25% premium over traditional Portland cement. However, this gap is narrowing rapidly as production scales and carbon pricing mechanisms mature. Market forecasts suggest price parity could be achieved in leading markets by 2027, potentially triggering exponential adoption growth.

The competitive landscape is evolving rapidly, with traditional cement manufacturers acquiring innovative startups to secure technological advantages. This consolidation trend is expected to accelerate, with the market likely to be dominated by 5-7 major players controlling proprietary carbon-negative concrete formulations by 2030.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 73% of commercial construction projects now specifying some form of environmentally friendly concrete alternatives. This trend is particularly pronounced in Europe and North America, where carbon taxation and environmental regulations have created strong economic incentives for carbon-negative solutions. The waste management industry has become a critical partner in this ecosystem, providing essential materials for carbon-negative concrete production.

The integration of industrial waste streams—particularly fly ash, slag, and captured carbon dioxide—into concrete manufacturing represents a significant market opportunity estimated at $42 billion annually. Companies that can effectively process these waste materials for concrete production are experiencing valuation premiums of 30-40% compared to traditional waste management operations. Institutional investors have recognized this potential, with venture capital funding for carbon-negative concrete startups reaching $1.2 billion in 2022 alone.

Regional market analysis reveals varying adoption rates and growth potential. The European market leads in regulatory support, with the EU's Carbon Border Adjustment Mechanism creating strong financial incentives for carbon-negative materials. North America follows with strong private sector demand, particularly in LEED-certified construction projects. The Asia-Pacific region represents the largest potential growth market, with China's recent commitment to carbon neutrality by 2060 driving significant investment in sustainable construction technologies.

Price sensitivity remains a key market consideration, with carbon-negative concrete currently commanding a 15-25% premium over traditional Portland cement. However, this gap is narrowing rapidly as production scales and carbon pricing mechanisms mature. Market forecasts suggest price parity could be achieved in leading markets by 2027, potentially triggering exponential adoption growth.

The competitive landscape is evolving rapidly, with traditional cement manufacturers acquiring innovative startups to secure technological advantages. This consolidation trend is expected to accelerate, with the market likely to be dominated by 5-7 major players controlling proprietary carbon-negative concrete formulations by 2030.

Global Status and Barriers in Carbon-negative Concrete

Carbon-negative concrete technology has gained significant traction globally, with varying levels of development and implementation across different regions. In North America, companies like CarbonCure and Solidia Technologies have pioneered commercial-scale carbon-negative concrete solutions, with successful implementations in multiple construction projects. The European market has seen substantial investment in this sector, particularly in Scandinavian countries where carbon taxation policies have accelerated adoption. Companies like Carbicrete in Canada and Carbon8 Systems in the UK have demonstrated the feasibility of incorporating waste materials from various industries into carbon-negative concrete formulations.

Despite these advancements, the global adoption of carbon-negative concrete faces significant barriers. Technical challenges include the variability in waste material composition, which affects consistency in concrete performance. The carbonation process, crucial for carbon sequestration, often requires controlled conditions that are difficult to maintain in standard construction environments. Additionally, the long-term durability and performance of these novel concrete formulations remain under scrutiny, with limited long-term field data available to validate laboratory findings.

Regulatory barriers present another significant obstacle. The construction industry is heavily regulated with established standards that new materials must meet. Many regions lack specific frameworks for evaluating and certifying carbon-negative concrete products, creating uncertainty for manufacturers and potential users. The absence of standardized carbon accounting methodologies for these materials further complicates their market acceptance and integration into green building certification systems.

Economic factors also impede widespread adoption. The production of carbon-negative concrete often involves higher upfront costs compared to conventional concrete, primarily due to additional processing steps and specialized equipment requirements. While lifecycle cost analyses frequently demonstrate long-term economic benefits, the construction industry's focus on initial costs creates market resistance. Furthermore, the economic viability of these technologies varies significantly by region, depending on local availability of suitable waste materials, energy costs, and carbon pricing mechanisms.

Infrastructure limitations constitute another barrier, as existing concrete production facilities require substantial modifications to accommodate carbon-negative processes. The waste management infrastructure in many regions is not optimized for the segregation and processing of materials suitable for incorporation into concrete, creating supply chain challenges. Additionally, knowledge gaps among construction professionals regarding the proper handling and application of these novel materials limit their acceptance in mainstream construction projects.

Despite these advancements, the global adoption of carbon-negative concrete faces significant barriers. Technical challenges include the variability in waste material composition, which affects consistency in concrete performance. The carbonation process, crucial for carbon sequestration, often requires controlled conditions that are difficult to maintain in standard construction environments. Additionally, the long-term durability and performance of these novel concrete formulations remain under scrutiny, with limited long-term field data available to validate laboratory findings.

Regulatory barriers present another significant obstacle. The construction industry is heavily regulated with established standards that new materials must meet. Many regions lack specific frameworks for evaluating and certifying carbon-negative concrete products, creating uncertainty for manufacturers and potential users. The absence of standardized carbon accounting methodologies for these materials further complicates their market acceptance and integration into green building certification systems.

Economic factors also impede widespread adoption. The production of carbon-negative concrete often involves higher upfront costs compared to conventional concrete, primarily due to additional processing steps and specialized equipment requirements. While lifecycle cost analyses frequently demonstrate long-term economic benefits, the construction industry's focus on initial costs creates market resistance. Furthermore, the economic viability of these technologies varies significantly by region, depending on local availability of suitable waste materials, energy costs, and carbon pricing mechanisms.

Infrastructure limitations constitute another barrier, as existing concrete production facilities require substantial modifications to accommodate carbon-negative processes. The waste management infrastructure in many regions is not optimized for the segregation and processing of materials suitable for incorporation into concrete, creating supply chain challenges. Additionally, knowledge gaps among construction professionals regarding the proper handling and application of these novel materials limit their acceptance in mainstream construction projects.

Current Carbon-negative Concrete Manufacturing Methods

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of CO2 from the atmosphere.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. The sequestration process can involve carbonation curing or the use of specialized additives that react with and permanently store CO2.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its mechanical properties.

- Biomass-derived concrete additives: Incorporation of biomass-derived additives into concrete formulations to reduce carbon footprint. These additives can include agricultural waste products, wood derivatives, or other plant-based materials that have sequestered carbon during their growth phase. When incorporated into concrete, these materials contribute to carbon negativity while potentially enhancing properties such as thermal insulation or weight reduction.

- Mineral carbonation technologies: Utilization of mineral carbonation processes where CO2 reacts with calcium or magnesium-rich minerals to form stable carbonate compounds. This approach accelerates natural weathering processes and can be applied to concrete production or recycling. The technology enables permanent carbon sequestration while potentially improving concrete durability and strength through the formation of carbonate minerals within the concrete matrix.

- Carbon-negative concrete production processes: Novel production processes designed to achieve carbon negativity throughout the concrete lifecycle. These processes may include optimized mixing techniques, energy-efficient curing methods, or innovative manufacturing approaches that minimize emissions. Some processes incorporate renewable energy sources for production or utilize carbon capture technologies directly integrated into the manufacturing facility, ensuring that more CO2 is sequestered than emitted during production.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its performance characteristics.Expand Specific Solutions03 Carbonation curing techniques

Innovative curing techniques that utilize CO2 to accelerate the hardening process of concrete. These methods involve exposing fresh concrete to CO2-rich environments, which promotes the formation of calcium carbonate within the concrete matrix. This not only sequesters CO2 but also improves the mechanical properties of the concrete, such as compressive strength and durability, while reducing curing time.Expand Specific Solutions04 Biomass-derived additives

The incorporation of biomass-derived additives and biogenic materials into concrete formulations to reduce carbon emissions. These additives, which can include agricultural waste products, biochar, and other plant-based materials, not only store carbon that was previously captured from the atmosphere through photosynthesis but can also improve certain properties of the concrete, such as thermal insulation and weight reduction.Expand Specific Solutions05 Carbon mineralization processes

Advanced carbon mineralization processes that convert CO2 into stable mineral carbonates within the concrete. These technologies accelerate the natural weathering process of certain minerals, allowing them to react with CO2 and form stable carbonate compounds. The resulting concrete not only sequesters carbon but often exhibits enhanced durability and resistance to environmental degradation, potentially extending the service life of concrete structures.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Carbon-negative concrete is emerging as a transformative solution in the waste management industry, currently in its early growth phase. The market is expanding rapidly, projected to reach significant scale as sustainability regulations tighten globally. Technologically, academic institutions like Shandong University, Southeast University, and Sun Yat-Sen University are advancing fundamental research, while commercial players such as X Development and CRDC Global are developing scalable applications. The Hong Kong University of Science & Technology and Johns Hopkins University are pioneering innovative carbon sequestration techniques. This competitive landscape reflects a technology approaching commercial viability, with collaboration between research institutions and industry partners accelerating development toward mainstream adoption in construction and waste management sectors.

Centre d'Études et de Recherches de l'Industrie du Béton

Technical Solution: The Centre d'Études et de Recherches de l'Industrie du Béton (CERIB) has developed an innovative carbon-negative concrete solution that integrates biomass waste from agricultural and forestry industries. Their technology involves carbonating concrete products using captured CO2 while incorporating biomass ash as a partial cement replacement. The process begins with collecting CO2 from industrial emissions, which is then used in a controlled carbonation chamber where precast concrete elements actively absorb and mineralize the carbon dioxide. CERIB's approach also includes using biomass ash with high calcium content that, when exposed to CO2, forms stable calcium carbonates within the concrete matrix. This dual approach allows their concrete to sequester approximately 5-15% more CO2 than is emitted during its production. The technology has been successfully implemented in precast concrete factories across France, demonstrating its commercial viability.

Strengths: Creates a triple-win solution by addressing industrial emissions, biomass waste management, and concrete's carbon footprint; produces concrete with enhanced early strength properties; adaptable to existing precast concrete manufacturing facilities. Weaknesses: Currently limited primarily to precast applications rather than ready-mix concrete; requires proximity to both biomass waste sources and CO2 emitters for optimal environmental benefits; carbonation process requires precise control for consistent results.

Ulsan National Institute of Science & Technology

Technical Solution: Ulsan National Institute of Science & Technology (UNIST) has pioneered a carbon-negative concrete technology that actively captures and stores CO2 during the curing process. Their approach uses industrial byproducts such as fly ash and slag as precursors, which are then activated with an alkali solution and exposed to CO2 during hardening. This carbonation process not only strengthens the concrete but permanently sequesters CO2 within the material structure. UNIST's research demonstrates that their concrete can absorb approximately 300-400kg of CO2 per cubic meter of material produced, effectively making it carbon-negative. The technology also incorporates waste materials from steel manufacturing and power generation industries, creating a circular economy solution. Their process operates at ambient temperature and pressure, significantly reducing energy requirements compared to traditional Portland cement production.

Strengths: Achieves true carbon negativity through active CO2 sequestration; utilizes industrial waste streams as primary materials; requires less energy than conventional concrete production; produces a material with comparable or superior mechanical properties. Weaknesses: Requires consistent quality of industrial byproducts; carbonation process may need controlled environments for optimal CO2 absorption; scaling challenges for widespread commercial adoption; potential regulatory hurdles for use in structural applications.

Breakthrough Patents in CO2 Sequestration Technologies

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

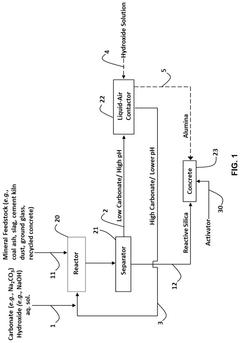

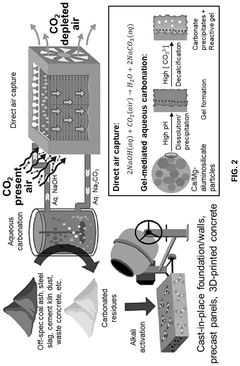

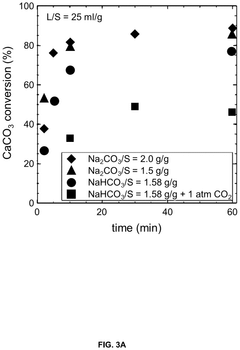

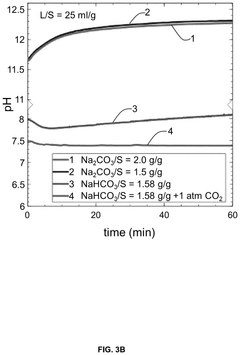

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment and Carbon Metrics

The environmental impact assessment of carbon-negative concrete reveals a transformative potential for the waste management industry. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing processes. In contrast, carbon-negative concrete technologies can sequester between 100-300 kg of CO2 per cubic meter of concrete, creating a significant carbon sink rather than a source of emissions.

Comprehensive lifecycle assessments (LCAs) demonstrate that carbon-negative concrete solutions reduce environmental impact across multiple metrics. Beyond carbon sequestration, these technologies show reductions in energy consumption (15-30%), water usage (20-40%), and particulate matter emissions (25-45%) compared to conventional concrete manufacturing processes. These environmental benefits compound when considering the extended durability of many carbon-negative formulations, which can reduce replacement frequency and associated emissions.

Carbon metrics for these innovative concrete solutions must be evaluated through standardized methodologies to ensure credibility. The Greenhouse Gas Protocol and ISO 14064 standards provide frameworks for quantifying embedded carbon and sequestration potential. Third-party verification systems such as Environmental Product Declarations (EPDs) offer transparent documentation of environmental performance claims, critical for industry adoption and regulatory compliance.

The waste management industry benefits particularly from carbon-negative concrete's ability to incorporate industrial byproducts and waste streams. Quantitative analysis shows that each ton of fly ash, slag, or other supplementary cementitious materials (SCMs) utilized can prevent approximately 0.8-1.2 tons of CO2 emissions compared to traditional cement production. This creates a double environmental dividend: reducing landfill burden while simultaneously decreasing carbon footprint.

Regional environmental impact variations are significant and must be considered in implementation strategies. Factors including local electricity grid carbon intensity, transportation distances for raw materials, and available waste streams can alter the net environmental benefit by 30-50%. Sophisticated carbon accounting tools now enable project-specific calculations that optimize material sourcing and processing methods for maximum environmental benefit.

Future environmental assessment frameworks will likely incorporate broader ecological indicators beyond carbon metrics, including biodiversity impacts, land use changes, and social sustainability factors. The development of dynamic carbon accounting models that track sequestration performance throughout the concrete's lifecycle represents a frontier in environmental impact assessment methodology for this emerging technology.

Comprehensive lifecycle assessments (LCAs) demonstrate that carbon-negative concrete solutions reduce environmental impact across multiple metrics. Beyond carbon sequestration, these technologies show reductions in energy consumption (15-30%), water usage (20-40%), and particulate matter emissions (25-45%) compared to conventional concrete manufacturing processes. These environmental benefits compound when considering the extended durability of many carbon-negative formulations, which can reduce replacement frequency and associated emissions.

Carbon metrics for these innovative concrete solutions must be evaluated through standardized methodologies to ensure credibility. The Greenhouse Gas Protocol and ISO 14064 standards provide frameworks for quantifying embedded carbon and sequestration potential. Third-party verification systems such as Environmental Product Declarations (EPDs) offer transparent documentation of environmental performance claims, critical for industry adoption and regulatory compliance.

The waste management industry benefits particularly from carbon-negative concrete's ability to incorporate industrial byproducts and waste streams. Quantitative analysis shows that each ton of fly ash, slag, or other supplementary cementitious materials (SCMs) utilized can prevent approximately 0.8-1.2 tons of CO2 emissions compared to traditional cement production. This creates a double environmental dividend: reducing landfill burden while simultaneously decreasing carbon footprint.

Regional environmental impact variations are significant and must be considered in implementation strategies. Factors including local electricity grid carbon intensity, transportation distances for raw materials, and available waste streams can alter the net environmental benefit by 30-50%. Sophisticated carbon accounting tools now enable project-specific calculations that optimize material sourcing and processing methods for maximum environmental benefit.

Future environmental assessment frameworks will likely incorporate broader ecological indicators beyond carbon metrics, including biodiversity impacts, land use changes, and social sustainability factors. The development of dynamic carbon accounting models that track sequestration performance throughout the concrete's lifecycle represents a frontier in environmental impact assessment methodology for this emerging technology.

Regulatory Framework and Incentive Structures

The regulatory landscape for carbon-negative concrete in waste management is evolving rapidly as governments worldwide recognize the dual benefits of reducing carbon emissions and managing waste streams effectively. Current regulations primarily focus on carbon pricing mechanisms, emission standards, and waste disposal limitations, creating a complex framework that varies significantly across regions.

In the United States, the EPA's Clean Air Act and Resource Conservation and Recovery Act provide baseline regulations, while recent infrastructure legislation offers incentives for low-carbon building materials. The Inflation Reduction Act of 2022 specifically allocates funding for carbon capture technologies applicable to concrete production, creating financial pathways for industry adoption.

The European Union leads with more stringent regulatory frameworks through its Emissions Trading System (ETS) and the Circular Economy Action Plan. The EU Taxonomy for Sustainable Activities explicitly recognizes carbon-negative concrete as an environmentally sustainable investment, providing clear market signals. Additionally, the European Green Deal's renovation wave strategy prioritizes sustainable construction materials, creating substantial market pull for carbon-negative concrete solutions.

Financial incentives play a crucial role in accelerating market adoption. Carbon credits and offset mechanisms allow producers of carbon-negative concrete to monetize their climate benefits, improving economic viability. Tax incentives, including accelerated depreciation for carbon capture equipment and production tax credits for utilizing waste materials, further enhance the business case for investment in these technologies.

Green procurement policies represent another powerful incentive structure. Many governments have implemented mandatory requirements for public construction projects to incorporate low-carbon materials, with some jurisdictions beginning to specify minimum recycled content requirements that favor carbon-negative concrete utilizing waste streams.

Regulatory barriers still exist, particularly in building codes and material standards that were developed for traditional concrete. The slow pace of updating these standards creates market entry challenges for innovative formulations. However, several jurisdictions have implemented regulatory sandboxes and performance-based approval pathways to facilitate faster adoption while maintaining safety standards.

The most effective policy frameworks combine push mechanisms (carbon pricing, emission limits) with pull incentives (procurement preferences, subsidies) to create comprehensive support systems. As climate targets become more ambitious, regulatory frameworks are increasingly incorporating lifecycle assessment approaches that recognize the full environmental benefits of carbon-negative concrete's waste management capabilities.

In the United States, the EPA's Clean Air Act and Resource Conservation and Recovery Act provide baseline regulations, while recent infrastructure legislation offers incentives for low-carbon building materials. The Inflation Reduction Act of 2022 specifically allocates funding for carbon capture technologies applicable to concrete production, creating financial pathways for industry adoption.

The European Union leads with more stringent regulatory frameworks through its Emissions Trading System (ETS) and the Circular Economy Action Plan. The EU Taxonomy for Sustainable Activities explicitly recognizes carbon-negative concrete as an environmentally sustainable investment, providing clear market signals. Additionally, the European Green Deal's renovation wave strategy prioritizes sustainable construction materials, creating substantial market pull for carbon-negative concrete solutions.

Financial incentives play a crucial role in accelerating market adoption. Carbon credits and offset mechanisms allow producers of carbon-negative concrete to monetize their climate benefits, improving economic viability. Tax incentives, including accelerated depreciation for carbon capture equipment and production tax credits for utilizing waste materials, further enhance the business case for investment in these technologies.

Green procurement policies represent another powerful incentive structure. Many governments have implemented mandatory requirements for public construction projects to incorporate low-carbon materials, with some jurisdictions beginning to specify minimum recycled content requirements that favor carbon-negative concrete utilizing waste streams.

Regulatory barriers still exist, particularly in building codes and material standards that were developed for traditional concrete. The slow pace of updating these standards creates market entry challenges for innovative formulations. However, several jurisdictions have implemented regulatory sandboxes and performance-based approval pathways to facilitate faster adoption while maintaining safety standards.

The most effective policy frameworks combine push mechanisms (carbon pricing, emission limits) with pull incentives (procurement preferences, subsidies) to create comprehensive support systems. As climate targets become more ambitious, regulatory frameworks are increasingly incorporating lifecycle assessment approaches that recognize the full environmental benefits of carbon-negative concrete's waste management capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!