Carbon-negative Concrete Application in Remote Infrastructure Projects

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, a fundamental building material in modern infrastructure, has traditionally been associated with significant carbon emissions due to its production process, particularly cement manufacturing which accounts for approximately 8% of global CO2 emissions. Carbon-negative concrete represents a revolutionary shift in construction materials technology, designed not only to reduce emissions but to actively sequester carbon dioxide throughout its lifecycle, resulting in a net environmental benefit.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations to more environmentally conscious alternatives. Early improvements focused on reducing clinker content through supplementary cementitious materials (SCMs) like fly ash and slag. Recent innovations have advanced toward carbon-neutral and now carbon-negative formulations, representing a paradigm shift in how we approach infrastructure materials.

Carbon-negative concrete technologies employ various mechanisms to achieve negative emissions, including carbon mineralization processes, alternative binding agents derived from industrial waste streams, and novel curing techniques that actively absorb CO2. These technologies have matured significantly over the past decade, moving from laboratory concepts to commercially viable products with demonstrable carbon sequestration capabilities.

The primary objective of researching carbon-negative concrete applications in remote infrastructure projects is to address the unique challenges these environments present while maximizing environmental benefits. Remote locations often face logistical constraints, extreme climate conditions, limited access to conventional materials, and minimal maintenance capabilities. These factors necessitate specialized concrete formulations that maintain durability and performance while achieving carbon negativity.

Technical goals include developing formulations that utilize locally available materials to reduce transportation emissions, creating mix designs that perform reliably under extreme temperature variations common in remote areas, and establishing simplified implementation protocols that require minimal specialized equipment or expertise. Additionally, research aims to quantify the total carbon lifecycle impact when factoring in transportation to remote sites.

Long-term objectives extend beyond immediate carbon benefits to include enhancing infrastructure resilience in remote communities, developing economically viable solutions that can be deployed at scale, and creating standardized methodologies for measuring and verifying carbon sequestration in these specialized applications. The research also seeks to establish a framework for integrating carbon-negative concrete into carbon credit markets, potentially creating additional revenue streams for remote infrastructure projects.

This technological trajectory aligns with global decarbonization goals while addressing the specific needs of remote infrastructure development, representing a convergence of environmental sustainability and practical engineering solutions for challenging environments.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations to more environmentally conscious alternatives. Early improvements focused on reducing clinker content through supplementary cementitious materials (SCMs) like fly ash and slag. Recent innovations have advanced toward carbon-neutral and now carbon-negative formulations, representing a paradigm shift in how we approach infrastructure materials.

Carbon-negative concrete technologies employ various mechanisms to achieve negative emissions, including carbon mineralization processes, alternative binding agents derived from industrial waste streams, and novel curing techniques that actively absorb CO2. These technologies have matured significantly over the past decade, moving from laboratory concepts to commercially viable products with demonstrable carbon sequestration capabilities.

The primary objective of researching carbon-negative concrete applications in remote infrastructure projects is to address the unique challenges these environments present while maximizing environmental benefits. Remote locations often face logistical constraints, extreme climate conditions, limited access to conventional materials, and minimal maintenance capabilities. These factors necessitate specialized concrete formulations that maintain durability and performance while achieving carbon negativity.

Technical goals include developing formulations that utilize locally available materials to reduce transportation emissions, creating mix designs that perform reliably under extreme temperature variations common in remote areas, and establishing simplified implementation protocols that require minimal specialized equipment or expertise. Additionally, research aims to quantify the total carbon lifecycle impact when factoring in transportation to remote sites.

Long-term objectives extend beyond immediate carbon benefits to include enhancing infrastructure resilience in remote communities, developing economically viable solutions that can be deployed at scale, and creating standardized methodologies for measuring and verifying carbon sequestration in these specialized applications. The research also seeks to establish a framework for integrating carbon-negative concrete into carbon credit markets, potentially creating additional revenue streams for remote infrastructure projects.

This technological trajectory aligns with global decarbonization goals while addressing the specific needs of remote infrastructure development, representing a convergence of environmental sustainability and practical engineering solutions for challenging environments.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the construction industry. Currently valued at approximately $299 billion globally, this market is projected to reach $641 billion by 2030, with a compound annual growth rate of 11.4% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this market, with particular relevance for remote infrastructure projects.

Demand for carbon-negative concrete is primarily driven by government infrastructure initiatives focused on sustainability, corporate commitments to carbon neutrality, and increasing carbon taxation policies worldwide. In remote infrastructure projects specifically, the market demand is influenced by unique factors including logistical challenges, extreme environmental conditions, and limited access to conventional materials. These projects often face higher scrutiny regarding environmental impact due to their locations in sensitive or underdeveloped regions.

Regional analysis reveals varying adoption rates of sustainable construction materials. Europe leads the market with stringent regulations and ambitious carbon reduction targets, particularly in Scandinavian countries where carbon taxes have accelerated adoption. North America follows with growing demand primarily in public infrastructure projects, while the Asia-Pacific region shows the highest growth potential, especially in developing economies investing heavily in infrastructure development.

The customer segmentation for carbon-negative concrete in remote projects spans several sectors. Government agencies and public works departments constitute approximately 45% of the market, particularly for critical infrastructure in remote areas. Private sector infrastructure developers represent about 30%, focusing on energy projects, mining operations, and telecommunications infrastructure. The remaining market share is divided among international development organizations, military applications, and disaster recovery projects.

Price sensitivity analysis indicates that while carbon-negative concrete currently commands a premium of 15-25% over traditional concrete, this gap is narrowing as production scales up and technology improves. For remote projects, the total cost calculation must factor in transportation savings, durability benefits, and carbon credit opportunities, which can offset the initial price premium in many scenarios.

Market barriers include limited awareness of carbon-negative concrete benefits, concerns about long-term performance in extreme conditions, supply chain constraints for remote locations, and regulatory frameworks that have not fully adapted to these innovative materials. However, these barriers are gradually diminishing as successful case studies emerge and climate-focused policies gain momentum globally.

Demand for carbon-negative concrete is primarily driven by government infrastructure initiatives focused on sustainability, corporate commitments to carbon neutrality, and increasing carbon taxation policies worldwide. In remote infrastructure projects specifically, the market demand is influenced by unique factors including logistical challenges, extreme environmental conditions, and limited access to conventional materials. These projects often face higher scrutiny regarding environmental impact due to their locations in sensitive or underdeveloped regions.

Regional analysis reveals varying adoption rates of sustainable construction materials. Europe leads the market with stringent regulations and ambitious carbon reduction targets, particularly in Scandinavian countries where carbon taxes have accelerated adoption. North America follows with growing demand primarily in public infrastructure projects, while the Asia-Pacific region shows the highest growth potential, especially in developing economies investing heavily in infrastructure development.

The customer segmentation for carbon-negative concrete in remote projects spans several sectors. Government agencies and public works departments constitute approximately 45% of the market, particularly for critical infrastructure in remote areas. Private sector infrastructure developers represent about 30%, focusing on energy projects, mining operations, and telecommunications infrastructure. The remaining market share is divided among international development organizations, military applications, and disaster recovery projects.

Price sensitivity analysis indicates that while carbon-negative concrete currently commands a premium of 15-25% over traditional concrete, this gap is narrowing as production scales up and technology improves. For remote projects, the total cost calculation must factor in transportation savings, durability benefits, and carbon credit opportunities, which can offset the initial price premium in many scenarios.

Market barriers include limited awareness of carbon-negative concrete benefits, concerns about long-term performance in extreme conditions, supply chain constraints for remote locations, and regulatory frameworks that have not fully adapted to these innovative materials. However, these barriers are gradually diminishing as successful case studies emerge and climate-focused policies gain momentum globally.

Current Status and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has seen significant advancements globally, yet faces substantial implementation challenges, particularly in remote infrastructure projects. Current research indicates that approximately 8% of global carbon emissions stem from concrete production, making carbon-negative alternatives crucial for climate change mitigation efforts. Leading markets including the European Union, United States, and parts of Asia have begun adopting these technologies, though at varying rates of implementation.

The current technological landscape features several promising approaches. Calcium carbonate looping (CCL) systems have demonstrated carbon capture efficiency rates of 70-85% in laboratory settings, while alternative binding materials such as geopolymers show 40-60% reduced carbon footprints compared to traditional Portland cement. Carbon mineralization techniques, which permanently sequester CO2 in concrete, have advanced from theoretical concepts to commercial applications within the past five years.

Despite these advancements, significant technical challenges persist. Carbon curing processes require precise environmental controls difficult to maintain in remote locations, with temperature and humidity variations affecting carbonation rates by up to 30%. Energy requirements for carbon capture and utilization remain high, typically adding 15-25% to production costs, creating economic barriers for widespread adoption in cost-sensitive infrastructure projects.

Geographic limitations present additional obstacles. Remote infrastructure projects often lack access to specialized materials and equipment necessary for carbon-negative concrete production. Transportation distances to remote sites can increase embedded carbon footprints by 10-40%, potentially negating carbon benefits. Limited local technical expertise in remote regions further complicates implementation and quality control.

Regulatory frameworks remain inconsistent globally, with only 23% of countries having specific standards for carbon-negative concrete. This regulatory uncertainty impedes investment and standardization efforts. Testing and certification processes are still evolving, with durability assessments typically requiring 2-5 years of data collection—a timeline incompatible with rapid infrastructure development needs.

Scale-up challenges are particularly pronounced in remote applications. Current carbon-negative concrete production facilities typically operate at 30-50% the capacity of traditional concrete plants, creating supply constraints. On-site production technologies remain in early development stages, with only prototype systems demonstrating feasibility in remote conditions. The technology readiness level (TRL) for most carbon-negative concrete solutions ranges from 6-8 in controlled environments but drops to 4-6 when applied to remote infrastructure contexts.

The current technological landscape features several promising approaches. Calcium carbonate looping (CCL) systems have demonstrated carbon capture efficiency rates of 70-85% in laboratory settings, while alternative binding materials such as geopolymers show 40-60% reduced carbon footprints compared to traditional Portland cement. Carbon mineralization techniques, which permanently sequester CO2 in concrete, have advanced from theoretical concepts to commercial applications within the past five years.

Despite these advancements, significant technical challenges persist. Carbon curing processes require precise environmental controls difficult to maintain in remote locations, with temperature and humidity variations affecting carbonation rates by up to 30%. Energy requirements for carbon capture and utilization remain high, typically adding 15-25% to production costs, creating economic barriers for widespread adoption in cost-sensitive infrastructure projects.

Geographic limitations present additional obstacles. Remote infrastructure projects often lack access to specialized materials and equipment necessary for carbon-negative concrete production. Transportation distances to remote sites can increase embedded carbon footprints by 10-40%, potentially negating carbon benefits. Limited local technical expertise in remote regions further complicates implementation and quality control.

Regulatory frameworks remain inconsistent globally, with only 23% of countries having specific standards for carbon-negative concrete. This regulatory uncertainty impedes investment and standardization efforts. Testing and certification processes are still evolving, with durability assessments typically requiring 2-5 years of data collection—a timeline incompatible with rapid infrastructure development needs.

Scale-up challenges are particularly pronounced in remote applications. Current carbon-negative concrete production facilities typically operate at 30-50% the capacity of traditional concrete plants, creating supply constraints. On-site production technologies remain in early development stages, with only prototype systems demonstrating feasibility in remote conditions. The technology readiness level (TRL) for most carbon-negative concrete solutions ranges from 6-8 in controlled environments but drops to 4-6 when applied to remote infrastructure contexts.

Current Carbon-negative Concrete Implementation Solutions

01 CO2 Capture and Sequestration in Concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve injecting CO2 into concrete mixtures where it reacts with calcium compounds to form stable carbonate minerals, effectively locking away carbon dioxide while simultaneously improving concrete strength and durability. This approach transforms concrete from a carbon source to a carbon sink.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively turning concrete from a carbon emitter to a carbon sink. This approach not only reduces the carbon footprint of concrete production but also helps in mitigating climate change by removing CO2 from the atmosphere.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement in concrete production. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials like fly ash, slag, and silica fume. These materials require less energy to produce and generate fewer CO2 emissions compared to conventional cement, contributing to the development of carbon-negative concrete solutions.

- Biomass incorporation in concrete: The integration of biomass or bio-based materials into concrete formulations to reduce carbon footprint. This approach involves using agricultural waste, wood products, or other plant-based materials as partial replacements for traditional concrete components. These bio-based materials store carbon absorbed during their growth phase, which remains sequestered in the concrete structure, contributing to carbon negativity.

- Mineral carbonation technologies: Advanced mineral carbonation technologies that accelerate the natural process of CO2 absorption by minerals. These technologies involve exposing calcium or magnesium-rich materials to CO2, resulting in the formation of stable carbonate minerals. When incorporated into concrete production, these carbonated minerals contribute to carbon sequestration while potentially enhancing concrete properties such as strength and durability.

- Novel curing methods for enhanced CO2 uptake: Innovative concrete curing methods designed to maximize CO2 absorption during the hardening process. These methods include CO2 injection during curing, pressure-enhanced carbonation, and specialized curing chambers with controlled CO2 atmospheres. By optimizing the curing conditions, these technologies enable concrete to absorb significant amounts of CO2, transforming it into a carbon-negative building material while potentially improving its mechanical properties.

02 Alternative Cementitious Materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete while maintaining or enhancing performance characteristics.Expand Specific Solutions03 Biomass and Bio-based Additives

Incorporation of biomass and bio-based additives into concrete formulations to reduce carbon footprint. These additives, derived from agricultural waste, wood products, or other renewable resources, can partially replace cement or serve as carbon-sequestering fillers. The organic materials can be processed to enhance their durability within the concrete matrix while contributing to carbon negativity through their inherent carbon storage capabilities.Expand Specific Solutions04 Mineral Carbonation Processes

Advanced mineral carbonation processes that accelerate the natural weathering of minerals to capture CO2. These technologies involve the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds. When incorporated into concrete production, these processes can significantly reduce the carbon footprint of the final product while potentially improving material properties such as strength and resistance to chemical attack.Expand Specific Solutions05 Energy-Efficient Curing Methods

Novel curing methods that reduce energy consumption while enhancing CO2 uptake in concrete. These approaches include ambient-temperature carbonation curing, accelerated carbonation techniques, and specialized curing chambers that optimize CO2 exposure. By replacing traditional energy-intensive thermal curing with these carbon-sequestering alternatives, the overall carbon footprint of concrete production is significantly reduced while potentially improving concrete quality and performance.Expand Specific Solutions

Key Industry Players in Carbon-negative Construction

The carbon-negative concrete market for remote infrastructure is in an early growth phase, characterized by increasing demand driven by sustainability goals but limited commercial-scale applications. The market size is expanding as infrastructure projects seek to reduce carbon footprints, with projections showing significant growth potential. Technologically, companies like CarbonCure Technologies and China Building Materials Academy are leading innovation, while academic institutions (Shenzhen University, Shandong University) focus on fundamental research. State-owned enterprises such as China State Railway Group and State Grid Corp. are exploring implementation in large-scale remote projects. The technology remains in development with varying maturity levels across applications, with specialized firms like Sobute New Materials and Bio Graphene Solutions advancing niche solutions for challenging remote environments.

China Building Materials Academy Co. Ltd.

Technical Solution: China Building Materials Academy (CBMA) has developed an advanced carbon-negative concrete system specifically engineered for remote infrastructure projects. Their technology combines alkali-activated materials with novel carbon-absorbing aggregates that continuously sequester CO2 throughout the concrete's lifecycle. For remote applications, CBMA has created a containerized production system that can be transported to isolated locations and operate with minimal external resource requirements. Their formulation utilizes up to 80% industrial by-products, significantly reducing the need for traditional cement while achieving comparable or superior performance characteristics. The concrete mixture incorporates specialized catalysts that accelerate carbonation processes, enabling rapid carbon sequestration even in challenging environmental conditions. CBMA's system includes proprietary monitoring technology that tracks carbon sequestration rates in real-time, providing valuable data for carbon credit verification and project sustainability metrics.

Strengths: Comprehensive solution including production equipment and monitoring systems; high utilization of locally available waste materials; excellent performance in extreme temperature conditions; minimal water requirements suitable for water-scarce regions. Weaknesses: Complex quality control requirements; higher technical expertise needed for implementation; limited track record in extremely remote locations compared to conventional solutions.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed an innovative carbon-negative concrete solution specifically designed for remote infrastructure projects. Their technology incorporates industrial by-products such as fly ash and slag with specialized carbon-capturing additives that actively absorb CO2 throughout the concrete's lifecycle. For remote applications, CNBM has engineered a modular production system that can be deployed in isolated areas with minimal infrastructure requirements. Their concrete formulation reduces cement content by up to 60% while maintaining structural integrity and durability in extreme environments. CNBM's solution includes a proprietary curing process that accelerates carbon sequestration, enabling the concrete to achieve carbon negativity within 1-2 years of installation rather than decades. The company has successfully implemented this technology in remote railway projects across western China's challenging terrains.

Strengths: Extensive experience in large-scale infrastructure projects; comprehensive supply chain management capabilities; significant R&D resources; proven implementation in remote locations. Weaknesses: Higher initial production costs compared to traditional concrete; requires specialized training for on-site personnel; performance data in extremely cold environments still being validated.

Core Patents and Innovations in Carbon Capture Concrete

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

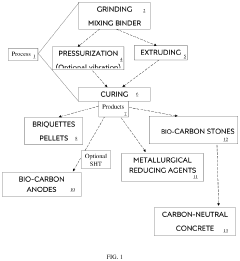

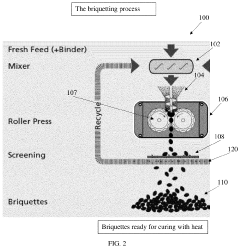

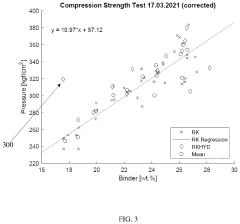

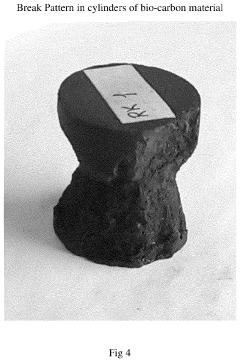

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

Low carbon emission concrete block

PatentWO2025036429A9

Innovation

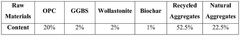

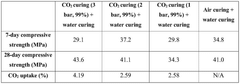

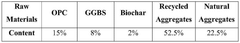

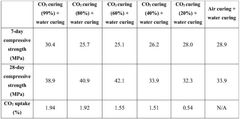

- A concrete formulation using recycled aggregates, natural aggregates, Ordinary Portland Cement, and low-carbon raw materials like ground granulated blast-furnace slag, fly ash, biochar, and wollastonite, combined with a carbon dioxide-enhanced curing process to achieve reduced carbon dioxide emission without compromising mechanical strength.

Logistical Considerations for Remote Infrastructure Projects

Implementing carbon-negative concrete in remote infrastructure projects presents unique logistical challenges that require careful planning and innovative solutions. Transportation to remote locations significantly impacts both project costs and carbon footprints, often requiring multimodal transport combinations including sea, air, road, and sometimes specialized equipment for final-mile delivery. The carbon emissions associated with these transportation activities can potentially offset the environmental benefits of carbon-negative concrete, necessitating comprehensive lifecycle assessments that account for all logistical operations.

Material storage in remote environments introduces additional complexities, particularly for carbon-negative concrete components that may have specific temperature, humidity, or handling requirements. Establishing appropriate storage facilities that protect these specialized materials from environmental exposure while maintaining their carbon-sequestering properties is essential for project success. These facilities must be designed to withstand local climate conditions, which may range from extreme heat to freezing temperatures depending on the project location.

Equipment mobilization represents another significant logistical consideration. Specialized mixing, pouring, and curing equipment may be required for carbon-negative concrete applications, and transporting this machinery to remote sites often demands substantial planning and resources. In many cases, equipment modifications or portable solutions must be developed to accommodate the constraints of remote locations while ensuring the concrete achieves its intended carbon-negative performance.

Workforce logistics also merit careful attention, as skilled personnel familiar with carbon-negative concrete technologies may need to be transported to and accommodated at remote sites. Training local workers presents an alternative approach that can reduce transportation requirements while building valuable skills within local communities, though this necessitates additional time for knowledge transfer and skill development.

Supply chain resilience is particularly critical for remote projects, where disruptions can cause severe delays and cost overruns. Developing redundant sourcing strategies for key materials, establishing buffer inventories, and implementing real-time tracking systems can help mitigate these risks. Additionally, local sourcing of complementary materials, where feasible, can reduce logistical complexity while potentially enhancing the project's overall sustainability profile.

Seasonal considerations must be factored into project planning, as weather conditions can significantly impact both transportation accessibility and concrete curing processes. In many remote regions, there may be limited windows of opportunity for material delivery and construction activities, requiring precise scheduling and contingency planning to avoid costly delays or material degradation.

Material storage in remote environments introduces additional complexities, particularly for carbon-negative concrete components that may have specific temperature, humidity, or handling requirements. Establishing appropriate storage facilities that protect these specialized materials from environmental exposure while maintaining their carbon-sequestering properties is essential for project success. These facilities must be designed to withstand local climate conditions, which may range from extreme heat to freezing temperatures depending on the project location.

Equipment mobilization represents another significant logistical consideration. Specialized mixing, pouring, and curing equipment may be required for carbon-negative concrete applications, and transporting this machinery to remote sites often demands substantial planning and resources. In many cases, equipment modifications or portable solutions must be developed to accommodate the constraints of remote locations while ensuring the concrete achieves its intended carbon-negative performance.

Workforce logistics also merit careful attention, as skilled personnel familiar with carbon-negative concrete technologies may need to be transported to and accommodated at remote sites. Training local workers presents an alternative approach that can reduce transportation requirements while building valuable skills within local communities, though this necessitates additional time for knowledge transfer and skill development.

Supply chain resilience is particularly critical for remote projects, where disruptions can cause severe delays and cost overruns. Developing redundant sourcing strategies for key materials, establishing buffer inventories, and implementing real-time tracking systems can help mitigate these risks. Additionally, local sourcing of complementary materials, where feasible, can reduce logistical complexity while potentially enhancing the project's overall sustainability profile.

Seasonal considerations must be factored into project planning, as weather conditions can significantly impact both transportation accessibility and concrete curing processes. In many remote regions, there may be limited windows of opportunity for material delivery and construction activities, requiring precise scheduling and contingency planning to avoid costly delays or material degradation.

Environmental Impact Assessment and Carbon Accounting Methods

The assessment of environmental impacts and carbon accounting methodologies is crucial for evaluating carbon-negative concrete applications in remote infrastructure projects. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making accurate measurement essential for validating carbon-negative claims. Current environmental impact assessment (EIA) frameworks must be adapted specifically for remote infrastructure contexts, where transportation emissions often significantly increase the carbon footprint of construction materials.

Life Cycle Assessment (LCA) represents the gold standard for comprehensive environmental impact evaluation of carbon-negative concrete. This methodology tracks emissions from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. For remote projects, the transportation phase requires particular scrutiny, as lengthy supply chains can negate carbon benefits achieved through innovative concrete formulations. The ISO 14040 and 14044 standards provide the foundational framework for conducting these assessments, though they require contextual adaptation for remote settings.

Carbon accounting methods for these applications must incorporate both direct and indirect emissions. Direct emissions include those from chemical reactions during cement production (calcination), while indirect emissions encompass energy consumption, transportation, and land-use changes. The Greenhouse Gas Protocol offers standardized approaches for quantifying these emissions, categorizing them into Scope 1 (direct), Scope 2 (purchased energy), and Scope 3 (value chain) emissions.

Emerging technologies are enhancing the precision of carbon accounting in remote settings. Satellite monitoring can track land-use changes associated with material extraction, while IoT sensors can measure real-time emissions during construction. Blockchain-based carbon tracking systems are also being deployed to ensure transparency and traceability throughout the concrete supply chain, particularly valuable when verifying carbon credits in offset markets.

Challenges specific to remote infrastructure projects include data gaps, inconsistent methodologies, and verification difficulties. Limited baseline data in remote regions complicates the establishment of accurate emission reduction benchmarks. Additionally, the lack of standardized carbon accounting protocols for novel carbon-negative concrete formulations creates uncertainty in environmental claims. Independent third-party verification becomes more complex and costly in remote locations, potentially undermining the credibility of carbon-negative assertions.

Future developments in this field are focusing on harmonizing carbon accounting methodologies across jurisdictions and developing simplified assessment tools specifically designed for remote applications. Machine learning algorithms are being trained to predict emissions based on limited data inputs, potentially overcoming the data scarcity challenges inherent to remote project sites.

Life Cycle Assessment (LCA) represents the gold standard for comprehensive environmental impact evaluation of carbon-negative concrete. This methodology tracks emissions from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. For remote projects, the transportation phase requires particular scrutiny, as lengthy supply chains can negate carbon benefits achieved through innovative concrete formulations. The ISO 14040 and 14044 standards provide the foundational framework for conducting these assessments, though they require contextual adaptation for remote settings.

Carbon accounting methods for these applications must incorporate both direct and indirect emissions. Direct emissions include those from chemical reactions during cement production (calcination), while indirect emissions encompass energy consumption, transportation, and land-use changes. The Greenhouse Gas Protocol offers standardized approaches for quantifying these emissions, categorizing them into Scope 1 (direct), Scope 2 (purchased energy), and Scope 3 (value chain) emissions.

Emerging technologies are enhancing the precision of carbon accounting in remote settings. Satellite monitoring can track land-use changes associated with material extraction, while IoT sensors can measure real-time emissions during construction. Blockchain-based carbon tracking systems are also being deployed to ensure transparency and traceability throughout the concrete supply chain, particularly valuable when verifying carbon credits in offset markets.

Challenges specific to remote infrastructure projects include data gaps, inconsistent methodologies, and verification difficulties. Limited baseline data in remote regions complicates the establishment of accurate emission reduction benchmarks. Additionally, the lack of standardized carbon accounting protocols for novel carbon-negative concrete formulations creates uncertainty in environmental claims. Independent third-party verification becomes more complex and costly in remote locations, potentially undermining the credibility of carbon-negative assertions.

Future developments in this field are focusing on harmonizing carbon accounting methodologies across jurisdictions and developing simplified assessment tools specifically designed for remote applications. Machine learning algorithms are being trained to predict emissions based on limited data inputs, potentially overcoming the data scarcity challenges inherent to remote project sites.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!