Carbon-negative Concrete for Low-emission Construction Practices

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete production has historically been one of the most carbon-intensive industrial processes, accounting for approximately 8% of global CO2 emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction materials science, moving from traditional Portland cement-based formulations toward innovative solutions that actively sequester carbon dioxide from the atmosphere. This technological trajectory began in the early 2000s with initial research into alternative cementitious materials, but has accelerated dramatically over the past decade as climate change mitigation has become a global priority.

The development path of carbon-negative concrete has progressed through several distinct phases. Initially, researchers focused on reducing emissions through partial cement replacement with supplementary cementitious materials like fly ash and slag. This evolved into more advanced approaches incorporating novel materials such as geopolymers and alkali-activated systems. The breakthrough toward truly carbon-negative formulations came with the introduction of CO2 curing technologies and carbonatable binders that chemically incorporate CO2 during the manufacturing process.

Recent technological innovations have enabled concrete to function as a carbon sink rather than a carbon source. These include mineralization processes that convert CO2 into stable carbonate minerals within the concrete matrix, biogenic approaches utilizing microorganisms to induce carbonate precipitation, and direct air capture technologies integrated with concrete production. The current technological frontier involves optimizing these processes for commercial-scale implementation while maintaining or enhancing concrete's mechanical properties and durability.

The primary objective of carbon-negative concrete research is to develop commercially viable construction materials that sequester more carbon than they emit throughout their lifecycle. Specific technical goals include achieving a net carbon sequestration of at least 100 kg CO2 per cubic meter of concrete, maintaining compressive strength comparable to conventional concrete (30-50 MPa), and ensuring durability for service lifespans of 50+ years under various environmental conditions.

Additional objectives include reducing production costs to achieve market competitiveness without relying on carbon credits or subsidies, developing scalable manufacturing processes compatible with existing concrete production infrastructure, and creating standardized testing protocols to verify carbon sequestration claims. The technology also aims to address regional adaptability by formulating solutions that can utilize locally available materials and function effectively across different climatic conditions.

The ultimate goal extends beyond technical performance to industry transformation—establishing carbon-negative concrete as the new standard in construction while supporting global decarbonization efforts in line with the Paris Agreement targets and contributing to circular economy principles through the beneficial reuse of industrial byproducts and waste streams.

The development path of carbon-negative concrete has progressed through several distinct phases. Initially, researchers focused on reducing emissions through partial cement replacement with supplementary cementitious materials like fly ash and slag. This evolved into more advanced approaches incorporating novel materials such as geopolymers and alkali-activated systems. The breakthrough toward truly carbon-negative formulations came with the introduction of CO2 curing technologies and carbonatable binders that chemically incorporate CO2 during the manufacturing process.

Recent technological innovations have enabled concrete to function as a carbon sink rather than a carbon source. These include mineralization processes that convert CO2 into stable carbonate minerals within the concrete matrix, biogenic approaches utilizing microorganisms to induce carbonate precipitation, and direct air capture technologies integrated with concrete production. The current technological frontier involves optimizing these processes for commercial-scale implementation while maintaining or enhancing concrete's mechanical properties and durability.

The primary objective of carbon-negative concrete research is to develop commercially viable construction materials that sequester more carbon than they emit throughout their lifecycle. Specific technical goals include achieving a net carbon sequestration of at least 100 kg CO2 per cubic meter of concrete, maintaining compressive strength comparable to conventional concrete (30-50 MPa), and ensuring durability for service lifespans of 50+ years under various environmental conditions.

Additional objectives include reducing production costs to achieve market competitiveness without relying on carbon credits or subsidies, developing scalable manufacturing processes compatible with existing concrete production infrastructure, and creating standardized testing protocols to verify carbon sequestration claims. The technology also aims to address regional adaptability by formulating solutions that can utilize locally available materials and function effectively across different climatic conditions.

The ultimate goal extends beyond technical performance to industry transformation—establishing carbon-negative concrete as the new standard in construction while supporting global decarbonization efforts in line with the Paris Agreement targets and contributing to circular economy principles through the beneficial reuse of industrial byproducts and waste streams.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations on carbon emissions. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. This remarkable expansion reflects the construction industry's shift toward more environmentally responsible practices and materials.

Carbon-negative concrete represents a revolutionary segment within this market, addressing the critical issue of concrete's carbon footprint, which accounts for nearly 8% of global CO2 emissions. Market research indicates that demand for carbon-negative concrete solutions is growing at 15-20% annually, outpacing traditional concrete products significantly.

Regional analysis reveals varying adoption rates, with Europe leading the market transformation. Countries like Sweden, Norway, and Germany have implemented carbon taxes and building codes that actively favor low-carbon construction materials. North America follows closely, with the United States seeing increased demand driven by LEED certification requirements and corporate sustainability commitments.

The Asia-Pacific region presents the largest growth opportunity, particularly in China and India, where massive infrastructure development coincides with new environmental policies. These markets are projected to grow at 18-22% annually for sustainable concrete alternatives, creating substantial commercial potential.

Consumer sentiment analysis indicates that 73% of commercial building developers are willing to pay a premium of 5-15% for carbon-negative construction materials if they deliver verifiable environmental benefits and comparable performance to traditional materials. This price tolerance is higher in developed markets but is rapidly expanding in emerging economies as well.

Market segmentation shows distinct customer profiles: government infrastructure projects (28% of market share), commercial real estate developers (35%), residential construction (22%), and specialized applications (15%). Each segment presents unique requirements and adoption barriers that must be addressed through tailored product development and marketing strategies.

Competitive analysis reveals that while established concrete manufacturers are developing their own low-carbon alternatives, innovative startups focused exclusively on carbon-negative solutions are gaining significant market traction through technological differentiation. This dynamic is creating both partnership opportunities and competitive pressures across the value chain.

Carbon-negative concrete represents a revolutionary segment within this market, addressing the critical issue of concrete's carbon footprint, which accounts for nearly 8% of global CO2 emissions. Market research indicates that demand for carbon-negative concrete solutions is growing at 15-20% annually, outpacing traditional concrete products significantly.

Regional analysis reveals varying adoption rates, with Europe leading the market transformation. Countries like Sweden, Norway, and Germany have implemented carbon taxes and building codes that actively favor low-carbon construction materials. North America follows closely, with the United States seeing increased demand driven by LEED certification requirements and corporate sustainability commitments.

The Asia-Pacific region presents the largest growth opportunity, particularly in China and India, where massive infrastructure development coincides with new environmental policies. These markets are projected to grow at 18-22% annually for sustainable concrete alternatives, creating substantial commercial potential.

Consumer sentiment analysis indicates that 73% of commercial building developers are willing to pay a premium of 5-15% for carbon-negative construction materials if they deliver verifiable environmental benefits and comparable performance to traditional materials. This price tolerance is higher in developed markets but is rapidly expanding in emerging economies as well.

Market segmentation shows distinct customer profiles: government infrastructure projects (28% of market share), commercial real estate developers (35%), residential construction (22%), and specialized applications (15%). Each segment presents unique requirements and adoption barriers that must be addressed through tailored product development and marketing strategies.

Competitive analysis reveals that while established concrete manufacturers are developing their own low-carbon alternatives, innovative startups focused exclusively on carbon-negative solutions are gaining significant market traction through technological differentiation. This dynamic is creating both partnership opportunities and competitive pressures across the value chain.

Global Status and Barriers in Carbon-negative Concrete Development

The development of carbon-negative concrete technology has gained significant momentum globally, yet its widespread adoption faces numerous challenges. Currently, several pioneering countries lead research efforts, with Scandinavian nations, particularly Sweden and Norway, at the forefront due to their stringent environmental regulations and carbon pricing mechanisms. North America, especially Canada and the United States, has established substantial research programs focused on carbon capture and utilization in concrete production.

In Asia, Japan and Singapore have made notable advancements in alternative cementitious materials, while China, despite being the world's largest concrete producer, has only recently begun transitioning toward carbon-negative solutions. The European Union maintains a coordinated approach through initiatives like Horizon Europe, funding collaborative research across member states.

Despite these developments, significant barriers impede global progress. Technical challenges remain paramount, including the limited scalability of carbon capture technologies and difficulties in maintaining concrete performance while reducing its carbon footprint. The integration of novel supplementary cementitious materials often results in unpredictable setting times and durability concerns, creating hesitation among construction professionals.

Economic obstacles present another major hurdle. Carbon-negative concrete production currently demands higher capital investment than conventional methods, with cost premiums ranging from 20% to 50%. Without robust carbon pricing mechanisms or regulatory incentives, market forces alone prove insufficient to drive widespread adoption. The fragmented nature of the construction industry further complicates implementation, as it comprises numerous small and medium enterprises with limited research capabilities.

Regulatory frameworks vary significantly across regions, creating an inconsistent landscape for technology development. While some jurisdictions have implemented progressive policies mandating low-carbon building materials, many regions lack clear standards for carbon-negative concrete certification and performance requirements. This regulatory uncertainty discourages investment and slows commercialization efforts.

Knowledge gaps and infrastructure limitations constitute additional barriers. The long-term performance of carbon-negative concrete remains inadequately documented, raising concerns about durability and maintenance requirements. Furthermore, the existing cement production infrastructure represents massive sunk costs, creating industry inertia against transformative changes. The specialized equipment required for carbon capture and alternative material processing is not readily available in many regions, particularly in developing economies where concrete demand continues to rise rapidly.

In Asia, Japan and Singapore have made notable advancements in alternative cementitious materials, while China, despite being the world's largest concrete producer, has only recently begun transitioning toward carbon-negative solutions. The European Union maintains a coordinated approach through initiatives like Horizon Europe, funding collaborative research across member states.

Despite these developments, significant barriers impede global progress. Technical challenges remain paramount, including the limited scalability of carbon capture technologies and difficulties in maintaining concrete performance while reducing its carbon footprint. The integration of novel supplementary cementitious materials often results in unpredictable setting times and durability concerns, creating hesitation among construction professionals.

Economic obstacles present another major hurdle. Carbon-negative concrete production currently demands higher capital investment than conventional methods, with cost premiums ranging from 20% to 50%. Without robust carbon pricing mechanisms or regulatory incentives, market forces alone prove insufficient to drive widespread adoption. The fragmented nature of the construction industry further complicates implementation, as it comprises numerous small and medium enterprises with limited research capabilities.

Regulatory frameworks vary significantly across regions, creating an inconsistent landscape for technology development. While some jurisdictions have implemented progressive policies mandating low-carbon building materials, many regions lack clear standards for carbon-negative concrete certification and performance requirements. This regulatory uncertainty discourages investment and slows commercialization efforts.

Knowledge gaps and infrastructure limitations constitute additional barriers. The long-term performance of carbon-negative concrete remains inadequately documented, raising concerns about durability and maintenance requirements. Furthermore, the existing cement production infrastructure represents massive sunk costs, creating industry inertia against transformative changes. The specialized equipment required for carbon capture and alternative material processing is not readily available in many regions, particularly in developing economies where concrete demand continues to rise rapidly.

Current Carbon-negative Concrete Formulations and Methods

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, effectively making the concrete a carbon sink. These methods involve introducing CO2 during manufacturing, which reacts with calcium compounds to form stable carbonates, reducing the carbon footprint of concrete production while enhancing material properties such as strength and durability.- Carbon capture and sequestration in concrete: Technologies that enable concrete to capture and store carbon dioxide during its lifecycle, effectively making it carbon-negative. These methods involve incorporating materials that can absorb CO2 from the atmosphere and chemically bind it within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can potentially transform concrete into a carbon sink that continues to absorb CO2 throughout its service life.

- Alternative cementitious materials for reduced emissions: Development of alternative binding materials that can replace traditional Portland cement, which is responsible for significant carbon emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts. By substituting carbon-intensive Portland cement with these alternatives, the overall carbon footprint of concrete production can be substantially reduced while maintaining or even improving performance characteristics.

- CO2 utilization in concrete curing processes: Innovative curing techniques that utilize carbon dioxide as a reactant in the concrete hardening process. These methods inject CO2 into fresh concrete during production, where it reacts with calcium compounds to form stable carbonate minerals. This process not only sequesters carbon dioxide but also improves concrete strength and durability, potentially reducing the amount of cement required and accelerating curing times.

- Monitoring and verification systems for carbon-negative concrete: Advanced systems and methodologies for measuring, reporting, and verifying the carbon sequestration capabilities of carbon-negative concrete. These technologies include sensors, data analytics platforms, and certification frameworks that quantify the amount of carbon captured and stored in concrete structures. Such systems are essential for validating carbon credits, ensuring regulatory compliance, and demonstrating the environmental benefits of carbon-negative concrete solutions.

- Biomass incorporation for carbon reduction in concrete: Integration of biomass-derived materials into concrete formulations to reduce carbon emissions. These approaches include using agricultural waste, wood products, or other plant-based materials as partial replacements for traditional concrete components. The biomass, having sequestered carbon during its growth phase, contributes to lowering the overall carbon footprint of the concrete. Additionally, these bio-based additives can impart beneficial properties such as improved thermal insulation and reduced weight.

02 Alternative cementitious materials for reduced emissions

Development of cement alternatives that require less energy to produce and generate fewer carbon emissions than traditional Portland cement. These include geopolymers, alkali-activated materials, and supplementary cementitious materials like fly ash, slag, and silica fume that can partially replace cement in concrete mixtures, significantly reducing the carbon footprint of concrete production.Expand Specific Solutions03 Carbon monitoring and accounting systems for concrete

Digital platforms and methodologies for accurately measuring, tracking, and reporting carbon emissions throughout the concrete lifecycle. These systems enable transparent carbon accounting, verification of carbon credits, and optimization of production processes to minimize emissions, supporting regulatory compliance and carbon trading in the construction industry.Expand Specific Solutions04 Biomass incorporation and carbonation techniques

Methods for incorporating biomass-derived materials and accelerated carbonation techniques in concrete production. These approaches include using agricultural waste, biochar, or other organic materials as aggregates or additives, combined with enhanced carbonation processes that promote CO2 absorption, resulting in concrete products with negative carbon footprints.Expand Specific Solutions05 Energy-efficient concrete production methods

Innovative manufacturing processes that reduce energy consumption and associated carbon emissions in concrete production. These include low-temperature curing techniques, electrification of production facilities, renewable energy integration, and optimized mix designs that require less cement while maintaining performance characteristics, contributing to overall carbon reduction in the concrete industry.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete technology is currently in the early development stage, with a growing market driven by increasing demand for sustainable construction materials. The global market for low-emission concrete alternatives is expanding rapidly as construction industries face pressure to reduce their carbon footprint. Key players include established cement manufacturers like Holcim Technology and Lafarge SA, who are investing in sustainable alternatives, alongside innovative startups such as Solidia Technologies, Biozeroc Ltd., and Carbon Limit Co. Academic institutions including MIT, Hong Kong Polytechnic University, and Central South University are conducting crucial research to advance the technology. Research centers like China Building Materials Academy and Centre National de la Recherche Scientifique are bridging the gap between laboratory innovations and commercial applications, though widespread adoption remains limited by cost and performance concerns.

Ecocem Materials Ltd.

Technical Solution: Ecocem has pioneered the development of Ground Granulated Blast Furnace Slag (GGBS) technology for low-carbon concrete production. Their innovative ACT (Accelerated Carbonation Technology) process incorporates industrial by-products like slag and fly ash to replace up to 80% of traditional cement content. Ecocem's latest breakthrough is their "Superfine" technology, an ultra-low carbon cement that reduces CO2 emissions by up to 70% compared to ordinary Portland cement. The company has developed a carbon mineralization process that actively sequesters CO2 during concrete curing, transforming the material from carbon-neutral to carbon-negative. Their proprietary limestone calcined clay cement (LC3) formulation combines locally available materials with advanced activation techniques to create high-performance, low-emission concrete suitable for structural applications. Ecocem has also developed specialized admixtures that enhance the carbon absorption capacity of concrete throughout its lifecycle.

Strengths: Utilizes industrial waste streams, compatible with existing concrete production infrastructure, proven performance in commercial applications. Weaknesses: Regional availability of raw materials can be inconsistent, slightly higher initial costs, requires education of construction professionals on new material properties.

Holcim Technology Ltd.

Technical Solution: Holcim has developed ECOPact, a carbon-negative concrete solution that incorporates carbon capture technology and alternative cementitious materials. Their approach combines calcined clay with limestone to create LC3 (Limestone Calcined Clay Cement), reducing clinker content by up to 50%. Holcim's CarbonCure technology injects captured CO2 during the concrete mixing process, where it mineralizes and permanently sequesters carbon while improving concrete strength. Their ECOPlanet cement line achieves at least 30% lower carbon footprint than standard cement. Holcim has also pioneered 3D concrete printing technology that reduces material usage by up to 60% compared to conventional construction methods, further lowering the carbon footprint of construction projects.

Strengths: Global scale implementation capability, comprehensive approach combining multiple carbon reduction strategies, strong R&D infrastructure. Weaknesses: High initial investment costs for implementation, requires significant changes to existing production infrastructure, performance in extreme environments still being validated.

Key Patents and Innovations in CO2 Sequestration Concrete

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

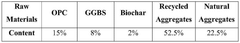

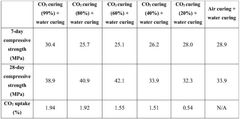

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Low carbon emission concrete block

PatentWO2025036429A9

Innovation

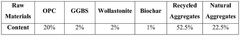

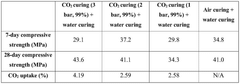

- A concrete formulation using recycled aggregates, natural aggregates, Ordinary Portland Cement, and low-carbon raw materials like ground granulated blast-furnace slag, fly ash, biochar, and wollastonite, combined with a carbon dioxide-enhanced curing process to achieve reduced carbon dioxide emission without compromising mechanical strength.

Lifecycle Assessment of Carbon-negative Concrete Solutions

Lifecycle Assessment of Carbon-negative Concrete Solutions requires a comprehensive evaluation of environmental impacts throughout the entire life cycle of concrete products. This assessment methodology follows ISO 14040 and 14044 standards, examining impacts from raw material extraction through manufacturing, transportation, use, and end-of-life disposal or recycling.

For carbon-negative concrete solutions, the assessment begins with quantifying carbon dioxide emissions during cement production, which traditionally accounts for approximately 8% of global CO2 emissions. Modern carbon-negative alternatives incorporate CO2 sequestration technologies that absorb more carbon than emitted during production. These include carbonation curing processes, where CO2 is injected during concrete hardening, and the use of supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume that reduce the cement content.

The raw material extraction phase analysis reveals significant differences between traditional and carbon-negative concrete. While conventional concrete relies heavily on Portland cement requiring limestone calcination at high temperatures (1450°C), carbon-negative alternatives utilize industrial byproducts and novel binders like geopolymers or alkali-activated materials. These alternatives can reduce carbon footprint by 30-90% compared to conventional concrete.

Transportation impacts vary considerably based on material sourcing strategies. Local sourcing of alternative materials can reduce emissions by up to 25% compared to traditional supply chains. The manufacturing phase assessment demonstrates that carbon-negative concrete production typically consumes 15-40% less energy than conventional methods, particularly when utilizing ambient temperature curing techniques.

During the use phase, carbon-negative concrete continues to sequester CO2 through natural carbonation processes. Research indicates that over a 50-year service life, these materials can absorb an additional 10-25 kg of CO2 per cubic meter beyond what was captured during production. This continuous carbon sequestration represents a significant advantage in lifecycle performance.

End-of-life considerations reveal further benefits, as crushed carbon-negative concrete can absorb additional CO2 when used as recycled aggregate. Studies show potential for capturing 5-15 kg of CO2 per ton of recycled material, creating a second carbon sink at the end of the product lifecycle.

Comparative lifecycle assessments demonstrate that carbon-negative concrete solutions can achieve net carbon reductions of 50-200 kg CO2 equivalent per cubic meter, depending on the specific technology employed. This represents a paradigm shift from concrete as a carbon source to a carbon sink, fundamentally transforming the environmental profile of construction materials.

For carbon-negative concrete solutions, the assessment begins with quantifying carbon dioxide emissions during cement production, which traditionally accounts for approximately 8% of global CO2 emissions. Modern carbon-negative alternatives incorporate CO2 sequestration technologies that absorb more carbon than emitted during production. These include carbonation curing processes, where CO2 is injected during concrete hardening, and the use of supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume that reduce the cement content.

The raw material extraction phase analysis reveals significant differences between traditional and carbon-negative concrete. While conventional concrete relies heavily on Portland cement requiring limestone calcination at high temperatures (1450°C), carbon-negative alternatives utilize industrial byproducts and novel binders like geopolymers or alkali-activated materials. These alternatives can reduce carbon footprint by 30-90% compared to conventional concrete.

Transportation impacts vary considerably based on material sourcing strategies. Local sourcing of alternative materials can reduce emissions by up to 25% compared to traditional supply chains. The manufacturing phase assessment demonstrates that carbon-negative concrete production typically consumes 15-40% less energy than conventional methods, particularly when utilizing ambient temperature curing techniques.

During the use phase, carbon-negative concrete continues to sequester CO2 through natural carbonation processes. Research indicates that over a 50-year service life, these materials can absorb an additional 10-25 kg of CO2 per cubic meter beyond what was captured during production. This continuous carbon sequestration represents a significant advantage in lifecycle performance.

End-of-life considerations reveal further benefits, as crushed carbon-negative concrete can absorb additional CO2 when used as recycled aggregate. Studies show potential for capturing 5-15 kg of CO2 per ton of recycled material, creating a second carbon sink at the end of the product lifecycle.

Comparative lifecycle assessments demonstrate that carbon-negative concrete solutions can achieve net carbon reductions of 50-200 kg CO2 equivalent per cubic meter, depending on the specific technology employed. This represents a paradigm shift from concrete as a carbon source to a carbon sink, fundamentally transforming the environmental profile of construction materials.

Regulatory Frameworks and Green Building Standards

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to reduce construction-related emissions. The European Union leads with its ambitious European Green Deal, which aims to achieve carbon neutrality by 2050 and includes specific provisions for construction materials. The EU Emissions Trading System (ETS) has been expanded to cover cement production, creating economic incentives for manufacturers to adopt carbon-negative technologies. Additionally, the EU's Construction Products Regulation now incorporates Environmental Product Declarations (EPDs) that document the carbon footprint of building materials.

In North America, regulatory approaches vary by jurisdiction. California's Buy Clean California Act requires state agencies to consider the embodied carbon of construction materials in procurement decisions, explicitly favoring low-carbon concrete alternatives. Canada's Greening Government Strategy similarly mandates federal buildings to reduce embodied carbon, creating market pull for carbon-negative concrete solutions.

Green building certification systems have become powerful market drivers for sustainable construction practices. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon-negative building materials, with specific pathways for innovative concrete solutions. The Living Building Challenge goes further, requiring carbon-neutral or carbon-negative materials for its certification. BREEAM (Building Research Establishment Environmental Assessment Method) has incorporated whole-life carbon assessments that incentivize carbon-negative concrete use.

The International Green Construction Code (IgCC) and ASHRAE Standard 189.1 have been harmonized to provide consistent regulatory frameworks for sustainable building practices, including provisions for low-carbon materials. These standards are increasingly being adopted into local building codes, transforming voluntary practices into mandatory requirements.

Emerging standards specifically for concrete include the Carbon Leadership Forum's materials carbon calculator and the Concrete Sustainability Council's certification system. These tools provide standardized methodologies for measuring and verifying the carbon performance of concrete products, creating transparency in the marketplace and enabling meaningful comparisons between different solutions.

Financial institutions are also developing green financing frameworks that favor carbon-negative building materials. The EU Taxonomy for Sustainable Activities and similar frameworks in other regions establish clear criteria for what constitutes sustainable construction, influencing capital flows toward projects utilizing carbon-negative concrete.

The regulatory landscape continues to evolve with increasing stringency. Several jurisdictions are developing carbon intensity limits for construction materials, which will progressively decrease over time, eventually requiring carbon-negative solutions. This regulatory trajectory provides a clear signal to the market about the direction of policy, enabling long-term investment in carbon-negative concrete technologies.

In North America, regulatory approaches vary by jurisdiction. California's Buy Clean California Act requires state agencies to consider the embodied carbon of construction materials in procurement decisions, explicitly favoring low-carbon concrete alternatives. Canada's Greening Government Strategy similarly mandates federal buildings to reduce embodied carbon, creating market pull for carbon-negative concrete solutions.

Green building certification systems have become powerful market drivers for sustainable construction practices. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon-negative building materials, with specific pathways for innovative concrete solutions. The Living Building Challenge goes further, requiring carbon-neutral or carbon-negative materials for its certification. BREEAM (Building Research Establishment Environmental Assessment Method) has incorporated whole-life carbon assessments that incentivize carbon-negative concrete use.

The International Green Construction Code (IgCC) and ASHRAE Standard 189.1 have been harmonized to provide consistent regulatory frameworks for sustainable building practices, including provisions for low-carbon materials. These standards are increasingly being adopted into local building codes, transforming voluntary practices into mandatory requirements.

Emerging standards specifically for concrete include the Carbon Leadership Forum's materials carbon calculator and the Concrete Sustainability Council's certification system. These tools provide standardized methodologies for measuring and verifying the carbon performance of concrete products, creating transparency in the marketplace and enabling meaningful comparisons between different solutions.

Financial institutions are also developing green financing frameworks that favor carbon-negative building materials. The EU Taxonomy for Sustainable Activities and similar frameworks in other regions establish clear criteria for what constitutes sustainable construction, influencing capital flows toward projects utilizing carbon-negative concrete.

The regulatory landscape continues to evolve with increasing stringency. Several jurisdictions are developing carbon intensity limits for construction materials, which will progressively decrease over time, eventually requiring carbon-negative solutions. This regulatory trajectory provides a clear signal to the market about the direction of policy, enabling long-term investment in carbon-negative concrete technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!