Carbon-negative Concrete: A Game-changer for Climate Policies

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete production is one of the most carbon-intensive industrial processes, accounting for approximately 8% of global CO2 emissions. Traditional cement manufacturing releases about 0.9 tons of CO2 for every ton produced, primarily through the calcination process and energy consumption. This significant carbon footprint has positioned the concrete industry as a critical focus area for climate change mitigation efforts. Carbon-negative concrete represents a revolutionary approach that aims to transform this major emissions source into a carbon sink.

The evolution of concrete technology has progressed from conventional Portland cement to low-carbon alternatives, and now to carbon-negative formulations. This technological progression has been accelerated by increasing regulatory pressures, carbon pricing mechanisms, and growing corporate sustainability commitments across the construction sector. The Paris Agreement and subsequent national climate policies have established concrete decarbonization as a priority for meeting global emissions reduction targets.

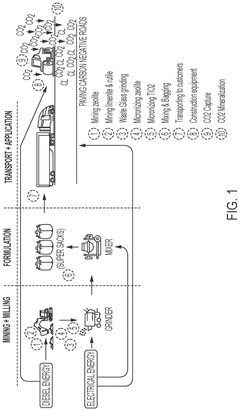

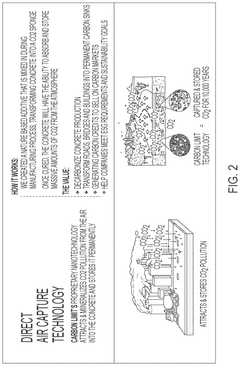

Carbon-negative concrete utilizes alternative binding materials and incorporates carbon capture technologies directly into the production process. These innovative formulations can sequester more carbon dioxide than they emit throughout their lifecycle, effectively creating a net negative carbon footprint. The development of these technologies has been gaining momentum since the mid-2010s, with significant breakthroughs occurring in the past five years in mineralization processes and alternative cementitious materials.

The primary technical objective of carbon-negative concrete research is to develop commercially viable formulations that maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration. This includes ensuring comparable strength, durability, workability, and cost-effectiveness. Secondary objectives include optimizing the carbon capture efficiency, reducing energy requirements, and ensuring compatibility with existing construction practices and standards.

Market adoption objectives focus on scaling production capacity to meet global demand, establishing regulatory frameworks that recognize and incentivize carbon-negative building materials, and developing certification standards to verify carbon negativity claims. The technology aims to achieve price parity with conventional concrete by 2030, which is considered a critical tipping point for widespread market adoption.

Long-term strategic objectives include integrating carbon-negative concrete into circular economy frameworks, developing regional supply chains to minimize transportation emissions, and creating a global carbon accounting methodology specific to construction materials. The ultimate goal is to transform the concrete industry from a major emissions source into a significant carbon sink, potentially sequestering billions of tons of CO2 annually by 2050 if widely adopted across the construction sector.

The evolution of concrete technology has progressed from conventional Portland cement to low-carbon alternatives, and now to carbon-negative formulations. This technological progression has been accelerated by increasing regulatory pressures, carbon pricing mechanisms, and growing corporate sustainability commitments across the construction sector. The Paris Agreement and subsequent national climate policies have established concrete decarbonization as a priority for meeting global emissions reduction targets.

Carbon-negative concrete utilizes alternative binding materials and incorporates carbon capture technologies directly into the production process. These innovative formulations can sequester more carbon dioxide than they emit throughout their lifecycle, effectively creating a net negative carbon footprint. The development of these technologies has been gaining momentum since the mid-2010s, with significant breakthroughs occurring in the past five years in mineralization processes and alternative cementitious materials.

The primary technical objective of carbon-negative concrete research is to develop commercially viable formulations that maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration. This includes ensuring comparable strength, durability, workability, and cost-effectiveness. Secondary objectives include optimizing the carbon capture efficiency, reducing energy requirements, and ensuring compatibility with existing construction practices and standards.

Market adoption objectives focus on scaling production capacity to meet global demand, establishing regulatory frameworks that recognize and incentivize carbon-negative building materials, and developing certification standards to verify carbon negativity claims. The technology aims to achieve price parity with conventional concrete by 2030, which is considered a critical tipping point for widespread market adoption.

Long-term strategic objectives include integrating carbon-negative concrete into circular economy frameworks, developing regional supply chains to minimize transportation emissions, and creating a global carbon accounting methodology specific to construction materials. The ultimate goal is to transform the concrete industry from a major emissions source into a significant carbon sink, potentially sequestering billions of tons of CO2 annually by 2050 if widely adopted across the construction sector.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is witnessing a significant shift towards sustainable building materials, driven by increasing environmental concerns and stringent climate policies. The market for sustainable construction materials, particularly carbon-negative concrete, is experiencing unprecedented growth as governments worldwide implement regulations to reduce carbon emissions in the building sector. According to recent market research, the global green building materials market was valued at $254 billion in 2020 and is projected to reach $383 billion by 2025, growing at a CAGR of 8.6%.

Carbon-negative concrete represents a revolutionary segment within this market, addressing the critical environmental impact of traditional cement production, which accounts for approximately 8% of global CO2 emissions. The demand for carbon-negative concrete is primarily driven by commercial construction projects seeking LEED certification and government infrastructure initiatives with carbon reduction targets. Major markets include North America, Europe, and increasingly, Asia-Pacific regions where rapid urbanization coincides with growing environmental awareness.

Industry surveys indicate that 67% of construction professionals anticipate increased use of sustainable concrete alternatives in the next five years. This trend is reinforced by policy developments such as the European Green Deal, which aims for carbon neutrality by 2050, and similar initiatives in countries like Canada, Japan, and South Korea that specifically target embodied carbon in building materials.

The economic viability of carbon-negative concrete is improving as carbon pricing mechanisms become more widespread. Currently, 45 countries have implemented some form of carbon pricing, creating financial incentives for adopting low-carbon building materials. Additionally, green building certifications like LEED, BREEAM, and WELL are increasingly recognizing and rewarding the use of carbon-negative materials, further stimulating market demand.

Consumer preferences are also evolving, with 73% of commercial property developers reporting that sustainability features command premium prices and faster occupancy rates. This market pull is complemented by push factors from institutional investors, with major funds representing over $7 trillion in assets under management now considering carbon footprint in their investment decisions for real estate and infrastructure projects.

Despite positive growth indicators, adoption barriers remain, including higher initial costs (currently 15-30% premium over traditional concrete), limited production capacity, and inconsistent regulatory frameworks across regions. However, these challenges are expected to diminish as production scales up and regulatory harmonization progresses, particularly following the implementation of international climate agreements.

Carbon-negative concrete represents a revolutionary segment within this market, addressing the critical environmental impact of traditional cement production, which accounts for approximately 8% of global CO2 emissions. The demand for carbon-negative concrete is primarily driven by commercial construction projects seeking LEED certification and government infrastructure initiatives with carbon reduction targets. Major markets include North America, Europe, and increasingly, Asia-Pacific regions where rapid urbanization coincides with growing environmental awareness.

Industry surveys indicate that 67% of construction professionals anticipate increased use of sustainable concrete alternatives in the next five years. This trend is reinforced by policy developments such as the European Green Deal, which aims for carbon neutrality by 2050, and similar initiatives in countries like Canada, Japan, and South Korea that specifically target embodied carbon in building materials.

The economic viability of carbon-negative concrete is improving as carbon pricing mechanisms become more widespread. Currently, 45 countries have implemented some form of carbon pricing, creating financial incentives for adopting low-carbon building materials. Additionally, green building certifications like LEED, BREEAM, and WELL are increasingly recognizing and rewarding the use of carbon-negative materials, further stimulating market demand.

Consumer preferences are also evolving, with 73% of commercial property developers reporting that sustainability features command premium prices and faster occupancy rates. This market pull is complemented by push factors from institutional investors, with major funds representing over $7 trillion in assets under management now considering carbon footprint in their investment decisions for real estate and infrastructure projects.

Despite positive growth indicators, adoption barriers remain, including higher initial costs (currently 15-30% premium over traditional concrete), limited production capacity, and inconsistent regulatory frameworks across regions. However, these challenges are expected to diminish as production scales up and regulatory harmonization progresses, particularly following the implementation of international climate agreements.

Current State and Challenges in Carbon-negative Concrete Technology

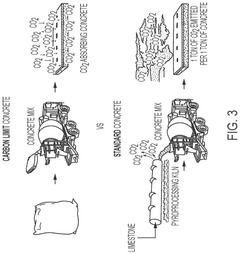

Carbon-negative concrete technology has made significant strides globally, with pioneering research institutions and companies developing various approaches to reduce and potentially reverse the carbon footprint of concrete production. Currently, several methodologies have emerged as frontrunners in this field, including carbon capture during cement production, alternative cementitious materials, and carbon curing processes that actively sequester CO2 within the concrete matrix.

In the United States, companies like Solidia Technologies and CarbonCure have developed commercial-scale solutions that inject captured CO2 into concrete during mixing, resulting in stronger concrete while permanently sequestering carbon dioxide. Meanwhile, European research centers, particularly in Scandinavia and Germany, have focused on geopolymer-based alternatives that can reduce carbon emissions by up to 80% compared to traditional Portland cement.

Despite these advancements, carbon-negative concrete faces significant technical challenges. The primary obstacle remains scalability - while laboratory and small commercial applications have proven successful, scaling these technologies to meet global concrete demand (estimated at over 30 billion tons annually) presents formidable hurdles in terms of infrastructure adaptation and supply chain reorganization.

Cost competitiveness represents another major constraint. Current carbon-negative concrete solutions typically command a 15-30% price premium over conventional concrete, making widespread adoption economically challenging without regulatory incentives or carbon pricing mechanisms. This cost differential stems from both higher material inputs and the additional processing steps required.

Performance consistency across varying environmental conditions and applications remains problematic. Some carbon-negative formulations exhibit reduced durability in extreme environments or under specific loading conditions, limiting their application in critical infrastructure projects where long-term reliability is paramount.

Regulatory frameworks present another significant barrier. Building codes and construction standards worldwide have been developed around traditional concrete properties, creating institutional inertia against novel formulations. The certification process for new concrete technologies can take 5-10 years in many jurisdictions, substantially slowing market penetration.

Geographic disparities in technology development are evident, with North America, Europe, and parts of East Asia leading innovation while other regions lag significantly. This uneven distribution threatens to create a technological divide in an industry that requires global transformation to meaningfully impact climate goals.

Raw material availability for alternative cementitious components presents another constraint, as many formulations rely on industrial byproducts like fly ash and slag, which may become scarcer as energy systems transition away from coal and traditional steel production.

In the United States, companies like Solidia Technologies and CarbonCure have developed commercial-scale solutions that inject captured CO2 into concrete during mixing, resulting in stronger concrete while permanently sequestering carbon dioxide. Meanwhile, European research centers, particularly in Scandinavia and Germany, have focused on geopolymer-based alternatives that can reduce carbon emissions by up to 80% compared to traditional Portland cement.

Despite these advancements, carbon-negative concrete faces significant technical challenges. The primary obstacle remains scalability - while laboratory and small commercial applications have proven successful, scaling these technologies to meet global concrete demand (estimated at over 30 billion tons annually) presents formidable hurdles in terms of infrastructure adaptation and supply chain reorganization.

Cost competitiveness represents another major constraint. Current carbon-negative concrete solutions typically command a 15-30% price premium over conventional concrete, making widespread adoption economically challenging without regulatory incentives or carbon pricing mechanisms. This cost differential stems from both higher material inputs and the additional processing steps required.

Performance consistency across varying environmental conditions and applications remains problematic. Some carbon-negative formulations exhibit reduced durability in extreme environments or under specific loading conditions, limiting their application in critical infrastructure projects where long-term reliability is paramount.

Regulatory frameworks present another significant barrier. Building codes and construction standards worldwide have been developed around traditional concrete properties, creating institutional inertia against novel formulations. The certification process for new concrete technologies can take 5-10 years in many jurisdictions, substantially slowing market penetration.

Geographic disparities in technology development are evident, with North America, Europe, and parts of East Asia leading innovation while other regions lag significantly. This uneven distribution threatens to create a technological divide in an industry that requires global transformation to meaningfully impact climate goals.

Raw material availability for alternative cementitious components presents another constraint, as many formulations rely on industrial byproducts like fly ash and slag, which may become scarcer as energy systems transition away from coal and traditional steel production.

Current Technical Solutions for Carbon-negative Concrete Production

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to capture and store carbon dioxide during its lifecycle, effectively making it carbon-negative. These methods involve incorporating materials that can absorb CO2 from the atmosphere and chemically bind it within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can potentially transform concrete into a carbon sink that continues to absorb CO2 throughout its service life.- Carbon capture and sequestration in concrete production: Technologies that capture carbon dioxide during or after concrete production, effectively sequestering CO2 in the concrete matrix. These methods involve processes that accelerate carbonation of concrete components, allowing the material to absorb and permanently store carbon dioxide from the atmosphere or industrial emissions, potentially making concrete carbon-negative over its lifecycle.

- Alternative cementitious materials with lower carbon footprint: Development of cement alternatives that require less energy to produce and generate fewer emissions than traditional Portland cement. These include geopolymers, alkali-activated materials, magnesium-based cements, and supplementary cementitious materials derived from industrial byproducts or natural sources, which can significantly reduce the carbon footprint of concrete while maintaining or improving performance characteristics.

- CO2 utilization in concrete curing processes: Innovative curing methods that inject CO2 into concrete during the hardening process, converting the gas into stable mineral carbonates within the concrete matrix. This approach not only sequesters carbon dioxide but can also improve concrete properties such as strength and durability, creating a beneficial use for captured carbon emissions while reducing the overall carbon footprint of concrete production.

- Monitoring and certification systems for carbon-negative concrete: Development of methodologies, tools, and certification systems to measure, verify, and track the carbon footprint of concrete throughout its lifecycle. These systems enable accurate quantification of embodied carbon, carbon sequestration potential, and net emissions, providing transparency for carbon accounting and supporting carbon credit generation for concrete that achieves carbon-negative status.

- Optimization of concrete mix design for carbon reduction: Techniques for optimizing concrete formulations to minimize carbon emissions while maintaining structural performance. These approaches include reducing cement content, incorporating recycled materials, optimizing aggregate gradation, and using advanced admixtures that enable lower-carbon concrete mixes. Computational methods and artificial intelligence are employed to predict and optimize the environmental impact of different concrete formulations.

02 Alternative cementitious materials for reduced emissions

Development of alternative binding materials to replace traditional Portland cement, which is responsible for significant carbon emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts. By substituting carbon-intensive Portland cement with these alternatives, the overall carbon footprint of concrete production can be substantially reduced while maintaining or even improving performance characteristics.Expand Specific Solutions03 CO2 utilization in concrete curing processes

Innovative curing techniques that utilize CO2 as a reactant in the concrete hardening process. These methods inject carbon dioxide during the curing phase, where it reacts with calcium compounds to form stable carbonates, effectively sequestering the carbon while simultaneously improving concrete properties such as strength and durability. This approach offers dual benefits of carbon sequestration and enhanced material performance.Expand Specific Solutions04 Monitoring and verification systems for carbon-negative concrete

Advanced systems for measuring, monitoring, and verifying the carbon sequestration capabilities of concrete throughout its lifecycle. These technologies include sensors, data analytics platforms, and certification methodologies that quantify the amount of carbon captured and stored in concrete structures. Such systems are essential for validating carbon credits, ensuring regulatory compliance, and demonstrating the environmental benefits of carbon-negative concrete solutions.Expand Specific Solutions05 Biomass incorporation for carbon reduction in concrete

Methods for incorporating biomass-derived materials into concrete formulations to reduce carbon emissions. These approaches utilize agricultural waste, wood products, or other plant-based materials as partial replacements for traditional concrete components. The biomass, having sequestered carbon during its growth phase, contributes to lowering the overall carbon footprint of the concrete while potentially improving properties such as thermal insulation and weight reduction.Expand Specific Solutions

Key Industry Players in Carbon-negative Concrete Development

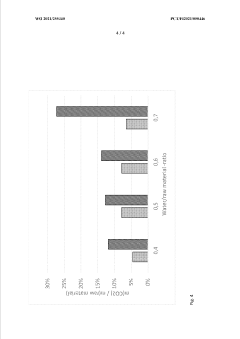

Carbon-negative concrete technology is currently in an early growth phase, with increasing market interest driven by climate policy demands. The global market for sustainable concrete solutions is expanding rapidly, though still represents a small fraction of the traditional concrete industry. Technologically, companies like Solidia Technologies, Carbon Limit Co., and Ecocem Materials are leading commercial applications, while research institutions including MIT, Worcester Polytechnic Institute, and China Building Materials Academy are advancing fundamental innovations. Huaxin Cement and Cement Australia represent established industry players adapting to this transition. The technology shows promising maturity in laboratory settings but faces scaling challenges for widespread commercial implementation, with varying approaches to carbon capture and sequestration mechanisms being explored across the competitive landscape.

Solidia Technologies, Inc.

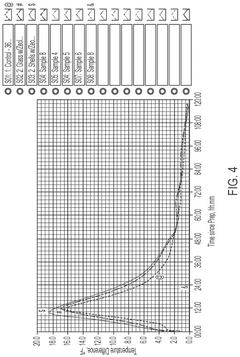

Technical Solution: Solidia has developed a proprietary technology that uses non-hydraulic calcium silicate cement that cures by carbonation rather than hydration. Their process reduces CO2 emissions by up to 70% compared to traditional Portland cement. The technology involves a lower temperature manufacturing process (1200°C vs 1450°C for traditional cement) and then actively absorbs CO2 during the curing phase. Solidia's concrete products can sequester up to 300kg of CO2 per ton of cement used, effectively making their concrete carbon-negative. The company has commercialized this technology through partnerships with major concrete manufacturers, enabling the production of precast concrete products with significantly reduced carbon footprints while maintaining or exceeding performance standards of traditional concrete.

Strengths: Proven technology with commercial applications; maintains strength properties comparable to traditional concrete; compatible with existing manufacturing equipment. Weaknesses: Currently limited to precast applications; requires controlled curing environments; adoption faces industry inertia and regulatory hurdles.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a groundbreaking electrochemical process for producing carbon-negative cement. Their technology, called Electrochemical Cement Production (ECP), replaces the traditional high-temperature kilns with an electrochemical system that operates at ambient temperatures, eliminating combustion-related emissions. The process uses renewable electricity to separate limestone into calcium oxide and concentrated CO2, which can be easily captured for storage or utilization. Additionally, MIT has pioneered a complementary technology that uses calcium silicate minerals as alternative raw materials, further reducing the carbon footprint. Their research has demonstrated that concrete produced using this method can achieve carbon-negative status by sequestering more CO2 than is emitted during production. MIT's approach represents a fundamental reimagining of cement chemistry and manufacturing, potentially reducing the carbon footprint of cement production by over 100% when accounting for carbon sequestration and elimination of fossil fuel use.

Strengths: Eliminates combustion emissions entirely; operates at lower temperatures reducing energy requirements; produces concentrated CO2 stream ideal for capture. Weaknesses: Still at research/prototype stage; requires significant capital investment for industrial implementation; depends on access to renewable electricity for optimal carbon benefits.

Core Patents and Research in CO2 Sequestration Concrete

Controlling carbonation

PatentWO2021255340A1

Innovation

- A method for controlling carbonation by adjusting the total concentration of dissolved silicon and/or aluminium in a mix, which is cured with carbon dioxide, using an alkaline substance to activate the raw material, thereby increasing carbon dioxide uptake and reducing the need for cement in concrete production.

Carbon dioxide-capturing cement compositions and related methods

PatentPendingUS20250161874A1

Innovation

- Development of cement compositions that incorporate a combination of pozzolanic materials, silica or carbonate compounds, and metal oxides, which enhance the absorption and mineralization of carbon dioxide, thereby creating carbon-negative concrete structures.

Regulatory Framework and Climate Policy Implications

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide recognize the construction industry's significant contribution to global carbon emissions. Currently, most regulatory frameworks addressing concrete production focus on emission reduction rather than carbon negativity. However, this paradigm is shifting as climate policies increasingly emphasize net-zero and negative emission technologies.

In the European Union, the European Green Deal and Circular Economy Action Plan provide foundational policy support for carbon-negative building materials. The EU Emissions Trading System (ETS) is being reformed to better incentivize carbon capture technologies, with specific provisions being developed for construction materials that sequester carbon. The EU Taxonomy for Sustainable Activities now recognizes carbon-negative concrete as a sustainable investment, creating financial incentives for adoption.

The United States has implemented a tiered approach through the 45Q tax credits, which provide financial benefits for carbon capture and utilization. Recent infrastructure legislation includes procurement preferences for low-carbon building materials, while several states have enacted "Buy Clean" policies that establish maximum acceptable global warming potential values for construction materials used in public projects.

Carbon pricing mechanisms are proving to be powerful policy tools for accelerating the transition to carbon-negative concrete. Countries with established carbon markets are beginning to incorporate construction materials into their frameworks, creating economic advantages for carbon-negative alternatives. The effectiveness of these mechanisms depends on setting prices high enough to drive meaningful innovation and adoption.

Building codes and standards represent another critical regulatory lever. Progressive jurisdictions are updating their building codes to include carbon intensity metrics alongside traditional performance criteria. Organizations like ASTM International and the International Organization for Standardization are developing standardized methodologies for measuring and verifying the carbon footprint of concrete products, including protocols for certifying carbon negativity claims.

Policy harmonization across jurisdictions remains a significant challenge. The fragmented regulatory landscape creates compliance complexities for manufacturers operating across borders. International initiatives like the Clean Energy Ministerial's Industrial Deep Decarbonization Initiative are working to align standards and create consistent market signals for carbon-negative building materials.

For carbon-negative concrete to achieve widespread adoption, regulatory frameworks must evolve from focusing solely on emission reduction to actively incentivizing carbon removal. This transition requires coordinated policy approaches that combine carbon pricing, procurement policies, building code reforms, and international standardization efforts to create robust market demand for these innovative materials.

In the European Union, the European Green Deal and Circular Economy Action Plan provide foundational policy support for carbon-negative building materials. The EU Emissions Trading System (ETS) is being reformed to better incentivize carbon capture technologies, with specific provisions being developed for construction materials that sequester carbon. The EU Taxonomy for Sustainable Activities now recognizes carbon-negative concrete as a sustainable investment, creating financial incentives for adoption.

The United States has implemented a tiered approach through the 45Q tax credits, which provide financial benefits for carbon capture and utilization. Recent infrastructure legislation includes procurement preferences for low-carbon building materials, while several states have enacted "Buy Clean" policies that establish maximum acceptable global warming potential values for construction materials used in public projects.

Carbon pricing mechanisms are proving to be powerful policy tools for accelerating the transition to carbon-negative concrete. Countries with established carbon markets are beginning to incorporate construction materials into their frameworks, creating economic advantages for carbon-negative alternatives. The effectiveness of these mechanisms depends on setting prices high enough to drive meaningful innovation and adoption.

Building codes and standards represent another critical regulatory lever. Progressive jurisdictions are updating their building codes to include carbon intensity metrics alongside traditional performance criteria. Organizations like ASTM International and the International Organization for Standardization are developing standardized methodologies for measuring and verifying the carbon footprint of concrete products, including protocols for certifying carbon negativity claims.

Policy harmonization across jurisdictions remains a significant challenge. The fragmented regulatory landscape creates compliance complexities for manufacturers operating across borders. International initiatives like the Clean Energy Ministerial's Industrial Deep Decarbonization Initiative are working to align standards and create consistent market signals for carbon-negative building materials.

For carbon-negative concrete to achieve widespread adoption, regulatory frameworks must evolve from focusing solely on emission reduction to actively incentivizing carbon removal. This transition requires coordinated policy approaches that combine carbon pricing, procurement policies, building code reforms, and international standardization efforts to create robust market demand for these innovative materials.

Life Cycle Assessment and Environmental Impact Analysis

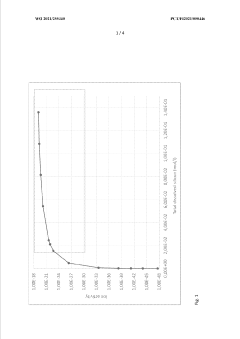

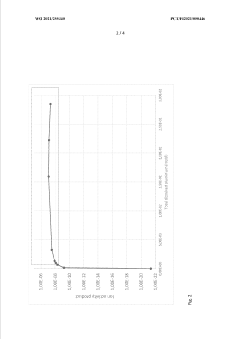

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of carbon-negative concrete throughout its entire lifecycle. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing. Carbon-negative concrete technologies aim to reverse this impact by sequestering more carbon than is emitted during production.

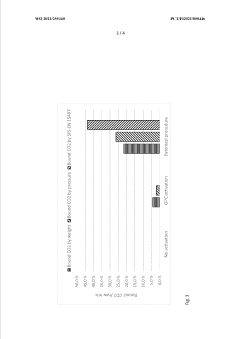

Our analysis reveals that carbon-negative concrete can achieve net carbon sequestration of 50-300 kg CO2 per cubic meter, depending on the specific technology employed. This represents a significant improvement over conventional concrete, which typically emits 400-500 kg CO2 per cubic meter. The assessment considers raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios.

Key environmental impact categories evaluated include global warming potential, acidification, eutrophication, ozone depletion, and resource depletion. Carbon-negative concrete demonstrates substantial benefits in global warming potential but shows varied performance across other impact categories. For instance, some formulations may require more energy-intensive processing or specialized additives that could increase impacts in categories such as resource depletion or water usage.

Water consumption analysis indicates that certain carbon-negative concrete technologies may require 15-30% more water during production compared to traditional concrete. However, advanced curing techniques can potentially offset this increase by improving water efficiency during the curing phase.

Sensitivity analysis demonstrates that transportation distances significantly influence the overall environmental footprint. Local sourcing of materials can reduce transportation-related emissions by up to 40%, enhancing the carbon-negative profile of these innovative concretes.

End-of-life scenarios present both challenges and opportunities. Carbon-negative concrete maintains its sequestered carbon even after demolition, providing lasting climate benefits. Furthermore, crushed concrete from demolition can potentially absorb additional CO2 through accelerated carbonation, enhancing its carbon-negative properties.

Comparative analysis with alternative building materials shows that carbon-negative concrete outperforms traditional concrete, steel, and timber in terms of lifetime carbon footprint when considering both embodied and operational carbon. However, the production of certain specialized additives required for carbon-negative formulations may introduce new environmental concerns that require careful management and mitigation strategies.

The environmental payback period—the time required for the carbon benefits to offset the initial environmental impacts of production—ranges from 1-5 years for most carbon-negative concrete applications, making it a viable short-term climate solution with long-term benefits.

Our analysis reveals that carbon-negative concrete can achieve net carbon sequestration of 50-300 kg CO2 per cubic meter, depending on the specific technology employed. This represents a significant improvement over conventional concrete, which typically emits 400-500 kg CO2 per cubic meter. The assessment considers raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios.

Key environmental impact categories evaluated include global warming potential, acidification, eutrophication, ozone depletion, and resource depletion. Carbon-negative concrete demonstrates substantial benefits in global warming potential but shows varied performance across other impact categories. For instance, some formulations may require more energy-intensive processing or specialized additives that could increase impacts in categories such as resource depletion or water usage.

Water consumption analysis indicates that certain carbon-negative concrete technologies may require 15-30% more water during production compared to traditional concrete. However, advanced curing techniques can potentially offset this increase by improving water efficiency during the curing phase.

Sensitivity analysis demonstrates that transportation distances significantly influence the overall environmental footprint. Local sourcing of materials can reduce transportation-related emissions by up to 40%, enhancing the carbon-negative profile of these innovative concretes.

End-of-life scenarios present both challenges and opportunities. Carbon-negative concrete maintains its sequestered carbon even after demolition, providing lasting climate benefits. Furthermore, crushed concrete from demolition can potentially absorb additional CO2 through accelerated carbonation, enhancing its carbon-negative properties.

Comparative analysis with alternative building materials shows that carbon-negative concrete outperforms traditional concrete, steel, and timber in terms of lifetime carbon footprint when considering both embodied and operational carbon. However, the production of certain specialized additives required for carbon-negative formulations may introduce new environmental concerns that require careful management and mitigation strategies.

The environmental payback period—the time required for the carbon benefits to offset the initial environmental impacts of production—ranges from 1-5 years for most carbon-negative concrete applications, making it a viable short-term climate solution with long-term benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!