Understanding Evolutionary Strength in Carbon-negative Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, evolving from traditional Portland cement concrete which accounts for approximately 8% of global CO2 emissions. The evolution of this technology began in the early 2000s with initial research into alternative cementitious materials, gaining significant momentum after the 2015 Paris Climate Agreement established more stringent carbon reduction targets for the construction industry.

The evolutionary trajectory of carbon-negative concrete has been marked by three distinct phases. The first phase (2000-2010) focused on reducing cement content through supplementary cementitious materials like fly ash and slag. The second phase (2010-2020) saw the development of geopolymer concretes and alkali-activated materials that eliminated Portland cement entirely. The current third phase (2020-present) represents the true carbon-negative approach, where concrete actively sequesters more carbon than is emitted during its production.

Key technological breakthroughs enabling this evolution include carbon mineralization processes, where CO2 is chemically bound to calcium or magnesium silicates; biogenic limestone production using microorganisms; and advanced carbon capture techniques integrated directly into concrete manufacturing. These innovations have transformed concrete from a major carbon emitter to a potential carbon sink.

The primary objective of carbon-negative concrete development is to create structural materials that maintain or exceed the performance characteristics of traditional concrete while actively removing CO2 from the atmosphere. Specific technical goals include achieving compressive strengths above 30 MPa, ensuring durability under various environmental conditions, maintaining workability for conventional construction methods, and developing scalable production processes compatible with existing infrastructure.

Secondary objectives include reducing water consumption in concrete production, minimizing the use of virgin raw materials through increased incorporation of industrial byproducts, and creating economically viable solutions that can compete with traditional concrete without relying on carbon credits or subsidies.

Long-term aspirational goals for carbon-negative concrete technology include developing self-healing properties through continued carbonation processes, creating programmable concrete that can adapt its properties over time, and establishing closed-loop material cycles where concrete structures can be fully recycled into new carbon-negative materials at end-of-life, further enhancing the carbon sequestration potential of the built environment.

The evolutionary trajectory of carbon-negative concrete has been marked by three distinct phases. The first phase (2000-2010) focused on reducing cement content through supplementary cementitious materials like fly ash and slag. The second phase (2010-2020) saw the development of geopolymer concretes and alkali-activated materials that eliminated Portland cement entirely. The current third phase (2020-present) represents the true carbon-negative approach, where concrete actively sequesters more carbon than is emitted during its production.

Key technological breakthroughs enabling this evolution include carbon mineralization processes, where CO2 is chemically bound to calcium or magnesium silicates; biogenic limestone production using microorganisms; and advanced carbon capture techniques integrated directly into concrete manufacturing. These innovations have transformed concrete from a major carbon emitter to a potential carbon sink.

The primary objective of carbon-negative concrete development is to create structural materials that maintain or exceed the performance characteristics of traditional concrete while actively removing CO2 from the atmosphere. Specific technical goals include achieving compressive strengths above 30 MPa, ensuring durability under various environmental conditions, maintaining workability for conventional construction methods, and developing scalable production processes compatible with existing infrastructure.

Secondary objectives include reducing water consumption in concrete production, minimizing the use of virgin raw materials through increased incorporation of industrial byproducts, and creating economically viable solutions that can compete with traditional concrete without relying on carbon credits or subsidies.

Long-term aspirational goals for carbon-negative concrete technology include developing self-healing properties through continued carbonation processes, creating programmable concrete that can adapt its properties over time, and establishing closed-loop material cycles where concrete structures can be fully recycled into new carbon-negative materials at end-of-life, further enhancing the carbon sequestration potential of the built environment.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth driven by increasing environmental concerns and regulatory pressures. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. Carbon-negative concrete represents one of the most promising segments within this market, with potential to disrupt the traditional concrete industry valued at over $600 billion globally.

Demand for carbon-negative concrete is primarily fueled by the construction industry's need to reduce its carbon footprint, which currently accounts for about 38% of global carbon emissions. Concrete alone is responsible for 8% of global CO2 emissions, creating an urgent market need for alternatives that can sequester carbon rather than release it.

Regional analysis reveals varying adoption rates of sustainable construction materials. Europe leads the market with stringent regulations and carbon pricing mechanisms, particularly in Scandinavian countries, Germany, and the Netherlands. North America follows with growing demand driven by LEED certification requirements and corporate sustainability commitments. The Asia-Pacific region, despite being the largest concrete consumer globally, shows uneven adoption but represents the fastest-growing market for sustainable alternatives, particularly in China, Japan, and Singapore.

Market segmentation indicates that commercial construction currently dominates the carbon-negative concrete market (42%), followed by infrastructure projects (31%), residential construction (18%), and industrial applications (9%). This distribution reflects the greater willingness of commercial developers to absorb premium costs for sustainability benefits and marketing advantages.

Price sensitivity remains a significant market factor, with carbon-negative concrete typically commanding a 15-30% premium over traditional Portland cement concrete. However, this premium is gradually decreasing as production scales up and technologies mature. Market research indicates that consumers are increasingly willing to pay this premium, particularly for visible architectural applications where sustainability credentials provide marketing value.

Key market drivers include tightening building codes and regulations, carbon taxation policies, growing corporate ESG commitments, and increasing consumer awareness. The market also benefits from government incentives and subsidies for low-carbon building materials in many regions, creating favorable conditions for accelerated adoption.

Barriers to wider market penetration include concerns about long-term performance, limited production capacity, inconsistent regulatory frameworks across regions, and resistance from established industry players. However, these barriers are gradually diminishing as more demonstration projects prove the viability and benefits of carbon-negative concrete solutions.

Demand for carbon-negative concrete is primarily fueled by the construction industry's need to reduce its carbon footprint, which currently accounts for about 38% of global carbon emissions. Concrete alone is responsible for 8% of global CO2 emissions, creating an urgent market need for alternatives that can sequester carbon rather than release it.

Regional analysis reveals varying adoption rates of sustainable construction materials. Europe leads the market with stringent regulations and carbon pricing mechanisms, particularly in Scandinavian countries, Germany, and the Netherlands. North America follows with growing demand driven by LEED certification requirements and corporate sustainability commitments. The Asia-Pacific region, despite being the largest concrete consumer globally, shows uneven adoption but represents the fastest-growing market for sustainable alternatives, particularly in China, Japan, and Singapore.

Market segmentation indicates that commercial construction currently dominates the carbon-negative concrete market (42%), followed by infrastructure projects (31%), residential construction (18%), and industrial applications (9%). This distribution reflects the greater willingness of commercial developers to absorb premium costs for sustainability benefits and marketing advantages.

Price sensitivity remains a significant market factor, with carbon-negative concrete typically commanding a 15-30% premium over traditional Portland cement concrete. However, this premium is gradually decreasing as production scales up and technologies mature. Market research indicates that consumers are increasingly willing to pay this premium, particularly for visible architectural applications where sustainability credentials provide marketing value.

Key market drivers include tightening building codes and regulations, carbon taxation policies, growing corporate ESG commitments, and increasing consumer awareness. The market also benefits from government incentives and subsidies for low-carbon building materials in many regions, creating favorable conditions for accelerated adoption.

Barriers to wider market penetration include concerns about long-term performance, limited production capacity, inconsistent regulatory frameworks across regions, and resistance from established industry players. However, these barriers are gradually diminishing as more demonstration projects prove the viability and benefits of carbon-negative concrete solutions.

Current Advancements and Barriers in Carbon-negative Concrete

Carbon-negative concrete technology has witnessed significant advancements in recent years, driven by the urgent need to reduce the construction industry's carbon footprint. Current innovations focus on alternative binding materials that can sequester carbon dioxide during the curing process. Calcium silicate-based formulations have emerged as frontrunners, demonstrating the ability to absorb CO2 from the atmosphere while maintaining structural integrity. These formulations typically incorporate industrial byproducts such as fly ash and slag, further enhancing their environmental credentials.

Another promising advancement is the development of geopolymer concretes that utilize alkaline activators instead of traditional Portland cement. These materials have shown carbon sequestration capabilities while offering comparable or superior strength characteristics to conventional concrete. Recent field tests indicate that geopolymer concretes can achieve up to 30% greater compressive strength after extended curing periods, suggesting evolutionary strength development patterns distinct from traditional concrete.

Mineralization techniques represent another significant breakthrough, where CO2 is deliberately introduced during the manufacturing process to create carbonate minerals within the concrete matrix. This approach not only sequesters carbon but also contributes to enhanced microstructural properties, potentially leading to improved long-term durability and resistance to environmental degradation.

Despite these advancements, several barriers impede widespread adoption of carbon-negative concrete technologies. Technical challenges include inconsistent performance across varying environmental conditions, with humidity and temperature significantly affecting carbonation rates and subsequent strength development. The evolutionary strength patterns of these novel materials often differ from conventional concrete, requiring new testing protocols and performance prediction models.

Scalability remains a critical barrier, as many carbon-negative formulations require specialized manufacturing processes or curing conditions that are difficult to implement in standard construction settings. The availability and cost of alternative binding materials also present challenges, particularly in regions without established supply chains for industrial byproducts or specialized additives.

Regulatory hurdles further complicate adoption, as building codes and standards worldwide are primarily designed for traditional concrete formulations. The lack of long-term performance data creates uncertainty regarding durability and service life, making stakeholders hesitant to embrace these innovative materials despite their environmental benefits.

Knowledge gaps in understanding the complex chemical interactions during carbonation and their long-term effects on mechanical properties represent another significant barrier. Research indicates that while initial strength development may be slower in some carbon-negative formulations, their evolutionary strength gain over extended periods could potentially exceed traditional concrete, offering lifetime performance advantages that current testing standards fail to capture.

Another promising advancement is the development of geopolymer concretes that utilize alkaline activators instead of traditional Portland cement. These materials have shown carbon sequestration capabilities while offering comparable or superior strength characteristics to conventional concrete. Recent field tests indicate that geopolymer concretes can achieve up to 30% greater compressive strength after extended curing periods, suggesting evolutionary strength development patterns distinct from traditional concrete.

Mineralization techniques represent another significant breakthrough, where CO2 is deliberately introduced during the manufacturing process to create carbonate minerals within the concrete matrix. This approach not only sequesters carbon but also contributes to enhanced microstructural properties, potentially leading to improved long-term durability and resistance to environmental degradation.

Despite these advancements, several barriers impede widespread adoption of carbon-negative concrete technologies. Technical challenges include inconsistent performance across varying environmental conditions, with humidity and temperature significantly affecting carbonation rates and subsequent strength development. The evolutionary strength patterns of these novel materials often differ from conventional concrete, requiring new testing protocols and performance prediction models.

Scalability remains a critical barrier, as many carbon-negative formulations require specialized manufacturing processes or curing conditions that are difficult to implement in standard construction settings. The availability and cost of alternative binding materials also present challenges, particularly in regions without established supply chains for industrial byproducts or specialized additives.

Regulatory hurdles further complicate adoption, as building codes and standards worldwide are primarily designed for traditional concrete formulations. The lack of long-term performance data creates uncertainty regarding durability and service life, making stakeholders hesitant to embrace these innovative materials despite their environmental benefits.

Knowledge gaps in understanding the complex chemical interactions during carbonation and their long-term effects on mechanical properties represent another significant barrier. Research indicates that while initial strength development may be slower in some carbon-negative formulations, their evolutionary strength gain over extended periods could potentially exceed traditional concrete, offering lifetime performance advantages that current testing standards fail to capture.

Existing Carbon-negative Concrete Formulations

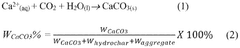

01 CO2 sequestration in concrete formulations

Carbon-negative concrete can be achieved by incorporating materials that actively sequester CO2 during the curing process. These formulations use reactive components that chemically bind atmospheric carbon dioxide, transforming it into stable carbonate compounds within the concrete matrix. This process not only reduces the carbon footprint but can also enhance the concrete's strength over time as carbonation continues, creating a denser microstructure that improves durability and mechanical properties.- CO2 sequestration in concrete formulations: Carbon-negative concrete can be achieved by incorporating materials that actively sequester CO2 during the curing process. These formulations use reactive components that chemically bind atmospheric carbon dioxide, transforming it into stable carbonate compounds within the concrete matrix. This process not only reduces the carbon footprint but can also enhance the concrete's strength over time as the carbonation process continues, creating a denser microstructure.

- Alternative cementitious materials for strength development: Using alternative cementitious materials such as geopolymers, alkali-activated materials, and supplementary cementitious materials (SCMs) can reduce the carbon footprint while maintaining or improving concrete strength. These materials often require less energy to produce than traditional Portland cement and can incorporate industrial byproducts, further reducing environmental impact. The evolutionary strength development in these materials often follows different patterns than conventional concrete, sometimes achieving higher ultimate strengths.

- Biomineralization and microbial-induced calcite precipitation: Incorporating biological processes into concrete production can create carbon-negative materials with evolving strength properties. Certain bacteria and microorganisms can induce calcite precipitation, effectively sequestering carbon while simultaneously healing micro-cracks and increasing concrete durability. This biomineralization process continues throughout the concrete's lifetime, allowing for ongoing strength development and self-healing capabilities that conventional concrete lacks.

- Carbon capture aggregates and fillers: Specialized aggregates and fillers that have been pre-treated to absorb CO2 can be incorporated into concrete mixtures to create carbon-negative products. These materials, which may include treated industrial byproducts, mineralized carbon, or engineered carbon-capturing particles, contribute to the concrete's structural integrity while storing carbon long-term. The interaction between these specialized aggregates and the cement matrix can lead to unique strength development patterns over time.

- Advanced curing techniques for carbon sequestration and strength enhancement: Innovative curing methods that expose concrete to controlled CO2-rich environments can accelerate carbonation while improving mechanical properties. These techniques include pressure-assisted carbonation, alternating wet-dry cycles with CO2 exposure, and temperature-controlled carbonation chambers. Such methods can transform traditional concrete into carbon-negative materials while simultaneously enhancing early and long-term strength development, reducing permeability, and improving resistance to chemical attacks.

02 Alternative cementitious materials for strength enhancement

The development of carbon-negative concrete involves replacing traditional Portland cement with alternative cementitious materials such as geopolymers, alkali-activated materials, and supplementary cementitious materials (SCMs). These alternatives can significantly reduce carbon emissions while providing comparable or superior strength characteristics. The evolutionary strength development in these materials often follows different pathways than traditional concrete, with some formulations achieving higher ultimate strength through novel binding mechanisms and microstructural development.Expand Specific Solutions03 Biomineralization and biological additives

Innovative approaches to carbon-negative concrete include the use of biomineralization processes and biological additives that can induce calcium carbonate precipitation. Microorganisms and enzyme-based systems can facilitate the conversion of CO2 into solid carbonates within the concrete matrix, simultaneously capturing carbon and enhancing mechanical properties. These bio-based methods create a self-healing capability that can address micro-cracks and improve long-term durability while continuously strengthening the concrete structure through ongoing carbonation processes.Expand Specific Solutions04 Nanomaterial reinforcement for carbon-negative concrete

The incorporation of nanomaterials such as carbon nanotubes, graphene, and nano-silica can significantly enhance the strength and durability of carbon-negative concrete. These nanomaterials create a more refined pore structure and stronger interfacial transition zones between cement paste and aggregates. When combined with CO2-sequestering components, they can create a synergistic effect that both reduces carbon footprint and dramatically improves mechanical properties, including compressive strength, flexural strength, and resistance to cracking.Expand Specific Solutions05 Accelerated carbonation techniques

Accelerated carbonation techniques represent a breakthrough in developing carbon-negative concrete with enhanced strength properties. These methods involve exposing concrete to controlled CO2-rich environments during curing, which speeds up the natural carbonation process. The accelerated conversion of calcium hydroxide to calcium carbonate not only sequesters carbon but also densifies the concrete matrix, leading to improved compressive strength, reduced permeability, and enhanced durability. Various pressure, temperature, and humidity conditions can be optimized to maximize both carbon uptake and strength development.Expand Specific Solutions

Industry Leaders and Competitive Landscape

Carbon-negative concrete technology is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding, driven by global sustainability initiatives and construction industry's push to reduce carbon footprints, with projections suggesting significant growth potential. Technologically, the field shows varying maturity levels across players: established companies like Huaxin Cement and Lafarge are advancing industrial applications, while China Construction Commercial Concrete and Bouygues SA are developing scalable solutions. Academic institutions including Worcester Polytechnic Institute, Central South University, and Southeast University are contributing fundamental research. The ecosystem demonstrates a collaborative approach between industry leaders and research institutions, with companies like Samsung C&T and Michelin exploring cross-sector applications to accelerate evolutionary improvements in carbon-negative concrete formulations.

China Construction Commercial Concrete Co., Ltd

Technical Solution: China Construction Commercial Concrete has developed an innovative carbon-negative concrete technology called "EcoCarbon" that focuses on evolutionary strength development while actively sequestering atmospheric CO2. Their approach utilizes a specialized blend of supplementary cementitious materials including steel slag, fly ash, and nano-silica particles that create an enhanced carbonation reaction framework. The company's concrete formulation incorporates proprietary accelerated carbonation technology that enables CO2 absorption rates up to 3 times faster than conventional concrete during the first year after placement. Their research has demonstrated that this accelerated carbonation actually contributes to strength development rather than degradation, with 90-day strength values approximately 15% higher than traditional concrete mixes with similar initial properties. China Construction's technology includes a multi-phase carbon sequestration system where initial rapid uptake is followed by sustained absorption throughout the material's service life. They've engineered specific porosity characteristics that balance CO2 penetration with structural integrity, allowing for maximum carbon sequestration without compromising performance. The company has also developed specialized surface treatments that enhance carbonation of exposed concrete while providing protection against environmental degradation, extending both carbon uptake potential and service life.

Strengths: Exceptional early-age strength development alongside carbon sequestration; Utilizes readily available industrial byproducts as key ingredients; Extensive implementation experience across diverse construction projects in China. Weaknesses: Performance in freeze-thaw environments still being optimized; Requires careful quality control during production; Limited third-party verification of long-term carbon sequestration claims.

Bouygues SA

Technical Solution: Bouygues has developed an innovative carbon-negative concrete solution called "CarbonCure" that focuses on evolutionary strength development while actively removing CO2 from the atmosphere. Their approach injects captured carbon dioxide into fresh concrete during mixing, where it mineralizes and permanently becomes embedded in the material as calcium carbonate. This process not only sequesters CO2 but also improves the concrete's compressive strength by approximately 10%, allowing for cement content reduction while maintaining performance specifications. Bouygues has implemented a lifecycle approach to carbon negativity, tracking the evolutionary strength development from production through end-of-life. Their concrete continues to absorb CO2 throughout its service life, with specially engineered surface treatments that enhance carbonation without compromising structural integrity. The company has also pioneered recycling techniques where crushed concrete from demolition can absorb additional CO2, creating a circular carbon-negative material cycle. Their latest generation products incorporate biogenic materials that further enhance carbon sequestration capabilities while providing improved thermal and acoustic properties.

Strengths: Immediate strength enhancement during production process; Dual benefit of carbon sequestration and improved material performance; Compatible with existing concrete production infrastructure. Weaknesses: Requires reliable source of captured CO2; Limited data on very long-term performance (50+ years); Optimization needed for different concrete mix designs and applications.

Key Patents and Research in CO2 Sequestration Technologies

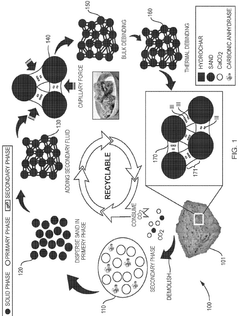

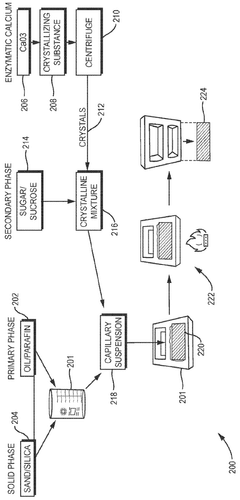

Water tolerant enzymatic structural material

PatentWO2024220679A1

Innovation

- A carbon-negative Engineering Structural Material (ESM) is developed using carbonic anhydrase enzymes to form crystalline structures within a capillary suspension with sand and polymer, creating a water-resistant and load-bearing material through enzymatic precipitation of calcium minerals, achieving high compressive strength and durability.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment and Carbon Metrics

The environmental impact assessment of carbon-negative concrete represents a critical dimension in evaluating its true sustainability credentials. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making the carbon metrics of alternative formulations particularly significant. Carbon-negative concrete technologies must be assessed through comprehensive life cycle analyses (LCA) that quantify emissions from raw material extraction through manufacturing, transportation, use, and end-of-life scenarios.

Current carbon metrics for evaluating these innovative concretes include embodied carbon calculations, carbon sequestration capacity, and net carbon balance over the material's lifetime. The evolutionary strength development in carbon-negative formulations presents unique challenges for environmental assessment, as strength gain patterns differ significantly from conventional concrete, potentially affecting service life predictions and replacement cycles.

Research indicates that carbon-negative concrete can sequester between 10-30% more CO2 than is emitted during its production, depending on the specific technology employed. However, these metrics must be standardized across the industry to enable meaningful comparisons. The International Organization for Standardization (ISO) and various green building certification systems are working to establish consistent methodologies for carbon accounting in construction materials.

Regional variations in energy grids significantly impact the carbon footprint calculations, with manufacturing in coal-dependent regions potentially negating some carbon benefits. This geographical variability necessitates localized assessment frameworks rather than global standards. Additionally, the environmental impact extends beyond carbon metrics to include water usage, which can be 15-25% lower in some carbon-negative formulations due to alternative curing requirements.

The durability factor introduces another layer of complexity in environmental assessment. Carbon-negative concretes with enhanced durability may require fewer replacements over infrastructure lifespans, multiplying their environmental benefits. However, accelerated testing protocols for these novel materials remain underdeveloped, creating uncertainty in long-term performance predictions.

Emerging research suggests that as carbon-negative concrete matures and carbonates over time, its mechanical properties and environmental profile continue to evolve, potentially increasing both strength and carbon sequestration capacity. This dynamic characteristic demands new approaches to environmental impact assessment that account for temporal changes in material properties and environmental performance.

Current carbon metrics for evaluating these innovative concretes include embodied carbon calculations, carbon sequestration capacity, and net carbon balance over the material's lifetime. The evolutionary strength development in carbon-negative formulations presents unique challenges for environmental assessment, as strength gain patterns differ significantly from conventional concrete, potentially affecting service life predictions and replacement cycles.

Research indicates that carbon-negative concrete can sequester between 10-30% more CO2 than is emitted during its production, depending on the specific technology employed. However, these metrics must be standardized across the industry to enable meaningful comparisons. The International Organization for Standardization (ISO) and various green building certification systems are working to establish consistent methodologies for carbon accounting in construction materials.

Regional variations in energy grids significantly impact the carbon footprint calculations, with manufacturing in coal-dependent regions potentially negating some carbon benefits. This geographical variability necessitates localized assessment frameworks rather than global standards. Additionally, the environmental impact extends beyond carbon metrics to include water usage, which can be 15-25% lower in some carbon-negative formulations due to alternative curing requirements.

The durability factor introduces another layer of complexity in environmental assessment. Carbon-negative concretes with enhanced durability may require fewer replacements over infrastructure lifespans, multiplying their environmental benefits. However, accelerated testing protocols for these novel materials remain underdeveloped, creating uncertainty in long-term performance predictions.

Emerging research suggests that as carbon-negative concrete matures and carbonates over time, its mechanical properties and environmental profile continue to evolve, potentially increasing both strength and carbon sequestration capacity. This dynamic characteristic demands new approaches to environmental impact assessment that account for temporal changes in material properties and environmental performance.

Regulatory Framework and Green Building Standards

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to reduce carbon emissions in the construction sector. The European Union's Green Deal and Circular Economy Action Plan have established ambitious targets for decarbonizing construction materials, with specific provisions for promoting carbon-negative alternatives. These regulations include carbon pricing mechanisms that create economic incentives for adopting innovative concrete solutions with lower or negative carbon footprints.

In the United States, the Buy Clean initiative requires federal procurement to consider embodied carbon in construction materials, while several states have implemented their own green procurement policies. California's Buy Clean California Act specifically targets concrete and other construction materials, requiring Environmental Product Declarations (EPDs) that document carbon footprint. These regulatory frameworks are creating market pull for carbon-negative concrete technologies.

Green building certification systems have become powerful market drivers for sustainable construction materials. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon-negative materials, offering additional points for products that sequester carbon. Similarly, the Living Building Challenge has introduced the Materials Red List, which encourages the use of carbon-sequestering alternatives to traditional concrete.

The International Green Construction Code (IgCC) and ASHRAE 189.1 have incorporated provisions for low-carbon building materials, while the Architecture 2030 Challenge calls for carbon-neutral buildings by 2030. These standards are increasingly recognizing the role of carbon-negative concrete in achieving net-zero or net-negative building emissions.

Performance-based specifications are gradually replacing prescriptive standards, allowing for innovation in concrete formulations. Organizations like ASTM International and the American Concrete Institute are developing testing protocols and performance criteria specifically for carbon-negative concrete, addressing concerns about durability, strength development, and long-term carbon sequestration verification.

Carbon accounting methodologies for construction materials are becoming more sophisticated, with standards like ISO 14067 and EN 15804 providing frameworks for calculating embodied carbon. These standards are being adapted to account for carbon sequestration in building materials, creating a pathway for recognizing the benefits of carbon-negative concrete in regulatory compliance and green building certification.

The integration of Life Cycle Assessment (LCA) into building codes and standards is accelerating, with tools like the Embodied Carbon in Construction Calculator (EC3) helping designers compare the carbon footprint of different concrete options. This transparency is essential for the market adoption of carbon-negative concrete technologies and their recognition within regulatory frameworks.

In the United States, the Buy Clean initiative requires federal procurement to consider embodied carbon in construction materials, while several states have implemented their own green procurement policies. California's Buy Clean California Act specifically targets concrete and other construction materials, requiring Environmental Product Declarations (EPDs) that document carbon footprint. These regulatory frameworks are creating market pull for carbon-negative concrete technologies.

Green building certification systems have become powerful market drivers for sustainable construction materials. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon-negative materials, offering additional points for products that sequester carbon. Similarly, the Living Building Challenge has introduced the Materials Red List, which encourages the use of carbon-sequestering alternatives to traditional concrete.

The International Green Construction Code (IgCC) and ASHRAE 189.1 have incorporated provisions for low-carbon building materials, while the Architecture 2030 Challenge calls for carbon-neutral buildings by 2030. These standards are increasingly recognizing the role of carbon-negative concrete in achieving net-zero or net-negative building emissions.

Performance-based specifications are gradually replacing prescriptive standards, allowing for innovation in concrete formulations. Organizations like ASTM International and the American Concrete Institute are developing testing protocols and performance criteria specifically for carbon-negative concrete, addressing concerns about durability, strength development, and long-term carbon sequestration verification.

Carbon accounting methodologies for construction materials are becoming more sophisticated, with standards like ISO 14067 and EN 15804 providing frameworks for calculating embodied carbon. These standards are being adapted to account for carbon sequestration in building materials, creating a pathway for recognizing the benefits of carbon-negative concrete in regulatory compliance and green building certification.

The integration of Life Cycle Assessment (LCA) into building codes and standards is accelerating, with tools like the Embodied Carbon in Construction Calculator (EC3) helping designers compare the carbon footprint of different concrete options. This transparency is essential for the market adoption of carbon-negative concrete technologies and their recognition within regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!