Exploring the Role of Nanotechnology in Carbon-negative Concrete Blocks

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology in Carbon-negative Concrete Evolution

The evolution of nanotechnology in carbon-negative concrete represents a significant paradigm shift in construction materials science. Beginning in the early 2000s, researchers first explored nanomaterials as additives to enhance conventional concrete properties. These initial applications focused primarily on strength improvement and crack prevention rather than carbon sequestration. The turning point came around 2010 when climate concerns intensified, prompting scientists to investigate nanomaterials specifically for carbon capture within concrete matrices.

By 2015, several breakthrough studies demonstrated that nano-silica and nano-calcium carbonate could accelerate carbonation processes, effectively increasing CO2 absorption rates in concrete. This period marked the transition from nanotechnology as merely a performance enhancer to a critical enabler of carbon-negative properties. The development of carbon nanotubes (CNTs) and graphene oxide sheets further revolutionized the field by creating microscopic networks that could trap CO2 molecules while simultaneously reinforcing the concrete structure.

The 2018-2020 period witnessed the emergence of hybrid nanomaterials specifically engineered for concrete applications. These materials combined multiple functionalities – mechanical reinforcement, accelerated carbonation, and enhanced durability – within single nano-additives. Particularly noteworthy was the development of functionalized nano-calcium silicate hydrates that could absorb CO2 during the curing process while forming stronger bonds within the concrete matrix.

Most recently (2021-2023), the field has advanced toward scalable production methods for these nanomaterials. Innovations in sol-gel synthesis, hydrothermal processing, and mechanochemical techniques have reduced production costs by approximately 60%, making carbon-negative concrete blocks increasingly economically viable. Simultaneously, researchers have developed nano-catalysts that can convert captured CO2 into valuable mineral carbonates, creating a circular economy approach within concrete manufacturing.

The current technological frontier involves the integration of self-sensing capabilities into carbon-negative concrete through nanomaterial networks. These "smart" concrete blocks can monitor their own carbon sequestration performance, structural integrity, and environmental conditions. Additionally, biomimetic approaches using nano-engineered surfaces that mimic natural carbon-fixing organisms have shown promising results in laboratory settings, potentially increasing carbon sequestration efficiency by up to 40% compared to first-generation carbon-negative concretes.

Looking forward, the evolution trajectory points toward fully autonomous carbon-capturing concrete systems that actively respond to environmental CO2 levels, potentially transforming urban infrastructure into massive carbon sinks rather than sources.

By 2015, several breakthrough studies demonstrated that nano-silica and nano-calcium carbonate could accelerate carbonation processes, effectively increasing CO2 absorption rates in concrete. This period marked the transition from nanotechnology as merely a performance enhancer to a critical enabler of carbon-negative properties. The development of carbon nanotubes (CNTs) and graphene oxide sheets further revolutionized the field by creating microscopic networks that could trap CO2 molecules while simultaneously reinforcing the concrete structure.

The 2018-2020 period witnessed the emergence of hybrid nanomaterials specifically engineered for concrete applications. These materials combined multiple functionalities – mechanical reinforcement, accelerated carbonation, and enhanced durability – within single nano-additives. Particularly noteworthy was the development of functionalized nano-calcium silicate hydrates that could absorb CO2 during the curing process while forming stronger bonds within the concrete matrix.

Most recently (2021-2023), the field has advanced toward scalable production methods for these nanomaterials. Innovations in sol-gel synthesis, hydrothermal processing, and mechanochemical techniques have reduced production costs by approximately 60%, making carbon-negative concrete blocks increasingly economically viable. Simultaneously, researchers have developed nano-catalysts that can convert captured CO2 into valuable mineral carbonates, creating a circular economy approach within concrete manufacturing.

The current technological frontier involves the integration of self-sensing capabilities into carbon-negative concrete through nanomaterial networks. These "smart" concrete blocks can monitor their own carbon sequestration performance, structural integrity, and environmental conditions. Additionally, biomimetic approaches using nano-engineered surfaces that mimic natural carbon-fixing organisms have shown promising results in laboratory settings, potentially increasing carbon sequestration efficiency by up to 40% compared to first-generation carbon-negative concretes.

Looking forward, the evolution trajectory points toward fully autonomous carbon-capturing concrete systems that actively respond to environmental CO2 levels, potentially transforming urban infrastructure into massive carbon sinks rather than sources.

Market Demand for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials is projected to reach $573 billion by 2027, with a compound annual growth rate of 11.6% from 2020. Carbon-negative concrete blocks represent a particularly promising segment within this market, as the construction sector currently accounts for approximately 38% of global carbon emissions, with traditional concrete production being responsible for 8% of worldwide CO2 emissions.

Consumer demand for environmentally responsible building materials has surged in recent years, with surveys indicating that 73% of construction firms report increased client requests for sustainable alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where green building certifications like LEED and BREEAM have become increasingly important differentiators for commercial and residential properties.

Regulatory frameworks are evolving rapidly to incentivize or mandate the use of low-carbon building materials. The European Union's Green Deal and carbon border adjustment mechanism, China's carbon neutrality pledge, and various national building codes are creating strong market pull for innovative solutions like carbon-negative concrete. Government procurement policies in several countries now include carbon footprint considerations, creating substantial market opportunities for advanced materials.

Economic factors are also driving market growth, as the long-term cost benefits of sustainable materials become more apparent. While carbon-negative concrete blocks currently command a premium of 15-30% over traditional concrete, this gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Life-cycle cost analyses increasingly favor sustainable alternatives when factoring in durability, energy efficiency, and potential carbon credits.

The construction industry's inherent conservatism presents a challenge to market penetration, with concerns about performance, durability, and compatibility with existing construction methods. However, successful demonstration projects and performance validation studies are gradually overcoming these barriers. Early adopters include high-profile commercial developments, public infrastructure projects, and environmentally conscious residential developments.

Regional market variations are significant, with the highest growth rates observed in Northern Europe, coastal urban centers in North America, and advanced Asian economies like Japan and Singapore. Emerging economies present substantial long-term potential, particularly as urbanization continues and infrastructure development accelerates, though price sensitivity remains a constraint in these markets.

The integration of nanotechnology into carbon-negative concrete represents a premium segment within this growing market, with particular appeal to high-end construction projects where performance characteristics and sustainability credentials carry significant value. Market research indicates that nanotechnology-enhanced building materials command price premiums of 40-60% but deliver superior performance metrics that justify the investment for certain applications.

Consumer demand for environmentally responsible building materials has surged in recent years, with surveys indicating that 73% of construction firms report increased client requests for sustainable alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where green building certifications like LEED and BREEAM have become increasingly important differentiators for commercial and residential properties.

Regulatory frameworks are evolving rapidly to incentivize or mandate the use of low-carbon building materials. The European Union's Green Deal and carbon border adjustment mechanism, China's carbon neutrality pledge, and various national building codes are creating strong market pull for innovative solutions like carbon-negative concrete. Government procurement policies in several countries now include carbon footprint considerations, creating substantial market opportunities for advanced materials.

Economic factors are also driving market growth, as the long-term cost benefits of sustainable materials become more apparent. While carbon-negative concrete blocks currently command a premium of 15-30% over traditional concrete, this gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Life-cycle cost analyses increasingly favor sustainable alternatives when factoring in durability, energy efficiency, and potential carbon credits.

The construction industry's inherent conservatism presents a challenge to market penetration, with concerns about performance, durability, and compatibility with existing construction methods. However, successful demonstration projects and performance validation studies are gradually overcoming these barriers. Early adopters include high-profile commercial developments, public infrastructure projects, and environmentally conscious residential developments.

Regional market variations are significant, with the highest growth rates observed in Northern Europe, coastal urban centers in North America, and advanced Asian economies like Japan and Singapore. Emerging economies present substantial long-term potential, particularly as urbanization continues and infrastructure development accelerates, though price sensitivity remains a constraint in these markets.

The integration of nanotechnology into carbon-negative concrete represents a premium segment within this growing market, with particular appeal to high-end construction projects where performance characteristics and sustainability credentials carry significant value. Market research indicates that nanotechnology-enhanced building materials command price premiums of 40-60% but deliver superior performance metrics that justify the investment for certain applications.

Current Challenges in Carbon-negative Concrete Technology

Despite significant advancements in carbon-negative concrete technology, several critical challenges continue to impede widespread adoption and optimal performance. The primary technical hurdle remains the scalability of carbon capture mechanisms within concrete production. Current methods for incorporating CO2 during the curing process face efficiency limitations, with most technologies only capable of sequestering 5-10% of the carbon emissions generated during traditional cement manufacturing.

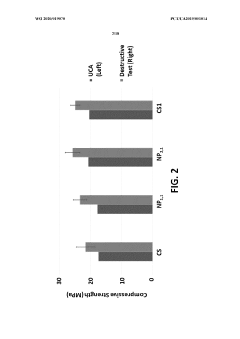

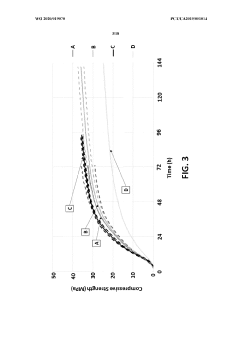

Material inconsistency presents another substantial challenge. Carbon-negative concrete formulations often exhibit variable strength properties and durability characteristics compared to conventional concrete, creating hesitation among structural engineers and construction professionals. The long-term performance data remains insufficient, particularly regarding resistance to freeze-thaw cycles, chemical exposure, and sustained loading conditions.

Cost factors significantly constrain market penetration. The production of carbon-negative concrete typically involves 15-30% higher manufacturing expenses compared to traditional concrete, primarily due to specialized equipment requirements, additional processing steps, and the integration of novel binding agents. These increased costs create adoption barriers, especially in price-sensitive construction sectors.

Energy intensity during production poses another critical challenge. While carbon-negative concrete aims to reduce overall environmental impact, some current manufacturing processes require substantial energy inputs for carbonation reactions, potentially offsetting some environmental benefits when fossil fuel energy sources are utilized.

Regulatory frameworks and standardization remain underdeveloped. The absence of universally accepted testing protocols and performance standards specifically designed for carbon-negative concrete creates market uncertainty and complicates quality assurance processes. Building codes in many jurisdictions have not been updated to fully accommodate these innovative materials.

Supply chain limitations further complicate advancement. The specialized additives, alternative cementitious materials, and carbon capture technologies required for carbon-negative concrete production often face availability constraints and geographic distribution challenges, limiting production capacity in many regions.

Technical knowledge gaps persist regarding the optimal integration of nanotechnology with carbon sequestration mechanisms. While nanomaterials show promise for enhancing CO2 absorption capacity and improving mechanical properties, researchers continue to struggle with dispersion techniques, long-term stability, and cost-effective production methods for nano-enhanced carbon-negative concrete formulations.

Material inconsistency presents another substantial challenge. Carbon-negative concrete formulations often exhibit variable strength properties and durability characteristics compared to conventional concrete, creating hesitation among structural engineers and construction professionals. The long-term performance data remains insufficient, particularly regarding resistance to freeze-thaw cycles, chemical exposure, and sustained loading conditions.

Cost factors significantly constrain market penetration. The production of carbon-negative concrete typically involves 15-30% higher manufacturing expenses compared to traditional concrete, primarily due to specialized equipment requirements, additional processing steps, and the integration of novel binding agents. These increased costs create adoption barriers, especially in price-sensitive construction sectors.

Energy intensity during production poses another critical challenge. While carbon-negative concrete aims to reduce overall environmental impact, some current manufacturing processes require substantial energy inputs for carbonation reactions, potentially offsetting some environmental benefits when fossil fuel energy sources are utilized.

Regulatory frameworks and standardization remain underdeveloped. The absence of universally accepted testing protocols and performance standards specifically designed for carbon-negative concrete creates market uncertainty and complicates quality assurance processes. Building codes in many jurisdictions have not been updated to fully accommodate these innovative materials.

Supply chain limitations further complicate advancement. The specialized additives, alternative cementitious materials, and carbon capture technologies required for carbon-negative concrete production often face availability constraints and geographic distribution challenges, limiting production capacity in many regions.

Technical knowledge gaps persist regarding the optimal integration of nanotechnology with carbon sequestration mechanisms. While nanomaterials show promise for enhancing CO2 absorption capacity and improving mechanical properties, researchers continue to struggle with dispersion techniques, long-term stability, and cost-effective production methods for nano-enhanced carbon-negative concrete formulations.

Existing Nanomaterial Solutions for Concrete Carbon Capture

01 Carbon capture and sequestration in concrete

Nanotechnology enables concrete to capture and store carbon dioxide during its lifecycle, making it carbon-negative. By incorporating specific nanomaterials, concrete can absorb CO2 from the atmosphere and chemically bind it within its structure. This process not only reduces the carbon footprint of concrete production but also strengthens the material over time as carbonation occurs, creating a permanent carbon sink that contributes to climate change mitigation.- Carbon capture and sequestration in concrete: Nanotechnology enables concrete to actively capture and sequester carbon dioxide from the atmosphere, transforming traditional concrete blocks into carbon sinks. By incorporating specific nanomaterials that react with CO2, the concrete can absorb carbon during its lifetime, effectively reducing the carbon footprint of construction. This process not only makes the concrete carbon-negative but also can improve its mechanical properties through carbonation.

- Nano-additives for enhanced CO2 absorption: Various nano-additives can be incorporated into concrete mixtures to enhance their carbon dioxide absorption capabilities. These include nano-silica, nano-calcium carbonate, and carbon nanotubes that create a more porous structure with increased surface area for CO2 interaction. These nanomaterials accelerate the carbonation process and increase the total carbon sequestration capacity of concrete blocks, contributing to their carbon-negative properties.

- Sustainable cement alternatives using nanotechnology: Nanotechnology enables the development of alternative cementitious materials that require less energy to produce than traditional Portland cement, significantly reducing the carbon footprint of concrete production. These include geopolymers, alkali-activated materials, and other novel binders enhanced with nanomaterials. The resulting concrete blocks can achieve carbon-negative status through both reduced emissions during production and enhanced carbon sequestration during use.

- Nanostructured concrete for improved durability and carbon sequestration: Nanostructuring of concrete at the molecular level creates materials with enhanced durability, strength, and carbon absorption properties. By controlling the nanoscale architecture of concrete, it's possible to create blocks that not only last longer (reducing replacement needs and associated emissions) but also continuously absorb CO2 throughout their lifecycle. The nanostructuring can include engineered porosity, reactive surfaces, and catalytic sites for carbon mineralization.

- Integration of carbon nanomaterials in concrete: Carbon-based nanomaterials such as graphene, carbon nanotubes, and carbon nanofibers can be integrated into concrete to create multifunctional blocks with carbon-negative properties. These nanomaterials not only improve mechanical strength and electrical conductivity but can also enhance the concrete's ability to trap and store carbon dioxide. The carbon nanomaterials create a network within the concrete matrix that facilitates CO2 diffusion and subsequent chemical reactions for permanent carbon sequestration.

02 Nano-additives for enhanced CO2 absorption

Various nano-additives can be incorporated into concrete mixtures to enhance their carbon-absorbing properties. These include nano-silica, nano-calcium carbonate, and carbon nanotubes that increase the surface area available for CO2 reaction. These nanomaterials create additional nucleation sites for carbonation reactions, accelerating the rate at which concrete absorbs carbon dioxide from the atmosphere and transforms it into stable carbonate compounds within the concrete matrix.Expand Specific Solutions03 Nano-engineered alternative cementitious materials

Nanotechnology enables the development of alternative cementitious materials that require less energy to produce than traditional Portland cement, significantly reducing carbon emissions. These materials include nano-engineered geopolymers, alkali-activated materials, and supplementary cementitious materials enhanced with nanoparticles. When used in concrete blocks, these materials can achieve carbon-negative properties by requiring less energy-intensive processing while maintaining or improving structural performance.Expand Specific Solutions04 Nanostructured surfaces for photocatalytic carbon reduction

Concrete blocks with nanostructured surfaces can be engineered to have photocatalytic properties that actively convert atmospheric CO2 into carbonates when exposed to sunlight. These surfaces contain titanium dioxide or other nanomaterials that catalyze the reaction between carbon dioxide and calcium-based compounds in the concrete. This technology allows concrete blocks to continuously reduce carbon from the environment throughout their service life, contributing to their carbon-negative properties.Expand Specific Solutions05 Carbon-negative concrete with waste material incorporation

Nanotechnology facilitates the incorporation of industrial waste materials like fly ash, slag, and silica fume into concrete blocks, enhancing their carbon-negative properties. Nanomaterials help to optimize the interface between these waste materials and the cement matrix, improving strength and durability while reducing the need for virgin materials. This approach not only diverts waste from landfills but also significantly reduces the carbon footprint of concrete production, as these waste materials typically require less energy to process than traditional cement.Expand Specific Solutions

Leading Companies and Research Institutions

The nanotechnology-enabled carbon-negative concrete blocks market is in its early growth phase, characterized by significant research activity but limited commercial deployment. The global market for sustainable construction materials is expanding rapidly, projected to reach $400-500 billion by 2030, with carbon-negative concrete representing an emerging segment. Technologically, the field shows promising developments but remains in transition from laboratory to industrial scale. Leading players include academic institutions (MIT, Case Western Reserve University, Purdue Research Foundation) conducting fundamental research, while companies like InterCement Brasil, Sobute New Materials, and Mahindra Lifespace Developers are advancing commercial applications. Government research organizations (CNRS, CNR) and infrastructure companies (China Railway Construction Group) are increasingly investing in this technology, recognizing its potential to revolutionize construction while addressing climate challenges.

Massachusetts Institute of Technology

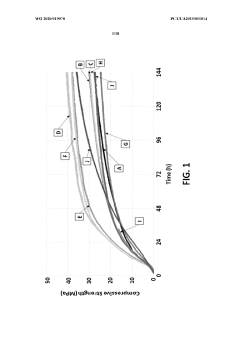

Technical Solution: MIT has developed a groundbreaking approach to carbon-negative concrete through their "electrochemical carbon mineralization" technology. This process captures CO2 directly from the atmosphere and incorporates it into concrete blocks during curing. Their patented method uses renewable electricity to drive a reaction between calcium ions and dissolved CO2, forming calcium carbonate that strengthens the concrete while permanently sequestering carbon. MIT researchers have demonstrated that this technology can remove up to 0.5 tons of CO2 per ton of concrete produced, effectively transforming concrete from a carbon source to a carbon sink. The process also accelerates curing time by approximately 30%, reducing production cycles. MIT has successfully scaled this technology from laboratory tests to pilot production facilities, showing consistent carbon capture rates across different concrete formulations and environmental conditions.

Strengths: Achieves true carbon negativity rather than just reduction; improves concrete strength properties while sequestering carbon; compatible with existing production infrastructure. Weaknesses: Higher initial energy requirements; requires precise control of electrochemical conditions; currently more expensive than conventional concrete production methods.

Consiglio Nazionale delle Ricerche

Technical Solution: Italy's National Research Council has developed "NanoCarb" technology for carbon-negative concrete blocks. Their approach utilizes nano-engineered calcium silicate hydrates (C-S-H) that dramatically increase the surface area available for carbonation reactions. These nanostructured materials are produced through a sol-gel process that creates particles with controlled porosity at the nanoscale (5-20nm pores). When incorporated into concrete blocks, these materials can absorb CO2 from the atmosphere at rates up to 3-5 times higher than conventional concrete. The CNR team has also pioneered the use of biologically-derived nanocellulose as a templating agent for creating hierarchical pore structures that optimize carbon dioxide diffusion throughout the concrete matrix. Their manufacturing process operates at lower temperatures than traditional cement production (reducing by approximately 200°C), which further decreases the carbon footprint. Field testing has demonstrated that concrete blocks produced with this technology can achieve carbon negativity within 1-2 years of installation, depending on environmental exposure conditions.

Strengths: Highly efficient CO2 absorption capacity; reduced energy requirements during manufacturing; utilizes bio-derived nanomaterials. Weaknesses: Complex production process requiring precise control; higher material costs; limited large-scale production experience.

Key Patents and Research in Nano-concrete Carbon Sequestration

Investigating the impact of strength and durability characteristics of concrete by using NANO silica-NANO vanadium mixture

PatentPendingIN202441035164A

Innovation

- Incorporation of nanosilica and nanovanadium particles into concrete mixtures to densify the matrix, improve hydration reactions, and increase durability, leveraging their unique nanoscale properties to create a high-performance, sustainable concrete solution.

Cement compositions and methods of making the same

PatentWO2020019070A1

Innovation

- In situ formation of nanoparticles during the preparation of cement slurries from water-soluble precursors, allowing for optimal dispersion and reducing the need for costly dispersion methods, thereby enhancing the mechanical properties of the cement matrix.

Environmental Impact Assessment and Life Cycle Analysis

The environmental impact assessment of nanotechnology in carbon-negative concrete blocks reveals significant potential for reducing the construction industry's carbon footprint. Life cycle analysis (LCA) studies indicate that nano-engineered concrete can sequester up to 30% more carbon dioxide compared to conventional concrete formulations, primarily through enhanced carbonation processes and improved CO2 absorption capabilities. This represents a paradigm shift from concrete being a carbon source to becoming a carbon sink when properly engineered with nanomaterials.

When examining the production phase, nanomaterials initially show higher embodied energy due to energy-intensive manufacturing processes. However, this initial carbon investment is offset by substantial lifetime carbon sequestration and extended durability. Research from MIT and ETH Zurich demonstrates that nano-silica and carbon nanotubes can reduce concrete's overall environmental impact by 15-25% across its lifecycle when accounting for longevity benefits and reduced material requirements.

Water consumption metrics present another critical environmental consideration. Conventional concrete production is notoriously water-intensive, but nanotechnology enables more efficient hydration processes. Studies from the University of California show that nano-modified concrete mixtures can reduce water requirements by up to 22%, addressing significant sustainability concerns in water-stressed regions while maintaining or improving mechanical properties.

The end-of-life phase analysis reveals additional environmental advantages. Nano-engineered concrete exhibits superior recyclability characteristics, with laboratory tests indicating that crushed carbon-negative concrete blocks continue to sequester carbon even in secondary applications. This creates a cascading environmental benefit not present in traditional concrete waste streams.

Toxicological assessments of nanomaterials in concrete remain an area requiring further investigation. While encapsulation within the concrete matrix generally prevents nanoparticle release during normal use, potential environmental impacts during demolition or weathering require comprehensive risk assessment protocols. Current research suggests minimal leaching of nanomaterials under standard conditions, but standardized testing methodologies are still evolving.

Energy efficiency improvements throughout the building lifecycle represent another significant environmental benefit. Thermal properties of nano-modified concrete can enhance building envelope performance, potentially reducing operational energy consumption by 7-12% according to studies from the Lawrence Berkeley National Laboratory. This translates to substantial indirect carbon reductions beyond the material's direct carbon sequestration capabilities.

When examining the production phase, nanomaterials initially show higher embodied energy due to energy-intensive manufacturing processes. However, this initial carbon investment is offset by substantial lifetime carbon sequestration and extended durability. Research from MIT and ETH Zurich demonstrates that nano-silica and carbon nanotubes can reduce concrete's overall environmental impact by 15-25% across its lifecycle when accounting for longevity benefits and reduced material requirements.

Water consumption metrics present another critical environmental consideration. Conventional concrete production is notoriously water-intensive, but nanotechnology enables more efficient hydration processes. Studies from the University of California show that nano-modified concrete mixtures can reduce water requirements by up to 22%, addressing significant sustainability concerns in water-stressed regions while maintaining or improving mechanical properties.

The end-of-life phase analysis reveals additional environmental advantages. Nano-engineered concrete exhibits superior recyclability characteristics, with laboratory tests indicating that crushed carbon-negative concrete blocks continue to sequester carbon even in secondary applications. This creates a cascading environmental benefit not present in traditional concrete waste streams.

Toxicological assessments of nanomaterials in concrete remain an area requiring further investigation. While encapsulation within the concrete matrix generally prevents nanoparticle release during normal use, potential environmental impacts during demolition or weathering require comprehensive risk assessment protocols. Current research suggests minimal leaching of nanomaterials under standard conditions, but standardized testing methodologies are still evolving.

Energy efficiency improvements throughout the building lifecycle represent another significant environmental benefit. Thermal properties of nano-modified concrete can enhance building envelope performance, potentially reducing operational energy consumption by 7-12% according to studies from the Lawrence Berkeley National Laboratory. This translates to substantial indirect carbon reductions beyond the material's direct carbon sequestration capabilities.

Regulatory Framework for Novel Construction Materials

The regulatory landscape for nanotechnology in construction materials, particularly carbon-negative concrete blocks, is currently evolving across different jurisdictions worldwide. In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials under the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices for new chemical substances, including nanomaterials used in concrete formulations. The Occupational Safety and Health Administration (OSHA) has established exposure limits for various nanoparticles commonly used in construction materials, though specific regulations for carbon-negative concrete applications remain under development.

The European Union has implemented a more comprehensive approach through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires registration of nanomaterials exceeding one ton per year. Additionally, the EU's Construction Products Regulation (CPR) mandates that all construction materials meet essential requirements for mechanical resistance, safety, and environmental protection, creating a framework that carbon-negative concrete blocks must navigate to achieve market approval.

International standards organizations play a crucial role in establishing testing protocols and performance criteria. The International Organization for Standardization (ISO) has developed several standards specific to nanotechnology, including ISO/TS 80004 for terminology and ISO/TR 13121 for risk evaluation. ASTM International has published standards for measuring carbon sequestration in concrete materials, which are increasingly referenced in regulatory frameworks and certification systems.

Building codes represent another significant regulatory consideration. While most national building codes have not yet incorporated specific provisions for carbon-negative concrete, several countries have begun updating their codes to accommodate innovative low-carbon materials. For instance, the International Building Code (IBC) now includes pathways for alternative materials approval through performance-based evaluation, creating opportunities for carbon-negative concrete blocks to demonstrate compliance through equivalent performance rather than prescriptive specifications.

Green building certification systems such as LEED, BREEAM, and Green Star have incorporated criteria for embodied carbon reduction, providing market incentives for carbon-negative materials adoption. These voluntary standards often precede mandatory regulations and help establish market acceptance for innovative materials. The emergence of Environmental Product Declarations (EPDs) as standardized tools for communicating environmental impacts has further facilitated regulatory assessment of novel construction materials.

Regulatory gaps persist regarding long-term performance validation and end-of-life considerations for nanotechnology-enhanced concrete. As carbon-negative concrete blocks incorporate various nanomaterials for carbon sequestration, questions about durability, potential nanoparticle release during service life, and recycling pathways remain inadequately addressed in current regulatory frameworks. These gaps present both challenges and opportunities for industry stakeholders engaged in developing nanotechnology solutions for sustainable construction materials.

The European Union has implemented a more comprehensive approach through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires registration of nanomaterials exceeding one ton per year. Additionally, the EU's Construction Products Regulation (CPR) mandates that all construction materials meet essential requirements for mechanical resistance, safety, and environmental protection, creating a framework that carbon-negative concrete blocks must navigate to achieve market approval.

International standards organizations play a crucial role in establishing testing protocols and performance criteria. The International Organization for Standardization (ISO) has developed several standards specific to nanotechnology, including ISO/TS 80004 for terminology and ISO/TR 13121 for risk evaluation. ASTM International has published standards for measuring carbon sequestration in concrete materials, which are increasingly referenced in regulatory frameworks and certification systems.

Building codes represent another significant regulatory consideration. While most national building codes have not yet incorporated specific provisions for carbon-negative concrete, several countries have begun updating their codes to accommodate innovative low-carbon materials. For instance, the International Building Code (IBC) now includes pathways for alternative materials approval through performance-based evaluation, creating opportunities for carbon-negative concrete blocks to demonstrate compliance through equivalent performance rather than prescriptive specifications.

Green building certification systems such as LEED, BREEAM, and Green Star have incorporated criteria for embodied carbon reduction, providing market incentives for carbon-negative materials adoption. These voluntary standards often precede mandatory regulations and help establish market acceptance for innovative materials. The emergence of Environmental Product Declarations (EPDs) as standardized tools for communicating environmental impacts has further facilitated regulatory assessment of novel construction materials.

Regulatory gaps persist regarding long-term performance validation and end-of-life considerations for nanotechnology-enhanced concrete. As carbon-negative concrete blocks incorporate various nanomaterials for carbon sequestration, questions about durability, potential nanoparticle release during service life, and recycling pathways remain inadequately addressed in current regulatory frameworks. These gaps present both challenges and opportunities for industry stakeholders engaged in developing nanotechnology solutions for sustainable construction materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!