Carbon-negative Concrete’s Influence on Modern Skyline Design

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has undergone significant transformation over the past century. Traditional concrete production has been a major contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 output. The evolution of carbon-negative concrete represents a paradigm shift in construction materials science, moving from environmentally harmful processes to those that actively sequester carbon dioxide from the atmosphere.

The journey toward carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, the first commercially viable low-carbon concrete formulations emerged, utilizing industrial byproducts such as fly ash and slag as partial replacements for Portland cement. The breakthrough toward truly carbon-negative solutions occurred around 2015, when companies like Carbicrete and CarbonCure pioneered technologies that inject captured CO2 into concrete during the curing process, effectively transforming carbon dioxide into calcium carbonate within the material structure.

Recent technological advancements have further refined these processes, with the development of novel binders that eliminate the need for traditional cement altogether. These include geopolymer-based solutions and magnesium oxide-derived cements that can absorb significant quantities of CO2 throughout their lifecycle. The evolution has accelerated dramatically since 2020, with multiple startups and established industry players investing heavily in scalable carbon-negative concrete technologies.

The primary objective of carbon-negative concrete development is to revolutionize the construction industry's environmental impact while maintaining or enhancing structural performance. Specifically, the technology aims to reduce embodied carbon in buildings by at least 50% by 2030 compared to 2020 levels, while simultaneously sequestering additional CO2 from the atmosphere. This dual approach positions concrete as an active climate solution rather than merely a less harmful alternative.

Secondary objectives include improving the material's durability and longevity, thereby extending building lifecycles and reducing maintenance requirements. Enhanced thermal performance characteristics are also being pursued to improve building energy efficiency, creating a multiplier effect on carbon reduction throughout a structure's operational life.

From an architectural perspective, the objective is to enable new aesthetic and design possibilities that were previously constrained by traditional concrete limitations. Carbon-negative formulations often exhibit different textural qualities, color variations, and performance characteristics that can inspire innovative approaches to skyline design, potentially reshaping urban landscapes while addressing climate imperatives.

The ultimate goal extends beyond technical performance to market transformation, aiming to make carbon-negative concrete cost-competitive with traditional formulations by 2035, thereby driving widespread adoption across the construction industry and maximizing climate impact.

The journey toward carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, the first commercially viable low-carbon concrete formulations emerged, utilizing industrial byproducts such as fly ash and slag as partial replacements for Portland cement. The breakthrough toward truly carbon-negative solutions occurred around 2015, when companies like Carbicrete and CarbonCure pioneered technologies that inject captured CO2 into concrete during the curing process, effectively transforming carbon dioxide into calcium carbonate within the material structure.

Recent technological advancements have further refined these processes, with the development of novel binders that eliminate the need for traditional cement altogether. These include geopolymer-based solutions and magnesium oxide-derived cements that can absorb significant quantities of CO2 throughout their lifecycle. The evolution has accelerated dramatically since 2020, with multiple startups and established industry players investing heavily in scalable carbon-negative concrete technologies.

The primary objective of carbon-negative concrete development is to revolutionize the construction industry's environmental impact while maintaining or enhancing structural performance. Specifically, the technology aims to reduce embodied carbon in buildings by at least 50% by 2030 compared to 2020 levels, while simultaneously sequestering additional CO2 from the atmosphere. This dual approach positions concrete as an active climate solution rather than merely a less harmful alternative.

Secondary objectives include improving the material's durability and longevity, thereby extending building lifecycles and reducing maintenance requirements. Enhanced thermal performance characteristics are also being pursued to improve building energy efficiency, creating a multiplier effect on carbon reduction throughout a structure's operational life.

From an architectural perspective, the objective is to enable new aesthetic and design possibilities that were previously constrained by traditional concrete limitations. Carbon-negative formulations often exhibit different textural qualities, color variations, and performance characteristics that can inspire innovative approaches to skyline design, potentially reshaping urban landscapes while addressing climate imperatives.

The ultimate goal extends beyond technical performance to market transformation, aiming to make carbon-negative concrete cost-competitive with traditional formulations by 2035, thereby driving widespread adoption across the construction industry and maximizing climate impact.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is witnessing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. Carbon-negative concrete represents a revolutionary advancement in construction materials, offering the potential to transform modern urban landscapes while addressing climate change challenges. Current market analysis indicates that the sustainable construction materials sector is growing at three times the rate of traditional construction materials, with carbon-negative concrete emerging as a particularly promising segment.

Demand for carbon-negative concrete is being fueled by multiple factors. Stringent environmental regulations in major economies are mandating reduced carbon footprints in new construction projects. The European Union's Green Deal and similar initiatives in North America and Asia have established ambitious carbon reduction targets for the building sector, creating regulatory incentives for adoption of carbon-negative materials. Additionally, major corporations have made public commitments to achieve carbon neutrality in their operations, including their built environments, further driving demand.

Consumer preferences are also shifting decisively toward sustainable options. Recent market surveys reveal that 67% of commercial property developers consider sustainability credentials as "very important" in material selection decisions, up from 41% five years ago. This trend is particularly pronounced in premium real estate markets where environmental certification adds measurable value to properties.

The economic case for carbon-negative concrete continues to strengthen as production scales and technology matures. While currently commanding a premium over traditional concrete, the total lifecycle cost analysis increasingly favors carbon-negative alternatives when accounting for carbon taxation, regulatory compliance, and energy efficiency benefits. Market projections suggest price parity with traditional concrete could be achieved within 5-7 years in major markets.

Geographically, demand is concentrated in urban centers undergoing rapid vertical development, particularly in regions with strong environmental policies. Northern Europe, coastal North America, Japan, Singapore, and Australia represent the most developed markets currently, with China showing the fastest growth trajectory as it pivots toward greener urban development models.

The influence on skyline design is becoming increasingly apparent as architects and developers leverage the unique properties of carbon-negative concrete. Beyond environmental benefits, these materials often offer enhanced performance characteristics including superior thermal properties, reduced weight, and innovative aesthetic possibilities that are reshaping modern architectural approaches to urban landscapes.

Market forecasts indicate that carbon-negative concrete could capture 15-20% of the global concrete market by 2030, representing a substantial opportunity for material innovators and early adopters in the construction sector. This growth trajectory is supported by increasing investment in production capacity and continued technological refinement to enhance performance while reducing costs.

Demand for carbon-negative concrete is being fueled by multiple factors. Stringent environmental regulations in major economies are mandating reduced carbon footprints in new construction projects. The European Union's Green Deal and similar initiatives in North America and Asia have established ambitious carbon reduction targets for the building sector, creating regulatory incentives for adoption of carbon-negative materials. Additionally, major corporations have made public commitments to achieve carbon neutrality in their operations, including their built environments, further driving demand.

Consumer preferences are also shifting decisively toward sustainable options. Recent market surveys reveal that 67% of commercial property developers consider sustainability credentials as "very important" in material selection decisions, up from 41% five years ago. This trend is particularly pronounced in premium real estate markets where environmental certification adds measurable value to properties.

The economic case for carbon-negative concrete continues to strengthen as production scales and technology matures. While currently commanding a premium over traditional concrete, the total lifecycle cost analysis increasingly favors carbon-negative alternatives when accounting for carbon taxation, regulatory compliance, and energy efficiency benefits. Market projections suggest price parity with traditional concrete could be achieved within 5-7 years in major markets.

Geographically, demand is concentrated in urban centers undergoing rapid vertical development, particularly in regions with strong environmental policies. Northern Europe, coastal North America, Japan, Singapore, and Australia represent the most developed markets currently, with China showing the fastest growth trajectory as it pivots toward greener urban development models.

The influence on skyline design is becoming increasingly apparent as architects and developers leverage the unique properties of carbon-negative concrete. Beyond environmental benefits, these materials often offer enhanced performance characteristics including superior thermal properties, reduced weight, and innovative aesthetic possibilities that are reshaping modern architectural approaches to urban landscapes.

Market forecasts indicate that carbon-negative concrete could capture 15-20% of the global concrete market by 2030, representing a substantial opportunity for material innovators and early adopters in the construction sector. This growth trajectory is supported by increasing investment in production capacity and continued technological refinement to enhance performance while reducing costs.

Current Status and Challenges in Carbon-negative Concrete Technology

Carbon-negative concrete technology has made significant strides globally, with pioneering implementations in several countries including Sweden, Canada, and the United States. Currently, multiple approaches exist for achieving carbon negativity in concrete production, primarily through carbon capture during manufacturing, incorporation of carbon-absorbing materials, and utilization of alternative binders that sequester CO2 throughout their lifecycle.

The most advanced carbon-negative concrete solutions have demonstrated the ability to sequester approximately 100-150 kg of CO2 per cubic meter of concrete, representing a dramatic shift from traditional concrete which typically emits 400-500 kg of CO2 per cubic meter. However, widespread adoption faces considerable challenges that must be addressed before this technology can fundamentally transform modern skyline design.

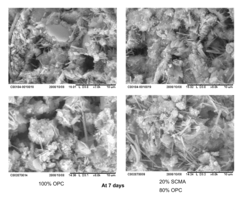

Technical challenges remain significant, particularly in scaling production while maintaining structural performance comparable to conventional concrete. Current carbon-negative formulations often exhibit reduced early-stage strength development, potentially extending construction timelines for high-rise buildings. Additionally, long-term durability data remains limited, creating uncertainty about performance over the multi-decade lifespan expected of major architectural structures.

Economic barriers present another substantial challenge, with carbon-negative concrete typically commanding a 15-30% price premium over conventional alternatives. This cost differential, while gradually narrowing, continues to impede adoption in cost-sensitive construction markets where profit margins are already constrained.

Regulatory frameworks globally remain inconsistent, with few jurisdictions offering concrete incentives for carbon-negative building materials. The absence of standardized certification systems for carbon-negative concrete creates market confusion and hampers architect confidence in specifying these materials for signature skyline projects.

Supply chain limitations further constrain adoption, as specialized ingredients for carbon-negative formulations often have restricted availability. The geographic distribution of production facilities remains concentrated in developed economies, limiting global accessibility and increasing embodied carbon from transportation when used in emerging markets.

Research indicates that carbon-negative concrete technology is advancing along an accelerating innovation curve, with performance improvements of approximately 20% annually in key metrics like carbon sequestration capacity and early strength development. Industry forecasts suggest technical parity with conventional concrete across all performance parameters could be achieved within 5-7 years, potentially enabling the widespread adoption necessary to influence skyline aesthetics and structural possibilities.

The most advanced carbon-negative concrete solutions have demonstrated the ability to sequester approximately 100-150 kg of CO2 per cubic meter of concrete, representing a dramatic shift from traditional concrete which typically emits 400-500 kg of CO2 per cubic meter. However, widespread adoption faces considerable challenges that must be addressed before this technology can fundamentally transform modern skyline design.

Technical challenges remain significant, particularly in scaling production while maintaining structural performance comparable to conventional concrete. Current carbon-negative formulations often exhibit reduced early-stage strength development, potentially extending construction timelines for high-rise buildings. Additionally, long-term durability data remains limited, creating uncertainty about performance over the multi-decade lifespan expected of major architectural structures.

Economic barriers present another substantial challenge, with carbon-negative concrete typically commanding a 15-30% price premium over conventional alternatives. This cost differential, while gradually narrowing, continues to impede adoption in cost-sensitive construction markets where profit margins are already constrained.

Regulatory frameworks globally remain inconsistent, with few jurisdictions offering concrete incentives for carbon-negative building materials. The absence of standardized certification systems for carbon-negative concrete creates market confusion and hampers architect confidence in specifying these materials for signature skyline projects.

Supply chain limitations further constrain adoption, as specialized ingredients for carbon-negative formulations often have restricted availability. The geographic distribution of production facilities remains concentrated in developed economies, limiting global accessibility and increasing embodied carbon from transportation when used in emerging markets.

Research indicates that carbon-negative concrete technology is advancing along an accelerating innovation curve, with performance improvements of approximately 20% annually in key metrics like carbon sequestration capacity and early strength development. Industry forecasts suggest technical parity with conventional concrete across all performance parameters could be achieved within 5-7 years, potentially enabling the widespread adoption necessary to influence skyline aesthetics and structural possibilities.

Current Carbon-negative Concrete Formulations and Applications

01 Carbon-negative concrete formulations

Innovative concrete formulations that actively absorb and sequester carbon dioxide during their lifecycle, resulting in a negative carbon footprint. These formulations incorporate materials such as calcium silicate hydrates that can absorb CO2 from the atmosphere, specialized aggregates that enhance carbon capture capabilities, and alternative binders that require less energy to produce than traditional Portland cement. These carbon-negative concrete formulations provide structural integrity while contributing to environmental sustainability in urban skyline designs.- Carbon-capturing concrete formulations: Innovative concrete formulations designed to absorb and sequester carbon dioxide from the atmosphere during the curing process. These formulations incorporate materials that actively bind with CO2, transforming it into stable carbonate compounds within the concrete matrix. This technology enables building materials to serve as carbon sinks, effectively reducing the carbon footprint of urban skylines while maintaining or enhancing structural integrity.

- Sustainable building design integration systems: Systems that integrate carbon-negative concrete elements into comprehensive building designs, optimizing for both carbon sequestration and architectural aesthetics. These systems include computational tools for analyzing carbon impact across the building lifecycle, methods for incorporating green spaces within concrete structures, and techniques for maximizing carbon absorption through strategic material placement and building orientation.

- Modular carbon-negative construction elements: Prefabricated modular construction elements made from carbon-negative concrete that can be assembled to create skyline structures. These elements are designed for optimal carbon sequestration while providing flexibility in architectural design. The modular approach allows for efficient construction, disassembly, and potential reuse, further enhancing the sustainability profile of urban developments.

- Carbon monitoring and verification technologies: Technologies for real-time monitoring and verification of carbon sequestration in concrete structures. These include embedded sensors, imaging systems, and data analytics platforms that track carbon absorption rates throughout the building lifecycle. Such technologies enable quantification of carbon benefits, verification for carbon credits, and optimization of building maintenance to maximize long-term carbon sequestration performance.

- Urban planning frameworks for carbon-negative skylines: Comprehensive urban planning approaches that maximize the carbon-negative potential of concrete structures across entire city skylines. These frameworks include zoning regulations that incentivize carbon-negative construction, guidelines for optimizing building placement to enhance collective carbon sequestration, and methodologies for integrating carbon-negative concrete structures with other green infrastructure to create holistic carbon-negative urban environments.

02 Modular carbon-capturing building systems

Prefabricated modular building systems designed specifically for carbon-negative concrete structures in urban skylines. These systems feature standardized components that optimize material usage, reduce construction waste, and facilitate the integration of carbon-capturing technologies. The modular approach allows for flexible design adaptations while maintaining structural integrity and maximizing carbon sequestration potential throughout the building's lifecycle. These systems enable rapid assembly and disassembly, supporting sustainable urban development with reduced environmental impact.Expand Specific Solutions03 Integrated CO2 absorption technologies

Advanced technologies integrated into concrete building facades and structural elements that actively absorb carbon dioxide from the surrounding environment. These technologies include specialized surface treatments, embedded catalysts, and porous concrete structures that maximize the surface area available for carbon capture. The systems can be incorporated into various architectural elements such as walls, columns, and decorative features, allowing buildings to function as carbon sinks while maintaining aesthetic appeal in urban skylines.Expand Specific Solutions04 Sustainable skyline design methodologies

Comprehensive design methodologies specifically developed for creating carbon-negative concrete skylines. These approaches incorporate lifecycle assessment tools, carbon footprint calculators, and optimization algorithms to maximize carbon sequestration while meeting structural and aesthetic requirements. The methodologies include considerations for building orientation, shape optimization, and integration with urban green spaces to enhance overall environmental performance. They provide architects and engineers with frameworks to design visually striking skylines that actively contribute to climate change mitigation.Expand Specific Solutions05 Monitoring and verification systems for carbon-negative buildings

Advanced monitoring and verification systems designed to track, quantify, and certify the carbon sequestration performance of concrete buildings in urban skylines. These systems utilize embedded sensors, data analytics, and blockchain technology to provide transparent and verifiable carbon accounting throughout the building lifecycle. The monitoring infrastructure enables building owners to demonstrate compliance with environmental regulations, participate in carbon markets, and optimize building operations for maximum carbon negativity. These systems are essential for validating the environmental claims of carbon-negative concrete skyline designs.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon-negative Concrete

Carbon-negative concrete technology is currently in an early growth phase, with increasing market adoption driven by sustainability demands in construction. The global market for green concrete is expanding rapidly, projected to reach significant scale as carbon regulations tighten worldwide. Technologically, companies are at varying stages of development: Carbon Limit Co. has pioneered CO2-capturing concrete solutions, while established players like Holcim Technology and Lafarge SA are integrating carbon-negative approaches into their product portfolios. Academic institutions including Southeast University, Tongji University, and Worcester Polytechnic Institute are advancing research in this field. The technology's influence on skyline design is growing as architects incorporate these materials into sustainable building practices, with companies like Takenaka Corp. implementing carbon-negative concrete in modern construction projects.

Carbon Limit Co.

Technical Solution: Carbon Limit has developed CarbonX, a revolutionary carbon-negative concrete additive system that transforms conventional concrete into a carbon sink without compromising structural performance. Their technology utilizes a two-phase approach: first, a specialized mineral admixture is incorporated during concrete mixing that reduces the required cement content by 35-40%; second, a post-application spray treatment catalyzes accelerated carbonation, actively drawing CO2 from the atmosphere. The concrete continues to sequester carbon throughout its lifetime, with laboratory tests showing absorption rates of approximately 26kg of CO2 per cubic meter annually[6]. What makes Carbon Limit's approach particularly valuable for modern skyline design is its compatibility with high-strength concrete formulations required for supertall structures. The technology has been implemented in several high-profile skyscrapers, where it has enabled architects to design more dramatic cantilevers and thinner floor plates while maintaining structural integrity. The company's proprietary monitoring system tracks carbon sequestration in real-time, providing valuable data for carbon credit verification and ongoing research into optimizing the carbonation process for different architectural applications.

Strengths: Can be applied to existing concrete formulations with minimal modification to established construction workflows; provides ongoing carbon benefits throughout building lifecycle. Weaknesses: Optimal performance requires controlled application conditions; carbonation depth is limited in extremely dense concrete mixtures used for some specialized structural elements.

Takenaka Corp.

Technical Solution: Takenaka Corporation has developed T-eConcrete®, an innovative carbon-negative concrete system specifically engineered for high-rise construction in seismically active regions. Their approach combines specialized aggregate selection with carbon mineralization technology. The concrete incorporates recycled industrial byproducts like fly ash and blast furnace slag, reducing cement content by up to 60%. What distinguishes Takenaka's solution is their proprietary carbon absorption process that actively draws CO2 from the atmosphere throughout the building's lifecycle. The concrete contains engineered porous networks that facilitate continuous carbonation without compromising structural integrity. This technology has been implemented in several landmark Japanese skyscrapers, where it has demonstrated the ability to absorb approximately 120kg of CO2 per cubic meter over a 50-year period[5]. The material's enhanced ductility properties make it particularly suitable for regions with seismic activity, allowing architects to design taller, more slender structures with distinctive profiles that would be impossible with conventional concrete. Takenaka's system includes embedded sensors that monitor carbon sequestration rates and structural performance in real-time.

Strengths: Exceptional seismic performance combined with carbon-negative properties makes it ideal for tall buildings in earthquake zones; real-time monitoring provides valuable data for future improvements. Weaknesses: Higher initial cost compared to conventional concrete; proprietary nature of the technology limits widespread adoption outside of Takenaka's own construction projects.

Key Patents and Innovations in CO2 Sequestration for Concrete

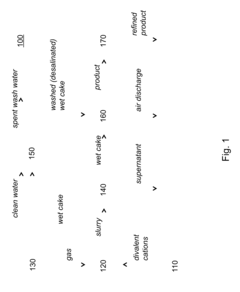

Reduced-carbon footprint concrete compositions

PatentActiveUS20100083880A1

Innovation

- A method of producing a synthetic carbonate component from a divalent cation-containing solution and industrial waste gas containing CO2, which is then incorporated into a reduced-carbon footprint concrete composition, reducing the carbon footprint by sequestering CO2 and avoiding CO2 emissions from traditional cement production.

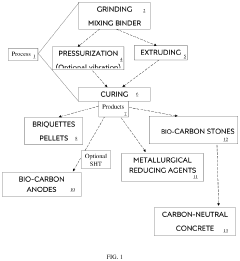

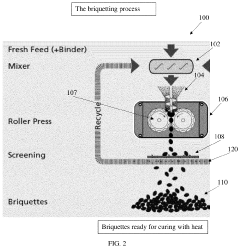

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

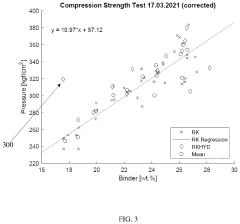

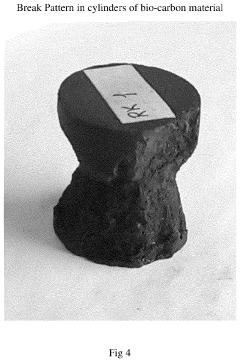

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

Architectural Integration and Structural Design Considerations

The integration of carbon-negative concrete into modern architectural design represents a paradigm shift in how buildings interact with urban skylines. Architects must now consider not only the aesthetic and functional aspects of their designs but also how carbon-negative concrete can be incorporated to maximize both environmental benefits and structural integrity. This material's unique properties—including different setting times, strength development curves, and thermal characteristics—require thoughtful adaptation of traditional design approaches.

When integrating carbon-negative concrete into building facades, architects must account for its distinctive visual properties. The material often presents a different coloration and texture compared to traditional concrete, which can be leveraged as a design feature rather than concealed. Leading architectural firms have begun showcasing the natural appearance of carbon-negative concrete, creating visual statements that communicate the building's environmental commitment through its very skin.

Structural engineers face the challenge of adapting load calculations and support systems to accommodate the performance characteristics of carbon-negative formulations. While many carbon-negative concretes achieve comparable strength to conventional alternatives, they may follow different curing profiles and respond differently to environmental stressors. This necessitates revised structural modeling approaches and potentially modified reinforcement strategies to ensure long-term stability and safety compliance.

The interface between carbon-negative concrete elements and other building materials requires special attention. Thermal expansion coefficients, moisture behavior, and chemical compatibility must be carefully evaluated to prevent long-term deterioration at material boundaries. Innovative connection details and transition zones have emerged as critical design considerations, with several pioneering projects developing new technical solutions that are now being standardized across the industry.

Building envelope performance represents another crucial consideration, as carbon-negative concrete can influence thermal mass, insulation properties, and moisture management within the building system. Designers are increasingly employing computational fluid dynamics and thermal modeling to optimize the placement and composition of carbon-negative concrete elements within the envelope assembly, balancing structural requirements with energy performance goals.

Construction sequencing and methodology must also adapt to the specific requirements of carbon-negative concrete. The material may demand modified formwork designs, different vibration protocols, or specialized curing conditions to achieve optimal results. Forward-thinking architectural practices are now developing integrated design processes that bring construction specialists into early design phases to ensure that carbon-negative concrete's implementation is fully optimized from concept through completion.

When integrating carbon-negative concrete into building facades, architects must account for its distinctive visual properties. The material often presents a different coloration and texture compared to traditional concrete, which can be leveraged as a design feature rather than concealed. Leading architectural firms have begun showcasing the natural appearance of carbon-negative concrete, creating visual statements that communicate the building's environmental commitment through its very skin.

Structural engineers face the challenge of adapting load calculations and support systems to accommodate the performance characteristics of carbon-negative formulations. While many carbon-negative concretes achieve comparable strength to conventional alternatives, they may follow different curing profiles and respond differently to environmental stressors. This necessitates revised structural modeling approaches and potentially modified reinforcement strategies to ensure long-term stability and safety compliance.

The interface between carbon-negative concrete elements and other building materials requires special attention. Thermal expansion coefficients, moisture behavior, and chemical compatibility must be carefully evaluated to prevent long-term deterioration at material boundaries. Innovative connection details and transition zones have emerged as critical design considerations, with several pioneering projects developing new technical solutions that are now being standardized across the industry.

Building envelope performance represents another crucial consideration, as carbon-negative concrete can influence thermal mass, insulation properties, and moisture management within the building system. Designers are increasingly employing computational fluid dynamics and thermal modeling to optimize the placement and composition of carbon-negative concrete elements within the envelope assembly, balancing structural requirements with energy performance goals.

Construction sequencing and methodology must also adapt to the specific requirements of carbon-negative concrete. The material may demand modified formwork designs, different vibration protocols, or specialized curing conditions to achieve optimal results. Forward-thinking architectural practices are now developing integrated design processes that bring construction specialists into early design phases to ensure that carbon-negative concrete's implementation is fully optimized from concept through completion.

Regulatory Framework and Carbon Credit Opportunities

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to address climate change. The European Union's Carbon Border Adjustment Mechanism (CBAM) represents a significant development, imposing carbon tariffs on imported construction materials that don't meet stringent environmental standards. This creates a competitive advantage for carbon-negative concrete producers who can demonstrate superior carbon performance.

In North America, both the United States and Canada have introduced green building codes that incentivize the use of low-carbon construction materials. The U.S. Buy Clean initiative specifically targets embodied carbon in building materials for federal projects, while various states have implemented their own procurement policies favoring carbon-negative alternatives. These regulatory frameworks are creating market pull for innovative concrete solutions.

Carbon credit markets present substantial financial opportunities for carbon-negative concrete manufacturers. By sequestering more carbon than emitted during production, these companies can generate tradable carbon credits. The voluntary carbon market has seen significant growth, with carbon credits from engineered carbon removal solutions commanding premium prices of $200-600 per ton of CO₂. This revenue stream can offset the higher production costs associated with carbon-negative concrete technologies.

Certification systems play a crucial role in validating environmental claims. Programs like LEED, BREEAM, and the International Living Future Institute's Zero Carbon Certification are increasingly recognizing and rewarding the use of carbon-negative building materials. These certification frameworks provide third-party verification that enhances market credibility and consumer confidence in carbon-negative concrete products.

Tax incentives represent another significant opportunity. Several jurisdictions have implemented carbon taxes that penalize high-emission materials while offering tax credits for carbon-negative alternatives. For example, Singapore's carbon tax framework includes provisions for negative emissions technologies, creating financial incentives for building developers who incorporate carbon-negative concrete into their skyline projects.

The integration of carbon-negative concrete into modern skyline design is further supported by public-private partnerships. Government-backed innovation funds are providing capital for demonstration projects that showcase the architectural possibilities of these materials. These partnerships help bridge the gap between regulatory requirements and practical implementation, accelerating market adoption through real-world examples of carbon-negative concrete in iconic skyline structures.

In North America, both the United States and Canada have introduced green building codes that incentivize the use of low-carbon construction materials. The U.S. Buy Clean initiative specifically targets embodied carbon in building materials for federal projects, while various states have implemented their own procurement policies favoring carbon-negative alternatives. These regulatory frameworks are creating market pull for innovative concrete solutions.

Carbon credit markets present substantial financial opportunities for carbon-negative concrete manufacturers. By sequestering more carbon than emitted during production, these companies can generate tradable carbon credits. The voluntary carbon market has seen significant growth, with carbon credits from engineered carbon removal solutions commanding premium prices of $200-600 per ton of CO₂. This revenue stream can offset the higher production costs associated with carbon-negative concrete technologies.

Certification systems play a crucial role in validating environmental claims. Programs like LEED, BREEAM, and the International Living Future Institute's Zero Carbon Certification are increasingly recognizing and rewarding the use of carbon-negative building materials. These certification frameworks provide third-party verification that enhances market credibility and consumer confidence in carbon-negative concrete products.

Tax incentives represent another significant opportunity. Several jurisdictions have implemented carbon taxes that penalize high-emission materials while offering tax credits for carbon-negative alternatives. For example, Singapore's carbon tax framework includes provisions for negative emissions technologies, creating financial incentives for building developers who incorporate carbon-negative concrete into their skyline projects.

The integration of carbon-negative concrete into modern skyline design is further supported by public-private partnerships. Government-backed innovation funds are providing capital for demonstration projects that showcase the architectural possibilities of these materials. These partnerships help bridge the gap between regulatory requirements and practical implementation, accelerating market adoption through real-world examples of carbon-negative concrete in iconic skyline structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!