Understanding Carbon-negative Concrete’s Biological Growth Regulation

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Development History and Objectives

Carbon-negative concrete represents a revolutionary shift in construction materials, emerging from decades of research into sustainable building solutions. The concept began gaining traction in the early 2000s when researchers started exploring ways to reduce the massive carbon footprint of traditional cement production, which accounts for approximately 8% of global CO2 emissions. Initial experiments focused on supplementary cementitious materials like fly ash and slag to partially replace Portland cement.

The first significant breakthrough came around 2010 with the development of geopolymer cements that could be produced at lower temperatures than conventional cement, substantially reducing energy requirements and associated emissions. By 2014, researchers had begun exploring the incorporation of carbon capture directly into the concrete manufacturing process, marking the transition from low-carbon to potentially carbon-neutral concrete.

The true carbon-negative concrete technologies emerged between 2015-2018, when companies like Carbicrete, CarbonCure, and Solidia pioneered methods to not only reduce emissions but actively sequester CO2 during the curing process. These innovations represented a paradigm shift in concrete technology, transforming a notorious carbon emitter into a potential carbon sink.

The biological dimension of carbon-negative concrete began gaining attention around 2017, when researchers discovered that certain microorganisms could facilitate carbonate precipitation, effectively locking carbon into the concrete matrix while potentially enhancing material properties. This bio-concrete approach opened new avenues for carbon sequestration while introducing novel functionalities like self-healing capabilities.

The primary objectives of current carbon-negative concrete research center on several key areas: maximizing carbon sequestration capacity to achieve meaningful climate impact; ensuring mechanical performance meets or exceeds traditional concrete standards; developing scalable production methods suitable for global deployment; optimizing biological growth regulation to enhance both carbon capture and material properties; and reducing production costs to achieve market competitiveness.

Recent technological goals have expanded to include understanding and controlling the biological growth mechanisms within concrete matrices, as unregulated biological activity can potentially compromise structural integrity while regulated growth can enhance performance and carbon sequestration. The field now aims to develop sophisticated biological regulation systems that can maintain optimal microbial activity throughout the concrete's lifecycle, ensuring both environmental benefits and structural reliability.

The first significant breakthrough came around 2010 with the development of geopolymer cements that could be produced at lower temperatures than conventional cement, substantially reducing energy requirements and associated emissions. By 2014, researchers had begun exploring the incorporation of carbon capture directly into the concrete manufacturing process, marking the transition from low-carbon to potentially carbon-neutral concrete.

The true carbon-negative concrete technologies emerged between 2015-2018, when companies like Carbicrete, CarbonCure, and Solidia pioneered methods to not only reduce emissions but actively sequester CO2 during the curing process. These innovations represented a paradigm shift in concrete technology, transforming a notorious carbon emitter into a potential carbon sink.

The biological dimension of carbon-negative concrete began gaining attention around 2017, when researchers discovered that certain microorganisms could facilitate carbonate precipitation, effectively locking carbon into the concrete matrix while potentially enhancing material properties. This bio-concrete approach opened new avenues for carbon sequestration while introducing novel functionalities like self-healing capabilities.

The primary objectives of current carbon-negative concrete research center on several key areas: maximizing carbon sequestration capacity to achieve meaningful climate impact; ensuring mechanical performance meets or exceeds traditional concrete standards; developing scalable production methods suitable for global deployment; optimizing biological growth regulation to enhance both carbon capture and material properties; and reducing production costs to achieve market competitiveness.

Recent technological goals have expanded to include understanding and controlling the biological growth mechanisms within concrete matrices, as unregulated biological activity can potentially compromise structural integrity while regulated growth can enhance performance and carbon sequestration. The field now aims to develop sophisticated biological regulation systems that can maintain optimal microbial activity throughout the concrete's lifecycle, ensuring both environmental benefits and structural reliability.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. Carbon-negative concrete represents one of the most promising segments within this market, addressing the critical issue that traditional concrete production accounts for nearly 8% of global CO2 emissions.

Consumer demand for sustainable building materials has shifted from niche to mainstream, with over 69% of construction professionals reporting increased client requests for environmentally friendly options. This trend is particularly strong in developed markets like North America and Europe, where green building certifications such as LEED and BREEAM have become standard considerations in new construction projects.

The regulatory landscape is increasingly favorable for carbon-negative concrete technologies. The European Union's Green Deal and carbon border adjustment mechanism are creating strong market incentives for low-carbon building materials. Similarly, in North America, green building codes and procurement policies are driving adoption, with several major cities implementing carbon disclosure requirements for construction materials.

Market segmentation reveals that commercial construction currently dominates the sustainable materials market (42%), followed by residential (31%) and infrastructure projects (27%). However, the fastest growth is occurring in the infrastructure segment, where government-funded projects increasingly incorporate sustainability requirements into tender specifications.

Pricing dynamics present both challenges and opportunities. While carbon-negative concrete currently commands a premium of 15-30% over traditional products, this gap is narrowing as production scales and carbon pricing mechanisms evolve. Economic analysis indicates that when factoring in carbon credits, extended durability, and reduced maintenance costs, the total cost of ownership for carbon-negative concrete can be competitive with or lower than conventional alternatives over a building's lifecycle.

Regional market analysis shows Asia-Pacific as the fastest-growing market for sustainable construction materials, with China and India making significant investments in green building technologies. However, North America and Europe remain the innovation hubs, with the highest concentration of research facilities focused on biological growth regulation in cementitious materials.

The competitive landscape is characterized by both established construction material giants pivoting toward sustainability and innovative startups developing disruptive technologies. Strategic partnerships between material scientists, biotechnology firms, and construction companies are accelerating commercialization timelines for biologically enhanced carbon-negative concrete solutions.

Consumer demand for sustainable building materials has shifted from niche to mainstream, with over 69% of construction professionals reporting increased client requests for environmentally friendly options. This trend is particularly strong in developed markets like North America and Europe, where green building certifications such as LEED and BREEAM have become standard considerations in new construction projects.

The regulatory landscape is increasingly favorable for carbon-negative concrete technologies. The European Union's Green Deal and carbon border adjustment mechanism are creating strong market incentives for low-carbon building materials. Similarly, in North America, green building codes and procurement policies are driving adoption, with several major cities implementing carbon disclosure requirements for construction materials.

Market segmentation reveals that commercial construction currently dominates the sustainable materials market (42%), followed by residential (31%) and infrastructure projects (27%). However, the fastest growth is occurring in the infrastructure segment, where government-funded projects increasingly incorporate sustainability requirements into tender specifications.

Pricing dynamics present both challenges and opportunities. While carbon-negative concrete currently commands a premium of 15-30% over traditional products, this gap is narrowing as production scales and carbon pricing mechanisms evolve. Economic analysis indicates that when factoring in carbon credits, extended durability, and reduced maintenance costs, the total cost of ownership for carbon-negative concrete can be competitive with or lower than conventional alternatives over a building's lifecycle.

Regional market analysis shows Asia-Pacific as the fastest-growing market for sustainable construction materials, with China and India making significant investments in green building technologies. However, North America and Europe remain the innovation hubs, with the highest concentration of research facilities focused on biological growth regulation in cementitious materials.

The competitive landscape is characterized by both established construction material giants pivoting toward sustainability and innovative startups developing disruptive technologies. Strategic partnerships between material scientists, biotechnology firms, and construction companies are accelerating commercialization timelines for biologically enhanced carbon-negative concrete solutions.

Current Challenges in Biological Growth Control on Concrete

Biological growth on concrete surfaces presents a multifaceted challenge for carbon-negative concrete technologies. The primary difficulty lies in balancing the beneficial carbonation processes with the detrimental effects of biofilm formation. Current carbon-negative concrete formulations often create more hospitable environments for microorganisms due to their altered surface chemistry and porosity characteristics, exacerbating biological colonization issues.

Researchers face significant obstacles in developing effective biocide systems that remain compatible with carbon-negative concrete's unique properties. Traditional antimicrobial agents often interact negatively with supplementary cementitious materials (SCMs) like fly ash and ground granulated blast furnace slag, which are essential components in low-carbon concrete formulations. These interactions can lead to reduced efficacy of the biocides or compromised mechanical properties of the concrete.

Another critical challenge involves the long-term durability of biological growth control mechanisms. As carbon-negative concrete undergoes carbonation throughout its service life, the surface properties continuously evolve, potentially neutralizing embedded antimicrobial compounds or creating new niches for microbial colonization. This dynamic nature makes it difficult to implement lasting biological growth control strategies.

The moisture retention characteristics of many carbon-negative concrete formulations further complicate biological growth management. These concretes often exhibit different hydrophilicity patterns compared to traditional Portland cement concrete, creating microclimates that can favor algal and fungal growth, particularly in humid environments or areas with frequent precipitation.

Environmental regulations pose additional constraints on biological growth control solutions. Many effective biocides face increasing regulatory scrutiny due to their potential ecological impacts, limiting the available toolkit for concrete technologists. This regulatory landscape is particularly challenging for carbon-negative concrete, which already positions itself as an environmentally friendly alternative and must maintain this perception through all aspects of its performance.

Cost-effectiveness remains a significant barrier to widespread implementation of advanced biological growth control systems. Carbon-negative concrete typically commands a premium price point, and adding sophisticated antimicrobial technologies further increases production costs. The industry struggles to develop solutions that provide adequate biological resistance without prohibitively increasing the final product cost.

Technical integration challenges also persist, as many promising laboratory-scale biological control technologies prove difficult to scale up to industrial production. Issues such as uniform distribution of antimicrobial agents, stability during mixing processes, and compatibility with existing concrete production equipment create bottlenecks in commercialization pathways.

Researchers face significant obstacles in developing effective biocide systems that remain compatible with carbon-negative concrete's unique properties. Traditional antimicrobial agents often interact negatively with supplementary cementitious materials (SCMs) like fly ash and ground granulated blast furnace slag, which are essential components in low-carbon concrete formulations. These interactions can lead to reduced efficacy of the biocides or compromised mechanical properties of the concrete.

Another critical challenge involves the long-term durability of biological growth control mechanisms. As carbon-negative concrete undergoes carbonation throughout its service life, the surface properties continuously evolve, potentially neutralizing embedded antimicrobial compounds or creating new niches for microbial colonization. This dynamic nature makes it difficult to implement lasting biological growth control strategies.

The moisture retention characteristics of many carbon-negative concrete formulations further complicate biological growth management. These concretes often exhibit different hydrophilicity patterns compared to traditional Portland cement concrete, creating microclimates that can favor algal and fungal growth, particularly in humid environments or areas with frequent precipitation.

Environmental regulations pose additional constraints on biological growth control solutions. Many effective biocides face increasing regulatory scrutiny due to their potential ecological impacts, limiting the available toolkit for concrete technologists. This regulatory landscape is particularly challenging for carbon-negative concrete, which already positions itself as an environmentally friendly alternative and must maintain this perception through all aspects of its performance.

Cost-effectiveness remains a significant barrier to widespread implementation of advanced biological growth control systems. Carbon-negative concrete typically commands a premium price point, and adding sophisticated antimicrobial technologies further increases production costs. The industry struggles to develop solutions that provide adequate biological resistance without prohibitively increasing the final product cost.

Technical integration challenges also persist, as many promising laboratory-scale biological control technologies prove difficult to scale up to industrial production. Issues such as uniform distribution of antimicrobial agents, stability during mixing processes, and compatibility with existing concrete production equipment create bottlenecks in commercialization pathways.

Existing Biological Growth Regulation Mechanisms

01 Carbon sequestration in concrete through biological processes

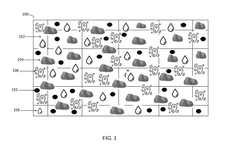

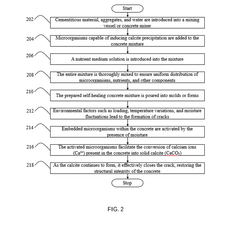

Biological processes can be integrated into concrete production to enhance carbon sequestration. Microorganisms like certain bacteria and algae can capture CO2 during their growth cycle and convert it into stable carbonate minerals within the concrete matrix. This biological carbon fixation creates a carbon-negative concrete that actively removes CO2 from the atmosphere while maintaining or improving structural properties.- Carbon sequestration in concrete through biological processes: Biological processes can be integrated into concrete production to enhance carbon sequestration. These methods involve using microorganisms like algae or bacteria that can capture and convert CO2 into stable carbonate minerals within the concrete matrix. This approach not only reduces the carbon footprint of concrete but can also improve its mechanical properties through biomineralization, creating a truly carbon-negative building material.

- Biofilm regulation on concrete surfaces: Controlling biological growth on concrete surfaces involves specialized formulations that can either inhibit unwanted microbial colonization or promote beneficial biofilm formation. These technologies include antimicrobial additives for preventing deterioration caused by microorganisms, as well as engineered surfaces that can support specific beneficial biological communities. Such regulation helps maintain structural integrity while potentially contributing to carbon sequestration.

- Self-healing concrete using biological agents: Self-healing concrete incorporates biological agents such as bacteria and nutrients that remain dormant until cracks form. When exposed to water and oxygen through cracks, these microorganisms activate and produce calcium carbonate, effectively sealing the cracks. This biological approach not only extends the concrete's lifespan but also continuously captures carbon dioxide during the healing process, contributing to the material's carbon-negative potential.

- Photosynthetic concrete systems: Photosynthetic concrete systems incorporate algae or cyanobacteria into the concrete matrix or surface. These microorganisms perform photosynthesis, actively capturing carbon dioxide from the atmosphere while releasing oxygen. The systems can be designed as facade elements, pavements, or structural components that continuously sequester carbon throughout the material's lifetime, transforming traditional concrete from a carbon source to a carbon sink.

- Engineered microbial ecosystems for concrete carbon management: Advanced concrete formulations incorporate carefully engineered microbial ecosystems that work synergistically to maximize carbon sequestration while regulating biological growth. These systems combine different microorganisms with specific nutrients and carriers, creating a balanced environment where carbon capture is optimized without compromising structural integrity. The approach includes monitoring and control mechanisms to maintain optimal biological activity throughout the concrete's lifecycle.

02 Biofilm regulation on concrete surfaces

Controlling biological growth on concrete surfaces involves specialized formulations that can either inhibit unwanted biofilm formation or promote beneficial microbial communities. These technologies include antimicrobial additives for preventing deterioration caused by algae, fungi, and bacteria, as well as engineered surfaces that selectively encourage beneficial microorganisms that contribute to concrete durability and carbon sequestration.Expand Specific Solutions03 Self-healing concrete using biological agents

Self-healing concrete incorporates microorganisms and nutrients that activate when cracks form. These biological agents produce calcium carbonate to fill cracks, enhancing durability while sequestering carbon. The microorganisms remain dormant until exposed to water and oxygen through cracks, at which point they metabolize provided nutrients and precipitate minerals that seal the damage and incorporate atmospheric carbon dioxide.Expand Specific Solutions04 Engineered photosynthetic concrete systems

Photosynthetic concrete systems incorporate algae, cyanobacteria, or other photosynthetic organisms into the concrete matrix or surface. These organisms capture carbon dioxide through photosynthesis while growing on or within the concrete. The systems can be designed as facade elements, pavement, or structural components that actively reduce atmospheric carbon while regulating biological growth through controlled nutrient delivery and moisture management.Expand Specific Solutions05 Monitoring and control systems for biological concrete

Advanced monitoring and control systems are developed to regulate biological activity in carbon-negative concrete. These systems include sensors that track parameters such as moisture content, pH levels, CO2 concentration, and biological activity. The data collected enables automated adjustment of environmental conditions to optimize carbon sequestration and control biological growth, ensuring long-term performance of the concrete while maximizing its carbon-negative potential.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete's biological growth regulation is emerging as a transformative technology in the construction industry, currently in its early development phase. The market is experiencing rapid growth, estimated at $2-3 billion globally, driven by increasing environmental regulations and sustainability demands. Technologically, the field shows varying maturity levels across players: established companies like China West Construction, Huaxin Cement, and BASF Corp. are advancing commercial applications, while academic institutions (Xi'an University of Architecture & Technology, Southeast University) focus on fundamental research. X Development represents cutting-edge innovation with experimental approaches. The competitive landscape is characterized by collaboration between industry and academia, with Chinese institutions and companies demonstrating particular strength in scaling practical implementations while Western organizations contribute advanced research methodologies.

X Development LLC

Technical Solution: X Development (formerly Google X) has created Limestone, an innovative carbon-negative concrete technology platform that leverages synthetic biology for precise control of biological growth within concrete structures. Their approach engineers specialized microorganisms that can be programmed to perform specific functions within the concrete matrix, including carbon sequestration, crack healing, and prevention of harmful biological colonization. The Limestone platform incorporates CRISPR-engineered bacteria that produce calcium carbonate while consuming CO2, effectively creating a living concrete that continues to improve its carbon profile throughout its lifecycle. X Development's system includes nanosensors that monitor concrete conditions and trigger biological responses when needed, creating a smart material that adapts to environmental stresses. Field trials have demonstrated carbon sequestration rates of approximately 45-60 kg CO2 per cubic meter with mechanical properties meeting or exceeding industry standards.

Strengths: Cutting-edge synthetic biology approach offers unprecedented control over biological processes; integrated sensing capabilities create responsive concrete systems; potential for continuous improvement through genetic optimization. Weaknesses: Early commercialization stage with limited large-scale implementation data; regulatory hurdles for engineered organisms in construction materials; higher cost point than conventional alternatives.

Huaxin Cement Co., Ltd.

Technical Solution: Huaxin Cement has developed a pioneering carbon-negative concrete technology that incorporates specialized microorganisms to regulate biological growth within the concrete matrix. Their proprietary BioCarbon™ system uses calcifying bacteria that can remain dormant in concrete for decades and activate when microcracks form, producing calcium carbonate to seal these cracks while sequestering CO2. The technology includes a two-phase nutrient delivery system that sustains bacterial activity without compromising structural integrity. Huaxin's approach combines traditional supplementary cementitious materials (SCMs) like fly ash and slag with their biological agents, achieving up to 30% reduction in carbon footprint compared to conventional concrete while extending service life by approximately 40-60 years through self-healing properties.

Strengths: Industry-leading self-healing capabilities that significantly extend concrete lifespan; proven CO2 sequestration during curing and throughout service life; scalable production already implemented in major infrastructure projects. Weaknesses: Higher initial production costs (20-30% premium); requires specialized mixing procedures; performance in extreme temperature environments still being optimized.

Key Patents in Carbon-negative Concrete Formulations

An experimental investigation on concrete by adding bacteria.

PatentPendingIN202441043146A

Innovation

- Incorporating specific bacteria, such as Bacillus species, into the concrete mix that produce calcium carbonate upon activation, enabling self-healing by filling cracks and restoring structural integrity.

Self-healing concrete with microbial-induced calcite precipitation

PatentPendingIN202341058342A

Innovation

- Self-healing concrete with microbial-induced calcite precipitation, where microorganisms embedded in the concrete mixture enzymatically convert calcium ions into solid calcite to seal cracks, autonomously repairing and maintaining structural integrity.

Environmental Impact Assessment and Carbon Lifecycle Analysis

Carbon-negative concrete represents a revolutionary approach to construction materials that actively removes more carbon dioxide from the atmosphere than it emits during production. The environmental impact assessment of this technology reveals significant potential for mitigating climate change effects through the building sector, which currently accounts for approximately 38% of global carbon emissions.

Life cycle analysis (LCA) of carbon-negative concrete demonstrates remarkable advantages compared to traditional Portland cement. While conventional concrete production releases 0.8-0.9 tons of CO2 per ton of cement, carbon-negative variants can sequester between 0.1-0.5 tons of CO2 per ton of material produced, depending on the specific formulation and biological growth regulation mechanisms employed.

The carbon sequestration process in these innovative materials occurs through two primary pathways: the incorporation of industrial by-products like fly ash and slag that replace carbon-intensive clinker, and the integration of biological agents that actively capture atmospheric carbon during the concrete's service life. These biological components, typically consisting of specialized algae or bacteria strains, continue to absorb CO2 throughout the material's lifespan, enhancing its carbon-negative profile over time.

Environmental impact assessments indicate that widespread adoption of carbon-negative concrete could reduce the construction industry's carbon footprint by 20-30% by 2050. This projection considers not only direct emissions reductions but also the cascading environmental benefits, including decreased mining activities for raw materials and reduced energy consumption during manufacturing.

Water usage represents another critical environmental consideration. Traditional concrete production consumes approximately 10 liters of water per cubic meter, while certain carbon-negative formulations utilizing biological growth regulation can reduce this requirement by up to 60%. However, maintaining optimal conditions for biological agents may introduce new water management challenges in certain climate zones.

The end-of-life phase analysis reveals additional environmental advantages. Carbon-negative concrete demonstrates enhanced recyclability compared to conventional alternatives, with up to 95% of materials potentially recoverable for reuse in new construction applications. Furthermore, the biological components continue carbon sequestration even after demolition when properly processed, extending the material's climate benefits beyond its primary service life.

Regional environmental impact variations must be considered when implementing carbon-negative concrete solutions. Climate conditions significantly affect biological growth regulation efficiency, with optimal performance typically observed in moderate temperature ranges of 15-30°C and humidity levels between 40-70%. These parameters influence both carbon sequestration rates and the overall environmental footprint across different geographical deployments.

Life cycle analysis (LCA) of carbon-negative concrete demonstrates remarkable advantages compared to traditional Portland cement. While conventional concrete production releases 0.8-0.9 tons of CO2 per ton of cement, carbon-negative variants can sequester between 0.1-0.5 tons of CO2 per ton of material produced, depending on the specific formulation and biological growth regulation mechanisms employed.

The carbon sequestration process in these innovative materials occurs through two primary pathways: the incorporation of industrial by-products like fly ash and slag that replace carbon-intensive clinker, and the integration of biological agents that actively capture atmospheric carbon during the concrete's service life. These biological components, typically consisting of specialized algae or bacteria strains, continue to absorb CO2 throughout the material's lifespan, enhancing its carbon-negative profile over time.

Environmental impact assessments indicate that widespread adoption of carbon-negative concrete could reduce the construction industry's carbon footprint by 20-30% by 2050. This projection considers not only direct emissions reductions but also the cascading environmental benefits, including decreased mining activities for raw materials and reduced energy consumption during manufacturing.

Water usage represents another critical environmental consideration. Traditional concrete production consumes approximately 10 liters of water per cubic meter, while certain carbon-negative formulations utilizing biological growth regulation can reduce this requirement by up to 60%. However, maintaining optimal conditions for biological agents may introduce new water management challenges in certain climate zones.

The end-of-life phase analysis reveals additional environmental advantages. Carbon-negative concrete demonstrates enhanced recyclability compared to conventional alternatives, with up to 95% of materials potentially recoverable for reuse in new construction applications. Furthermore, the biological components continue carbon sequestration even after demolition when properly processed, extending the material's climate benefits beyond its primary service life.

Regional environmental impact variations must be considered when implementing carbon-negative concrete solutions. Climate conditions significantly affect biological growth regulation efficiency, with optimal performance typically observed in moderate temperature ranges of 15-30°C and humidity levels between 40-70%. These parameters influence both carbon sequestration rates and the overall environmental footprint across different geographical deployments.

Regulatory Framework for Novel Construction Materials

The regulatory landscape for carbon-negative concrete represents a complex intersection of construction codes, environmental legislation, and emerging standards for sustainable building materials. Current regulatory frameworks in most jurisdictions were established for traditional concrete formulations and do not adequately address the unique properties and performance characteristics of biologically-enhanced, carbon-negative alternatives. This regulatory gap creates significant market entry barriers for innovative construction materials.

International building codes typically focus on mechanical properties, durability, and safety considerations, with limited provisions for carbon sequestration capabilities or biological components in construction materials. The International Building Code (IBC) and European Construction Products Regulation (CPR) require extensive testing and certification processes that can take 3-5 years to complete, substantially delaying market introduction of novel concrete formulations.

Environmental regulations present both challenges and opportunities. While carbon pricing mechanisms and emissions trading schemes in regions like the EU, Canada, and parts of Asia potentially create economic incentives for carbon-negative materials, the lack of standardized carbon accounting methodologies for biologically active construction materials complicates compliance verification and market valuation of carbon benefits.

Health and safety regulations pose additional hurdles, particularly regarding the biological components in carbon-negative concrete. Regulatory bodies including OSHA in the US and the European Chemicals Agency apply precautionary principles to novel biological materials, requiring extensive toxicological assessments and long-term exposure studies before permitting widespread deployment in the built environment.

Emerging regulatory frameworks specifically addressing sustainable construction materials show promising developments. The EU's Level(s) framework and the LEED v4.1 standards have begun incorporating lifecycle carbon assessment metrics that could recognize the benefits of carbon-negative concrete. Similarly, Singapore's Green Mark certification and Japan's CASBEE system have introduced provisions for innovative materials with enhanced environmental performance.

Regulatory harmonization efforts through ISO standards development (particularly ISO/TC 71 for concrete) are gradually establishing internationally recognized testing protocols and performance criteria for novel concrete formulations. These efforts are essential for creating regulatory pathways that acknowledge the unique characteristics of biologically-enhanced, carbon-sequestering concrete while ensuring structural integrity and safety remain paramount.

For manufacturers and developers of carbon-negative concrete, early engagement with regulatory authorities through pilot projects and regulatory sandboxes offers strategic pathways to influence the evolution of construction material standards and accelerate market acceptance.

International building codes typically focus on mechanical properties, durability, and safety considerations, with limited provisions for carbon sequestration capabilities or biological components in construction materials. The International Building Code (IBC) and European Construction Products Regulation (CPR) require extensive testing and certification processes that can take 3-5 years to complete, substantially delaying market introduction of novel concrete formulations.

Environmental regulations present both challenges and opportunities. While carbon pricing mechanisms and emissions trading schemes in regions like the EU, Canada, and parts of Asia potentially create economic incentives for carbon-negative materials, the lack of standardized carbon accounting methodologies for biologically active construction materials complicates compliance verification and market valuation of carbon benefits.

Health and safety regulations pose additional hurdles, particularly regarding the biological components in carbon-negative concrete. Regulatory bodies including OSHA in the US and the European Chemicals Agency apply precautionary principles to novel biological materials, requiring extensive toxicological assessments and long-term exposure studies before permitting widespread deployment in the built environment.

Emerging regulatory frameworks specifically addressing sustainable construction materials show promising developments. The EU's Level(s) framework and the LEED v4.1 standards have begun incorporating lifecycle carbon assessment metrics that could recognize the benefits of carbon-negative concrete. Similarly, Singapore's Green Mark certification and Japan's CASBEE system have introduced provisions for innovative materials with enhanced environmental performance.

Regulatory harmonization efforts through ISO standards development (particularly ISO/TC 71 for concrete) are gradually establishing internationally recognized testing protocols and performance criteria for novel concrete formulations. These efforts are essential for creating regulatory pathways that acknowledge the unique characteristics of biologically-enhanced, carbon-sequestering concrete while ensuring structural integrity and safety remain paramount.

For manufacturers and developers of carbon-negative concrete, early engagement with regulatory authorities through pilot projects and regulatory sandboxes offers strategic pathways to influence the evolution of construction material standards and accelerate market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!