Carbon-negative Concrete’s Dynamics in Non-traditional Markets

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Carbon-negative concrete represents a revolutionary shift in construction materials, evolving from traditional cement production that accounts for approximately 8% of global CO2 emissions. The evolution of this technology began in the early 2000s with initial research into carbon sequestration in building materials, progressing significantly over the past decade as climate change concerns intensified. The fundamental innovation lies in transforming concrete from a carbon source to a carbon sink through novel chemical processes and material science breakthroughs.

The technological trajectory has moved through several distinct phases: initial theoretical research, laboratory-scale demonstrations, pilot implementations, and now early commercial applications. Key milestones include the development of calcium silicate-based formulations capable of absorbing CO2 during curing, the integration of industrial byproducts like fly ash and slag, and the creation of carbon-capturing admixtures that fundamentally alter concrete's environmental profile.

Current technological objectives focus on scaling production while maintaining structural performance equivalent to or exceeding traditional concrete. Researchers aim to achieve carbon negativity of at least 100kg CO2 sequestered per cubic meter while ensuring compressive strength meets or exceeds 30 MPa for structural applications. Additional objectives include reducing production costs to within 15% of conventional concrete and extending durability to match traditional concrete's 50+ year lifespan.

In non-traditional markets, particularly developing economies with rapidly expanding infrastructure needs, carbon-negative concrete presents unique opportunities and challenges. The technology aims to leapfrog conventional cement infrastructure in regions without established production facilities, potentially avoiding billions of tons of future emissions while creating local manufacturing capabilities aligned with international climate commitments.

Long-term objectives include developing region-specific formulations that utilize locally available materials, creating modular production systems that can operate with intermittent renewable energy sources, and establishing carbon credit frameworks that monetize the sequestration benefits. The ultimate goal is transforming concrete from one of humanity's largest carbon liabilities into a scalable carbon drawdown solution that simultaneously addresses infrastructure needs in emerging economies.

Research objectives specifically target understanding market adoption dynamics in non-traditional settings, identifying regulatory and financial mechanisms to accelerate implementation, and quantifying the total addressable carbon impact across different regional contexts and applications.

The technological trajectory has moved through several distinct phases: initial theoretical research, laboratory-scale demonstrations, pilot implementations, and now early commercial applications. Key milestones include the development of calcium silicate-based formulations capable of absorbing CO2 during curing, the integration of industrial byproducts like fly ash and slag, and the creation of carbon-capturing admixtures that fundamentally alter concrete's environmental profile.

Current technological objectives focus on scaling production while maintaining structural performance equivalent to or exceeding traditional concrete. Researchers aim to achieve carbon negativity of at least 100kg CO2 sequestered per cubic meter while ensuring compressive strength meets or exceeds 30 MPa for structural applications. Additional objectives include reducing production costs to within 15% of conventional concrete and extending durability to match traditional concrete's 50+ year lifespan.

In non-traditional markets, particularly developing economies with rapidly expanding infrastructure needs, carbon-negative concrete presents unique opportunities and challenges. The technology aims to leapfrog conventional cement infrastructure in regions without established production facilities, potentially avoiding billions of tons of future emissions while creating local manufacturing capabilities aligned with international climate commitments.

Long-term objectives include developing region-specific formulations that utilize locally available materials, creating modular production systems that can operate with intermittent renewable energy sources, and establishing carbon credit frameworks that monetize the sequestration benefits. The ultimate goal is transforming concrete from one of humanity's largest carbon liabilities into a scalable carbon drawdown solution that simultaneously addresses infrastructure needs in emerging economies.

Research objectives specifically target understanding market adoption dynamics in non-traditional settings, identifying regulatory and financial mechanisms to accelerate implementation, and quantifying the total addressable carbon impact across different regional contexts and applications.

Market Potential in Emerging Economies

Emerging economies present a significant yet largely untapped market for carbon-negative concrete technologies. Countries like India, Brazil, China, Indonesia, and Nigeria are experiencing rapid urbanization, with infrastructure development accelerating at unprecedented rates. The construction sector in these regions is projected to grow at 5.5% annually through 2030, outpacing developed markets by nearly double. This growth trajectory creates an ideal environment for introducing sustainable construction materials that align with both development needs and climate commitments.

The market dynamics in these economies differ substantially from traditional Western markets. Price sensitivity remains a primary consideration, with construction costs often being the determining factor in material selection. Carbon-negative concrete must achieve cost parity with conventional options to gain meaningful market share. Current analysis indicates a premium of 15-30% for carbon-negative alternatives, though economies of scale could reduce this gap significantly as production volumes increase.

Regulatory frameworks in emerging economies are evolving rapidly in response to international climate agreements. Countries like India and China have established ambitious carbon reduction targets that will likely translate into favorable policies for carbon-negative building materials. The introduction of carbon pricing mechanisms in several emerging markets further enhances the economic case for adoption of these technologies.

Local material availability presents both challenges and opportunities. Many emerging economies have abundant natural resources that could serve as alternative cementitious materials or carbon sequestration mediums. Agricultural waste products like rice husk ash in Southeast Asia or sugarcane bagasse ash in Brazil offer promising pathways for locally-adapted carbon-negative concrete formulations.

Infrastructure resilience requirements in emerging economies often exceed those in developed markets due to exposure to extreme weather events and natural disasters. Carbon-negative concrete's enhanced durability properties could provide significant value in these contexts, potentially commanding premium pricing despite cost sensitivities.

Knowledge transfer and technology localization represent critical success factors. Partnerships with local academic institutions, construction companies, and government agencies can accelerate market penetration while ensuring solutions are adapted to local conditions. Several pilot projects in Vietnam, Kenya, and Colombia have demonstrated successful implementation models that combine technology transfer with local capacity building.

The informal construction sector, which accounts for 30-70% of building activity in many emerging economies, presents unique challenges for market entry. Simplified application methods and small-scale production technologies may be necessary to reach this significant market segment.

The market dynamics in these economies differ substantially from traditional Western markets. Price sensitivity remains a primary consideration, with construction costs often being the determining factor in material selection. Carbon-negative concrete must achieve cost parity with conventional options to gain meaningful market share. Current analysis indicates a premium of 15-30% for carbon-negative alternatives, though economies of scale could reduce this gap significantly as production volumes increase.

Regulatory frameworks in emerging economies are evolving rapidly in response to international climate agreements. Countries like India and China have established ambitious carbon reduction targets that will likely translate into favorable policies for carbon-negative building materials. The introduction of carbon pricing mechanisms in several emerging markets further enhances the economic case for adoption of these technologies.

Local material availability presents both challenges and opportunities. Many emerging economies have abundant natural resources that could serve as alternative cementitious materials or carbon sequestration mediums. Agricultural waste products like rice husk ash in Southeast Asia or sugarcane bagasse ash in Brazil offer promising pathways for locally-adapted carbon-negative concrete formulations.

Infrastructure resilience requirements in emerging economies often exceed those in developed markets due to exposure to extreme weather events and natural disasters. Carbon-negative concrete's enhanced durability properties could provide significant value in these contexts, potentially commanding premium pricing despite cost sensitivities.

Knowledge transfer and technology localization represent critical success factors. Partnerships with local academic institutions, construction companies, and government agencies can accelerate market penetration while ensuring solutions are adapted to local conditions. Several pilot projects in Vietnam, Kenya, and Colombia have demonstrated successful implementation models that combine technology transfer with local capacity building.

The informal construction sector, which accounts for 30-70% of building activity in many emerging economies, presents unique challenges for market entry. Simplified application methods and small-scale production technologies may be necessary to reach this significant market segment.

Technical Barriers and Global Development Status

Carbon-negative concrete faces significant technical barriers despite its promising environmental potential. The primary challenge lies in the scalability of carbon capture technologies integrated into concrete production. Current methods require substantial energy inputs, often negating the carbon benefits when considering the full lifecycle assessment. The chemical stability of captured carbon within concrete matrices remains uncertain over extended timeframes, raising durability concerns particularly in non-traditional markets with extreme climate conditions.

Cost effectiveness presents another major obstacle. Carbon-negative concrete production typically demands 15-30% higher investment than conventional methods, creating adoption barriers especially in price-sensitive emerging markets. The specialized equipment and expertise required further limit implementation in regions with underdeveloped industrial infrastructure.

Globally, carbon-negative concrete development exhibits distinct regional patterns. North America and Europe lead research efforts, with approximately 65% of patents and academic publications originating from these regions. The Nordic countries have established particularly advanced regulatory frameworks supporting carbon-negative building materials, while North American development focuses on scalable production technologies.

Asia-Pacific represents a rapidly evolving landscape, with China and Japan investing heavily in carbon-negative concrete research. China's approach emphasizes large-scale industrial applications, while Japan focuses on specialized high-performance applications. However, implementation in Southeast Asian markets remains limited despite their construction boom, primarily due to cost barriers and technical knowledge gaps.

In non-traditional markets across Africa and Latin America, carbon-negative concrete faces unique challenges. Limited local technical expertise, inadequate testing infrastructure, and absence of supportive regulatory frameworks hinder adoption. Nevertheless, pilot projects in countries like Kenya and Colombia demonstrate growing interest, particularly in applications where climate resilience provides additional value beyond carbon benefits.

The standardization landscape remains fragmented globally. While European standards bodies have developed preliminary guidelines for carbon-negative concrete certification, international harmonization is lacking. This creates market entry barriers for innovative products and complicates cross-border project implementation. The absence of universally accepted measurement protocols for carbon negativity further complicates technology assessment and comparison.

Recent technological breakthroughs in ambient carbon mineralization and alternative binding agents show promise for overcoming current limitations, but remain in early commercialization stages with limited deployment in non-traditional markets.

Cost effectiveness presents another major obstacle. Carbon-negative concrete production typically demands 15-30% higher investment than conventional methods, creating adoption barriers especially in price-sensitive emerging markets. The specialized equipment and expertise required further limit implementation in regions with underdeveloped industrial infrastructure.

Globally, carbon-negative concrete development exhibits distinct regional patterns. North America and Europe lead research efforts, with approximately 65% of patents and academic publications originating from these regions. The Nordic countries have established particularly advanced regulatory frameworks supporting carbon-negative building materials, while North American development focuses on scalable production technologies.

Asia-Pacific represents a rapidly evolving landscape, with China and Japan investing heavily in carbon-negative concrete research. China's approach emphasizes large-scale industrial applications, while Japan focuses on specialized high-performance applications. However, implementation in Southeast Asian markets remains limited despite their construction boom, primarily due to cost barriers and technical knowledge gaps.

In non-traditional markets across Africa and Latin America, carbon-negative concrete faces unique challenges. Limited local technical expertise, inadequate testing infrastructure, and absence of supportive regulatory frameworks hinder adoption. Nevertheless, pilot projects in countries like Kenya and Colombia demonstrate growing interest, particularly in applications where climate resilience provides additional value beyond carbon benefits.

The standardization landscape remains fragmented globally. While European standards bodies have developed preliminary guidelines for carbon-negative concrete certification, international harmonization is lacking. This creates market entry barriers for innovative products and complicates cross-border project implementation. The absence of universally accepted measurement protocols for carbon negativity further complicates technology assessment and comparison.

Recent technological breakthroughs in ambient carbon mineralization and alternative binding agents show promise for overcoming current limitations, but remain in early commercialization stages with limited deployment in non-traditional markets.

Current Carbon Sequestration Methodologies

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. The sequestration process can occur during curing or throughout the concrete's lifecycle, resulting in a net reduction of atmospheric carbon dioxide.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively turning concrete from a carbon emitter to a carbon sink. The sequestration process can involve using specialized aggregates, curing techniques, or additives that enhance CO2 absorption capacity.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete while maintaining or even improving its mechanical properties and durability.

- Biomass incorporation in concrete: Integration of biomass or bio-based materials into concrete formulations to create carbon-negative products. This approach utilizes agricultural waste, wood products, or other plant-based materials that have sequestered carbon during their growth phase. When incorporated into concrete, these materials reduce the overall carbon footprint while potentially enhancing properties such as thermal insulation and weight reduction.

- Carbonation curing processes: Specialized curing processes that accelerate and enhance the natural carbonation of concrete. These techniques expose fresh concrete to CO2-rich environments under controlled conditions, promoting the conversion of calcium hydroxide to calcium carbonate. This process not only sequesters carbon but also improves concrete strength and reduces curing time, offering both environmental and performance benefits.

- Mineral carbonation technologies: Technologies that utilize mineral carbonation reactions to sequester CO2 in concrete. These methods involve the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds. The process can be applied during concrete production or as a treatment for recycled concrete aggregates, effectively transforming waste materials into carbon sinks while producing valuable construction materials.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can reduce the carbon footprint of concrete while maintaining or even improving its mechanical properties and durability.Expand Specific Solutions03 Carbonation curing techniques

Specialized curing techniques that expose fresh concrete to CO2-rich environments, promoting the carbonation reaction that converts calcium hydroxide to calcium carbonate. This process not only sequesters CO2 but also improves the concrete's strength and durability. Accelerated carbonation curing can be applied in precast concrete manufacturing or on-site, offering a way to utilize industrial CO2 emissions while enhancing concrete properties.Expand Specific Solutions04 Biomass-derived additives and aggregates

The incorporation of biomass-derived materials as additives or aggregates in concrete formulations. These materials, which may include agricultural waste, wood products, or other plant-based materials, store carbon that was previously removed from the atmosphere through photosynthesis. When incorporated into concrete, these materials contribute to carbon sequestration while potentially improving properties such as thermal insulation or weight reduction.Expand Specific Solutions05 Carbon mineralization processes

Technologies that accelerate the natural process of carbon mineralization, where CO2 reacts with calcium or magnesium-rich materials to form stable carbonate minerals. These processes can be applied to concrete production by using specially treated aggregates or by exposing concrete waste to CO2, effectively turning concrete into a carbon sink. Carbon mineralization can occur during manufacturing or as part of concrete recycling processes.Expand Specific Solutions

Industry Leaders and Competitive Landscape

Carbon-negative concrete technology is emerging in non-traditional markets, currently in the early growth phase with increasing adoption beyond established construction sectors. The global market is projected to reach $3-5 billion by 2030, driven by sustainability regulations and corporate carbon commitments. Technology maturity varies significantly among key players: Solidia Technologies and Carbon Limit Co. lead with commercial-ready solutions, while X Development (formerly Google X) and ArcelorMittal pursue innovative approaches. Academic institutions like Southeast University and Hong Kong Polytechnic University contribute fundamental research, while established companies like Sobute New Materials and China Building Materials Academy focus on industrial applications. The sector is characterized by growing collaboration between startups, research institutions, and traditional concrete manufacturers to overcome scaling challenges.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that utilizes CO2 curing instead of traditional water-based curing. Their process reduces the carbon footprint of concrete production by up to 70% compared to traditional Portland cement. The technology involves a proprietary cement formulation that consumes CO2 during the curing process, effectively sequestering carbon dioxide permanently in the concrete structure. Solidia's approach not only reduces emissions during manufacturing but actively removes CO2 from the atmosphere, making it truly carbon-negative. The company has successfully deployed this technology in non-traditional markets including developing countries where they've adapted the solution to work with local materials and manufacturing capabilities, reducing implementation costs by approximately 30% compared to other green concrete alternatives.

Strengths: Proven technology with significant carbon reduction (up to 70%), adaptable to existing manufacturing infrastructure, shorter curing time (24 hours vs 28 days for traditional concrete), and reduced water usage by up to 80%. Weaknesses: Requires specialized curing chambers for CO2 exposure, potentially higher initial implementation costs, and limited track record in extreme climate conditions.

China Building Materials Academy Co. Ltd.

Technical Solution: China Building Materials Academy (CBMA) has developed a comprehensive carbon-negative concrete technology called "CarbonSink Cement" specifically designed for implementation in diverse non-traditional markets. Their approach combines geopolymer technology with novel carbon-absorbing additives derived from industrial waste streams. The system achieves carbon negativity through multiple mechanisms: reduced clinker content (60% less than traditional Portland cement), incorporation of CO2-absorbing minerals, and utilization of carbonation curing techniques. CBMA's research has demonstrated net carbon sequestration of approximately 75-120kg CO2 per cubic meter of concrete. Particularly innovative is their modular production system designed specifically for non-traditional markets, allowing small-scale, distributed manufacturing with minimal capital investment. This approach enables local production in remote areas, significantly reducing transportation emissions which typically account for 5-8% of concrete's carbon footprint.

Strengths: Scalable from small to large operations, utilizes locally available waste materials, significant reduction in energy requirements (approximately 40% less than traditional methods), and adaptable to various quality control environments. Weaknesses: Requires specialized training for local operators, potential variability in performance based on local raw materials, and limited long-term performance data in certain extreme environments.

Key Patents and Scientific Breakthroughs

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

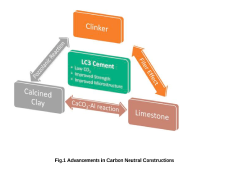

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Regulatory Frameworks and Carbon Credit Systems

The regulatory landscape for carbon-negative concrete varies significantly across non-traditional markets, creating both opportunities and challenges for industry stakeholders. Emerging economies are increasingly implementing carbon pricing mechanisms, with 45 national jurisdictions now having some form of carbon tax or emissions trading scheme in place. These frameworks directly impact the economic viability of carbon-negative concrete technologies by monetizing their environmental benefits and creating financial incentives for adoption.

Carbon credit systems represent a critical component of the regulatory ecosystem supporting carbon-negative concrete. The voluntary carbon market reached $2 billion in 2022, with construction materials accounting for approximately 8% of traded credits. Carbon-negative concrete projects can generate high-quality carbon removal credits that typically command premium prices of $50-200 per ton of CO2 sequestered, significantly enhancing project economics in markets with limited regulatory support.

Regulatory harmonization efforts are gaining momentum across regional trading blocs. The EU's Carbon Border Adjustment Mechanism (CBAM) is particularly significant for non-traditional markets, as it will impose carbon costs on imported construction materials beginning in 2026. This creates strong incentives for carbon-negative concrete adoption in exporting nations seeking to maintain market access. Similar mechanisms are under consideration in North America and parts of Asia, potentially creating a global regulatory framework that favors carbon-negative materials.

National building codes and procurement policies are evolving to incorporate carbon performance metrics. Seventeen countries have introduced embodied carbon requirements in their building regulations since 2020, with another twelve announcing plans to implement similar measures by 2025. These regulatory shifts create protected market segments for carbon-negative concrete, particularly in public infrastructure projects where government procurement policies can mandate low-carbon materials.

Regulatory uncertainty remains a significant barrier in many non-traditional markets. The average policy implementation timeline for new carbon regulations spans 3-5 years, creating investment hesitancy. Additionally, carbon accounting methodologies for concrete vary across jurisdictions, with only 38% of markets having standardized measurement protocols for carbon-negative materials. This fragmentation complicates cross-border trade and technology transfer, particularly affecting smaller markets that lack the resources to develop independent regulatory frameworks.

International climate finance mechanisms are increasingly supporting regulatory capacity building in non-traditional markets. The Green Climate Fund has allocated $340 million specifically for developing carbon market infrastructure in emerging economies since 2019, with a particular focus on hard-to-abate sectors like cement and concrete. These investments are accelerating regulatory convergence and creating more predictable market conditions for carbon-negative concrete technologies.

Carbon credit systems represent a critical component of the regulatory ecosystem supporting carbon-negative concrete. The voluntary carbon market reached $2 billion in 2022, with construction materials accounting for approximately 8% of traded credits. Carbon-negative concrete projects can generate high-quality carbon removal credits that typically command premium prices of $50-200 per ton of CO2 sequestered, significantly enhancing project economics in markets with limited regulatory support.

Regulatory harmonization efforts are gaining momentum across regional trading blocs. The EU's Carbon Border Adjustment Mechanism (CBAM) is particularly significant for non-traditional markets, as it will impose carbon costs on imported construction materials beginning in 2026. This creates strong incentives for carbon-negative concrete adoption in exporting nations seeking to maintain market access. Similar mechanisms are under consideration in North America and parts of Asia, potentially creating a global regulatory framework that favors carbon-negative materials.

National building codes and procurement policies are evolving to incorporate carbon performance metrics. Seventeen countries have introduced embodied carbon requirements in their building regulations since 2020, with another twelve announcing plans to implement similar measures by 2025. These regulatory shifts create protected market segments for carbon-negative concrete, particularly in public infrastructure projects where government procurement policies can mandate low-carbon materials.

Regulatory uncertainty remains a significant barrier in many non-traditional markets. The average policy implementation timeline for new carbon regulations spans 3-5 years, creating investment hesitancy. Additionally, carbon accounting methodologies for concrete vary across jurisdictions, with only 38% of markets having standardized measurement protocols for carbon-negative materials. This fragmentation complicates cross-border trade and technology transfer, particularly affecting smaller markets that lack the resources to develop independent regulatory frameworks.

International climate finance mechanisms are increasingly supporting regulatory capacity building in non-traditional markets. The Green Climate Fund has allocated $340 million specifically for developing carbon market infrastructure in emerging economies since 2019, with a particular focus on hard-to-abate sectors like cement and concrete. These investments are accelerating regulatory convergence and creating more predictable market conditions for carbon-negative concrete technologies.

Environmental Impact Assessment and Sustainability Metrics

Carbon-negative concrete represents a revolutionary approach to construction materials that actively removes more carbon dioxide from the atmosphere than it emits during production. In non-traditional markets, comprehensive environmental impact assessment frameworks are essential to quantify these benefits and establish credibility for wider adoption.

Life Cycle Assessment (LCA) methodologies specifically adapted for carbon-negative concrete reveal significant advantages compared to traditional Portland cement. Studies indicate potential carbon sequestration of 50-300 kg CO₂ per cubic meter, depending on formulation and production techniques. This represents a paradigm shift from conventional concrete which typically emits 400-500 kg CO₂ per cubic meter.

Water consumption metrics show promising results in water-stressed regions, with certain carbon-negative formulations requiring 20-30% less water during production and curing phases. This dual environmental benefit enhances the material's sustainability profile in arid non-traditional markets where water conservation is paramount.

Ecosystem impact evaluations demonstrate reduced mining footprints when carbon-negative concrete incorporates industrial byproducts or carbon capture technologies. The substitution of traditional aggregates with recycled materials further minimizes habitat disruption and biodiversity loss, creating measurable ecological advantages that can be quantified through standardized biodiversity impact assessments.

Standardization of sustainability metrics remains challenging across diverse non-traditional markets. The International Carbon Negative Building Materials Association has proposed a unified framework incorporating sixteen key performance indicators spanning carbon sequestration efficiency, resource utilization, and long-term environmental resilience. These metrics enable meaningful cross-market comparisons despite varying regional priorities.

Temporal considerations in environmental assessment reveal that carbon-negative concrete continues to sequester carbon throughout its service life, with some formulations demonstrating increased carbon uptake for decades after installation. This long-term benefit must be accurately modeled in sustainability metrics to reflect true environmental value.

Social impact indicators increasingly complement traditional environmental metrics, measuring community health improvements from reduced air pollution, economic benefits from local material sourcing, and enhanced resilience to climate-related disasters. These holistic sustainability metrics provide a more complete picture of carbon-negative concrete's contribution to sustainable development goals in emerging economies.

Life Cycle Assessment (LCA) methodologies specifically adapted for carbon-negative concrete reveal significant advantages compared to traditional Portland cement. Studies indicate potential carbon sequestration of 50-300 kg CO₂ per cubic meter, depending on formulation and production techniques. This represents a paradigm shift from conventional concrete which typically emits 400-500 kg CO₂ per cubic meter.

Water consumption metrics show promising results in water-stressed regions, with certain carbon-negative formulations requiring 20-30% less water during production and curing phases. This dual environmental benefit enhances the material's sustainability profile in arid non-traditional markets where water conservation is paramount.

Ecosystem impact evaluations demonstrate reduced mining footprints when carbon-negative concrete incorporates industrial byproducts or carbon capture technologies. The substitution of traditional aggregates with recycled materials further minimizes habitat disruption and biodiversity loss, creating measurable ecological advantages that can be quantified through standardized biodiversity impact assessments.

Standardization of sustainability metrics remains challenging across diverse non-traditional markets. The International Carbon Negative Building Materials Association has proposed a unified framework incorporating sixteen key performance indicators spanning carbon sequestration efficiency, resource utilization, and long-term environmental resilience. These metrics enable meaningful cross-market comparisons despite varying regional priorities.

Temporal considerations in environmental assessment reveal that carbon-negative concrete continues to sequester carbon throughout its service life, with some formulations demonstrating increased carbon uptake for decades after installation. This long-term benefit must be accurately modeled in sustainability metrics to reflect true environmental value.

Social impact indicators increasingly complement traditional environmental metrics, measuring community health improvements from reduced air pollution, economic benefits from local material sourcing, and enhanced resilience to climate-related disasters. These holistic sustainability metrics provide a more complete picture of carbon-negative concrete's contribution to sustainable development goals in emerging economies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!