What Innovations Drive Carbon-negative Concrete Efficiency

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-Negative Concrete Background and Objectives

Concrete production has been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. This environmental impact has driven extensive research into carbon-negative concrete technologies over the past two decades. The evolution of these technologies has progressed from initial carbon reduction strategies to current innovations that actively sequester carbon, transforming concrete from an emissions source to a potential carbon sink.

The concept of carbon-negative concrete emerged in the early 2000s, gaining momentum as climate change concerns intensified. Traditional Portland cement production releases approximately one ton of CO2 for every ton of cement produced, primarily through limestone calcination and fossil fuel combustion during manufacturing. This environmental burden has catalyzed the development of alternative binding materials and production processes that minimize or eliminate these emissions.

Recent technological breakthroughs have shifted the paradigm from merely reducing concrete's carbon footprint to creating materials that actively remove carbon from the atmosphere throughout their lifecycle. These innovations include alternative cementitious materials derived from industrial byproducts, carbon capture during production, and novel curing processes that enhance CO2 absorption. The integration of these approaches has demonstrated the potential for concrete to sequester more carbon than is emitted during its production.

The primary objective of carbon-negative concrete research is to develop commercially viable solutions that maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration. This includes optimizing mechanical properties such as compressive strength, durability, and workability while maximizing carbon uptake capacity. Additionally, researchers aim to ensure these solutions are economically competitive and scalable for widespread industry adoption.

Technical goals in this field include developing standardized methodologies for measuring carbon sequestration in concrete products, improving the efficiency of carbon capture mechanisms, and extending the carbon absorption capacity throughout the material's lifecycle. Researchers are also focused on reducing energy requirements for production processes and identifying renewable energy integration opportunities to further enhance environmental benefits.

The trajectory of carbon-negative concrete technology points toward increasingly sophisticated carbon utilization strategies, where captured CO2 becomes a valuable resource rather than a waste product. Future developments will likely focus on enhancing mineralization processes, optimizing material microstructures for carbon storage, and developing hybrid solutions that combine multiple carbon reduction and sequestration approaches for maximum efficiency.

The concept of carbon-negative concrete emerged in the early 2000s, gaining momentum as climate change concerns intensified. Traditional Portland cement production releases approximately one ton of CO2 for every ton of cement produced, primarily through limestone calcination and fossil fuel combustion during manufacturing. This environmental burden has catalyzed the development of alternative binding materials and production processes that minimize or eliminate these emissions.

Recent technological breakthroughs have shifted the paradigm from merely reducing concrete's carbon footprint to creating materials that actively remove carbon from the atmosphere throughout their lifecycle. These innovations include alternative cementitious materials derived from industrial byproducts, carbon capture during production, and novel curing processes that enhance CO2 absorption. The integration of these approaches has demonstrated the potential for concrete to sequester more carbon than is emitted during its production.

The primary objective of carbon-negative concrete research is to develop commercially viable solutions that maintain or exceed the performance characteristics of traditional concrete while achieving net carbon sequestration. This includes optimizing mechanical properties such as compressive strength, durability, and workability while maximizing carbon uptake capacity. Additionally, researchers aim to ensure these solutions are economically competitive and scalable for widespread industry adoption.

Technical goals in this field include developing standardized methodologies for measuring carbon sequestration in concrete products, improving the efficiency of carbon capture mechanisms, and extending the carbon absorption capacity throughout the material's lifecycle. Researchers are also focused on reducing energy requirements for production processes and identifying renewable energy integration opportunities to further enhance environmental benefits.

The trajectory of carbon-negative concrete technology points toward increasingly sophisticated carbon utilization strategies, where captured CO2 becomes a valuable resource rather than a waste product. Future developments will likely focus on enhancing mineralization processes, optimizing material microstructures for carbon storage, and developing hybrid solutions that combine multiple carbon reduction and sequestration approaches for maximum efficiency.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $299 billion globally, this market is projected to reach $561 billion by 2030, with a compound annual growth rate of 11.2% between 2023 and 2030. Carbon-negative concrete solutions represent one of the fastest-growing segments within this category, with market adoption accelerating as construction firms seek to meet increasingly stringent sustainability targets.

Demand for carbon-negative concrete is particularly strong in developed regions including North America, Western Europe, and parts of Asia-Pacific, where green building certifications like LEED, BREEAM, and regional equivalents have become standard requirements for new commercial construction. Government procurement policies are increasingly mandating low-carbon building materials, with countries like Sweden, Finland, and Canada implementing carbon footprint limits for public infrastructure projects.

The commercial building sector currently represents the largest market share for sustainable concrete at 41%, followed by residential construction at 32% and infrastructure projects at 27%. However, infrastructure is expected to become the dominant application area by 2028 due to massive government investments in sustainable public works globally.

Consumer willingness to pay premiums for sustainable building materials varies significantly by region and application. Commercial developers typically accept 5-15% premiums for materials that contribute to certification goals, while residential consumers show more price sensitivity with acceptance thresholds around 3-8% above conventional materials. This price sensitivity remains a key market barrier, though the gap is narrowing as production scales and technologies mature.

Supply chain challenges present significant market constraints, with limited availability of key ingredients like supplementary cementitious materials (SCMs) and carbon capture technologies. Geographic distribution of production facilities remains concentrated in innovation hubs, creating logistical challenges for widespread adoption in developing markets where construction activity is highest.

Market forecasts indicate that carbon-negative concrete will capture approximately 18% of the global concrete market by 2030, up from less than 2% today. This growth trajectory is supported by venture capital investments exceeding $1.2 billion in carbon-negative concrete startups since 2020, and major cement producers allocating an average of 9% of R&D budgets to carbon reduction technologies, signaling strong confidence in the long-term market potential of these innovations.

Demand for carbon-negative concrete is particularly strong in developed regions including North America, Western Europe, and parts of Asia-Pacific, where green building certifications like LEED, BREEAM, and regional equivalents have become standard requirements for new commercial construction. Government procurement policies are increasingly mandating low-carbon building materials, with countries like Sweden, Finland, and Canada implementing carbon footprint limits for public infrastructure projects.

The commercial building sector currently represents the largest market share for sustainable concrete at 41%, followed by residential construction at 32% and infrastructure projects at 27%. However, infrastructure is expected to become the dominant application area by 2028 due to massive government investments in sustainable public works globally.

Consumer willingness to pay premiums for sustainable building materials varies significantly by region and application. Commercial developers typically accept 5-15% premiums for materials that contribute to certification goals, while residential consumers show more price sensitivity with acceptance thresholds around 3-8% above conventional materials. This price sensitivity remains a key market barrier, though the gap is narrowing as production scales and technologies mature.

Supply chain challenges present significant market constraints, with limited availability of key ingredients like supplementary cementitious materials (SCMs) and carbon capture technologies. Geographic distribution of production facilities remains concentrated in innovation hubs, creating logistical challenges for widespread adoption in developing markets where construction activity is highest.

Market forecasts indicate that carbon-negative concrete will capture approximately 18% of the global concrete market by 2030, up from less than 2% today. This growth trajectory is supported by venture capital investments exceeding $1.2 billion in carbon-negative concrete startups since 2020, and major cement producers allocating an average of 9% of R&D budgets to carbon reduction technologies, signaling strong confidence in the long-term market potential of these innovations.

Current State and Challenges in Carbon-Negative Concrete

The global concrete industry currently faces a significant carbon footprint challenge, accounting for approximately 8% of worldwide CO2 emissions. Traditional concrete production, particularly the manufacturing of Portland cement, releases substantial amounts of carbon dioxide through both chemical reactions and energy consumption. Despite this environmental burden, recent technological advancements have begun to transform concrete from a carbon-intensive material to potentially carbon-negative.

Carbon-negative concrete technologies have progressed significantly in recent years, with several approaches showing promise. Carbon capture and utilization (CCU) methods have been developed to inject CO2 directly into concrete during mixing, where it mineralizes and becomes permanently sequestered. Companies like CarbonCure and Solidia have demonstrated commercial viability with these technologies, achieving carbon reductions of 5-30% depending on implementation specifics.

Alternative binding materials represent another significant advancement, with geopolymers, alkali-activated materials, and magnesium-based cements showing potential to reduce carbon emissions by 40-90% compared to traditional Portland cement. These materials utilize industrial byproducts like fly ash and slag, further enhancing their environmental credentials through circular economy principles.

Despite these promising developments, carbon-negative concrete faces substantial challenges. Scale remains a primary obstacle, as most innovative solutions have been demonstrated at pilot or limited commercial scales but struggle to achieve the massive production volumes required by the global construction industry. The conservative nature of the construction sector, with its stringent safety requirements and established building codes, further impedes rapid adoption of novel concrete technologies.

Economic barriers present another significant challenge. Many carbon-negative concrete solutions currently carry price premiums of 15-50% over conventional concrete, making widespread adoption difficult without regulatory incentives or carbon pricing mechanisms. Additionally, the geographic distribution of necessary raw materials for alternative cements is uneven, creating supply chain challenges for global implementation.

Technical performance issues also persist. While many alternative concretes show promising environmental profiles, questions remain about their long-term durability, strength development rates, and compatibility with existing construction practices. The lack of standardized testing protocols and long-term performance data creates uncertainty that discourages adoption by risk-averse stakeholders in the construction industry.

Regulatory frameworks have not kept pace with technological innovation, with building codes in many regions still oriented toward traditional Portland cement-based concrete. This regulatory lag creates significant market entry barriers for innovative carbon-negative concrete solutions, regardless of their technical merits or environmental benefits.

Carbon-negative concrete technologies have progressed significantly in recent years, with several approaches showing promise. Carbon capture and utilization (CCU) methods have been developed to inject CO2 directly into concrete during mixing, where it mineralizes and becomes permanently sequestered. Companies like CarbonCure and Solidia have demonstrated commercial viability with these technologies, achieving carbon reductions of 5-30% depending on implementation specifics.

Alternative binding materials represent another significant advancement, with geopolymers, alkali-activated materials, and magnesium-based cements showing potential to reduce carbon emissions by 40-90% compared to traditional Portland cement. These materials utilize industrial byproducts like fly ash and slag, further enhancing their environmental credentials through circular economy principles.

Despite these promising developments, carbon-negative concrete faces substantial challenges. Scale remains a primary obstacle, as most innovative solutions have been demonstrated at pilot or limited commercial scales but struggle to achieve the massive production volumes required by the global construction industry. The conservative nature of the construction sector, with its stringent safety requirements and established building codes, further impedes rapid adoption of novel concrete technologies.

Economic barriers present another significant challenge. Many carbon-negative concrete solutions currently carry price premiums of 15-50% over conventional concrete, making widespread adoption difficult without regulatory incentives or carbon pricing mechanisms. Additionally, the geographic distribution of necessary raw materials for alternative cements is uneven, creating supply chain challenges for global implementation.

Technical performance issues also persist. While many alternative concretes show promising environmental profiles, questions remain about their long-term durability, strength development rates, and compatibility with existing construction practices. The lack of standardized testing protocols and long-term performance data creates uncertainty that discourages adoption by risk-averse stakeholders in the construction industry.

Regulatory frameworks have not kept pace with technological innovation, with building codes in many regions still oriented toward traditional Portland cement-based concrete. This regulatory lag creates significant market entry barriers for innovative carbon-negative concrete solutions, regardless of their technical merits or environmental benefits.

Existing Carbon-Negative Concrete Solutions and Methods

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively turning concrete from a carbon source into a carbon sink. The efficiency of these processes depends on the specific materials used and the manufacturing conditions.- CO2 capture and sequestration in concrete: Carbon-negative concrete can be achieved through technologies that capture and sequester CO2 during the concrete manufacturing process. These methods involve incorporating CO2 into the concrete mixture where it reacts with calcium compounds to form stable carbonates, effectively locking away carbon dioxide. This approach not only reduces the carbon footprint of concrete production but can actually make the concrete carbon-negative by storing more CO2 than is emitted during production, while potentially improving concrete strength and durability.

- Alternative cementitious materials: Using alternative cementitious materials can significantly reduce the carbon footprint of concrete. These include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans that can partially replace traditional Portland cement. Additionally, novel binders such as geopolymers, alkali-activated materials, and magnesium-based cements can be used to create carbon-negative concrete. These alternatives require less energy to produce and often incorporate industrial byproducts, further enhancing their environmental benefits.

- Biomass incorporation and carbonation curing: Incorporating biomass materials such as agricultural waste, wood products, or algae into concrete mixtures can increase carbon sequestration. These organic materials store carbon absorbed during their growth phase. When combined with accelerated carbonation curing techniques, where concrete is exposed to concentrated CO2 environments during curing, the efficiency of carbon sequestration is significantly enhanced. This dual approach creates concrete that effectively serves as a carbon sink while maintaining or improving structural performance.

- Nanotechnology for enhanced carbon sequestration: Nanotechnology applications in carbon-negative concrete involve using nanomaterials to enhance CO2 absorption and improve concrete properties. Nano-engineered surfaces can increase the reactive surface area available for carbonation, while nanoadditives can catalyze carbonation reactions. Carbon nanotubes, graphene, and other nanomaterials can also strengthen the concrete matrix while facilitating carbon sequestration, resulting in stronger, more durable concrete with improved carbon-negative efficiency.

- Process optimization and energy efficiency: Optimizing manufacturing processes and improving energy efficiency are crucial for carbon-negative concrete production. This includes using renewable energy sources for concrete production, implementing more efficient kilns and grinding technologies, and developing low-temperature synthesis methods. Advanced mixing techniques, precise material proportioning, and innovative curing methods can also reduce energy consumption while maximizing CO2 uptake. These process improvements, combined with life cycle assessment approaches, ensure that concrete achieves true carbon negativity across its entire production and use cycle.

02 Alternative binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials (SCMs) to replace traditional Portland cement in concrete production. These materials, such as fly ash, slag, silica fume, and natural pozzolans, can significantly reduce the carbon footprint of concrete while maintaining or even improving its performance characteristics. The efficiency of carbon reduction depends on the proportion of cement replacement and the properties of the alternative materials.Expand Specific Solutions03 Carbonation curing techniques

Advanced carbonation curing techniques that accelerate the absorption of CO2 into concrete during the curing phase. These methods involve exposing fresh concrete to CO2-rich environments under controlled conditions, which promotes the formation of calcium carbonate within the concrete matrix. This not only sequesters carbon but can also enhance concrete strength and durability, improving the overall efficiency of the material.Expand Specific Solutions04 Biomass and waste incorporation

The incorporation of biomass and industrial waste products into concrete formulations to reduce carbon emissions. These materials, which might include agricultural residues, wood ash, or recycled aggregates, can replace portions of traditional concrete components while sequestering carbon that was previously captured by organic materials. The efficiency of these approaches varies based on the specific waste materials used and their processing methods.Expand Specific Solutions05 Optimization of concrete mix design and production processes

Innovative approaches to optimizing concrete mix designs and production processes to enhance carbon efficiency. These methods include precise proportioning of ingredients, energy-efficient manufacturing techniques, and advanced curing methods that minimize resource consumption while maximizing concrete performance. The efficiency gains come from reduced material usage, lower energy requirements, and extended service life of the resulting concrete structures.Expand Specific Solutions

Leading Companies and Research Institutions in Green Cement

The carbon-negative concrete innovation landscape is currently in an early growth phase, characterized by increasing market adoption but still evolving technological maturity. The global market for sustainable concrete solutions is expanding rapidly, driven by stringent carbon regulations and growing environmental consciousness in construction. Leading players like Solidia Technologies and CarbonCure Technologies have developed commercially viable CO2 sequestration technologies, while established industry giants such as Holcim are investing heavily in sustainable cement alternatives. Academic institutions including Worcester Polytechnic Institute, Colorado School of Mines, and Arizona State University are advancing fundamental research, often in partnership with industry. The competitive landscape features a mix of specialized startups, traditional cement manufacturers pivoting toward sustainability, and research institutions collaborating across borders to accelerate technological breakthroughs in reducing concrete's carbon footprint.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete production process that fundamentally alters traditional cement chemistry. Their technology uses non-hydraulic calcium silicate cement that cures through carbonation rather than hydration, consuming CO2 during the curing process. The Solidia Cement™ can be produced in existing cement kilns at lower temperatures (1200°C vs 1450°C for traditional Portland cement), reducing energy consumption by up to 30% and associated CO2 emissions by 30-40%. During the concrete curing process, Solidia's technology absorbs additional CO2 (up to 5% by weight), effectively sequestering carbon within the concrete structure. This dual approach—reducing emissions during production and absorbing CO2 during curing—creates a concrete product with up to 70% lower carbon footprint compared to conventional concrete. The technology also reduces water usage by up to 80% as the water used in production can be captured and recycled rather than being consumed in the chemical reaction.

Strengths: Significantly lower carbon footprint (up to 70% reduction); reduced energy requirements; substantial water conservation; compatible with existing manufacturing infrastructure; creates stronger final products with faster curing times. Weaknesses: Requires controlled CO2 curing environment; market adoption challenges due to industry conservatism; potential limitations in certain applications requiring specific traditional concrete properties.

Holcim Technology Ltd.

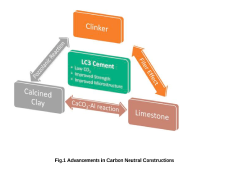

Technical Solution: Holcim has developed ECOPact, a comprehensive carbon-negative concrete solution that combines multiple innovative approaches. Their technology incorporates supplementary cementitious materials (SCMs) like calcined clay, fly ash, and ground granulated blast furnace slag to partially replace traditional Portland cement, reducing the carbon footprint by up to 90% compared to standard concrete. Holcim's ECOPlanet cement utilizes alternative raw materials and renewable energy in production, while their proprietary clinker substitution technology maintains performance with significantly lower emissions. The company has also pioneered carbon capture implementation at scale, with their Ste. Genevieve plant in Missouri demonstrating industrial carbon capture capabilities. Additionally, Holcim employs innovative concrete mix designs that optimize particle packing to reduce cement content while maintaining or improving performance characteristics. Their carbon-negative approach is completed through the integration of captured carbon into concrete products, effectively sequestering CO2 within the building material itself. Holcim's technology roadmap includes the development of novel binders that can act as carbon sinks throughout their lifecycle.

Strengths: Comprehensive approach combining multiple carbon reduction strategies; global scale implementation capabilities; maintains high performance standards; backed by extensive R&D resources and testing facilities. Weaknesses: Some solutions remain in development phase; varying availability of supplementary materials across regions; requires significant capital investment for full implementation across production facilities.

Key Innovations in CO2 Sequestration for Concrete

Development of sustainable concrete for structural applications

PatentPendingIN202331073958A

Innovation

- The use of precipitated calcium carbonate (PCC) to replace up to 30% of Portland cement and upcycled recycled concrete aggregate (UCA) to replace both fine and coarse aggregates in concrete mixes, leveraging waste products from the sugar industry and recycled concrete materials to enhance mechanical properties and reduce carbon footprint.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Regulatory Framework and Carbon Credit Opportunities

The global regulatory landscape for carbon-negative concrete is rapidly evolving, creating both compliance requirements and economic opportunities. The European Union's Carbon Border Adjustment Mechanism (CBAM) represents a significant development, imposing carbon pricing on cement imports and incentivizing low-carbon production methods. Similarly, the United States has introduced the Low Carbon Concrete Standards in federal procurement policies, while Canada's Clean Fuel Standard provides regulatory frameworks that reward carbon reduction in construction materials.

These regulations are complemented by voluntary certification systems such as LEED, BREEAM, and the newer EC3 (Embodied Carbon in Construction Calculator), which provide market recognition for buildings utilizing carbon-negative concrete solutions. Such frameworks create market pull by enabling project developers to demonstrate environmental compliance and achieve sustainability ratings.

Carbon credit markets present substantial economic opportunities for carbon-negative concrete technologies. The voluntary carbon market reached $2 billion in 2022, with projections suggesting growth to $10-40 billion by 2030. Carbon removal credits specifically for concrete-based carbon sequestration have emerged as a premium category, commanding prices of $100-300 per ton of CO2 removed—significantly higher than conventional carbon offset prices.

Project developers can leverage methodologies such as Verra's VM0043 for quantifying carbon sequestration in concrete products. The development of Monitoring, Reporting, and Verification (MRV) protocols specific to carbon-negative concrete is accelerating, with blockchain-based tracking systems enhancing transparency and credibility of carbon removal claims.

Policy innovations like Carbon Contracts for Difference (CCfDs) are emerging as mechanisms to reduce investment risk in carbon-negative technologies by guaranteeing minimum carbon prices. Meanwhile, green procurement policies in major economies are creating guaranteed markets for low-carbon building materials, with California's Buy Clean California Act and similar policies in New York and Washington state serving as models.

The integration of carbon-negative concrete into national climate commitments (NDCs) under the Paris Agreement represents another significant opportunity, as countries seek verifiable pathways to meet their emission reduction targets. This regulatory recognition is essential for scaling carbon-negative concrete technologies beyond niche applications into mainstream construction practices.

These regulations are complemented by voluntary certification systems such as LEED, BREEAM, and the newer EC3 (Embodied Carbon in Construction Calculator), which provide market recognition for buildings utilizing carbon-negative concrete solutions. Such frameworks create market pull by enabling project developers to demonstrate environmental compliance and achieve sustainability ratings.

Carbon credit markets present substantial economic opportunities for carbon-negative concrete technologies. The voluntary carbon market reached $2 billion in 2022, with projections suggesting growth to $10-40 billion by 2030. Carbon removal credits specifically for concrete-based carbon sequestration have emerged as a premium category, commanding prices of $100-300 per ton of CO2 removed—significantly higher than conventional carbon offset prices.

Project developers can leverage methodologies such as Verra's VM0043 for quantifying carbon sequestration in concrete products. The development of Monitoring, Reporting, and Verification (MRV) protocols specific to carbon-negative concrete is accelerating, with blockchain-based tracking systems enhancing transparency and credibility of carbon removal claims.

Policy innovations like Carbon Contracts for Difference (CCfDs) are emerging as mechanisms to reduce investment risk in carbon-negative technologies by guaranteeing minimum carbon prices. Meanwhile, green procurement policies in major economies are creating guaranteed markets for low-carbon building materials, with California's Buy Clean California Act and similar policies in New York and Washington state serving as models.

The integration of carbon-negative concrete into national climate commitments (NDCs) under the Paris Agreement represents another significant opportunity, as countries seek verifiable pathways to meet their emission reduction targets. This regulatory recognition is essential for scaling carbon-negative concrete technologies beyond niche applications into mainstream construction practices.

Life Cycle Assessment of Carbon-Negative Concrete Products

Life Cycle Assessment (LCA) methodologies are essential for evaluating the environmental performance of carbon-negative concrete products throughout their entire lifecycle. These assessments typically encompass raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. For carbon-negative concrete, LCA provides critical insights into the actual carbon sequestration capabilities and overall environmental impact.

Standard LCA frameworks for concrete products include ISO 14040 and ISO 14044, which establish principles for conducting comprehensive assessments. However, carbon-negative concrete requires specialized assessment parameters that account for carbon capture during curing processes and long-term sequestration potential. Recent advancements in LCA methodologies have incorporated these unique characteristics, enabling more accurate evaluation of innovative concrete formulations.

Key environmental impact categories in carbon-negative concrete LCAs include global warming potential, acidification potential, eutrophication potential, and resource depletion. The global warming potential metric is particularly significant as it quantifies the net carbon dioxide equivalent emissions or removals throughout the product lifecycle. For truly carbon-negative products, this value must demonstrate net carbon sequestration when all lifecycle phases are considered.

Comparative LCA studies between conventional Portland cement concrete and carbon-negative alternatives reveal substantial differences in environmental performance. While conventional concrete typically emits 250-400 kg CO2e per cubic meter, carbon-negative formulations can sequester between 50-200 kg CO2e per cubic meter, depending on the specific technology employed. These comparisons provide valuable benchmarks for industry stakeholders and policymakers.

Temporal considerations in carbon-negative concrete LCAs present unique challenges. The carbon sequestration benefits may occur over extended timeframes, requiring appropriate time horizons for accurate assessment. Most current LCA models employ 100-year time horizons, though some researchers advocate for longer periods to fully capture sequestration benefits.

Data quality and uncertainty analysis remain critical challenges in carbon-negative concrete LCAs. Limited field data on long-term performance and variability in production processes can introduce significant uncertainty. Advanced statistical methods, such as Monte Carlo simulations, are increasingly employed to quantify these uncertainties and provide confidence intervals for environmental impact results.

Standardization efforts for carbon-negative concrete LCAs are progressing through organizations like the International EPD System and the Carbon Leadership Forum. These initiatives aim to establish consistent methodologies that enable fair comparisons between different products and technologies, ultimately facilitating market adoption of truly sustainable concrete solutions.

Standard LCA frameworks for concrete products include ISO 14040 and ISO 14044, which establish principles for conducting comprehensive assessments. However, carbon-negative concrete requires specialized assessment parameters that account for carbon capture during curing processes and long-term sequestration potential. Recent advancements in LCA methodologies have incorporated these unique characteristics, enabling more accurate evaluation of innovative concrete formulations.

Key environmental impact categories in carbon-negative concrete LCAs include global warming potential, acidification potential, eutrophication potential, and resource depletion. The global warming potential metric is particularly significant as it quantifies the net carbon dioxide equivalent emissions or removals throughout the product lifecycle. For truly carbon-negative products, this value must demonstrate net carbon sequestration when all lifecycle phases are considered.

Comparative LCA studies between conventional Portland cement concrete and carbon-negative alternatives reveal substantial differences in environmental performance. While conventional concrete typically emits 250-400 kg CO2e per cubic meter, carbon-negative formulations can sequester between 50-200 kg CO2e per cubic meter, depending on the specific technology employed. These comparisons provide valuable benchmarks for industry stakeholders and policymakers.

Temporal considerations in carbon-negative concrete LCAs present unique challenges. The carbon sequestration benefits may occur over extended timeframes, requiring appropriate time horizons for accurate assessment. Most current LCA models employ 100-year time horizons, though some researchers advocate for longer periods to fully capture sequestration benefits.

Data quality and uncertainty analysis remain critical challenges in carbon-negative concrete LCAs. Limited field data on long-term performance and variability in production processes can introduce significant uncertainty. Advanced statistical methods, such as Monte Carlo simulations, are increasingly employed to quantify these uncertainties and provide confidence intervals for environmental impact results.

Standardization efforts for carbon-negative concrete LCAs are progressing through organizations like the International EPD System and the Carbon Leadership Forum. These initiatives aim to establish consistent methodologies that enable fair comparisons between different products and technologies, ultimately facilitating market adoption of truly sustainable concrete solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!