Unlocking the Potential of Carbon-negative Concrete for Net-zero Targets

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has historically been a significant contributor to global carbon emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction technology, moving from traditional carbon-intensive processes toward innovative solutions that actively remove carbon dioxide from the atmosphere. This technological journey began in the early 2000s with initial research into alternative cementitious materials and has accelerated dramatically in the past decade as climate change concerns intensified.

The development trajectory of carbon-negative concrete has been marked by several key milestones. Early approaches focused primarily on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, research expanded to include novel binding agents and carbon capture technologies integrated directly into the concrete manufacturing process. Recent breakthroughs have enabled concrete formulations that can sequester more carbon than they emit throughout their lifecycle.

Current technological objectives in this field are multifaceted and ambitious. Primary goals include developing scalable production methods that maintain or exceed the performance characteristics of traditional concrete while achieving net-negative carbon emissions. Researchers aim to optimize carbon sequestration capacity without compromising structural integrity, durability, or cost-effectiveness. Additionally, there is a focus on creating solutions adaptable to various climate conditions and construction requirements worldwide.

The advancement of carbon-negative concrete aligns with global sustainability initiatives, particularly the Paris Agreement and various national net-zero carbon commitments. By 2030, the construction industry aims to reduce its carbon footprint by 50%, with carbon-negative concrete playing a pivotal role in this transition. Long-term objectives extend to 2050, targeting widespread adoption of carbon-negative building materials as standard practice in construction.

Technical challenges being addressed include enhancing carbonation rates, improving mechanical properties of alternative formulations, and developing efficient carbon capture mechanisms within the concrete matrix. Parallel research streams focus on optimizing the entire value chain, from raw material sourcing to end-of-life recycling, ensuring a holistic approach to sustainability. The ultimate goal remains creating a commercially viable product that can be manufactured at scale while delivering meaningful climate benefits through permanent carbon sequestration.

The development trajectory of carbon-negative concrete has been marked by several key milestones. Early approaches focused primarily on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, research expanded to include novel binding agents and carbon capture technologies integrated directly into the concrete manufacturing process. Recent breakthroughs have enabled concrete formulations that can sequester more carbon than they emit throughout their lifecycle.

Current technological objectives in this field are multifaceted and ambitious. Primary goals include developing scalable production methods that maintain or exceed the performance characteristics of traditional concrete while achieving net-negative carbon emissions. Researchers aim to optimize carbon sequestration capacity without compromising structural integrity, durability, or cost-effectiveness. Additionally, there is a focus on creating solutions adaptable to various climate conditions and construction requirements worldwide.

The advancement of carbon-negative concrete aligns with global sustainability initiatives, particularly the Paris Agreement and various national net-zero carbon commitments. By 2030, the construction industry aims to reduce its carbon footprint by 50%, with carbon-negative concrete playing a pivotal role in this transition. Long-term objectives extend to 2050, targeting widespread adoption of carbon-negative building materials as standard practice in construction.

Technical challenges being addressed include enhancing carbonation rates, improving mechanical properties of alternative formulations, and developing efficient carbon capture mechanisms within the concrete matrix. Parallel research streams focus on optimizing the entire value chain, from raw material sourcing to end-of-life recycling, ensuring a holistic approach to sustainability. The ultimate goal remains creating a commercially viable product that can be manufactured at scale while delivering meaningful climate benefits through permanent carbon sequestration.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete, has shown remarkable growth in recent years. According to recent market research, the global green concrete market was valued at approximately $26.2 billion in 2021 and is projected to reach $43.6 billion by 2028, growing at a CAGR of 8.7%.

This growth is primarily fueled by stringent environmental regulations and carbon emission targets set by governments worldwide. The European Union's Green Deal aims for carbon neutrality by 2050, while countries like the UK have set interim targets to reduce carbon emissions by 78% by 2035. These regulatory frameworks are creating substantial demand for carbon-negative building materials, especially in developed economies.

The construction sector accounts for approximately 38% of global carbon emissions, with traditional concrete production being a major contributor. This has created an urgent market need for alternative solutions that can reduce the carbon footprint of construction projects. Surveys indicate that 67% of construction companies are now prioritizing sustainability in their material selection processes, compared to just 32% five years ago.

Consumer preferences are also evolving rapidly. A 2022 survey revealed that 73% of commercial property developers consider sustainability credentials as "very important" in their purchasing decisions, up from 45% in 2018. This shift is particularly pronounced in premium real estate markets, where green building certifications like LEED and BREEAM have become significant value drivers.

Regional analysis shows varying adoption rates of sustainable construction materials. North America and Europe lead the market, accounting for approximately 60% of global demand for green concrete solutions. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming decade due to rapid urbanization and increasing environmental awareness.

The economic viability of carbon-negative concrete has improved substantially. While early sustainable concrete alternatives commanded a premium of 15-20% over traditional options, technological advancements and economies of scale have reduced this gap to 5-10% in many markets. Furthermore, lifecycle cost analyses demonstrate that buildings constructed with carbon-negative materials often achieve lower total ownership costs due to improved energy efficiency and higher property values.

Industry forecasts suggest that carbon-negative concrete could capture up to 30% of the global concrete market by 2035, representing a potential market value of $217 billion. This growth trajectory is supported by increasing corporate commitments to net-zero targets and the integration of carbon accounting into business operations.

This growth is primarily fueled by stringent environmental regulations and carbon emission targets set by governments worldwide. The European Union's Green Deal aims for carbon neutrality by 2050, while countries like the UK have set interim targets to reduce carbon emissions by 78% by 2035. These regulatory frameworks are creating substantial demand for carbon-negative building materials, especially in developed economies.

The construction sector accounts for approximately 38% of global carbon emissions, with traditional concrete production being a major contributor. This has created an urgent market need for alternative solutions that can reduce the carbon footprint of construction projects. Surveys indicate that 67% of construction companies are now prioritizing sustainability in their material selection processes, compared to just 32% five years ago.

Consumer preferences are also evolving rapidly. A 2022 survey revealed that 73% of commercial property developers consider sustainability credentials as "very important" in their purchasing decisions, up from 45% in 2018. This shift is particularly pronounced in premium real estate markets, where green building certifications like LEED and BREEAM have become significant value drivers.

Regional analysis shows varying adoption rates of sustainable construction materials. North America and Europe lead the market, accounting for approximately 60% of global demand for green concrete solutions. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming decade due to rapid urbanization and increasing environmental awareness.

The economic viability of carbon-negative concrete has improved substantially. While early sustainable concrete alternatives commanded a premium of 15-20% over traditional options, technological advancements and economies of scale have reduced this gap to 5-10% in many markets. Furthermore, lifecycle cost analyses demonstrate that buildings constructed with carbon-negative materials often achieve lower total ownership costs due to improved energy efficiency and higher property values.

Industry forecasts suggest that carbon-negative concrete could capture up to 30% of the global concrete market by 2035, representing a potential market value of $217 billion. This growth trajectory is supported by increasing corporate commitments to net-zero targets and the integration of carbon accounting into business operations.

Global Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete development has gained significant momentum globally, yet faces substantial barriers to widespread adoption. Currently, several pioneering projects across North America, Europe, and parts of Asia demonstrate the technical feasibility of carbon-negative concrete solutions. Companies like CarbonCure, Solidia, and Carbicrete have developed technologies that sequester CO2 during concrete production, while academic institutions in countries including the United States, Canada, United Kingdom, and China lead research initiatives focused on enhancing carbon capture capabilities in cementitious materials.

Despite these advancements, the global landscape remains fragmented, with most carbon-negative concrete technologies still at pilot or early commercial stages. Market penetration remains below 2% of global concrete production, concentrated primarily in developed economies with strong environmental regulations and carbon pricing mechanisms.

Technical barriers represent significant challenges to widespread implementation. Current carbon-negative concrete formulations often face performance limitations, including reduced early-stage strength development, increased setting time, and uncertain long-term durability under various environmental conditions. These technical uncertainties create hesitation among structural engineers and construction firms regarding specification for critical infrastructure projects.

Economic barriers further impede adoption, with carbon-negative concrete typically commanding a 15-30% price premium over conventional products. Without robust carbon pricing mechanisms or regulatory incentives, this cost differential significantly limits market uptake, particularly in price-sensitive construction sectors and developing economies where infrastructure needs are greatest.

Regulatory frameworks present another substantial barrier. The construction industry operates under conservative building codes and standards that evolve slowly and often fail to accommodate innovative materials. Many jurisdictions lack clear pathways for certifying and approving carbon-negative concrete products, creating regulatory uncertainty that discourages investment and adoption.

Supply chain constraints also limit scalability. The production of specialized additives, alternative binders, and carbon capture technologies requires new manufacturing infrastructure and reliable CO2 sources. Additionally, the geographical distribution of production facilities remains limited, creating logistical challenges for widespread implementation.

Knowledge gaps and industry inertia further complicate adoption. The construction sector traditionally demonstrates resistance to change, with established practices deeply entrenched. Limited awareness of carbon-negative concrete technologies among architects, engineers, and contractors, coupled with insufficient technical training and demonstration projects, slows diffusion of these innovations throughout the global construction ecosystem.

Despite these advancements, the global landscape remains fragmented, with most carbon-negative concrete technologies still at pilot or early commercial stages. Market penetration remains below 2% of global concrete production, concentrated primarily in developed economies with strong environmental regulations and carbon pricing mechanisms.

Technical barriers represent significant challenges to widespread implementation. Current carbon-negative concrete formulations often face performance limitations, including reduced early-stage strength development, increased setting time, and uncertain long-term durability under various environmental conditions. These technical uncertainties create hesitation among structural engineers and construction firms regarding specification for critical infrastructure projects.

Economic barriers further impede adoption, with carbon-negative concrete typically commanding a 15-30% price premium over conventional products. Without robust carbon pricing mechanisms or regulatory incentives, this cost differential significantly limits market uptake, particularly in price-sensitive construction sectors and developing economies where infrastructure needs are greatest.

Regulatory frameworks present another substantial barrier. The construction industry operates under conservative building codes and standards that evolve slowly and often fail to accommodate innovative materials. Many jurisdictions lack clear pathways for certifying and approving carbon-negative concrete products, creating regulatory uncertainty that discourages investment and adoption.

Supply chain constraints also limit scalability. The production of specialized additives, alternative binders, and carbon capture technologies requires new manufacturing infrastructure and reliable CO2 sources. Additionally, the geographical distribution of production facilities remains limited, creating logistical challenges for widespread implementation.

Knowledge gaps and industry inertia further complicate adoption. The construction sector traditionally demonstrates resistance to change, with established practices deeply entrenched. Limited awareness of carbon-negative concrete technologies among architects, engineers, and contractors, coupled with insufficient technical training and demonstration projects, slows diffusion of these innovations throughout the global construction ecosystem.

Current Carbon Capture and Utilization Methods in Concrete

01 CO2 capture and sequestration in concrete production

Carbon-negative concrete can be achieved by capturing and sequestering CO2 during the production process. This involves incorporating technologies that absorb CO2 from the atmosphere or industrial emissions and permanently store it within the concrete matrix. These methods can transform traditional concrete manufacturing from a carbon-emitting process to one that serves as a carbon sink, effectively removing more carbon from the atmosphere than is released during production.- CO2 capture and sequestration in concrete production: Technologies that capture and sequester carbon dioxide during the concrete manufacturing process, transforming concrete from a carbon source to a carbon sink. These methods involve injecting CO2 into concrete mixtures during curing, where it reacts with calcium compounds to form stable carbonates, permanently storing the carbon while simultaneously improving concrete strength and durability.

- Alternative low-carbon binders and supplementary cementitious materials: Utilization of alternative binding materials and supplementary cementitious materials (SCMs) that reduce or eliminate the need for traditional Portland cement. These include geopolymers, alkali-activated materials, and industrial byproducts like fly ash, slag, and silica fume that can partially replace cement while reducing the carbon footprint of concrete and potentially enabling carbon-negative formulations.

- Biomass incorporation and biogenic carbon storage: Integration of biomass-derived materials into concrete formulations to store biogenic carbon. These approaches include incorporating agricultural waste, wood products, or other plant-based materials that have sequestered atmospheric CO2 during growth. When these materials are embedded in concrete, they create a long-term carbon sink while potentially improving properties like thermal insulation and weight reduction.

- Enhanced carbonation processes and accelerated curing: Advanced carbonation techniques and curing processes designed to maximize CO2 uptake in concrete. These methods use controlled environments with elevated CO2 concentrations, optimized temperature and humidity conditions, and sometimes catalysts to accelerate the natural carbonation process. The enhanced carbonation not only sequesters more carbon but can also improve concrete performance characteristics.

- Carbon-negative concrete systems with renewable energy integration: Holistic concrete production systems that combine multiple carbon reduction strategies with renewable energy sources to achieve carbon-negative outcomes. These integrated approaches may include on-site renewable energy generation, carbon capture technologies, alternative raw materials, and optimized manufacturing processes that collectively result in concrete products that sequester more carbon than is emitted during their production.

02 Alternative cementitious materials for carbon reduction

Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials can partially or completely replace traditional Portland cement, which is responsible for the majority of carbon emissions in concrete production. Alternative binders often require less energy to produce and can incorporate industrial byproducts, further contributing to carbon negativity.Expand Specific Solutions03 Carbonation curing techniques

Carbonation curing involves exposing fresh concrete to CO2-rich environments during the curing process, allowing the concrete to absorb carbon dioxide as it hardens. This technique not only sequesters carbon but can also improve the mechanical properties and durability of the concrete. Advanced carbonation methods can accelerate the natural carbonation process that occurs in concrete over time, making it a viable approach for producing carbon-negative concrete products.Expand Specific Solutions04 Biomass incorporation and biogenic materials

Incorporating biomass or biogenic materials into concrete mixtures can contribute to carbon negativity. These materials, such as agricultural waste, wood products, or algae-based additives, store carbon that was previously removed from the atmosphere through photosynthesis. When these materials are integrated into concrete, the carbon remains sequestered for the lifetime of the structure, effectively creating a long-term carbon sink while potentially improving certain properties of the concrete.Expand Specific Solutions05 Carbon mineralization processes

Carbon mineralization involves converting CO2 into stable carbonate minerals that can be used as concrete aggregates or cement replacements. This process mimics natural weathering reactions but accelerates them significantly. By transforming carbon dioxide into solid minerals that become permanent components of the concrete, carbon mineralization offers a pathway to create truly carbon-negative building materials that can help mitigate climate change while meeting construction industry needs.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Innovation

The carbon-negative concrete market is in its early growth phase, characterized by increasing momentum as industries seek sustainable construction solutions to meet net-zero targets. The global market size for green cement is projected to expand significantly, driven by stringent environmental regulations and corporate sustainability commitments. While the technology shows promising potential for carbon sequestration, it remains in various stages of development across companies. Academic institutions like MIT, Hong Kong Polytechnic University, and Wuhan University of Technology are leading fundamental research, while commercial entities such as Carbon Limit Co., Cement Australia, and Procarbon Bio AB are working to scale practical applications. The competitive landscape features collaboration between research institutions and industry players to overcome technical challenges and reduce implementation costs.

Procarbon Bio AB

Technical Solution: Procarbon Bio has developed an innovative carbon-negative concrete technology called "BioCarb Concrete" that incorporates biogenic carbon capture mechanisms. Their approach utilizes specialized microalgae strains that are cultivated using industrial CO2 emissions, then processed into a carbon-rich biomass additive for concrete production. When incorporated into concrete mixtures, this biomass not only replaces a portion of traditional cement but also introduces captured carbon that becomes permanently sequestered in the concrete matrix. The biological approach enables carbon sequestration of approximately 200-250 kg CO2 per cubic meter of concrete, significantly exceeding most competing technologies. Additionally, Procarbon's process enhances concrete durability by creating a more refined pore structure that improves resistance to freeze-thaw cycles and chloride penetration. The company has successfully scaled their technology from laboratory to pilot production facilities, with commercial implementation underway in several European markets.

Strengths: Achieves exceptionally high carbon sequestration rates; creates value from industrial emissions; improves concrete durability properties; represents a truly innovative biological approach to carbon-negative materials. Weaknesses: Production process is more complex than conventional methods; requires establishing algae cultivation infrastructure; seasonal variations may affect biomass production; relatively new technology with limited long-term performance data.

Cement Australia Pty Ltd.

Technical Solution: Cement Australia has pioneered a carbon-negative concrete solution called "GeoCarb" that combines supplementary cementitious materials (SCMs) with innovative CO2 curing technology. Their approach replaces up to 70% of traditional Portland cement with industrial byproducts such as fly ash, slag, and silica fume, significantly reducing the carbon footprint at the production stage. The concrete then undergoes a specialized CO2 curing process where captured carbon dioxide is injected into the concrete during mixing and curing, becoming permanently mineralized within the material structure. This dual approach not only reduces initial emissions but actively sequesters additional CO2, resulting in a net-negative carbon footprint. Cement Australia's technology has demonstrated carbon sequestration capabilities of approximately 120-180 kg CO2 per cubic meter of concrete while maintaining or exceeding industry performance standards for strength and durability. The company has implemented this technology across various infrastructure projects in Australia, proving its viability at commercial scale.

Strengths: Dual approach combining SCMs and CO2 curing maximizes carbon reduction; utilizes industrial waste streams; maintains high performance standards; commercially deployed across multiple projects. Weaknesses: Requires specialized curing equipment; optimal performance dependent on quality and availability of SCMs; higher initial production costs compared to conventional concrete.

Key Patents and Research in CO2 Mineralization Technologies

Development of sustainable concrete for structural applications

PatentPendingIN202331073958A

Innovation

- The use of precipitated calcium carbonate (PCC) to replace up to 30% of Portland cement and upcycled recycled concrete aggregate (UCA) to replace both fine and coarse aggregates in concrete mixes, leveraging waste products from the sugar industry and recycled concrete materials to enhance mechanical properties and reduce carbon footprint.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

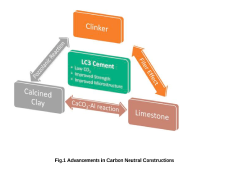

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Regulatory Framework and Carbon Credit Opportunities

The global regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to achieve net-zero emissions targets. The European Union leads with its Carbon Border Adjustment Mechanism (CBAM), which imposes carbon pricing on imported cement and concrete products, creating strong incentives for carbon-negative alternatives. Similarly, the United States has introduced tax incentives through the Inflation Reduction Act, offering up to $85 per ton for carbon capture and storage technologies applicable to concrete production.

In Asia, countries like Singapore have implemented a carbon tax framework specifically targeting construction materials, while China has included cement in its national emissions trading scheme. These regulatory frameworks are creating a favorable environment for carbon-negative concrete adoption by internalizing the environmental costs of traditional concrete production.

Carbon credit opportunities represent a significant economic driver for carbon-negative concrete technologies. The voluntary carbon market has seen substantial growth, with carbon credits for engineered carbon removal solutions commanding premium prices of $200-600 per ton of CO2 removed. This creates a dual revenue stream for carbon-negative concrete producers: selling the concrete product itself and monetizing the associated carbon credits.

Several certification standards have emerged to validate carbon removal claims in concrete, including Verra's Carbon Capture Utilization and Storage methodology and the Gold Standard's framework for carbon-negative materials. These standards ensure credibility in the carbon marketplace and facilitate the trading of high-quality carbon credits derived from concrete production.

Corporate net-zero commitments are further driving demand for carbon credits from engineered solutions like carbon-negative concrete. Major technology and financial companies have pledged billions in advance purchase agreements for carbon removal credits, creating market certainty for developers of carbon-negative concrete technologies.

The intersection of regulatory compliance and carbon credit opportunities creates a powerful economic case for scaling carbon-negative concrete. Projects can potentially offset higher production costs through carbon credit revenues, particularly in jurisdictions with carbon pricing mechanisms. Analysis suggests that at carbon prices above $50-70 per ton, carbon-negative concrete becomes economically competitive with traditional concrete even without considering performance advantages.

As regulatory frameworks continue to tighten globally and carbon markets mature, the financial incentives for carbon-negative concrete will likely strengthen, accelerating commercial adoption and technological innovation in this critical sector for achieving net-zero targets.

In Asia, countries like Singapore have implemented a carbon tax framework specifically targeting construction materials, while China has included cement in its national emissions trading scheme. These regulatory frameworks are creating a favorable environment for carbon-negative concrete adoption by internalizing the environmental costs of traditional concrete production.

Carbon credit opportunities represent a significant economic driver for carbon-negative concrete technologies. The voluntary carbon market has seen substantial growth, with carbon credits for engineered carbon removal solutions commanding premium prices of $200-600 per ton of CO2 removed. This creates a dual revenue stream for carbon-negative concrete producers: selling the concrete product itself and monetizing the associated carbon credits.

Several certification standards have emerged to validate carbon removal claims in concrete, including Verra's Carbon Capture Utilization and Storage methodology and the Gold Standard's framework for carbon-negative materials. These standards ensure credibility in the carbon marketplace and facilitate the trading of high-quality carbon credits derived from concrete production.

Corporate net-zero commitments are further driving demand for carbon credits from engineered solutions like carbon-negative concrete. Major technology and financial companies have pledged billions in advance purchase agreements for carbon removal credits, creating market certainty for developers of carbon-negative concrete technologies.

The intersection of regulatory compliance and carbon credit opportunities creates a powerful economic case for scaling carbon-negative concrete. Projects can potentially offset higher production costs through carbon credit revenues, particularly in jurisdictions with carbon pricing mechanisms. Analysis suggests that at carbon prices above $50-70 per ton, carbon-negative concrete becomes economically competitive with traditional concrete even without considering performance advantages.

As regulatory frameworks continue to tighten globally and carbon markets mature, the financial incentives for carbon-negative concrete will likely strengthen, accelerating commercial adoption and technological innovation in this critical sector for achieving net-zero targets.

Life Cycle Assessment and Environmental Impact Metrics

Life Cycle Assessment (LCA) serves as a critical framework for evaluating the environmental performance of carbon-negative concrete technologies across their entire lifecycle. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making comprehensive assessment methodologies essential for validating claims of carbon negativity. The ISO 14040 and 14044 standards provide the foundational structure for these assessments, ensuring consistency in boundary definition, inventory analysis, impact assessment, and interpretation phases.

Carbon-negative concrete technologies must be evaluated using cradle-to-grave or cradle-to-cradle approaches that capture raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios. Key environmental impact categories include Global Warming Potential (GWP), measured in CO2-equivalent emissions; Acidification Potential; Eutrophication Potential; Ozone Depletion Potential; and Resource Depletion metrics. These indicators collectively provide a holistic view of environmental performance beyond carbon footprint alone.

Recent advancements in LCA methodologies have introduced dynamic carbon accounting approaches that consider the temporal dimension of carbon sequestration in concrete. This represents a significant improvement over static models, as carbon-negative concrete technologies often exhibit complex carbon uptake patterns over decades or centuries. The Environmental Product Declaration (EPD) system has emerged as the standardized communication tool for conveying these metrics to stakeholders, though challenges remain in ensuring comparability across different concrete formulations.

Water footprint analysis has gained prominence in concrete LCA studies, particularly as novel carbon-negative formulations may alter water requirements during production and curing phases. The Water Footprint Network methodology and ISO 14046 standard provide frameworks for quantifying blue, green, and grey water footprints associated with concrete production and use.

Sensitivity and uncertainty analyses are increasingly recognized as essential components of concrete LCAs, addressing variability in raw material sourcing, production conditions, and end-of-life scenarios. Monte Carlo simulations and other probabilistic approaches help quantify confidence intervals for environmental impact claims, enhancing the credibility of carbon-negative assertions.

Emerging metrics focus on circularity potential, including recyclability indices, secondary material incorporation rates, and design-for-disassembly scores. These metrics complement traditional environmental indicators by addressing resource efficiency dimensions critical to achieving net-zero targets. The development of standardized circularity metrics specific to the concrete industry remains an active area of research and standardization efforts.

Carbon-negative concrete technologies must be evaluated using cradle-to-grave or cradle-to-cradle approaches that capture raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios. Key environmental impact categories include Global Warming Potential (GWP), measured in CO2-equivalent emissions; Acidification Potential; Eutrophication Potential; Ozone Depletion Potential; and Resource Depletion metrics. These indicators collectively provide a holistic view of environmental performance beyond carbon footprint alone.

Recent advancements in LCA methodologies have introduced dynamic carbon accounting approaches that consider the temporal dimension of carbon sequestration in concrete. This represents a significant improvement over static models, as carbon-negative concrete technologies often exhibit complex carbon uptake patterns over decades or centuries. The Environmental Product Declaration (EPD) system has emerged as the standardized communication tool for conveying these metrics to stakeholders, though challenges remain in ensuring comparability across different concrete formulations.

Water footprint analysis has gained prominence in concrete LCA studies, particularly as novel carbon-negative formulations may alter water requirements during production and curing phases. The Water Footprint Network methodology and ISO 14046 standard provide frameworks for quantifying blue, green, and grey water footprints associated with concrete production and use.

Sensitivity and uncertainty analyses are increasingly recognized as essential components of concrete LCAs, addressing variability in raw material sourcing, production conditions, and end-of-life scenarios. Monte Carlo simulations and other probabilistic approaches help quantify confidence intervals for environmental impact claims, enhancing the credibility of carbon-negative assertions.

Emerging metrics focus on circularity potential, including recyclability indices, secondary material incorporation rates, and design-for-disassembly scores. These metrics complement traditional environmental indicators by addressing resource efficiency dimensions critical to achieving net-zero targets. The development of standardized circularity metrics specific to the concrete industry remains an active area of research and standardization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!