Understanding the Lifecycle Impacts of Carbon-negative Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete production has been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. This environmental impact has driven extensive research into carbon-negative concrete technologies over the past two decades. Carbon-negative concrete represents a revolutionary approach that aims not only to reduce emissions but to actively sequester carbon dioxide throughout its lifecycle, transforming a traditionally carbon-intensive material into a potential carbon sink.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations to low-carbon alternatives, and now to carbon-negative solutions. This progression reflects the construction industry's response to increasing environmental regulations and the global push toward carbon neutrality. The technical trajectory has been marked by innovations in material science, chemistry, and manufacturing processes that enable concrete to capture and permanently store CO2.

Carbon-negative concrete technologies operate through several mechanisms, including the incorporation of CO2-absorbing materials, the use of alternative binders that require less energy to produce, and the integration of carbon capture during the curing process. These approaches represent a significant departure from conventional concrete production methods and require fundamental rethinking of material composition and manufacturing techniques.

The primary objective of understanding the lifecycle impacts of carbon-negative concrete is to quantify its true environmental benefit compared to traditional concrete. This requires comprehensive analysis across all stages: raw material extraction, processing, manufacturing, transportation, installation, use phase, and end-of-life scenarios. Such analysis must account for both direct and indirect carbon emissions and sequestration potential throughout the material's existence.

Another critical objective is to establish standardized methodologies for measuring and verifying carbon sequestration in concrete products. The lack of universally accepted metrics has hindered widespread adoption and recognition of carbon-negative concrete technologies in regulatory frameworks and green building certification systems.

Technical goals also include optimizing the balance between carbon sequestration capacity and essential performance characteristics such as strength, durability, and workability. Carbon-negative concrete must meet or exceed existing building code requirements to achieve market acceptance, regardless of its environmental benefits.

The development trajectory aims toward scalable production methods that can be implemented within existing concrete manufacturing infrastructure, minimizing the capital investment required for industry transition. This includes research into compatible admixtures, alternative aggregates, and modified curing processes that can be adopted by conventional concrete producers.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations to low-carbon alternatives, and now to carbon-negative solutions. This progression reflects the construction industry's response to increasing environmental regulations and the global push toward carbon neutrality. The technical trajectory has been marked by innovations in material science, chemistry, and manufacturing processes that enable concrete to capture and permanently store CO2.

Carbon-negative concrete technologies operate through several mechanisms, including the incorporation of CO2-absorbing materials, the use of alternative binders that require less energy to produce, and the integration of carbon capture during the curing process. These approaches represent a significant departure from conventional concrete production methods and require fundamental rethinking of material composition and manufacturing techniques.

The primary objective of understanding the lifecycle impacts of carbon-negative concrete is to quantify its true environmental benefit compared to traditional concrete. This requires comprehensive analysis across all stages: raw material extraction, processing, manufacturing, transportation, installation, use phase, and end-of-life scenarios. Such analysis must account for both direct and indirect carbon emissions and sequestration potential throughout the material's existence.

Another critical objective is to establish standardized methodologies for measuring and verifying carbon sequestration in concrete products. The lack of universally accepted metrics has hindered widespread adoption and recognition of carbon-negative concrete technologies in regulatory frameworks and green building certification systems.

Technical goals also include optimizing the balance between carbon sequestration capacity and essential performance characteristics such as strength, durability, and workability. Carbon-negative concrete must meet or exceed existing building code requirements to achieve market acceptance, regardless of its environmental benefits.

The development trajectory aims toward scalable production methods that can be implemented within existing concrete manufacturing infrastructure, minimizing the capital investment required for industry transition. This includes research into compatible admixtures, alternative aggregates, and modified curing processes that can be adopted by conventional concrete producers.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion globally, this market is projected to reach $432 billion by 2027, with a compound annual growth rate of 11.2%. Carbon-negative concrete represents one of the fastest-growing segments within this market, with demand increasing by over 30% annually in key markets like Europe and North America.

The construction industry accounts for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created significant market pull for carbon-negative alternatives, particularly in regions with stringent carbon reduction targets. Countries implementing carbon pricing mechanisms, such as Canada, the European Union, and increasingly parts of Asia, are seeing accelerated adoption of sustainable construction materials.

Market segmentation reveals distinct customer profiles driving demand. Public infrastructure projects represent the largest market segment (38%), followed by commercial construction (27%), residential buildings (22%), and industrial facilities (13%). Government procurement policies favoring low-carbon materials have become powerful market drivers, with over 60 countries now incorporating carbon footprint considerations into public construction tenders.

Regional analysis shows Europe leading adoption with a 42% market share of sustainable construction materials, followed by North America (28%), Asia-Pacific (21%), and other regions (9%). However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, driven by rapid urbanization and increasing environmental regulations in China and India.

Consumer willingness to pay premiums for sustainable materials varies significantly by market segment. Commercial developers typically accept 5-12% price premiums for green building materials that contribute to certification standards like LEED or BREEAM, while residential consumers show more price sensitivity, generally accepting premiums of 3-7%. The public sector increasingly incorporates lifecycle cost analysis rather than focusing solely on initial investment, creating favorable conditions for carbon-negative concrete despite higher upfront costs.

Market barriers include supply chain limitations, with production capacity for carbon-negative concrete currently meeting only 4% of global concrete demand. Technical performance concerns and conservative industry practices also slow adoption, though these barriers are diminishing as more demonstration projects prove long-term performance and durability of carbon-negative alternatives.

The construction industry accounts for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created significant market pull for carbon-negative alternatives, particularly in regions with stringent carbon reduction targets. Countries implementing carbon pricing mechanisms, such as Canada, the European Union, and increasingly parts of Asia, are seeing accelerated adoption of sustainable construction materials.

Market segmentation reveals distinct customer profiles driving demand. Public infrastructure projects represent the largest market segment (38%), followed by commercial construction (27%), residential buildings (22%), and industrial facilities (13%). Government procurement policies favoring low-carbon materials have become powerful market drivers, with over 60 countries now incorporating carbon footprint considerations into public construction tenders.

Regional analysis shows Europe leading adoption with a 42% market share of sustainable construction materials, followed by North America (28%), Asia-Pacific (21%), and other regions (9%). However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, driven by rapid urbanization and increasing environmental regulations in China and India.

Consumer willingness to pay premiums for sustainable materials varies significantly by market segment. Commercial developers typically accept 5-12% price premiums for green building materials that contribute to certification standards like LEED or BREEAM, while residential consumers show more price sensitivity, generally accepting premiums of 3-7%. The public sector increasingly incorporates lifecycle cost analysis rather than focusing solely on initial investment, creating favorable conditions for carbon-negative concrete despite higher upfront costs.

Market barriers include supply chain limitations, with production capacity for carbon-negative concrete currently meeting only 4% of global concrete demand. Technical performance concerns and conservative industry practices also slow adoption, though these barriers are diminishing as more demonstration projects prove long-term performance and durability of carbon-negative alternatives.

Current State and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has made significant strides globally, yet faces substantial challenges in widespread adoption. Currently, several pioneering companies have developed functional carbon-negative concrete solutions through various approaches, including carbon capture during production, alternative cementitious materials, and carbon sequestration techniques. These technologies have demonstrated the technical feasibility of producing concrete that absorbs more carbon dioxide than it emits throughout its lifecycle.

Despite these advancements, the market penetration of carbon-negative concrete remains limited, accounting for less than 1% of global concrete production. This marginal adoption stems from multiple technical and economic barriers that continue to challenge the industry. Production scalability represents a primary obstacle, as most carbon-negative concrete technologies have been validated only in laboratory settings or small-scale demonstrations, with few achieving industrial-scale production capabilities.

Cost competitiveness presents another significant hurdle. Carbon-negative concrete typically commands a 20-40% price premium over conventional concrete, making it economically prohibitive for many construction projects, particularly in price-sensitive markets. This cost differential derives from specialized production processes, novel materials, and carbon capture technologies that have not yet achieved economies of scale.

Performance verification and standardization issues further impede adoption. The long-term durability, strength, and safety characteristics of carbon-negative concrete remain inadequately documented across diverse environmental conditions and applications. Regulatory frameworks and building codes in most countries have not fully incorporated provisions for these innovative materials, creating uncertainty for designers, engineers, and contractors considering their use.

The geographical distribution of carbon-negative concrete technology development shows notable concentration in North America and Europe, with emerging activities in China and Japan. This uneven development pattern reflects disparities in research funding, regulatory incentives, and market readiness across regions. Developing economies, despite representing the fastest-growing concrete markets globally, lag significantly in carbon-negative concrete research and implementation.

Supply chain constraints also present formidable challenges. Many carbon-negative concrete formulations rely on specialized materials with limited availability, such as specific industrial byproducts or novel binding agents. The infrastructure for carbon capture, utilization, and storage (CCUS) remains underdeveloped in most regions, creating bottlenecks in the carbon-negative concrete production process.

Technical limitations persist in optimizing the carbon absorption capacity while maintaining concrete performance. Current carbon-negative formulations typically absorb 5-15% of their weight in CO2, but theoretical models suggest potential for significantly higher absorption rates with advanced material science breakthroughs and process innovations.

Despite these advancements, the market penetration of carbon-negative concrete remains limited, accounting for less than 1% of global concrete production. This marginal adoption stems from multiple technical and economic barriers that continue to challenge the industry. Production scalability represents a primary obstacle, as most carbon-negative concrete technologies have been validated only in laboratory settings or small-scale demonstrations, with few achieving industrial-scale production capabilities.

Cost competitiveness presents another significant hurdle. Carbon-negative concrete typically commands a 20-40% price premium over conventional concrete, making it economically prohibitive for many construction projects, particularly in price-sensitive markets. This cost differential derives from specialized production processes, novel materials, and carbon capture technologies that have not yet achieved economies of scale.

Performance verification and standardization issues further impede adoption. The long-term durability, strength, and safety characteristics of carbon-negative concrete remain inadequately documented across diverse environmental conditions and applications. Regulatory frameworks and building codes in most countries have not fully incorporated provisions for these innovative materials, creating uncertainty for designers, engineers, and contractors considering their use.

The geographical distribution of carbon-negative concrete technology development shows notable concentration in North America and Europe, with emerging activities in China and Japan. This uneven development pattern reflects disparities in research funding, regulatory incentives, and market readiness across regions. Developing economies, despite representing the fastest-growing concrete markets globally, lag significantly in carbon-negative concrete research and implementation.

Supply chain constraints also present formidable challenges. Many carbon-negative concrete formulations rely on specialized materials with limited availability, such as specific industrial byproducts or novel binding agents. The infrastructure for carbon capture, utilization, and storage (CCUS) remains underdeveloped in most regions, creating bottlenecks in the carbon-negative concrete production process.

Technical limitations persist in optimizing the carbon absorption capacity while maintaining concrete performance. Current carbon-negative formulations typically absorb 5-15% of their weight in CO2, but theoretical models suggest potential for significantly higher absorption rates with advanced material science breakthroughs and process innovations.

Current Carbon-negative Concrete Formulations and Methods

01 Carbon capture and sequestration in concrete production

Technologies that capture carbon dioxide during or after concrete production, effectively sequestering CO2 in the concrete matrix. These methods transform concrete from a carbon source to a carbon sink by incorporating CO2 into the curing process or using carbonation techniques that allow concrete to absorb CO2 throughout its lifecycle, resulting in carbon-negative concrete products.- Carbon capture and sequestration in concrete production: Technologies that enable the capture and permanent sequestration of carbon dioxide during concrete manufacturing processes. These methods involve incorporating CO2 directly into concrete mixtures where it mineralizes and becomes permanently trapped, effectively turning concrete into a carbon sink. This approach can significantly reduce the carbon footprint of concrete production and potentially make it carbon-negative over its lifecycle.

- Alternative cementitious materials for reduced carbon impact: Development of novel cement formulations and alternative binders that require less energy to produce than traditional Portland cement. These materials include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts. By replacing conventional cement with these alternatives, the embodied carbon in concrete can be substantially reduced while maintaining or improving performance characteristics.

- Lifecycle assessment and monitoring systems for concrete: Advanced methodologies and digital tools for accurately measuring, tracking, and reporting the carbon footprint throughout the entire concrete lifecycle. These systems incorporate sensors, data analytics, and blockchain technology to provide transparent verification of carbon impacts from raw material extraction through manufacturing, use, and end-of-life recycling. Such monitoring enables optimization of processes to achieve carbon-negative outcomes.

- Concrete recycling and circular economy approaches: Innovative techniques for recycling and reusing concrete waste to minimize environmental impact and create closed-loop material cycles. These methods include crushing and processing end-of-life concrete for use as aggregate in new concrete, extracting and reactivating cement components, and developing design approaches that facilitate future disassembly and material recovery. These circular economy strategies significantly reduce the lifecycle carbon footprint of concrete structures.

- Biomimetic and biogenic concrete technologies: Bio-inspired concrete formulations that leverage natural biological processes to achieve carbon negativity. These include concrete that incorporates photosynthetic microorganisms, biomineralization processes that sequester carbon, and biogenic materials derived from plants or algae. By harnessing natural carbon-fixing mechanisms, these technologies can transform concrete from a carbon source to a significant carbon sink over its lifecycle.

02 Alternative cementitious materials for reduced carbon footprint

Use of alternative materials to replace traditional Portland cement, which is responsible for significant carbon emissions in concrete production. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and novel binders derived from industrial byproducts or natural materials that require less energy to produce and generate fewer emissions during manufacturing.Expand Specific Solutions03 Lifecycle assessment and carbon accounting methodologies

Systems and methods for accurately measuring, tracking, and reporting the carbon footprint throughout the entire concrete lifecycle. These technologies include digital platforms, monitoring systems, and standardized methodologies that quantify emissions from raw material extraction through manufacturing, transportation, use, and end-of-life phases, enabling verification of carbon-negative claims and supporting carbon credit generation.Expand Specific Solutions04 Circular economy approaches for concrete waste

Technologies that enable the recycling and reuse of concrete waste to reduce the environmental impact of concrete production and disposal. These include methods for processing demolished concrete into recycled aggregates, techniques for recarbonating concrete waste to sequester additional CO2, and systems for closing the material loop in concrete production, thereby reducing the need for virgin materials and associated emissions.Expand Specific Solutions05 Energy-efficient concrete production processes

Innovations in manufacturing processes that significantly reduce energy consumption and associated emissions in concrete production. These include low-temperature curing techniques, renewable energy integration in production facilities, electrification of traditionally fossil fuel-powered processes, and optimization algorithms that reduce resource consumption while maintaining or improving concrete performance characteristics.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Development

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activities and pilot implementations. Market size is expanding rapidly due to global decarbonization efforts, with projections suggesting significant growth as construction industries seek sustainable alternatives. Technologically, the field shows varying maturity levels across players. Academic institutions (Southeast University, Hong Kong Polytechnic University, Shenzhen University) are advancing fundamental research, while established companies like Huaxin Cement and X Development (formerly Google X) are developing commercial applications. Chinese companies dominate the landscape with significant investments in R&D, while Western organizations focus on innovative approaches. The ecosystem demonstrates a collaborative environment between academic institutions and industry players, accelerating the transition from laboratory research to practical implementation.

Huaxin Cement Co., Ltd.

Technical Solution: Huaxin Cement has developed a comprehensive carbon-negative concrete lifecycle management system that integrates alternative raw materials and carbon capture technologies. Their approach involves using industrial byproducts like fly ash and slag to replace traditional clinker, reducing carbon emissions by up to 30%. The company has implemented a closed-loop manufacturing process where CO2 emissions are captured during cement production and then utilized for concrete curing, effectively sequestering carbon within the final product. Their innovative carbonation curing technology accelerates the natural process of CO2 absorption, allowing concrete to absorb more carbon dioxide during its service life than emitted during production. Huaxin has also pioneered the use of biomass and waste-derived alternative fuels in their kilns, further reducing the carbon footprint of their cement production by approximately 20% compared to industry standards. Their lifecycle assessment protocols track carbon metrics from raw material extraction through end-of-life recycling, providing transparent documentation of the negative carbon balance achieved.

Strengths: Established manufacturing infrastructure allows for immediate large-scale implementation; integrated supply chain control enables consistent quality and carbon performance monitoring. Weaknesses: Higher initial production costs compared to traditional concrete; technology effectiveness varies with regional availability of alternative materials and carbon capture infrastructure.

Wisconsin Alumni Research Foundation

Technical Solution: Wisconsin Alumni Research Foundation has developed a novel carbon-negative concrete technology called "Carbicrete" that eliminates the need for cement entirely. Their approach replaces traditional Portland cement with steel slag, a byproduct of steel manufacturing, and uses CO2 for curing instead of water and heat. This process effectively sequesters approximately 150 kg of CO2 per ton of concrete produced. Their lifecycle impact assessment demonstrates that the carbon sequestration during manufacturing exceeds the emissions from material sourcing and transportation, resulting in a net negative carbon footprint. The foundation has also pioneered advanced carbonation techniques that enhance the concrete's ability to absorb additional CO2 throughout its service life. Their research includes comprehensive end-of-life strategies where demolished concrete can be crushed and used as aggregate in new carbon-negative concrete, creating a circular economy model. The technology has been validated through pilot projects showing comparable or superior mechanical properties to traditional concrete while maintaining a negative carbon balance across the entire lifecycle.

Strengths: Complete elimination of cement results in significantly higher carbon reduction potential than incremental approaches; utilizes industrial waste streams as primary inputs. Weaknesses: Requires specialized curing chambers and CO2 sourcing infrastructure; market adoption faces challenges due to established industry practices and regulatory frameworks.

Key Innovations in CO2 Sequestration for Concrete

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

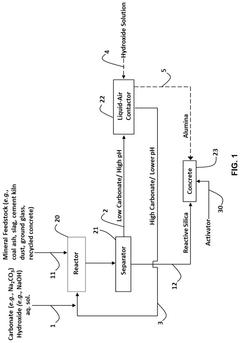

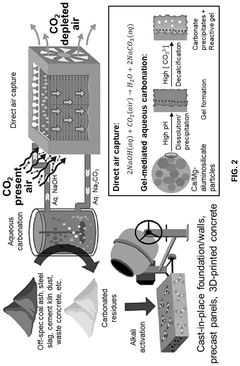

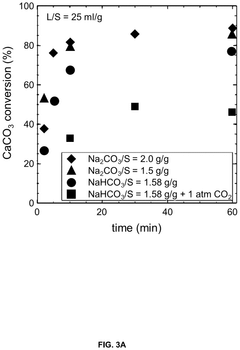

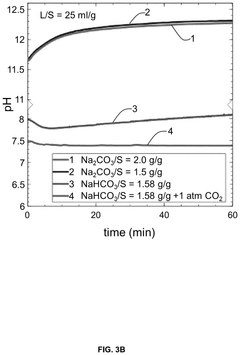

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Policy Frameworks Affecting Low-Carbon Construction

The global regulatory landscape for low-carbon construction has evolved significantly in response to climate change imperatives. The Paris Agreement established a framework requiring nations to implement policies reducing carbon emissions across all sectors, including construction. This has catalyzed the development of specific regulations targeting embodied carbon in building materials, particularly concrete, which accounts for approximately 8% of global CO2 emissions.

In the European Union, the Construction Products Regulation (CPR) has been updated to include Environmental Product Declarations (EPDs) that quantify the lifecycle environmental impacts of construction materials. The EU Taxonomy for Sustainable Activities further classifies construction activities based on their climate impact, providing financial incentives for low-carbon alternatives. The European Green Deal's Renovation Wave strategy explicitly promotes carbon-negative building materials as part of its decarbonization pathway.

North American policy frameworks vary by jurisdiction. California's Buy Clean California Act requires state-funded building projects to use materials with EPDs meeting specific Global Warming Potential thresholds. Canada's Greening Government Strategy similarly mandates lifecycle assessments for major construction projects, with preferential treatment for carbon-negative solutions.

In Asia, China's 14th Five-Year Plan includes specific targets for green building materials, while Japan's Building Energy Efficiency Act now incorporates embodied carbon considerations. Singapore's Green Mark certification system awards additional points for carbon-negative materials, creating market incentives for their adoption.

International standards like ISO 14067 (Carbon Footprint of Products) and ISO 21930 (Sustainability in Buildings and Civil Engineering Works) provide methodological frameworks for assessing the carbon impacts of concrete throughout its lifecycle. These standards are increasingly referenced in procurement policies and building codes worldwide.

Carbon pricing mechanisms are becoming integral to construction policy frameworks. The inclusion of cement production in emissions trading schemes in the EU, China, and other regions creates direct economic incentives for carbon-negative concrete technologies. Some jurisdictions have implemented carbon border adjustment mechanisms that may affect the competitiveness of imported construction materials based on their carbon intensity.

Procurement policies represent another powerful policy lever. Government green procurement programs in countries including Sweden, Netherlands, and South Korea now include specific provisions for low-carbon concrete. These policies often incorporate lifecycle assessment methodologies that can recognize and reward the carbon sequestration benefits of carbon-negative concrete formulations.

In the European Union, the Construction Products Regulation (CPR) has been updated to include Environmental Product Declarations (EPDs) that quantify the lifecycle environmental impacts of construction materials. The EU Taxonomy for Sustainable Activities further classifies construction activities based on their climate impact, providing financial incentives for low-carbon alternatives. The European Green Deal's Renovation Wave strategy explicitly promotes carbon-negative building materials as part of its decarbonization pathway.

North American policy frameworks vary by jurisdiction. California's Buy Clean California Act requires state-funded building projects to use materials with EPDs meeting specific Global Warming Potential thresholds. Canada's Greening Government Strategy similarly mandates lifecycle assessments for major construction projects, with preferential treatment for carbon-negative solutions.

In Asia, China's 14th Five-Year Plan includes specific targets for green building materials, while Japan's Building Energy Efficiency Act now incorporates embodied carbon considerations. Singapore's Green Mark certification system awards additional points for carbon-negative materials, creating market incentives for their adoption.

International standards like ISO 14067 (Carbon Footprint of Products) and ISO 21930 (Sustainability in Buildings and Civil Engineering Works) provide methodological frameworks for assessing the carbon impacts of concrete throughout its lifecycle. These standards are increasingly referenced in procurement policies and building codes worldwide.

Carbon pricing mechanisms are becoming integral to construction policy frameworks. The inclusion of cement production in emissions trading schemes in the EU, China, and other regions creates direct economic incentives for carbon-negative concrete technologies. Some jurisdictions have implemented carbon border adjustment mechanisms that may affect the competitiveness of imported construction materials based on their carbon intensity.

Procurement policies represent another powerful policy lever. Government green procurement programs in countries including Sweden, Netherlands, and South Korea now include specific provisions for low-carbon concrete. These policies often incorporate lifecycle assessment methodologies that can recognize and reward the carbon sequestration benefits of carbon-negative concrete formulations.

Lifecycle Assessment Methodologies for Carbon-negative Materials

Lifecycle Assessment Methodologies for Carbon-negative Materials represents a critical framework for evaluating the environmental performance of innovative construction materials like carbon-negative concrete. These methodologies employ systematic approaches to quantify environmental impacts throughout a material's entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

The ISO 14040 and 14044 standards provide the foundational structure for conducting comprehensive lifecycle assessments (LCAs) of carbon-negative concrete. These assessments typically follow four distinct phases: goal and scope definition, inventory analysis, impact assessment, and interpretation. For carbon-negative materials, particular emphasis must be placed on carbon accounting methodologies that accurately capture both emissions and sequestration.

Process-based LCA represents the traditional approach, tracking material and energy flows through each production stage. However, this method often struggles with system boundary definition when assessing novel materials like carbon-negative concrete. Economic Input-Output LCA offers a complementary approach by utilizing economic transaction data to estimate environmental impacts, though it may lack the specificity required for innovative materials.

Hybrid LCA methodologies combine these approaches to leverage their respective strengths, particularly valuable for carbon-negative concrete where both direct process emissions and broader supply chain impacts must be considered. Dynamic LCA further enhances assessment by incorporating temporal factors, essential for materials that sequester carbon over extended timeframes.

Carbon accounting within these assessments requires particular attention to biogenic carbon flows, carbonation processes, and long-term sequestration stability. Methodological challenges include allocation procedures for multi-output processes, defining appropriate functional units that reflect performance characteristics, and establishing suitable system boundaries that capture relevant upstream and downstream processes.

Emerging methodologies incorporate uncertainty analysis through Monte Carlo simulations and sensitivity analyses to address data limitations common in novel materials. Additionally, consequential LCA approaches are gaining prominence for their ability to assess market-mediated effects of widespread carbon-negative concrete adoption.

Standardization efforts are advancing to establish consistent carbon accounting protocols specifically for carbon-negative materials, with organizations like the World Resources Institute and International EPD System developing specialized Product Category Rules (PCRs) for concrete products with carbon sequestration properties.

The ISO 14040 and 14044 standards provide the foundational structure for conducting comprehensive lifecycle assessments (LCAs) of carbon-negative concrete. These assessments typically follow four distinct phases: goal and scope definition, inventory analysis, impact assessment, and interpretation. For carbon-negative materials, particular emphasis must be placed on carbon accounting methodologies that accurately capture both emissions and sequestration.

Process-based LCA represents the traditional approach, tracking material and energy flows through each production stage. However, this method often struggles with system boundary definition when assessing novel materials like carbon-negative concrete. Economic Input-Output LCA offers a complementary approach by utilizing economic transaction data to estimate environmental impacts, though it may lack the specificity required for innovative materials.

Hybrid LCA methodologies combine these approaches to leverage their respective strengths, particularly valuable for carbon-negative concrete where both direct process emissions and broader supply chain impacts must be considered. Dynamic LCA further enhances assessment by incorporating temporal factors, essential for materials that sequester carbon over extended timeframes.

Carbon accounting within these assessments requires particular attention to biogenic carbon flows, carbonation processes, and long-term sequestration stability. Methodological challenges include allocation procedures for multi-output processes, defining appropriate functional units that reflect performance characteristics, and establishing suitable system boundaries that capture relevant upstream and downstream processes.

Emerging methodologies incorporate uncertainty analysis through Monte Carlo simulations and sensitivity analyses to address data limitations common in novel materials. Additionally, consequential LCA approaches are gaining prominence for their ability to assess market-mediated effects of widespread carbon-negative concrete adoption.

Standardization efforts are advancing to establish consistent carbon accounting protocols specifically for carbon-negative materials, with organizations like the World Resources Institute and International EPD System developing specialized Product Category Rules (PCRs) for concrete products with carbon sequestration properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!