Strategic Materials in the Formulation of Carbon-negative Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete, the most widely used construction material globally, has traditionally been associated with significant carbon emissions, primarily due to the production of Portland cement. As the construction industry faces increasing pressure to reduce its environmental footprint, carbon-negative concrete has emerged as a revolutionary solution that not only minimizes emissions but actively sequesters carbon dioxide from the atmosphere. This technological advancement represents a paradigm shift in sustainable construction materials.

The evolution of concrete technology has progressed from conventional high-emission formulations to low-carbon alternatives, and now to carbon-negative variants. This progression reflects the industry's response to global climate challenges and regulatory pressures. Carbon-negative concrete technology builds upon decades of research in alternative cementitious materials, carbon capture techniques, and innovative aggregate solutions, representing the convergence of multiple scientific disciplines.

The primary objective of carbon-negative concrete development is to create a construction material that permanently sequesters more carbon dioxide than is emitted during its production and use. This ambitious goal requires fundamental rethinking of concrete's composition, manufacturing processes, and application methods. Secondary objectives include maintaining or enhancing the mechanical properties, durability, and cost-effectiveness of traditional concrete while dramatically improving its environmental profile.

Current technological trajectories indicate several promising approaches to carbon-negative concrete, including the incorporation of industrial byproducts like fly ash and slag, the use of novel binders such as geopolymers and alkali-activated materials, and the integration of carbon-sequestering aggregates. These approaches are complemented by innovations in carbon capture during the curing process, which transforms CO2 into stable carbonate minerals within the concrete matrix.

The development of carbon-negative concrete aligns with broader sustainability initiatives, including circular economy principles and decarbonization strategies across industries. As governments worldwide implement stricter carbon regulations and incentivize green building practices, the market demand for carbon-negative construction materials is projected to accelerate significantly in the coming decades.

Technical challenges remain in scaling production, standardizing formulations, and ensuring long-term performance under various environmental conditions. However, recent breakthroughs in material science and process engineering suggest that these obstacles are increasingly surmountable. The ultimate goal is to transform concrete from one of the largest contributors to global carbon emissions into a net carbon sink, fundamentally altering the environmental impact of the built environment.

The evolution of concrete technology has progressed from conventional high-emission formulations to low-carbon alternatives, and now to carbon-negative variants. This progression reflects the industry's response to global climate challenges and regulatory pressures. Carbon-negative concrete technology builds upon decades of research in alternative cementitious materials, carbon capture techniques, and innovative aggregate solutions, representing the convergence of multiple scientific disciplines.

The primary objective of carbon-negative concrete development is to create a construction material that permanently sequesters more carbon dioxide than is emitted during its production and use. This ambitious goal requires fundamental rethinking of concrete's composition, manufacturing processes, and application methods. Secondary objectives include maintaining or enhancing the mechanical properties, durability, and cost-effectiveness of traditional concrete while dramatically improving its environmental profile.

Current technological trajectories indicate several promising approaches to carbon-negative concrete, including the incorporation of industrial byproducts like fly ash and slag, the use of novel binders such as geopolymers and alkali-activated materials, and the integration of carbon-sequestering aggregates. These approaches are complemented by innovations in carbon capture during the curing process, which transforms CO2 into stable carbonate minerals within the concrete matrix.

The development of carbon-negative concrete aligns with broader sustainability initiatives, including circular economy principles and decarbonization strategies across industries. As governments worldwide implement stricter carbon regulations and incentivize green building practices, the market demand for carbon-negative construction materials is projected to accelerate significantly in the coming decades.

Technical challenges remain in scaling production, standardizing formulations, and ensuring long-term performance under various environmental conditions. However, recent breakthroughs in material science and process engineering suggest that these obstacles are increasingly surmountable. The ultimate goal is to transform concrete from one of the largest contributors to global carbon emissions into a net carbon sink, fundamentally altering the environmental impact of the built environment.

Market Analysis for Carbon-negative Construction Materials

The global market for carbon-negative construction materials, particularly carbon-negative concrete, is experiencing unprecedented growth driven by increasing environmental regulations and sustainability commitments across the construction industry. Current market valuations indicate that the green concrete market reached approximately $26.2 billion in 2021 and is projected to grow at a CAGR of 9.1% through 2030, with carbon-negative variants representing the fastest-growing segment within this category.

Regionally, Europe leads the adoption of carbon-negative concrete technologies, accounting for roughly 38% of the global market share. This dominance stems from stringent EU carbon regulations and ambitious climate targets set by countries like Germany, France, and the Nordic nations. North America follows with approximately 29% market share, with particularly strong growth in states with progressive climate policies such as California and New York.

The Asia-Pacific region, while currently representing about 24% of the market, is projected to witness the highest growth rate over the next decade. China's recent commitment to carbon neutrality by 2060 has significantly accelerated investments in sustainable construction materials, while countries like Singapore and Japan have implemented green building standards that specifically incentivize carbon-negative materials.

Demand drivers for carbon-negative concrete extend beyond regulatory compliance. Corporate sustainability commitments have emerged as a powerful market force, with over 60% of Fortune 500 companies now having established net-zero targets that include their building and infrastructure projects. Additionally, the growing influence of green building certification systems like LEED, BREEAM, and WELL has created premium market segments where carbon-negative materials command price premiums of 15-30% over conventional alternatives.

Consumer awareness and preferences are also shifting dramatically. Recent market surveys indicate that 73% of commercial property developers now consider carbon footprint in material selection decisions, up from just 31% five years ago. This shift is particularly pronounced in high-visibility projects such as corporate headquarters, public buildings, and luxury residential developments.

The economic viability of carbon-negative concrete continues to improve as production scales and technologies mature. While early carbon-negative concrete formulations carried a cost premium of 50-100% over traditional concrete, current market leaders have reduced this premium to 20-35% through process optimization and strategic material sourcing. Industry analysts project price parity with conventional concrete could be achieved in select markets by 2028, potentially triggering exponential market growth.

Regionally, Europe leads the adoption of carbon-negative concrete technologies, accounting for roughly 38% of the global market share. This dominance stems from stringent EU carbon regulations and ambitious climate targets set by countries like Germany, France, and the Nordic nations. North America follows with approximately 29% market share, with particularly strong growth in states with progressive climate policies such as California and New York.

The Asia-Pacific region, while currently representing about 24% of the market, is projected to witness the highest growth rate over the next decade. China's recent commitment to carbon neutrality by 2060 has significantly accelerated investments in sustainable construction materials, while countries like Singapore and Japan have implemented green building standards that specifically incentivize carbon-negative materials.

Demand drivers for carbon-negative concrete extend beyond regulatory compliance. Corporate sustainability commitments have emerged as a powerful market force, with over 60% of Fortune 500 companies now having established net-zero targets that include their building and infrastructure projects. Additionally, the growing influence of green building certification systems like LEED, BREEAM, and WELL has created premium market segments where carbon-negative materials command price premiums of 15-30% over conventional alternatives.

Consumer awareness and preferences are also shifting dramatically. Recent market surveys indicate that 73% of commercial property developers now consider carbon footprint in material selection decisions, up from just 31% five years ago. This shift is particularly pronounced in high-visibility projects such as corporate headquarters, public buildings, and luxury residential developments.

The economic viability of carbon-negative concrete continues to improve as production scales and technologies mature. While early carbon-negative concrete formulations carried a cost premium of 50-100% over traditional concrete, current market leaders have reduced this premium to 20-35% through process optimization and strategic material sourcing. Industry analysts project price parity with conventional concrete could be achieved in select markets by 2028, potentially triggering exponential market growth.

Current Status and Challenges in Carbon-negative Concrete Development

The development of carbon-negative concrete is currently at a critical juncture, with significant advancements in research but limited large-scale commercial implementation. Leading research institutions in North America, Europe, and Asia have demonstrated the technical feasibility of concrete formulations that can sequester more carbon than emitted during production, primarily through innovative binding materials and carbonation processes.

The primary technical challenge facing carbon-negative concrete development is achieving comparable mechanical properties to traditional Portland cement concrete while maintaining carbon negativity. Current formulations often exhibit lower early-stage strength development, which limits their application in structural components requiring rapid construction timelines. Additionally, long-term durability under various environmental conditions remains insufficiently validated, creating barriers to widespread adoption in critical infrastructure projects.

Material availability presents another significant challenge, as many carbon-negative formulations rely on industrial byproducts such as fly ash, slag, and silica fume, which have variable regional availability and inconsistent chemical compositions. The supply chain for these supplementary cementitious materials (SCMs) is not yet robust enough to support large-scale transition to carbon-negative concrete production globally.

Standardization and regulatory frameworks lag behind technological development, with building codes in most countries still oriented toward traditional concrete specifications. This regulatory gap creates uncertainty for designers and contractors considering carbon-negative alternatives, as performance criteria and testing protocols specific to these materials remain underdeveloped.

Cost factors continue to impede widespread adoption, with current carbon-negative formulations typically commanding a 15-30% premium over conventional concrete. This cost differential is primarily driven by specialized material sourcing, additional processing requirements, and economies of scale limitations. Without carbon pricing mechanisms or regulatory mandates, market penetration remains constrained by economic considerations.

Geographically, research leadership is distributed across multiple regions, with notable centers of excellence in the Netherlands, Australia, Canada, and the United States. Commercial implementation has been most advanced in Northern Europe, where supportive policy frameworks and carbon pricing mechanisms have created more favorable market conditions for innovative concrete technologies.

The knowledge gap between laboratory research and field implementation represents a persistent challenge, with many promising formulations demonstrating excellent performance under controlled conditions but encountering unexpected variables in real-world applications. This translational research deficit has slowed the technology readiness level advancement of several promising approaches.

The primary technical challenge facing carbon-negative concrete development is achieving comparable mechanical properties to traditional Portland cement concrete while maintaining carbon negativity. Current formulations often exhibit lower early-stage strength development, which limits their application in structural components requiring rapid construction timelines. Additionally, long-term durability under various environmental conditions remains insufficiently validated, creating barriers to widespread adoption in critical infrastructure projects.

Material availability presents another significant challenge, as many carbon-negative formulations rely on industrial byproducts such as fly ash, slag, and silica fume, which have variable regional availability and inconsistent chemical compositions. The supply chain for these supplementary cementitious materials (SCMs) is not yet robust enough to support large-scale transition to carbon-negative concrete production globally.

Standardization and regulatory frameworks lag behind technological development, with building codes in most countries still oriented toward traditional concrete specifications. This regulatory gap creates uncertainty for designers and contractors considering carbon-negative alternatives, as performance criteria and testing protocols specific to these materials remain underdeveloped.

Cost factors continue to impede widespread adoption, with current carbon-negative formulations typically commanding a 15-30% premium over conventional concrete. This cost differential is primarily driven by specialized material sourcing, additional processing requirements, and economies of scale limitations. Without carbon pricing mechanisms or regulatory mandates, market penetration remains constrained by economic considerations.

Geographically, research leadership is distributed across multiple regions, with notable centers of excellence in the Netherlands, Australia, Canada, and the United States. Commercial implementation has been most advanced in Northern Europe, where supportive policy frameworks and carbon pricing mechanisms have created more favorable market conditions for innovative concrete technologies.

The knowledge gap between laboratory research and field implementation represents a persistent challenge, with many promising formulations demonstrating excellent performance under controlled conditions but encountering unexpected variables in real-world applications. This translational research deficit has slowed the technology readiness level advancement of several promising approaches.

Current Strategic Material Solutions for Carbon-negative Concrete

01 Carbon capture and sequestration in concrete production

Technologies that capture and store carbon dioxide during the concrete manufacturing process, effectively making the concrete carbon-negative. These methods involve injecting CO2 into concrete during curing, where it becomes permanently mineralized and enhances the material's strength. This approach not only reduces the carbon footprint of concrete production but can transform concrete into a carbon sink.- Carbon capture and sequestration in concrete production: Technologies that capture and store carbon dioxide during the concrete manufacturing process, effectively making the concrete carbon-negative. These methods involve incorporating CO2 during the curing process, where the gas reacts with calcium compounds to form stable carbonates, permanently sequestering carbon within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can potentially transform concrete into a carbon sink.

- Alternative cementitious materials for carbon reduction: The use of alternative materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include supplementary cementitious materials like fly ash, slag, silica fume, and natural pozzolans that require less energy to produce and generate fewer emissions. Some innovative formulations incorporate industrial byproducts or waste materials, further reducing the environmental impact while maintaining or improving concrete performance characteristics.

- Carbon mineralization technologies: Processes that accelerate the natural carbonation of minerals to capture and store CO2. These technologies involve exposing calcium or magnesium-rich materials to carbon dioxide, resulting in the formation of stable carbonate minerals. When applied to concrete production or recycling, carbon mineralization can significantly reduce the net carbon footprint. Some approaches use industrial waste streams as feedstock for mineralization, providing dual environmental benefits.

- Biomass incorporation and biogenic materials: The integration of biomass or biogenic materials into concrete formulations to reduce carbon emissions. These approaches include incorporating plant-based materials, agricultural residues, or biochar into concrete mixes. Since these materials have sequestered carbon during their growth phase, their inclusion effectively transfers this stored carbon into the concrete. Some formulations also utilize bio-based binders or additives that further enhance the carbon-negative properties of the resulting concrete.

- Energy-efficient production methods and renewable energy integration: Innovative production techniques that significantly reduce energy consumption during concrete manufacturing, coupled with the integration of renewable energy sources. These methods include low-temperature cement synthesis, advanced grinding technologies, and optimized kiln designs. By powering these processes with renewable energy, the carbon footprint is further reduced. Some approaches also incorporate waste heat recovery systems and smart process controls to maximize energy efficiency throughout the production cycle.

02 Alternative cementitious materials for carbon reduction

Development of novel cement alternatives that require less energy to produce and generate fewer emissions than traditional Portland cement. These materials include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts. By replacing conventional cement with these alternatives, concrete can achieve carbon neutrality or even carbon negativity while maintaining or improving performance characteristics.Expand Specific Solutions03 Biomass incorporation for carbon sequestration

Integration of biomass materials into concrete formulations to enhance carbon sequestration capabilities. These biomass additives, which may include agricultural waste, wood products, or algae-based materials, store carbon that was previously removed from the atmosphere through photosynthesis. When incorporated into concrete, these materials create a permanent carbon sink while potentially improving certain concrete properties like thermal insulation.Expand Specific Solutions04 Enhanced carbonation techniques for concrete

Advanced methods to accelerate and maximize the natural carbonation process in concrete, where atmospheric CO2 reacts with calcium hydroxide to form calcium carbonate. These techniques include controlled exposure environments, catalysts, and specialized curing processes that promote carbon uptake throughout the concrete's lifecycle. By optimizing this process, concrete structures can absorb significant amounts of CO2 over time.Expand Specific Solutions05 Carbon-negative concrete lifecycle management

Comprehensive approaches to achieving carbon negativity across the entire concrete lifecycle, from raw material sourcing to end-of-life recycling. These systems integrate multiple carbon reduction strategies including renewable energy use in production, carbon capture during manufacturing, optimization of concrete mix designs, and enhanced end-of-life carbon sequestration. This holistic approach ensures that concrete removes more carbon from the atmosphere than is emitted throughout its lifecycle.Expand Specific Solutions

Key Industry Players in Carbon-negative Concrete Market

Carbon-negative concrete technology is in an early growth phase, with significant market potential driven by global decarbonization efforts. The market is expanding rapidly as construction industries seek sustainable alternatives to traditional cement, which accounts for approximately 8% of global CO2 emissions. The competitive landscape features a mix of established players and innovative startups. Companies like Holcim Technology, Lafarge, and Bouygues represent traditional industry giants adapting to sustainability demands, while specialized innovators such as Carbonbuilt, Biozeroc, Carbon Limit, and Carbicrete are developing proprietary carbon-negative concrete technologies. Academic institutions including Worcester Polytechnic Institute, Southeast University, and University of South Carolina are advancing research in this field. The technology is approaching commercial viability, with several companies demonstrating scalable solutions that can achieve 70-100% reduction in embodied carbon while maintaining structural performance comparable to conventional concrete.

Carbonbuilt, Inc.

Technical Solution: Carbonbuilt has developed a revolutionary concrete curing technology that directly utilizes dilute CO2 from industrial sources or directly from the air, eliminating the need for carbon capture concentration steps. Their Reversa™ process replaces up to 50% of traditional Portland cement with a proprietary mix of widely available low-cost materials, significantly reducing embodied carbon. During concrete curing, the technology chemically transforms and permanently embeds CO2 into the concrete matrix, forming stable calcium carbonate compounds that contribute to the material's strength. The process can operate using CO2 concentrations as low as 0.1%, making it compatible with direct flue gas from industrial facilities without requiring energy-intensive purification. Each concrete product made with Carbonbuilt's technology can reduce carbon emissions by 100-150 pounds per ton compared to traditional concrete. The technology is particularly innovative as it works with existing concrete manufacturing equipment, requiring minimal capital investment for implementation, and produces concrete that meets or exceeds industry performance standards.

Strengths: Works with dilute CO2 sources without concentration requirements; compatible with existing manufacturing equipment; reduces cement content while maintaining performance; economically viable without carbon credits. Weaknesses: Still requires some Portland cement in the mix; CO2 absorption capacity limited by formulation constraints; requires proximity to CO2 sources for optimal implementation; technology scaling still in progress.

Biozeroc Ltd.

Technical Solution: Biozeroc has developed an innovative carbon-negative concrete formulation that incorporates biochar derived from agricultural and forestry waste as a strategic material. Their proprietary process involves pyrolyzing biomass under controlled conditions to produce highly porous biochar that is then functionalized and incorporated into concrete mixtures. The biochar serves multiple functions: it acts as a partial cement replacement, provides internal curing through its water retention properties, and permanently sequesters carbon that was originally captured from the atmosphere through photosynthesis. Biozeroc's technology also includes a specialized admixture system that enhances the interfacial bonding between biochar particles and the cement matrix, improving mechanical performance while maintaining workability. The resulting concrete can sequester up to 25kg of CO2 equivalent per cubic meter, while simultaneously reducing the cement content by 20-30%. Additionally, their formulation incorporates other supplementary cementitious materials like calcined clays and industrial byproducts to further reduce the carbon footprint of the final product.

Strengths: Creates permanent carbon sequestration through biochar incorporation; utilizes agricultural waste streams; improves concrete's thermal insulation properties; reduces cement content significantly. Weaknesses: Biochar quality variability affects performance consistency; limited large-scale production capacity; potential impact on long-term durability still being studied; higher material costs compared to conventional concrete.

Critical Patents and Innovations in Carbon-negative Concrete Materials

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Cementitious materials and methods of making and using same

PatentWO2025030083A1

Innovation

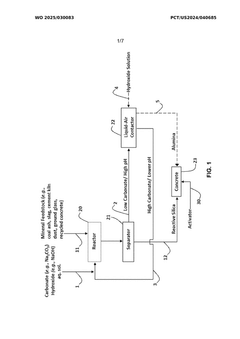

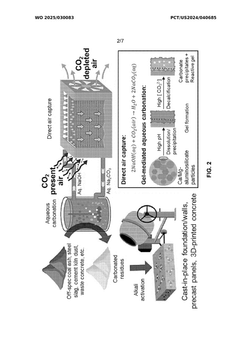

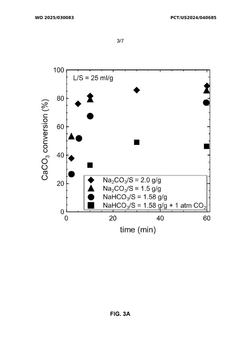

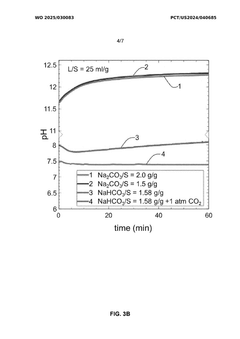

- The method involves a carbon mineralization-based direct-air capture process using an aqueous carbonation cycle to capture CO2 from the air and enhance the pozzolanic reactivity of industrial mineral wastes, which are then used to produce carbon-negative cementitious materials that can replace or reduce Portland cement in concrete production.

Environmental Impact Assessment and Carbon Accounting Methodologies

The assessment of environmental impact and carbon accounting methodologies is crucial for validating the carbon-negative claims of concrete formulations. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making accurate measurement methodologies essential for evaluating alternative solutions.

Life Cycle Assessment (LCA) represents the gold standard for environmental impact evaluation of carbon-negative concrete. This methodology examines impacts across the entire product lifecycle—from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. For carbon-negative concrete, LCA must account for both emissions generated during production and CO2 sequestered within the material over its lifetime.

Carbon accounting methodologies specifically tailored for construction materials have evolved significantly in recent years. The Greenhouse Gas Protocol provides standardized frameworks that many organizations adopt, while ISO 14067 offers specific guidelines for calculating the carbon footprint of products. These frameworks must be adapted to address the unique characteristics of carbon-negative concrete, particularly its capacity for long-term carbon sequestration.

Emerging methodologies incorporate dynamic carbon accounting, which considers the temporal dimension of carbon sequestration. This approach recognizes that carbon-negative concrete continues to absorb CO2 throughout its service life, with absorption rates varying based on exposure conditions and material composition. Advanced models now integrate these time-dependent factors to provide more accurate assessments of net carbon impact.

Boundary definition represents a significant challenge in environmental assessment of carbon-negative concrete. Practitioners must determine whether to include indirect emissions from supply chains, transportation logistics, and end-of-life scenarios. The choice of system boundaries dramatically influences the calculated environmental footprint and can lead to inconsistent comparisons between different concrete formulations.

Verification and certification systems are developing to validate carbon-negative claims. These include third-party verification protocols that ensure methodological consistency and prevent greenwashing. Organizations like the Carbon Trust and various green building certification programs have begun establishing specific criteria for carbon-negative materials, though standardization remains incomplete.

Future developments in carbon accounting for concrete will likely incorporate real-time monitoring technologies. Embedded sensors capable of measuring ongoing carbonation rates could provide continuous data on carbon sequestration, enabling more accurate lifetime assessments and potentially creating opportunities for carbon credit generation based on verified sequestration.

Life Cycle Assessment (LCA) represents the gold standard for environmental impact evaluation of carbon-negative concrete. This methodology examines impacts across the entire product lifecycle—from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. For carbon-negative concrete, LCA must account for both emissions generated during production and CO2 sequestered within the material over its lifetime.

Carbon accounting methodologies specifically tailored for construction materials have evolved significantly in recent years. The Greenhouse Gas Protocol provides standardized frameworks that many organizations adopt, while ISO 14067 offers specific guidelines for calculating the carbon footprint of products. These frameworks must be adapted to address the unique characteristics of carbon-negative concrete, particularly its capacity for long-term carbon sequestration.

Emerging methodologies incorporate dynamic carbon accounting, which considers the temporal dimension of carbon sequestration. This approach recognizes that carbon-negative concrete continues to absorb CO2 throughout its service life, with absorption rates varying based on exposure conditions and material composition. Advanced models now integrate these time-dependent factors to provide more accurate assessments of net carbon impact.

Boundary definition represents a significant challenge in environmental assessment of carbon-negative concrete. Practitioners must determine whether to include indirect emissions from supply chains, transportation logistics, and end-of-life scenarios. The choice of system boundaries dramatically influences the calculated environmental footprint and can lead to inconsistent comparisons between different concrete formulations.

Verification and certification systems are developing to validate carbon-negative claims. These include third-party verification protocols that ensure methodological consistency and prevent greenwashing. Organizations like the Carbon Trust and various green building certification programs have begun establishing specific criteria for carbon-negative materials, though standardization remains incomplete.

Future developments in carbon accounting for concrete will likely incorporate real-time monitoring technologies. Embedded sensors capable of measuring ongoing carbonation rates could provide continuous data on carbon sequestration, enabling more accurate lifetime assessments and potentially creating opportunities for carbon credit generation based on verified sequestration.

Regulatory Framework and Policy Incentives for Carbon-negative Materials

The regulatory landscape for carbon-negative concrete is evolving rapidly as governments worldwide recognize the critical role of construction materials in climate change mitigation. The European Union leads with its ambitious European Green Deal, which includes specific provisions for low-carbon building materials through the Construction Products Regulation (CPR) and the EU Emissions Trading System (ETS). These frameworks increasingly incorporate carbon-negative materials, offering financial incentives and market advantages for early adopters.

In North America, the United States has implemented the 45Q tax credit, providing up to $50 per metric ton of CO2 sequestered, directly benefiting carbon-negative concrete producers. The Inflation Reduction Act of 2022 further expanded these incentives, allocating substantial funding for sustainable building materials. Canada's Clean Fuel Standard and provincial carbon pricing mechanisms similarly create economic drivers for carbon-negative construction materials.

The Asia-Pacific region demonstrates varied approaches, with China's national emissions trading scheme gradually incorporating building materials sectors, while Singapore's Green Mark certification system offers tangible benefits for projects utilizing carbon-negative concrete. Japan's carbon pricing mechanisms and India's Perform, Achieve, and Trade (PAT) scheme represent emerging policy frameworks with significant implications for carbon-negative materials.

International standards and certification systems play a crucial role in market development. The International Organization for Standardization (ISO) is developing specific standards for carbon-negative materials, while green building certification programs like LEED, BREEAM, and WELL increasingly award additional points for carbon-negative material usage, creating market pull for these innovative products.

Public procurement policies represent perhaps the most powerful near-term driver for carbon-negative concrete adoption. The "Buy Clean" initiatives in California and other jurisdictions establish carbon intensity thresholds for materials used in public projects, while the EU's Green Public Procurement guidelines increasingly favor carbon-negative solutions. These procurement frameworks create guaranteed markets for innovative materials, reducing investment risk and accelerating commercialization.

Financial mechanisms supporting carbon-negative materials include green bonds specifically targeting sustainable infrastructure, concessional financing from development banks, and specialized venture capital focused on climate-tech materials. These funding sources are increasingly aligned with taxonomies that explicitly recognize carbon-negative materials as sustainable investments, facilitating capital flow to this emerging sector.

In North America, the United States has implemented the 45Q tax credit, providing up to $50 per metric ton of CO2 sequestered, directly benefiting carbon-negative concrete producers. The Inflation Reduction Act of 2022 further expanded these incentives, allocating substantial funding for sustainable building materials. Canada's Clean Fuel Standard and provincial carbon pricing mechanisms similarly create economic drivers for carbon-negative construction materials.

The Asia-Pacific region demonstrates varied approaches, with China's national emissions trading scheme gradually incorporating building materials sectors, while Singapore's Green Mark certification system offers tangible benefits for projects utilizing carbon-negative concrete. Japan's carbon pricing mechanisms and India's Perform, Achieve, and Trade (PAT) scheme represent emerging policy frameworks with significant implications for carbon-negative materials.

International standards and certification systems play a crucial role in market development. The International Organization for Standardization (ISO) is developing specific standards for carbon-negative materials, while green building certification programs like LEED, BREEAM, and WELL increasingly award additional points for carbon-negative material usage, creating market pull for these innovative products.

Public procurement policies represent perhaps the most powerful near-term driver for carbon-negative concrete adoption. The "Buy Clean" initiatives in California and other jurisdictions establish carbon intensity thresholds for materials used in public projects, while the EU's Green Public Procurement guidelines increasingly favor carbon-negative solutions. These procurement frameworks create guaranteed markets for innovative materials, reducing investment risk and accelerating commercialization.

Financial mechanisms supporting carbon-negative materials include green bonds specifically targeting sustainable infrastructure, concessional financing from development banks, and specialized venture capital focused on climate-tech materials. These funding sources are increasingly aligned with taxonomies that explicitly recognize carbon-negative materials as sustainable investments, facilitating capital flow to this emerging sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!