Defining Quality Assurance Metrics for Carbon-negative Concrete

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, emerging as a response to the significant carbon footprint of traditional cement production. Conventional concrete manufacturing accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. The evolution of carbon-negative concrete technology began in the early 2000s with initial research into alternative cementitious materials, but has gained substantial momentum over the past decade as climate change mitigation has become a global priority.

The technological trajectory has progressed from carbon-neutral formulations to truly carbon-negative solutions that actively sequester CO2 during the production process. This evolution has been marked by key innovations in material science, including the development of novel binders, alternative aggregates, and carbon capture methodologies specifically designed for concrete applications. Recent breakthroughs in mineralization processes have enabled the permanent chemical binding of CO2 within the concrete matrix, transforming a climate liability into a potential carbon sink.

The primary objective of carbon-negative concrete technology is to revolutionize the construction industry by providing structural materials that maintain or exceed the performance characteristics of traditional concrete while dramatically reducing environmental impact. Specific technical goals include achieving compressive strength comparable to Portland cement concrete (30-40 MPa), ensuring durability under various environmental conditions, and demonstrating carbon sequestration capacity of at least 100kg CO2 per ton of concrete produced.

Secondary objectives focus on scalability and economic viability, as widespread adoption requires production processes compatible with existing manufacturing infrastructure. The technology aims to achieve cost parity with conventional concrete within the next decade, recognizing that market penetration depends on competitive pricing even with carbon pricing mechanisms in place.

Quality assurance metrics represent a critical frontier in this field, as standardized testing protocols and performance benchmarks are essential for industry acceptance and regulatory approval. The development of these metrics must address both traditional concrete performance parameters and novel characteristics specific to carbon-negative formulations, including carbon sequestration verification, long-term carbon retention stability, and lifecycle assessment methodologies.

The technology's development is increasingly influenced by policy frameworks supporting decarbonization, including carbon pricing, green building standards, and government procurement policies that favor low-carbon construction materials. These drivers are accelerating research investment and commercial deployment, creating a favorable environment for continued innovation in carbon-negative concrete technologies.

The technological trajectory has progressed from carbon-neutral formulations to truly carbon-negative solutions that actively sequester CO2 during the production process. This evolution has been marked by key innovations in material science, including the development of novel binders, alternative aggregates, and carbon capture methodologies specifically designed for concrete applications. Recent breakthroughs in mineralization processes have enabled the permanent chemical binding of CO2 within the concrete matrix, transforming a climate liability into a potential carbon sink.

The primary objective of carbon-negative concrete technology is to revolutionize the construction industry by providing structural materials that maintain or exceed the performance characteristics of traditional concrete while dramatically reducing environmental impact. Specific technical goals include achieving compressive strength comparable to Portland cement concrete (30-40 MPa), ensuring durability under various environmental conditions, and demonstrating carbon sequestration capacity of at least 100kg CO2 per ton of concrete produced.

Secondary objectives focus on scalability and economic viability, as widespread adoption requires production processes compatible with existing manufacturing infrastructure. The technology aims to achieve cost parity with conventional concrete within the next decade, recognizing that market penetration depends on competitive pricing even with carbon pricing mechanisms in place.

Quality assurance metrics represent a critical frontier in this field, as standardized testing protocols and performance benchmarks are essential for industry acceptance and regulatory approval. The development of these metrics must address both traditional concrete performance parameters and novel characteristics specific to carbon-negative formulations, including carbon sequestration verification, long-term carbon retention stability, and lifecycle assessment methodologies.

The technology's development is increasingly influenced by policy frameworks supporting decarbonization, including carbon pricing, green building standards, and government procurement policies that favor low-carbon construction materials. These drivers are accelerating research investment and commercial deployment, creating a favorable environment for continued innovation in carbon-negative concrete technologies.

Market Analysis for Carbon-negative Concrete Products

The global market for carbon-negative concrete products is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market size estimates place the green concrete sector at approximately $30 billion globally, with carbon-negative variants representing an emerging segment projected to grow at a compound annual rate of 9.2% through 2030. This growth trajectory significantly outpaces traditional concrete markets, which maintain steady but modest 3-4% annual expansion.

Demand patterns show notable regional variations, with European markets demonstrating the highest adoption rates for carbon-negative concrete products, followed by North America and developed Asian economies. The European market benefits from stringent carbon regulations and well-established carbon pricing mechanisms that create economic incentives for low-carbon building materials. Particularly strong demand exists in Scandinavian countries, Germany, and the Netherlands, where government procurement policies actively favor carbon-negative building materials.

Market segmentation reveals that commercial construction represents the largest current application segment (42% of carbon-negative concrete usage), followed by public infrastructure projects (31%) and residential construction (18%). The remaining market share is distributed across specialized applications including marine construction and precast concrete products. Premium pricing remains a significant market characteristic, with carbon-negative concrete products commanding 15-25% price premiums over conventional alternatives.

Consumer willingness to pay these premiums varies substantially across market segments. Large commercial developers with explicit ESG commitments demonstrate the highest acceptance of premium pricing, while price sensitivity remains higher in residential and small commercial segments. This differential creates distinct market entry opportunities for producers targeting specific construction sectors.

Key market drivers include tightening building codes and environmental regulations, growing corporate carbon neutrality commitments, and increasing investor pressure for sustainable construction practices. The implementation of carbon border adjustment mechanisms in major economies is expected to further accelerate market adoption by creating economic penalties for carbon-intensive imported building materials.

Market barriers include persistent cost premiums, technical performance concerns among conservative industry stakeholders, and limited production capacity for key carbon-negative concrete ingredients. Supply chain constraints for materials like supplementary cementitious materials (SCMs) and carbon capture technologies represent significant limiting factors for market expansion in the near term.

Forecasts indicate that market growth will accelerate as production scales and costs decline, with carbon-negative concrete potentially capturing 12-15% of the global concrete market by 2035. This transition will be accelerated by regulatory support, technological improvements in carbon sequestration methods, and growing market acceptance of these innovative building materials.

Demand patterns show notable regional variations, with European markets demonstrating the highest adoption rates for carbon-negative concrete products, followed by North America and developed Asian economies. The European market benefits from stringent carbon regulations and well-established carbon pricing mechanisms that create economic incentives for low-carbon building materials. Particularly strong demand exists in Scandinavian countries, Germany, and the Netherlands, where government procurement policies actively favor carbon-negative building materials.

Market segmentation reveals that commercial construction represents the largest current application segment (42% of carbon-negative concrete usage), followed by public infrastructure projects (31%) and residential construction (18%). The remaining market share is distributed across specialized applications including marine construction and precast concrete products. Premium pricing remains a significant market characteristic, with carbon-negative concrete products commanding 15-25% price premiums over conventional alternatives.

Consumer willingness to pay these premiums varies substantially across market segments. Large commercial developers with explicit ESG commitments demonstrate the highest acceptance of premium pricing, while price sensitivity remains higher in residential and small commercial segments. This differential creates distinct market entry opportunities for producers targeting specific construction sectors.

Key market drivers include tightening building codes and environmental regulations, growing corporate carbon neutrality commitments, and increasing investor pressure for sustainable construction practices. The implementation of carbon border adjustment mechanisms in major economies is expected to further accelerate market adoption by creating economic penalties for carbon-intensive imported building materials.

Market barriers include persistent cost premiums, technical performance concerns among conservative industry stakeholders, and limited production capacity for key carbon-negative concrete ingredients. Supply chain constraints for materials like supplementary cementitious materials (SCMs) and carbon capture technologies represent significant limiting factors for market expansion in the near term.

Forecasts indicate that market growth will accelerate as production scales and costs decline, with carbon-negative concrete potentially capturing 12-15% of the global concrete market by 2035. This transition will be accelerated by regulatory support, technological improvements in carbon sequestration methods, and growing market acceptance of these innovative building materials.

Technical Challenges in Carbon-negative Concrete Development

The development of carbon-negative concrete faces several significant technical challenges that must be addressed to achieve widespread adoption. One of the primary obstacles is the complexity of carbon capture and sequestration within the concrete matrix. Current technologies struggle to efficiently bind CO2 during the curing process, with variable effectiveness depending on environmental conditions such as temperature, humidity, and pressure.

Material inconsistency presents another major challenge. The incorporation of alternative cementitious materials like fly ash, slag, and natural pozzolans—essential for reducing the carbon footprint—often results in unpredictable performance characteristics. These variations make it difficult to establish standardized quality metrics that can be consistently applied across different formulations and production environments.

Durability verification poses a substantial hurdle for carbon-negative concrete. Traditional concrete has decades of performance data, while newer carbon-negative formulations lack long-term field validation. Accelerated aging tests may not accurately predict real-world performance, creating uncertainty about structural integrity and longevity that complicates the development of appropriate quality assurance frameworks.

Measurement methodology standardization remains underdeveloped. The industry lacks consensus on how to quantify carbon sequestration in concrete products accurately. Different testing protocols yield varying results, making it challenging to establish reliable benchmarks for carbon negativity claims. This inconsistency undermines confidence in environmental performance metrics and hinders regulatory acceptance.

Scale-up challenges further complicate quality assurance efforts. Laboratory-scale successes often encounter significant hurdles when implemented in commercial production environments. Maintaining consistent carbon sequestration rates while meeting production demands requires sophisticated process controls that many concrete manufacturers currently lack.

Regulatory frameworks are still evolving, with no universally accepted standards for carbon-negative concrete certification. This regulatory uncertainty creates a fragmented landscape where quality metrics vary by jurisdiction, complicating international trade and technology transfer.

Cost-effectiveness remains a significant barrier. Current carbon-negative concrete technologies typically involve higher production costs compared to conventional concrete. These economic constraints limit research investment and slow the development of cost-effective quality assurance methodologies that could accelerate industry adoption.

Addressing these technical challenges requires coordinated efforts across the concrete industry, research institutions, and regulatory bodies to develop standardized testing protocols, performance benchmarks, and certification frameworks specifically designed for carbon-negative concrete technologies.

Material inconsistency presents another major challenge. The incorporation of alternative cementitious materials like fly ash, slag, and natural pozzolans—essential for reducing the carbon footprint—often results in unpredictable performance characteristics. These variations make it difficult to establish standardized quality metrics that can be consistently applied across different formulations and production environments.

Durability verification poses a substantial hurdle for carbon-negative concrete. Traditional concrete has decades of performance data, while newer carbon-negative formulations lack long-term field validation. Accelerated aging tests may not accurately predict real-world performance, creating uncertainty about structural integrity and longevity that complicates the development of appropriate quality assurance frameworks.

Measurement methodology standardization remains underdeveloped. The industry lacks consensus on how to quantify carbon sequestration in concrete products accurately. Different testing protocols yield varying results, making it challenging to establish reliable benchmarks for carbon negativity claims. This inconsistency undermines confidence in environmental performance metrics and hinders regulatory acceptance.

Scale-up challenges further complicate quality assurance efforts. Laboratory-scale successes often encounter significant hurdles when implemented in commercial production environments. Maintaining consistent carbon sequestration rates while meeting production demands requires sophisticated process controls that many concrete manufacturers currently lack.

Regulatory frameworks are still evolving, with no universally accepted standards for carbon-negative concrete certification. This regulatory uncertainty creates a fragmented landscape where quality metrics vary by jurisdiction, complicating international trade and technology transfer.

Cost-effectiveness remains a significant barrier. Current carbon-negative concrete technologies typically involve higher production costs compared to conventional concrete. These economic constraints limit research investment and slow the development of cost-effective quality assurance methodologies that could accelerate industry adoption.

Addressing these technical challenges requires coordinated efforts across the concrete industry, research institutions, and regulatory bodies to develop standardized testing protocols, performance benchmarks, and certification frameworks specifically designed for carbon-negative concrete technologies.

Current Quality Assurance Methodologies for Carbon-negative Concrete

01 Carbon sequestration measurement in concrete

Methods and systems for measuring and verifying carbon sequestration in concrete materials. These technologies enable accurate quantification of CO2 absorbed during concrete production and curing, which is essential for certifying carbon-negative concrete products. The measurement techniques include specialized sensors and analytical methods to determine the amount of carbon captured in various concrete formulations, providing reliable metrics for quality assurance in carbon-negative concrete manufacturing.- Carbon sequestration measurement in concrete: Methods and systems for measuring and verifying carbon sequestration in concrete materials. These technologies enable accurate quantification of CO2 absorbed during concrete curing and throughout its lifecycle, providing essential data for carbon-negative certification. The measurement techniques include specialized sensors, imaging technologies, and chemical analysis to determine the amount of carbon dioxide permanently captured in concrete structures.

- Quality control systems for carbon-negative concrete: Automated quality assurance systems specifically designed for monitoring and controlling the production of carbon-negative concrete. These systems integrate real-time data collection, analysis, and feedback mechanisms to ensure consistent carbon sequestration performance while maintaining structural integrity. The technologies include continuous monitoring of mix ratios, curing conditions, and final product characteristics to verify compliance with carbon-negative specifications.

- Data analytics for concrete carbon performance: Advanced data analytics platforms that process and analyze large datasets related to concrete performance and carbon metrics. These solutions employ machine learning algorithms and statistical models to identify patterns, predict outcomes, and optimize formulations for enhanced carbon sequestration. The analytics tools help manufacturers and quality assurance teams to make data-driven decisions for improving the carbon-negative properties of concrete products.

- Supply chain verification for carbon-negative concrete: Systems and methods for tracking and verifying the entire supply chain of carbon-negative concrete, from raw material sourcing to final installation. These technologies ensure transparency and accountability in carbon claims through distributed ledger technologies, digital certificates, and automated verification protocols. The solutions help to authenticate the carbon-negative status of concrete products and prevent greenwashing in the construction industry.

- Lifecycle assessment tools for carbon-negative concrete: Comprehensive lifecycle assessment tools specifically designed for evaluating the environmental impact of carbon-negative concrete from cradle to grave. These technologies provide standardized metrics and methodologies for quantifying net carbon impact, considering manufacturing emissions, operational carbon sequestration, and end-of-life scenarios. The assessment frameworks help stakeholders to validate carbon-negative claims and optimize concrete formulations for maximum climate benefit.

02 Quality control systems for sustainable concrete

Automated quality control systems specifically designed for monitoring and ensuring the performance of carbon-negative concrete. These systems incorporate real-time monitoring of concrete properties, data analytics for performance prediction, and verification protocols to ensure that the concrete meets both structural requirements and carbon sequestration targets. The technologies enable manufacturers to maintain consistent quality while optimizing the environmental benefits of carbon-negative concrete formulations.Expand Specific Solutions03 Blockchain-based verification for carbon credits

Blockchain technologies applied to verify and track carbon sequestration in concrete manufacturing. These systems provide immutable records of carbon metrics throughout the concrete production lifecycle, enabling transparent verification for carbon credit certification. The blockchain-based approach ensures data integrity and traceability, which is crucial for validating carbon-negative claims and facilitating carbon credit trading in the construction materials market.Expand Specific Solutions04 AI-powered predictive analytics for concrete performance

Artificial intelligence and machine learning systems that analyze concrete performance data to predict long-term carbon sequestration capabilities and structural integrity. These technologies process multiple variables affecting concrete quality and environmental performance, enabling manufacturers to optimize formulations for maximum carbon negativity while maintaining required strength and durability. The predictive models help establish reliable quality assurance metrics by identifying key performance indicators for carbon-negative concrete.Expand Specific Solutions05 Integrated monitoring systems for concrete manufacturing

Comprehensive monitoring systems that track multiple parameters throughout the concrete manufacturing process to ensure quality and carbon sequestration targets are met. These systems integrate sensors, IoT devices, and data management platforms to monitor raw material inputs, production conditions, curing environments, and final product characteristics. The collected data provides standardized metrics for quality assurance in carbon-negative concrete, enabling certification against established environmental and structural performance standards.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon-negative Concrete

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial pilot projects. The global market size is expanding rapidly, driven by sustainability mandates and carbon reduction goals in construction, though still representing a small fraction of the $400+ billion conventional concrete market. Technologically, the field shows varying maturity levels, with companies like Carbicrete demonstrating commercial-ready solutions through their patented CO2 utilization process, while academic institutions (Wuhan University of Technology, Shandong University) focus on fundamental research. Major cement producers (Taiheiyo Cement, Huaxin Cement, Sumitomo Osaka Cement) are investing in R&D, while construction firms (Kajima, TAISEI, Obayashi) are piloting implementations. Quality assurance metrics remain an evolving challenge, with research institutes like VTT and PWRI developing standardized testing protocols for durability, carbon sequestration verification, and lifecycle performance.

Carbicrete, Inc.

Technical Solution: Carbicrete has developed a groundbreaking carbon-negative concrete technology that replaces cement with steel slag and cures concrete blocks with carbon dioxide instead of heat and steam. Their process involves injecting and mineralizing CO2 into concrete during the curing phase, permanently sequestering approximately 30kg of CO2 per ton of concrete produced. The company's quality assurance metrics focus on compressive strength (achieving >30 MPa), freeze-thaw durability (>300 cycles), and carbon sequestration verification through mass balance calculations and spectroscopic analysis. Carbicrete implements continuous monitoring systems that track CO2 injection rates, reaction completion, and final carbon content in finished products. Their QA framework includes regular testing against ASTM and CSA standards while maintaining digital traceability of carbon credits generated through blockchain-based verification protocols.

Strengths: Achieves true carbon-negative concrete production rather than just reduction; utilizes industrial waste (steel slag) as raw material; produces concrete with superior strength and durability metrics compared to traditional Portland cement concrete. Weaknesses: Requires specialized curing chambers and CO2 delivery infrastructure; currently limited to precast applications rather than ready-mix concrete; quality consistency may vary based on steel slag composition from different sources.

Taiheiyo Cement Corp.

Technical Solution: Taiheiyo Cement has developed a comprehensive quality assurance framework for carbon-negative concrete focusing on their CO2-SUICOM technology. This innovative approach combines special admixtures, industrial by-products, and a CO2 curing process to create concrete that absorbs more carbon than emitted during production. Their QA metrics include carbon uptake measurement using thermogravimetric analysis (TGA) and X-ray diffraction (XRD) to quantify carbonation levels, with targets of 100-200kg CO2 absorption per cubic meter. The company employs life cycle assessment (LCA) methodologies compliant with ISO 14040/14044 standards to verify net carbon negativity across the entire production chain. Taiheiyo's quality control system monitors key performance indicators including compressive strength development (targeting >40 MPa at 28 days), dimensional stability, and durability factors such as chloride penetration resistance and freeze-thaw performance. Their approach includes statistical process control methods to ensure batch-to-batch consistency in both mechanical properties and carbon sequestration performance.

Strengths: Well-established industrial infrastructure allows for large-scale implementation; comprehensive testing facilities enable thorough quality verification; integration with existing concrete standards ensures market acceptance and regulatory compliance. Weaknesses: Higher initial production costs compared to conventional concrete; requires specialized equipment for CO2 curing process; limited long-term performance data under varied environmental conditions.

Key Patents and Standards for Carbon-negative Concrete Testing

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

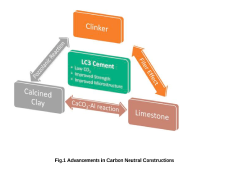

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Environmental Impact Assessment Frameworks

Environmental impact assessment frameworks for carbon-negative concrete require comprehensive methodologies that accurately measure and validate the environmental benefits claimed by manufacturers. These frameworks must integrate life cycle assessment (LCA) principles with specific metrics tailored to carbon-negative concrete technologies. The ISO 14040 and 14044 standards provide foundational guidelines for conducting LCAs, but specialized adaptations are necessary for carbon-negative materials.

The Environmental Product Declaration (EPD) system represents a standardized approach to quantifying environmental impacts across the concrete lifecycle. For carbon-negative concrete, EPDs must be expanded to include carbon sequestration capabilities, durability factors, and end-of-life scenarios that may differ significantly from traditional concrete products. The Product Environmental Footprint (PEF) methodology developed by the European Commission offers another robust framework that can be adapted for carbon-negative concrete assessment.

Emerging frameworks specifically designed for carbon-negative materials include the Carbon Leadership Forum's Material Carbon Calculator and the International EPD System's Product Category Rules for Construction Products. These frameworks incorporate metrics for embodied carbon, operational carbon, and sequestered carbon throughout the product lifecycle. The World Green Building Council's "Bringing Embodied Carbon Upfront" initiative also provides guidance on measuring and reducing embodied carbon in construction materials.

Key performance indicators within these frameworks typically include Global Warming Potential (GWP), measured in CO2 equivalent per functional unit; carbon sequestration capacity over time; energy consumption during production; and resource efficiency metrics. Advanced frameworks also incorporate indicators for air quality impacts, water usage, and potential ecological toxicity associated with novel binding agents or additives used in carbon-negative formulations.

Verification protocols within these frameworks require third-party certification to ensure credibility of carbon-negative claims. Organizations such as the Cement Sustainability Initiative (CSI) and the International Concrete Sustainability Council have developed verification methodologies specifically for concrete products. These protocols typically involve laboratory testing, production facility audits, and ongoing monitoring to validate performance claims.

Challenges in framework implementation include standardizing functional units for comparison, accounting for regional variations in production methods and energy grids, and establishing appropriate temporal boundaries for carbon sequestration claims. Addressing these challenges requires collaborative efforts between industry stakeholders, regulatory bodies, and research institutions to develop consensus-based approaches that balance scientific rigor with practical applicability.

The Environmental Product Declaration (EPD) system represents a standardized approach to quantifying environmental impacts across the concrete lifecycle. For carbon-negative concrete, EPDs must be expanded to include carbon sequestration capabilities, durability factors, and end-of-life scenarios that may differ significantly from traditional concrete products. The Product Environmental Footprint (PEF) methodology developed by the European Commission offers another robust framework that can be adapted for carbon-negative concrete assessment.

Emerging frameworks specifically designed for carbon-negative materials include the Carbon Leadership Forum's Material Carbon Calculator and the International EPD System's Product Category Rules for Construction Products. These frameworks incorporate metrics for embodied carbon, operational carbon, and sequestered carbon throughout the product lifecycle. The World Green Building Council's "Bringing Embodied Carbon Upfront" initiative also provides guidance on measuring and reducing embodied carbon in construction materials.

Key performance indicators within these frameworks typically include Global Warming Potential (GWP), measured in CO2 equivalent per functional unit; carbon sequestration capacity over time; energy consumption during production; and resource efficiency metrics. Advanced frameworks also incorporate indicators for air quality impacts, water usage, and potential ecological toxicity associated with novel binding agents or additives used in carbon-negative formulations.

Verification protocols within these frameworks require third-party certification to ensure credibility of carbon-negative claims. Organizations such as the Cement Sustainability Initiative (CSI) and the International Concrete Sustainability Council have developed verification methodologies specifically for concrete products. These protocols typically involve laboratory testing, production facility audits, and ongoing monitoring to validate performance claims.

Challenges in framework implementation include standardizing functional units for comparison, accounting for regional variations in production methods and energy grids, and establishing appropriate temporal boundaries for carbon sequestration claims. Addressing these challenges requires collaborative efforts between industry stakeholders, regulatory bodies, and research institutions to develop consensus-based approaches that balance scientific rigor with practical applicability.

Regulatory Compliance and Certification Pathways

The regulatory landscape for carbon-negative concrete is evolving rapidly as governments worldwide implement policies to reduce carbon emissions in construction. In the United States, the EPA's Clean Air Act and various state-level initiatives provide frameworks that increasingly recognize and incentivize low-carbon building materials. The EU's more stringent approach includes the Construction Products Regulation (CPR) and the European Green Deal, which specifically targets embodied carbon in construction materials.

For manufacturers of carbon-negative concrete, navigating these regulations requires a comprehensive compliance strategy. Primary certification pathways include Environmental Product Declarations (EPDs), which document the environmental impact of products throughout their lifecycle. These third-party verified documents are becoming essential for market access in regions with advanced climate policies.

Industry-specific certifications such as LEED v4.1, BREEAM, and the International Living Future Institute's Zero Carbon Certification provide frameworks that recognize carbon-negative materials. These certifications not only validate environmental claims but also create market differentiation opportunities for manufacturers.

The technical standards landscape is equally important, with organizations like ASTM International, the American Concrete Institute (ACI), and the European Committee for Standardization (CEN) developing specific standards for testing and verifying carbon-negative concrete performance. These standards establish the methodologies for measuring carbon sequestration, ensuring durability, and confirming mechanical properties.

Emerging certification challenges include the need for standardized methodologies to verify carbon negativity claims over the full lifecycle of concrete products. Current gaps exist in accounting for long-term carbon sequestration potential and the durability of novel formulations under various environmental conditions.

For market entry, manufacturers must develop a strategic certification roadmap that prioritizes certifications based on target markets and regulatory requirements. This typically involves a phased approach beginning with basic safety and performance certifications, followed by environmental certifications that substantiate carbon-negative claims.

The cost implications of certification are substantial, with comprehensive testing regimes and third-party verification adding significant expense to product development. However, these costs should be viewed as essential investments that enable market access and potentially command price premiums in environmentally conscious markets.

For manufacturers of carbon-negative concrete, navigating these regulations requires a comprehensive compliance strategy. Primary certification pathways include Environmental Product Declarations (EPDs), which document the environmental impact of products throughout their lifecycle. These third-party verified documents are becoming essential for market access in regions with advanced climate policies.

Industry-specific certifications such as LEED v4.1, BREEAM, and the International Living Future Institute's Zero Carbon Certification provide frameworks that recognize carbon-negative materials. These certifications not only validate environmental claims but also create market differentiation opportunities for manufacturers.

The technical standards landscape is equally important, with organizations like ASTM International, the American Concrete Institute (ACI), and the European Committee for Standardization (CEN) developing specific standards for testing and verifying carbon-negative concrete performance. These standards establish the methodologies for measuring carbon sequestration, ensuring durability, and confirming mechanical properties.

Emerging certification challenges include the need for standardized methodologies to verify carbon negativity claims over the full lifecycle of concrete products. Current gaps exist in accounting for long-term carbon sequestration potential and the durability of novel formulations under various environmental conditions.

For market entry, manufacturers must develop a strategic certification roadmap that prioritizes certifications based on target markets and regulatory requirements. This typically involves a phased approach beginning with basic safety and performance certifications, followed by environmental certifications that substantiate carbon-negative claims.

The cost implications of certification are substantial, with comprehensive testing regimes and third-party verification adding significant expense to product development. However, these costs should be viewed as essential investments that enable market access and potentially command price premiums in environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!