How to Benchmark Carbon-negative Concrete Against Standard Practices

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, a fundamental building material in modern construction, has undergone significant evolution since its widespread adoption in the 20th century. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. The concept of carbon-negative concrete represents a paradigm shift in construction materials, aiming not only to reduce emissions but to actively sequester carbon dioxide from the atmosphere during its lifecycle.

The development trajectory of carbon-negative concrete technology can be traced back to early experiments with alternative cementitious materials in the 1990s. However, significant breakthroughs emerged in the 2010s with the introduction of novel binding agents capable of absorbing CO2 during the curing process. This technological evolution has accelerated in recent years, driven by increasing environmental regulations, corporate sustainability commitments, and the urgent need to address climate change.

Current carbon-negative concrete technologies employ various approaches, including the use of supplementary cementitious materials (SCMs), carbon capture during production, and innovative binding agents that absorb CO2 as they harden. These technologies have progressed from laboratory experiments to pilot projects, with some now entering commercial application phases in specific markets.

The primary technical objective in benchmarking carbon-negative concrete against standard practices is to establish comprehensive, standardized metrics that accurately reflect the total environmental impact throughout the material's lifecycle. This includes quantifying carbon sequestration capacity, evaluating mechanical performance relative to conventional concrete, and assessing long-term durability under various environmental conditions.

Secondary objectives include developing testing protocols that account for the unique properties of carbon-negative formulations, creating industry-accepted certification standards, and establishing economic models that incorporate carbon credits and environmental benefits into cost calculations. These benchmarks must be scientifically rigorous while remaining practical for industry adoption.

The ultimate goal extends beyond simple carbon accounting to creating a holistic evaluation framework that enables fair comparison between traditional and innovative concrete technologies. This framework must consider regional variations in materials, production methods, and regulatory environments while maintaining sufficient standardization to facilitate global adoption and recognition.

As the construction industry faces increasing pressure to decarbonize, establishing reliable benchmarking methodologies for carbon-negative concrete will be crucial in accelerating market adoption, informing policy decisions, and guiding future research and development efforts in this rapidly evolving technological landscape.

The development trajectory of carbon-negative concrete technology can be traced back to early experiments with alternative cementitious materials in the 1990s. However, significant breakthroughs emerged in the 2010s with the introduction of novel binding agents capable of absorbing CO2 during the curing process. This technological evolution has accelerated in recent years, driven by increasing environmental regulations, corporate sustainability commitments, and the urgent need to address climate change.

Current carbon-negative concrete technologies employ various approaches, including the use of supplementary cementitious materials (SCMs), carbon capture during production, and innovative binding agents that absorb CO2 as they harden. These technologies have progressed from laboratory experiments to pilot projects, with some now entering commercial application phases in specific markets.

The primary technical objective in benchmarking carbon-negative concrete against standard practices is to establish comprehensive, standardized metrics that accurately reflect the total environmental impact throughout the material's lifecycle. This includes quantifying carbon sequestration capacity, evaluating mechanical performance relative to conventional concrete, and assessing long-term durability under various environmental conditions.

Secondary objectives include developing testing protocols that account for the unique properties of carbon-negative formulations, creating industry-accepted certification standards, and establishing economic models that incorporate carbon credits and environmental benefits into cost calculations. These benchmarks must be scientifically rigorous while remaining practical for industry adoption.

The ultimate goal extends beyond simple carbon accounting to creating a holistic evaluation framework that enables fair comparison between traditional and innovative concrete technologies. This framework must consider regional variations in materials, production methods, and regulatory environments while maintaining sufficient standardization to facilitate global adoption and recognition.

As the construction industry faces increasing pressure to decarbonize, establishing reliable benchmarking methodologies for carbon-negative concrete will be crucial in accelerating market adoption, informing policy decisions, and guiding future research and development efforts in this rapidly evolving technological landscape.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete, has shown remarkable growth in recent years. According to recent market research, the global green concrete market was valued at approximately $26.2 billion in 2021 and is projected to reach $65.8 billion by 2030, growing at a CAGR of 10.7% during the forecast period.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The European Union's Green Deal and similar initiatives worldwide have established ambitious targets for carbon neutrality, creating substantial demand for innovative building materials that can help achieve these goals.

Consumer preferences are also evolving, with increasing awareness about environmental sustainability driving demand for eco-friendly construction materials. A survey conducted among property developers revealed that 68% of respondents consider sustainability features as important factors in their purchasing decisions, with 42% willing to pay a premium for buildings constructed with carbon-negative materials.

The commercial building segment currently dominates the sustainable construction materials market, accounting for approximately 45% of the total market share. This is attributed to corporate sustainability commitments and the growing importance of green building certifications such as LEED and BREEAM in commercial real estate valuation.

Regionally, Europe leads the market for sustainable construction materials, followed by North America and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China and India.

Despite the promising market outlook, several challenges persist. The higher initial cost of carbon-negative concrete compared to traditional concrete remains a significant barrier to widespread adoption. Additionally, there is a lack of standardized benchmarking methods to accurately compare the performance and environmental benefits of carbon-negative concrete against conventional alternatives.

The market also faces challenges related to supply chain constraints, with limited availability of raw materials required for producing carbon-negative concrete. Furthermore, there is a need for increased awareness and education among construction professionals about the benefits and applications of sustainable building materials.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The European Union's Green Deal and similar initiatives worldwide have established ambitious targets for carbon neutrality, creating substantial demand for innovative building materials that can help achieve these goals.

Consumer preferences are also evolving, with increasing awareness about environmental sustainability driving demand for eco-friendly construction materials. A survey conducted among property developers revealed that 68% of respondents consider sustainability features as important factors in their purchasing decisions, with 42% willing to pay a premium for buildings constructed with carbon-negative materials.

The commercial building segment currently dominates the sustainable construction materials market, accounting for approximately 45% of the total market share. This is attributed to corporate sustainability commitments and the growing importance of green building certifications such as LEED and BREEAM in commercial real estate valuation.

Regionally, Europe leads the market for sustainable construction materials, followed by North America and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China and India.

Despite the promising market outlook, several challenges persist. The higher initial cost of carbon-negative concrete compared to traditional concrete remains a significant barrier to widespread adoption. Additionally, there is a lack of standardized benchmarking methods to accurately compare the performance and environmental benefits of carbon-negative concrete against conventional alternatives.

The market also faces challenges related to supply chain constraints, with limited availability of raw materials required for producing carbon-negative concrete. Furthermore, there is a need for increased awareness and education among construction professionals about the benefits and applications of sustainable building materials.

Current Status and Challenges in Carbon-negative Concrete Development

Carbon-negative concrete technology has made significant strides globally, though it remains in relatively early stages of commercial deployment. Currently, several pioneering companies have developed functional carbon-negative concrete solutions through various approaches, including carbon capture during production, alternative cementitious materials, and novel curing techniques that absorb CO2. These technologies have progressed from laboratory testing to limited commercial applications, with pilot projects demonstrating their viability in real-world construction scenarios.

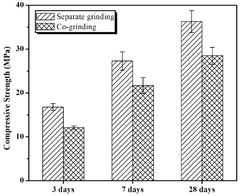

Despite these advancements, carbon-negative concrete faces substantial technical challenges. The most significant hurdle is achieving consistent performance characteristics comparable to traditional Portland cement concrete while maintaining carbon-negative properties. Current formulations often exhibit variable strength development curves, durability concerns in aggressive environments, and workability issues that complicate placement and finishing. These inconsistencies create barriers to widespread adoption, as construction specifications typically demand predictable performance.

Scalability represents another major challenge. Many carbon-negative concrete technologies rely on specialized materials or production processes that cannot yet be implemented at the scale required by the global construction industry. Limited availability of alternative binders such as calcined clays, alkali-activated materials, or carbon-capturing additives restricts production capacity. Additionally, the geographic distribution of necessary raw materials creates supply chain complexities that impede global adoption.

Regulatory frameworks and standardization pose significant obstacles. Most building codes and construction standards were developed for traditional concrete and do not adequately address carbon-negative alternatives. The absence of universally accepted testing protocols specifically designed for carbon-negative concrete makes performance verification difficult and complicates benchmarking against conventional materials. This regulatory uncertainty increases perceived risk for stakeholders considering adoption.

Cost competitiveness remains problematic, with most carbon-negative concrete solutions currently commanding price premiums of 15-50% over conventional concrete. While carbon credits and environmental incentives help offset these costs in some markets, the economic case for widespread adoption remains challenging without further technological improvements or supportive policy frameworks.

The knowledge gap among construction professionals represents another constraint. Limited familiarity with carbon-negative concrete properties, placement techniques, and long-term performance creates resistance to adoption among contractors, engineers, and building officials. This technical knowledge deficit is compounded by insufficient performance data from long-term field applications, creating uncertainty about durability and service life that further inhibits market acceptance.

Despite these advancements, carbon-negative concrete faces substantial technical challenges. The most significant hurdle is achieving consistent performance characteristics comparable to traditional Portland cement concrete while maintaining carbon-negative properties. Current formulations often exhibit variable strength development curves, durability concerns in aggressive environments, and workability issues that complicate placement and finishing. These inconsistencies create barriers to widespread adoption, as construction specifications typically demand predictable performance.

Scalability represents another major challenge. Many carbon-negative concrete technologies rely on specialized materials or production processes that cannot yet be implemented at the scale required by the global construction industry. Limited availability of alternative binders such as calcined clays, alkali-activated materials, or carbon-capturing additives restricts production capacity. Additionally, the geographic distribution of necessary raw materials creates supply chain complexities that impede global adoption.

Regulatory frameworks and standardization pose significant obstacles. Most building codes and construction standards were developed for traditional concrete and do not adequately address carbon-negative alternatives. The absence of universally accepted testing protocols specifically designed for carbon-negative concrete makes performance verification difficult and complicates benchmarking against conventional materials. This regulatory uncertainty increases perceived risk for stakeholders considering adoption.

Cost competitiveness remains problematic, with most carbon-negative concrete solutions currently commanding price premiums of 15-50% over conventional concrete. While carbon credits and environmental incentives help offset these costs in some markets, the economic case for widespread adoption remains challenging without further technological improvements or supportive policy frameworks.

The knowledge gap among construction professionals represents another constraint. Limited familiarity with carbon-negative concrete properties, placement techniques, and long-term performance creates resistance to adoption among contractors, engineers, and building officials. This technical knowledge deficit is compounded by insufficient performance data from long-term field applications, creating uncertainty about durability and service life that further inhibits market acceptance.

Current Benchmarking Methodologies for Carbon-negative Concrete

01 Carbon capture and sequestration in concrete production

Technologies that capture and store carbon dioxide during the concrete manufacturing process, resulting in carbon-negative concrete. These methods involve incorporating CO2 into the concrete mixture where it reacts with calcium compounds to form stable carbonates, effectively sequestering carbon while improving concrete properties. This approach reduces the carbon footprint of concrete production while potentially enhancing strength and durability.- Carbon capture and sequestration in concrete production: Technologies that capture and store carbon dioxide during the concrete manufacturing process, effectively making the concrete carbon-negative. These methods involve incorporating CO2 into the concrete mixture where it reacts with calcium compounds to form stable carbonates, permanently sequestering the carbon while potentially improving concrete strength and durability. This approach addresses the high carbon footprint of traditional cement production by transforming concrete from a carbon source to a carbon sink.

- Performance benchmarking systems for carbon-negative concrete: Systems and methods for measuring, analyzing, and comparing the performance of carbon-negative concrete formulations against industry standards. These benchmarking frameworks evaluate key parameters such as compressive strength, durability, carbon sequestration capacity, and overall environmental impact. The systems utilize standardized testing protocols and metrics to enable objective comparison between different carbon-negative concrete technologies, helping stakeholders make informed decisions about adoption and implementation.

- Alternative cementitious materials for carbon reduction: Development of alternative binding materials that can partially or completely replace traditional Portland cement in concrete, significantly reducing carbon emissions. These include supplementary cementitious materials like fly ash, slag, silica fume, and novel binders such as geopolymers and alkali-activated materials. These alternatives typically require less energy to produce and generate fewer CO2 emissions during manufacturing, while still providing comparable or superior performance characteristics to conventional concrete.

- Life cycle assessment and carbon footprint calculation methods: Methodologies for comprehensive evaluation of the environmental impact of concrete throughout its entire life cycle, from raw material extraction to end-of-life disposal or recycling. These assessment frameworks quantify carbon emissions, energy consumption, and other environmental indicators at each stage of the concrete's life cycle. The methods enable accurate calculation of carbon footprints and identification of opportunities for emission reductions, supporting the development and validation of truly carbon-negative concrete solutions.

- Monitoring and verification systems for carbon credits: Technologies and methodologies for accurately measuring, reporting, and verifying the carbon sequestration achieved by carbon-negative concrete, enabling participation in carbon credit markets. These systems employ sensors, data analytics, and blockchain technology to track and authenticate carbon capture throughout the concrete's lifecycle. By providing transparent and reliable verification of carbon sequestration, these systems facilitate the monetization of environmental benefits through carbon credits, creating additional economic incentives for the adoption of carbon-negative concrete technologies.

02 Alternative low-carbon binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and industrial byproducts such as fly ash and slag. By reducing the amount of Portland cement required, these materials can significantly lower the carbon footprint of concrete while maintaining or improving performance characteristics.Expand Specific Solutions03 Performance benchmarking and standardization methods for carbon-negative concrete

Systems and methods for evaluating and comparing the performance of carbon-negative concrete formulations against established standards. These benchmarking approaches assess mechanical properties, durability, carbon sequestration capacity, and lifecycle environmental impact. Standardized testing protocols enable consistent evaluation across different formulations, facilitating industry adoption and regulatory compliance of carbon-negative concrete technologies.Expand Specific Solutions04 Carbon accounting and certification systems for concrete

Frameworks and methodologies for quantifying, tracking, and verifying the carbon footprint of concrete throughout its lifecycle. These systems enable accurate measurement of embodied carbon and carbon sequestration in concrete products, supporting carbon credit generation, environmental product declarations, and green building certifications. Digital platforms and blockchain technologies are employed to ensure transparency and traceability in carbon accounting for concrete products.Expand Specific Solutions05 Innovative manufacturing processes for carbon-negative concrete

Novel production methods and equipment designed specifically for manufacturing carbon-negative concrete at industrial scale. These innovations include specialized curing chambers that enhance carbonation, energy-efficient mixing technologies, and automated systems for precise dosing of carbon-capturing additives. Advanced process control systems optimize the carbon sequestration potential while ensuring consistent quality and performance of the final concrete product.Expand Specific Solutions

Key Industry Players in Carbon-negative Concrete Innovation

The carbon-negative concrete market is in an early growth phase, characterized by increasing innovation but limited commercial scale. The global market is projected to expand significantly as sustainability regulations tighten, with current estimates valuing it at approximately $1-2 billion but expected to grow substantially. Companies like CarbonCure Technologies and Carbicrete are leading technological innovation with proven CO2 sequestration methods, while Neustark AG and Procarbon Bio represent emerging players with novel approaches. Academic institutions including ETH Zurich, University of South Carolina, and several Chinese universities (Southeast, Chongqing, Shenzhen) are advancing fundamental research. Traditional cement manufacturers such as Sumitomo Osaka Cement, Kobe Steel, and St. Marys Cement are gradually incorporating carbon-reduction technologies, indicating industry-wide recognition of the transition toward sustainable concrete practices.

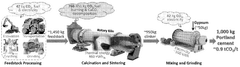

Carbicrete, Inc.

Technical Solution: Carbicrete has developed a carbon-negative concrete production process that replaces cement with steel slag and cures concrete blocks with CO2 instead of heat and steam. Their benchmarking methodology compares carbon-negative concrete against traditional Portland cement concrete using a comprehensive life cycle assessment (LCA) framework. The company quantifies carbon sequestration during production, measuring approximately 40kg of CO2 absorbed per cubic meter of concrete produced. Their benchmarking protocol includes mechanical performance testing (compressive strength, flexural strength, and durability) alongside environmental metrics (embodied carbon, energy consumption, and resource efficiency). Carbicrete's approach incorporates third-party verification through Environmental Product Declarations (EPDs) to validate carbon negativity claims against industry standards.

Strengths: Complete elimination of cement with industrial byproduct utilization; permanent carbon sequestration during manufacturing; third-party verified carbon metrics. Weaknesses: Limited to precast applications currently; requires access to CO2 sources; performance data in extreme weather conditions still being accumulated.

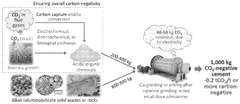

Sumitomo Osaka Cement Co., Ltd.

Technical Solution: Sumitomo Osaka Cement has developed a carbon-negative concrete benchmarking system based on their innovative CO2-SUICOM technology. Their approach quantifies carbon reduction through multiple mechanisms: reduced clinker content, utilization of industrial byproducts, and direct CO2 capture through a special admixture that promotes accelerated carbonation. The company's benchmarking methodology includes standardized testing protocols that measure CO2 uptake during curing using thermal analysis and pH monitoring. Their framework compares mechanical performance against Japanese Industrial Standards (JIS) requirements while simultaneously tracking carbon metrics. Sumitomo's benchmarking includes durability testing specific to the Japanese market, including resistance to freeze-thaw cycles, chloride penetration, and alkali-silica reaction. Their carbon accounting methodology has been validated through collaboration with the Japan Concrete Institute and aligns with the ISO 14067 standard for carbon footprint quantification.

Strengths: Integration of multiple carbon reduction strategies; extensive field validation in Japanese infrastructure projects; specialized durability testing for regional conditions. Weaknesses: Some proprietary admixtures may limit widespread adoption; optimization primarily for Japanese construction standards; requires specialized curing conditions for maximum carbon uptake.

Critical Patents and Research in Carbon Sequestration Concrete

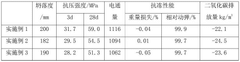

All-solid waste negative carbon concrete and preparation method thereof

PatentPendingCN118598588A

Innovation

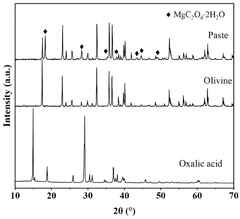

- Using cement-free cementitious materials, recycled aggregates and carbon dioxide curing technology, by mixing and grinding the materials in proportion, combined with normal temperature ventilation pre-curing and high CO2 gas concentration carbonization curing, a fully solid waste negative carbon with performance that meets the C30 standard is prepared Concrete.

Multi-fold carbon-negative organic alternative cement

PatentWO2025024556A1

Innovation

- A method of forming alternative cement by mixing a mineral base with an acidic component, such as oxalic acid or its salts, to create a carbon-negative organic cement. The acidic component is derived from sources like CO2, biomass, or organic acids, and the mineral base includes non-carbonate rocks, minerals, or industrial wastes.

Regulatory Framework and Carbon Credit Opportunities

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to reduce carbon emissions in the construction sector. The European Union's Emissions Trading System (ETS) has expanded to include cement production, creating financial incentives for manufacturers to adopt carbon-negative technologies. Similarly, the United States has introduced tax credits through the Inflation Reduction Act specifically targeting carbon capture in industrial processes, including concrete production.

Carbon credit markets present significant opportunities for carbon-negative concrete producers. These markets allow companies to monetize their carbon reduction efforts by selling verified carbon credits to organizations seeking to offset their emissions. The voluntary carbon market has grown exponentially, with carbon credits for engineered carbon removal solutions commanding premium prices ranging from $100 to $600 per ton of CO2 removed, substantially higher than traditional offset credits.

Certification frameworks are emerging to validate carbon-negative concrete claims. The Cement Sustainability Initiative's Product Category Rules provide standardized methodologies for calculating embodied carbon in concrete products. Additionally, third-party verification systems like Verra and Gold Standard have developed specific protocols for quantifying and certifying carbon removal in building materials, ensuring market credibility.

National building codes are increasingly incorporating carbon performance metrics. Countries like France, Sweden, and Canada have implemented regulations requiring lifecycle carbon assessments for new construction projects, creating market pull for low-carbon building materials. These regulatory frameworks often include specific provisions for carbon-negative materials, allowing them to contribute more significantly toward compliance targets.

Procurement policies represent another regulatory lever driving adoption. Several jurisdictions have implemented "Buy Clean" policies that establish maximum carbon intensity thresholds for construction materials in public projects. California's Buy Clean California Act and similar policies in Colorado and Washington state create guaranteed markets for low-carbon concrete alternatives, with preferential treatment for carbon-negative options.

The intersection of carbon markets and building regulations creates a dual revenue stream potential for carbon-negative concrete: cost savings through regulatory compliance and additional income through carbon credit generation. This dual benefit significantly improves the economic case for adoption, potentially offsetting the higher production costs associated with carbon-negative technologies.

Carbon credit markets present significant opportunities for carbon-negative concrete producers. These markets allow companies to monetize their carbon reduction efforts by selling verified carbon credits to organizations seeking to offset their emissions. The voluntary carbon market has grown exponentially, with carbon credits for engineered carbon removal solutions commanding premium prices ranging from $100 to $600 per ton of CO2 removed, substantially higher than traditional offset credits.

Certification frameworks are emerging to validate carbon-negative concrete claims. The Cement Sustainability Initiative's Product Category Rules provide standardized methodologies for calculating embodied carbon in concrete products. Additionally, third-party verification systems like Verra and Gold Standard have developed specific protocols for quantifying and certifying carbon removal in building materials, ensuring market credibility.

National building codes are increasingly incorporating carbon performance metrics. Countries like France, Sweden, and Canada have implemented regulations requiring lifecycle carbon assessments for new construction projects, creating market pull for low-carbon building materials. These regulatory frameworks often include specific provisions for carbon-negative materials, allowing them to contribute more significantly toward compliance targets.

Procurement policies represent another regulatory lever driving adoption. Several jurisdictions have implemented "Buy Clean" policies that establish maximum carbon intensity thresholds for construction materials in public projects. California's Buy Clean California Act and similar policies in Colorado and Washington state create guaranteed markets for low-carbon concrete alternatives, with preferential treatment for carbon-negative options.

The intersection of carbon markets and building regulations creates a dual revenue stream potential for carbon-negative concrete: cost savings through regulatory compliance and additional income through carbon credit generation. This dual benefit significantly improves the economic case for adoption, potentially offsetting the higher production costs associated with carbon-negative technologies.

Life Cycle Assessment Methods for Carbon-negative Concrete

Life Cycle Assessment (LCA) serves as the cornerstone methodology for evaluating carbon-negative concrete against conventional practices. This systematic approach quantifies environmental impacts throughout the entire concrete lifecycle, from raw material extraction to end-of-life scenarios. The ISO 14040 and 14044 standards provide the fundamental framework for conducting these assessments, ensuring methodological consistency and result comparability across different concrete formulations.

For carbon-negative concrete specifically, LCA methodologies must be adapted to account for unique carbon sequestration mechanisms. This requires careful boundary setting that encompasses not only traditional production emissions but also carbon uptake during curing and service life. The functional unit definition becomes particularly critical, as performance characteristics may differ between conventional and carbon-negative formulations, necessitating equivalence adjustments based on strength, durability, and service life parameters.

Inventory analysis for carbon-negative concrete demands meticulous data collection regarding alternative binders, supplementary cementitious materials, and novel aggregates. This includes quantifying emissions from material sourcing, transportation, manufacturing processes, and the carbon sequestration potential of specific ingredients. Emerging databases like the Embodied Carbon in Construction Calculator (EC3) and the ICE Database provide valuable reference points, though they require continuous updates to reflect rapidly evolving carbon-negative technologies.

Impact assessment methodologies must be carefully selected to properly evaluate climate change mitigation potential. The Global Warming Potential (GWP) metric, measured in CO2-equivalent units, remains the primary indicator, but time-horizon considerations become especially relevant for carbon-negative materials. The choice between GWP100 (100-year timeframe) and GWP20 (20-year timeframe) can significantly influence comparative results and should align with organizational climate goals.

Sensitivity and uncertainty analyses are essential components of robust benchmarking. These analyses should address variability in raw material sourcing, production efficiency, transportation distances, and carbon sequestration rates. Monte Carlo simulations and scenario modeling provide valuable insights into the range of potential environmental outcomes and identify key parameters that most significantly influence carbon performance.

Third-party verification through Environmental Product Declarations (EPDs) offers credibility to carbon-negative concrete claims. However, standardization challenges persist, as current Product Category Rules (PCRs) for concrete may inadequately address carbon sequestration mechanisms. Industry stakeholders are actively developing specialized verification protocols to ensure transparent and accurate reporting of negative emissions claims.

For carbon-negative concrete specifically, LCA methodologies must be adapted to account for unique carbon sequestration mechanisms. This requires careful boundary setting that encompasses not only traditional production emissions but also carbon uptake during curing and service life. The functional unit definition becomes particularly critical, as performance characteristics may differ between conventional and carbon-negative formulations, necessitating equivalence adjustments based on strength, durability, and service life parameters.

Inventory analysis for carbon-negative concrete demands meticulous data collection regarding alternative binders, supplementary cementitious materials, and novel aggregates. This includes quantifying emissions from material sourcing, transportation, manufacturing processes, and the carbon sequestration potential of specific ingredients. Emerging databases like the Embodied Carbon in Construction Calculator (EC3) and the ICE Database provide valuable reference points, though they require continuous updates to reflect rapidly evolving carbon-negative technologies.

Impact assessment methodologies must be carefully selected to properly evaluate climate change mitigation potential. The Global Warming Potential (GWP) metric, measured in CO2-equivalent units, remains the primary indicator, but time-horizon considerations become especially relevant for carbon-negative materials. The choice between GWP100 (100-year timeframe) and GWP20 (20-year timeframe) can significantly influence comparative results and should align with organizational climate goals.

Sensitivity and uncertainty analyses are essential components of robust benchmarking. These analyses should address variability in raw material sourcing, production efficiency, transportation distances, and carbon sequestration rates. Monte Carlo simulations and scenario modeling provide valuable insights into the range of potential environmental outcomes and identify key parameters that most significantly influence carbon performance.

Third-party verification through Environmental Product Declarations (EPDs) offers credibility to carbon-negative concrete claims. However, standardization challenges persist, as current Product Category Rules (PCRs) for concrete may inadequately address carbon sequestration mechanisms. Industry stakeholders are actively developing specialized verification protocols to ensure transparent and accurate reporting of negative emissions claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!