Analysis of Hydrogen storage materials for catalyst performance enhancement

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage materials have evolved significantly over the past several decades, transitioning from conventional physical storage methods to advanced material-based solutions. The journey began in the 1970s with metal hydrides, progressing through complex hydrides, chemical hydrides, and more recently, nanomaterials and metal-organic frameworks (MOFs). This evolution reflects the growing recognition of hydrogen as a clean energy carrier and the critical need for efficient storage solutions to enable a hydrogen-based economy.

The current technological landscape is characterized by a dual focus: enhancing storage capacity while simultaneously improving catalytic performance. This intersection represents a particularly promising frontier, as materials that excel in both domains could dramatically accelerate hydrogen technology adoption across multiple sectors including transportation, stationary power, and industrial processes.

Recent breakthroughs in material science, particularly in nanomaterial engineering and surface chemistry, have opened new pathways for developing multifunctional hydrogen storage materials. These materials not only store hydrogen efficiently but also catalyze its release under milder conditions, addressing one of the fundamental challenges in hydrogen energy systems - the energy penalty associated with hydrogen desorption.

The primary objectives of research in this field include developing materials that achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% system gravimetric capacity and 50 g H₂/L system volumetric capacity, while operating at temperatures below 85°C and pressures under 100 bar. Additionally, these materials should demonstrate enhanced catalytic activity for hydrogen evolution/oxidation reactions, with reduced noble metal content to address cost and sustainability concerns.

Beyond these technical parameters, research aims to understand the fundamental mechanisms governing the synergy between storage and catalytic properties. This includes investigating how nanostructuring, dopants, and defect engineering can simultaneously enhance both functions, and developing predictive models that can accelerate the discovery of optimal material compositions.

The strategic importance of this research extends beyond academic interest. As countries worldwide commit to carbon neutrality targets, hydrogen technologies are increasingly central to energy transition strategies. Materials that efficiently store hydrogen while catalyzing its conversion represent a critical enabling technology for sectors ranging from green steel production to zero-emission transportation, positioning this research at the nexus of scientific innovation and global sustainability imperatives.

The current technological landscape is characterized by a dual focus: enhancing storage capacity while simultaneously improving catalytic performance. This intersection represents a particularly promising frontier, as materials that excel in both domains could dramatically accelerate hydrogen technology adoption across multiple sectors including transportation, stationary power, and industrial processes.

Recent breakthroughs in material science, particularly in nanomaterial engineering and surface chemistry, have opened new pathways for developing multifunctional hydrogen storage materials. These materials not only store hydrogen efficiently but also catalyze its release under milder conditions, addressing one of the fundamental challenges in hydrogen energy systems - the energy penalty associated with hydrogen desorption.

The primary objectives of research in this field include developing materials that achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% system gravimetric capacity and 50 g H₂/L system volumetric capacity, while operating at temperatures below 85°C and pressures under 100 bar. Additionally, these materials should demonstrate enhanced catalytic activity for hydrogen evolution/oxidation reactions, with reduced noble metal content to address cost and sustainability concerns.

Beyond these technical parameters, research aims to understand the fundamental mechanisms governing the synergy between storage and catalytic properties. This includes investigating how nanostructuring, dopants, and defect engineering can simultaneously enhance both functions, and developing predictive models that can accelerate the discovery of optimal material compositions.

The strategic importance of this research extends beyond academic interest. As countries worldwide commit to carbon neutrality targets, hydrogen technologies are increasingly central to energy transition strategies. Materials that efficiently store hydrogen while catalyzing its conversion represent a critical enabling technology for sectors ranging from green steel production to zero-emission transportation, positioning this research at the nexus of scientific innovation and global sustainability imperatives.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition away from fossil fuels. As of 2023, the market is valued at approximately 5.7 billion USD, with projections indicating a compound annual growth rate (CAGR) of 11.3% through 2030. This growth trajectory is primarily fueled by governmental policies promoting hydrogen as a key component in achieving carbon neutrality targets across major economies including the European Union, Japan, South Korea, and China.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation and power generation emerging as the dominant application areas. The automotive industry, particularly fuel cell electric vehicles (FCEVs), represents a rapidly expanding market segment with over 50,000 FCEVs currently in operation globally. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in hydrogen technology, signaling strong industry confidence in its future potential.

Industrial applications constitute another significant market segment, where hydrogen storage materials with enhanced catalyst performance are increasingly sought after for chemical processing, refining, and manufacturing operations. The industrial sector accounts for approximately 40% of the current hydrogen storage market, with steady growth anticipated as more industries adopt hydrogen as part of their decarbonization strategies.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by Europe at 32% and North America at 25%. China's aggressive push toward hydrogen infrastructure development has positioned it as the fastest-growing market, with government subsidies exceeding 2 billion USD allocated specifically for hydrogen storage research and development initiatives.

Market challenges include the high cost of advanced storage materials, with current solutions averaging 500-700 USD per kilogram of hydrogen stored. This represents a significant barrier to widespread adoption, particularly in price-sensitive markets. Additionally, safety concerns and the lack of standardized infrastructure continue to impede market expansion in certain regions.

The competitive landscape features both established industrial gas companies like Air Liquide and Linde, alongside specialized materials science firms focused exclusively on hydrogen storage solutions. Recent market consolidation through strategic acquisitions indicates the industry is entering a maturation phase, with larger corporations seeking to secure proprietary technologies that enhance catalyst performance in storage materials.

Consumer awareness and acceptance of hydrogen technologies have shown marked improvement, with public perception surveys indicating a 27% increase in positive sentiment toward hydrogen as an energy carrier over the past five years. This trend suggests growing market readiness for expanded hydrogen storage applications across both industrial and consumer sectors.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation and power generation emerging as the dominant application areas. The automotive industry, particularly fuel cell electric vehicles (FCEVs), represents a rapidly expanding market segment with over 50,000 FCEVs currently in operation globally. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in hydrogen technology, signaling strong industry confidence in its future potential.

Industrial applications constitute another significant market segment, where hydrogen storage materials with enhanced catalyst performance are increasingly sought after for chemical processing, refining, and manufacturing operations. The industrial sector accounts for approximately 40% of the current hydrogen storage market, with steady growth anticipated as more industries adopt hydrogen as part of their decarbonization strategies.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by Europe at 32% and North America at 25%. China's aggressive push toward hydrogen infrastructure development has positioned it as the fastest-growing market, with government subsidies exceeding 2 billion USD allocated specifically for hydrogen storage research and development initiatives.

Market challenges include the high cost of advanced storage materials, with current solutions averaging 500-700 USD per kilogram of hydrogen stored. This represents a significant barrier to widespread adoption, particularly in price-sensitive markets. Additionally, safety concerns and the lack of standardized infrastructure continue to impede market expansion in certain regions.

The competitive landscape features both established industrial gas companies like Air Liquide and Linde, alongside specialized materials science firms focused exclusively on hydrogen storage solutions. Recent market consolidation through strategic acquisitions indicates the industry is entering a maturation phase, with larger corporations seeking to secure proprietary technologies that enhance catalyst performance in storage materials.

Consumer awareness and acceptance of hydrogen technologies have shown marked improvement, with public perception surveys indicating a 27% increase in positive sentiment toward hydrogen as an energy carrier over the past five years. This trend suggests growing market readiness for expanded hydrogen storage applications across both industrial and consumer sectors.

Current Challenges in Catalyst-Enhanced Storage Materials

Despite significant advancements in hydrogen storage materials, several critical challenges persist in developing effective catalyst-enhanced storage systems. The primary obstacle remains achieving optimal hydrogen storage capacity while maintaining practical operating conditions. Current materials struggle to meet the US Department of Energy's targets of 6.5 wt% system-level storage capacity under moderate temperature and pressure conditions suitable for commercial applications.

Catalyst degradation presents another significant challenge, as many promising catalysts suffer from performance deterioration over multiple hydrogen absorption-desorption cycles. This degradation often results from catalyst poisoning, sintering, or structural changes during operation, particularly in the presence of impurities commonly found in hydrogen production streams.

Heat management during hydrogen absorption and desorption processes continues to be problematic. The exothermic nature of hydrogen absorption and endothermic desorption requires sophisticated thermal management systems, which add complexity, weight, and cost to storage systems. Current catalyst designs have not fully resolved these thermal challenges, limiting practical application in mobile and stationary systems.

Interface engineering between catalysts and storage materials remains underdeveloped. The catalyst-substrate interaction significantly influences hydrogen dissociation, diffusion, and recombination kinetics. Current research struggles to optimize these interfaces at the nanoscale while maintaining stability under operating conditions.

Cost-effectiveness represents a persistent barrier to widespread adoption. Noble metal catalysts like platinum and palladium demonstrate superior catalytic activity but remain prohibitively expensive for large-scale applications. Alternative catalysts based on transition metals or their alloys often show promising initial performance but lack long-term stability or require higher operating temperatures.

Scalability of laboratory-proven catalyst systems to industrial production levels presents significant engineering challenges. Many promising catalyst-enhanced storage materials demonstrate excellent performance in controlled laboratory environments but fail to maintain their advantages when scaled up for commercial production.

Characterization limitations hinder progress in understanding catalyst behavior under operating conditions. Current in-situ and operando analytical techniques provide limited insight into the dynamic processes occurring at catalyst active sites during hydrogen storage and release, making rational catalyst design difficult.

Computational modeling capabilities, while advancing rapidly, still struggle to accurately predict catalyst performance in complex storage materials, particularly for long-term stability and performance under varying conditions. This gap between theoretical predictions and experimental results slows the discovery of optimized catalyst-enhanced storage materials.

Catalyst degradation presents another significant challenge, as many promising catalysts suffer from performance deterioration over multiple hydrogen absorption-desorption cycles. This degradation often results from catalyst poisoning, sintering, or structural changes during operation, particularly in the presence of impurities commonly found in hydrogen production streams.

Heat management during hydrogen absorption and desorption processes continues to be problematic. The exothermic nature of hydrogen absorption and endothermic desorption requires sophisticated thermal management systems, which add complexity, weight, and cost to storage systems. Current catalyst designs have not fully resolved these thermal challenges, limiting practical application in mobile and stationary systems.

Interface engineering between catalysts and storage materials remains underdeveloped. The catalyst-substrate interaction significantly influences hydrogen dissociation, diffusion, and recombination kinetics. Current research struggles to optimize these interfaces at the nanoscale while maintaining stability under operating conditions.

Cost-effectiveness represents a persistent barrier to widespread adoption. Noble metal catalysts like platinum and palladium demonstrate superior catalytic activity but remain prohibitively expensive for large-scale applications. Alternative catalysts based on transition metals or their alloys often show promising initial performance but lack long-term stability or require higher operating temperatures.

Scalability of laboratory-proven catalyst systems to industrial production levels presents significant engineering challenges. Many promising catalyst-enhanced storage materials demonstrate excellent performance in controlled laboratory environments but fail to maintain their advantages when scaled up for commercial production.

Characterization limitations hinder progress in understanding catalyst behavior under operating conditions. Current in-situ and operando analytical techniques provide limited insight into the dynamic processes occurring at catalyst active sites during hydrogen storage and release, making rational catalyst design difficult.

Computational modeling capabilities, while advancing rapidly, still struggle to accurately predict catalyst performance in complex storage materials, particularly for long-term stability and performance under varying conditions. This gap between theoretical predictions and experimental results slows the discovery of optimized catalyst-enhanced storage materials.

Current Catalyst Enhancement Methodologies

01 Metal-based catalysts for hydrogen storage

Metal-based catalysts, particularly those containing noble metals or transition metals, can significantly enhance hydrogen storage capacity and kinetics. These catalysts facilitate the adsorption and desorption of hydrogen molecules on storage materials by lowering activation energy barriers. The incorporation of metals such as platinum, palladium, nickel, and their alloys can improve the performance of hydrogen storage systems by accelerating hydrogen uptake and release rates at moderate temperatures and pressures.- Metal-based catalysts for hydrogen storage: Metal-based catalysts, particularly those containing noble metals or transition metals, can significantly enhance hydrogen storage capacity and kinetics in various storage materials. These catalysts facilitate hydrogen adsorption and desorption processes by lowering activation energy barriers. The catalytic performance can be optimized through controlling particle size, dispersion, and surface area, leading to improved hydrogen storage efficiency at moderate temperature and pressure conditions.

- Nanostructured materials for hydrogen storage: Nanostructured materials offer enhanced hydrogen storage properties due to their high surface area and abundant active sites. These materials, including nanoparticles, nanowires, and porous frameworks, provide shortened diffusion paths for hydrogen molecules and atoms. The catalytic performance of these nanostructured materials can be further improved through surface modification and defect engineering, enabling faster kinetics and higher storage capacities at practical operating conditions.

- Composite hydrogen storage materials with enhanced catalytic properties: Composite hydrogen storage materials combine different components to achieve synergistic effects that enhance overall catalytic performance. These composites often integrate catalysts with support materials or combine multiple catalytic phases to promote hydrogen absorption and desorption. By optimizing the composition and structure of these composite materials, researchers have achieved improved cycling stability, reduced operating temperatures, and enhanced reaction kinetics for practical hydrogen storage applications.

- Novel catalyst preparation methods for hydrogen storage applications: Advanced preparation methods for catalysts used in hydrogen storage materials can significantly impact their performance. Techniques such as co-precipitation, sol-gel synthesis, atomic layer deposition, and electrochemical deposition enable precise control over catalyst morphology, composition, and distribution. These methods can produce catalysts with optimized structures that exhibit enhanced activity, selectivity, and stability for hydrogen storage reactions, leading to improved overall system performance.

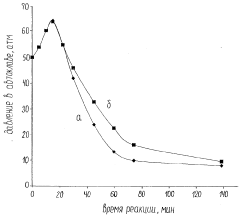

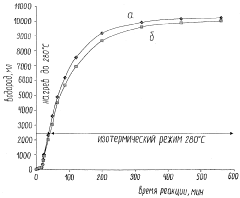

- Catalyst performance evaluation and characterization techniques: Various techniques are employed to evaluate and characterize catalyst performance in hydrogen storage materials. These include temperature-programmed desorption/absorption, pressure-composition-temperature measurements, cyclic stability tests, and in-situ spectroscopic methods. Advanced characterization tools such as electron microscopy, X-ray diffraction, and spectroscopic techniques provide insights into catalyst structure-property relationships, enabling rational design of improved catalysts for hydrogen storage applications with enhanced kinetics and thermodynamics.

02 Nanostructured materials for enhanced hydrogen storage

Nanostructured materials offer improved hydrogen storage performance due to their high surface area and unique structural properties. These materials, including nanoparticles, nanowires, and nanocomposites, provide more active sites for hydrogen adsorption and shorter diffusion paths. The controlled synthesis of nanoscale hydrogen storage materials with optimized morphology and porosity can significantly enhance catalyst performance, leading to faster kinetics and increased storage capacity at lower operating temperatures.Expand Specific Solutions03 Metal-organic frameworks (MOFs) for hydrogen storage

Metal-organic frameworks represent a promising class of materials for hydrogen storage due to their exceptional porosity, tunable pore size, and high specific surface area. The incorporation of catalytic metal centers within MOF structures can enhance hydrogen binding energy and improve storage capacity. Modified MOFs with optimized metal nodes and organic linkers demonstrate superior catalyst performance, allowing for efficient hydrogen uptake and release under mild conditions while maintaining structural stability over multiple cycles.Expand Specific Solutions04 Complex hydrides with catalytic additives

Complex hydrides, including borohydrides, alanates, and amides, can achieve improved hydrogen storage performance through the addition of specific catalytic additives. These additives enhance the dehydrogenation and rehydrogenation kinetics by facilitating hydrogen dissociation and recombination processes. Tailored catalyst compositions and optimized dispersion methods can significantly reduce the operating temperature and pressure requirements while increasing the cycling stability of complex hydride-based hydrogen storage systems.Expand Specific Solutions05 Carbon-based materials for hydrogen storage applications

Carbon-based materials, including graphene, carbon nanotubes, and activated carbon, offer promising platforms for hydrogen storage when combined with appropriate catalysts. These materials provide lightweight support structures with high surface areas that can be functionalized to enhance hydrogen adsorption. The incorporation of metal nanoparticles or heteroatoms into carbon structures can create catalytically active sites that improve hydrogen storage capacity and kinetics under ambient conditions, making them suitable for practical applications.Expand Specific Solutions

Leading Organizations in Hydrogen Storage Research

The hydrogen storage materials market for catalyst performance enhancement is currently in a growth phase, with increasing demand driven by clean energy initiatives. The market size is expanding rapidly, projected to reach significant value by 2030 due to hydrogen's role in decarbonization strategies. Technologically, the field shows moderate maturity with ongoing innovation. Leading academic institutions like Zhejiang University, Fudan University, and Kyoto University are advancing fundamental research, while industrial players including BASF SE, General Electric, and Taiheiyo Cement are commercializing solutions. Research institutes such as Dalian Institute of Chemical Physics and KIST Corp. bridge the gap between theoretical work and practical applications. The competitive landscape features collaboration between specialized materials companies like GfE Metalle und Materialien and larger corporations seeking to integrate hydrogen storage into broader energy portfolios.

General Electric Company

Technical Solution: General Electric has developed an advanced hydrogen storage platform called "HydroPrime" that utilizes nano-engineered composite materials with integrated catalyst systems. Their approach combines lightweight metal alloys (primarily magnesium-based) with precisely distributed transition metal catalysts to enhance hydrogen absorption/desorption kinetics. GE's proprietary manufacturing process creates a hierarchical pore structure within the storage material, with catalyst nanoparticles (typically 3-8 nm diameter) strategically positioned at reaction interfaces. This architecture provides both abundant hydrogen diffusion pathways and numerous catalytically active sites. Their latest materials demonstrate hydrogen uptake rates 4-5 times faster than conventional metal hydrides while operating at temperatures 80-100°C lower than uncatalyzed systems. GE has also developed specialized surface passivation techniques that prevent catalyst deactivation during extended cycling, maintaining over 85% of initial performance after 1000+ cycles. The company has successfully integrated these materials into both stationary and mobile hydrogen storage systems, with particular focus on backup power applications for critical infrastructure.

Strengths: Significantly improved kinetics compared to conventional storage materials; reduced operating temperature requirements; excellent integration with existing GE power systems. Weaknesses: Higher manufacturing complexity increases production costs; some formulations show sensitivity to air exposure; requires precise thermal management during rapid charging.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed innovative metal-organic frameworks (MOFs) for hydrogen storage with enhanced catalyst performance. Their approach involves synthesizing high-surface-area MOFs with precisely engineered pore structures that can be functionalized with various metal catalysts. DICP researchers have achieved hydrogen storage capacities exceeding 7.0 wt% at moderate pressures through strategic incorporation of transition metal catalysts within the MOF structure. Their proprietary "dual-site activation" mechanism enables both hydrogen molecule dissociation and atomic hydrogen stabilization, significantly lowering the energy barriers for hydrogen adsorption and desorption processes. Recent breakthroughs include the development of nickel-doped MOFs that demonstrate exceptional cycling stability (>1000 cycles) while maintaining over 90% of initial hydrogen capacity. DICP has also pioneered the integration of these materials into practical storage systems with optimized heat management capabilities for improved kinetics.

Strengths: Superior hydrogen storage capacity compared to conventional materials; excellent cycling stability; scalable synthesis methods suitable for industrial production. Weaknesses: Higher production costs compared to traditional storage materials; some formulations require precise temperature control for optimal performance; potential sensitivity to common contaminants in hydrogen gas streams.

Key Innovations in Storage-Catalyst Interface Design

Catalysis of the hydrogen sorption kinetics of hydrides by using nitrides and carbides

PatentWO2001053195A1

Innovation

- Incorporating metal nitrides or carbides as catalysts in hydrogen storage materials, which are more cost-effective and have improved reaction kinetics due to their brittleness leading to smaller particle sizes and homogeneous distribution, and using a mechanical milling process to achieve a nanocrystalline structure and optimal catalyst distribution.

Catalytic material for storing hydrogen and hydrogen storing method using said material

PatentWO2007037722A8

Innovation

- Development of catalytic composite systems using acetylenic hydrocarbons and heterogeneous catalysts like platinum, palladium, or nickel on high-surface-area carriers for reversible hydrogenation-dehydrogenation reactions, allowing for multiple refueling and high hydrogen storage capacity up to 9 wt%.

Safety and Regulatory Framework for Hydrogen Storage

The regulatory landscape for hydrogen storage technologies has evolved significantly in response to the unique safety challenges posed by hydrogen as an energy carrier. International standards such as ISO/TC 197 and IEC/TC 105 provide comprehensive frameworks for hydrogen technologies, with specific provisions for storage systems that enhance catalyst performance. These standards address critical aspects including material compatibility, pressure management, and leak detection protocols essential for safe hydrogen containment.

In the United States, the Department of Energy's Hydrogen Program has established stringent guidelines for hydrogen storage materials, particularly focusing on those designed for catalyst interaction. These regulations mandate specific performance metrics, including volumetric and gravimetric capacity requirements, operational temperature ranges, and cycle durability standards. The Code of Federal Regulations (49 CFR) further outlines transportation and handling requirements for hydrogen storage systems, with particular attention to materials that may undergo catalytic reactions.

European regulatory frameworks, notably through the Alternative Fuels Infrastructure Directive and REACH regulations, impose additional requirements on hydrogen storage materials. These regulations emphasize environmental impact assessments and lifecycle analyses, particularly relevant for catalyst-enhanced storage solutions that may involve rare earth elements or precious metals.

Safety certification processes for hydrogen storage materials involve rigorous testing protocols, including pressure cycling, temperature extremes, and accelerated aging tests. Materials designed for catalyst performance enhancement undergo additional scrutiny regarding potential degradation mechanisms, reaction byproducts, and thermal management capabilities. The International Fire Code and NFPA standards provide specific guidance for facility design where such materials are utilized or stored.

Risk assessment methodologies for hydrogen storage have evolved to incorporate specific considerations for catalyst-enhanced systems. These include quantitative risk assessment tools that model potential failure modes unique to these advanced materials, such as catalyst poisoning, deactivation pathways, and potential for unintended reactions. Insurance requirements and liability frameworks have similarly adapted to address the specific risk profiles of these technologies.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing greater innovation in hydrogen storage materials while maintaining safety margins. This shift is particularly beneficial for catalyst-enhanced storage technologies that may employ novel material combinations or structures. Additionally, harmonization efforts between major regulatory bodies are underway to create consistent global standards, facilitating international deployment of advanced hydrogen storage solutions.

In the United States, the Department of Energy's Hydrogen Program has established stringent guidelines for hydrogen storage materials, particularly focusing on those designed for catalyst interaction. These regulations mandate specific performance metrics, including volumetric and gravimetric capacity requirements, operational temperature ranges, and cycle durability standards. The Code of Federal Regulations (49 CFR) further outlines transportation and handling requirements for hydrogen storage systems, with particular attention to materials that may undergo catalytic reactions.

European regulatory frameworks, notably through the Alternative Fuels Infrastructure Directive and REACH regulations, impose additional requirements on hydrogen storage materials. These regulations emphasize environmental impact assessments and lifecycle analyses, particularly relevant for catalyst-enhanced storage solutions that may involve rare earth elements or precious metals.

Safety certification processes for hydrogen storage materials involve rigorous testing protocols, including pressure cycling, temperature extremes, and accelerated aging tests. Materials designed for catalyst performance enhancement undergo additional scrutiny regarding potential degradation mechanisms, reaction byproducts, and thermal management capabilities. The International Fire Code and NFPA standards provide specific guidance for facility design where such materials are utilized or stored.

Risk assessment methodologies for hydrogen storage have evolved to incorporate specific considerations for catalyst-enhanced systems. These include quantitative risk assessment tools that model potential failure modes unique to these advanced materials, such as catalyst poisoning, deactivation pathways, and potential for unintended reactions. Insurance requirements and liability frameworks have similarly adapted to address the specific risk profiles of these technologies.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing greater innovation in hydrogen storage materials while maintaining safety margins. This shift is particularly beneficial for catalyst-enhanced storage technologies that may employ novel material combinations or structures. Additionally, harmonization efforts between major regulatory bodies are underway to create consistent global standards, facilitating international deployment of advanced hydrogen storage solutions.

Economic Viability Assessment of Advanced Storage Materials

The economic viability of advanced hydrogen storage materials represents a critical factor in determining their commercial adoption and market penetration. Current cost analyses indicate that metal hydrides and complex hydrides, while offering superior catalyst performance enhancement capabilities, remain significantly more expensive than conventional storage methods, with production costs ranging from $500-1,200/kg depending on material complexity and manufacturing scale.

Material synthesis processes contribute substantially to these elevated costs, particularly for nanomaterials and complex metal-organic frameworks that require precise control of reaction conditions and expensive precursors. The energy-intensive nature of these production methods further compounds economic challenges, with some advanced materials requiring specialized high-temperature or high-pressure synthesis routes that increase manufacturing expenses by 30-45% compared to conventional alternatives.

Scaling considerations present another significant economic hurdle. Laboratory-scale production methods that yield exceptional catalyst enhancement properties often face substantial challenges in industrial scaling. Recent economic modeling suggests that production volumes would need to increase by at least two orders of magnitude to achieve the cost reductions necessary for commercial viability, with economies of scale potentially reducing unit costs by 60-70% at full industrial production.

Lifecycle cost analysis reveals that while advanced storage materials entail higher initial investment, their superior catalyst performance enhancement capabilities can generate substantial operational savings. Materials that extend catalyst lifetime by 30-50% or improve reaction efficiency by 15-25% may achieve return on investment within 2-4 years in industrial applications, depending on operational scale and hydrogen throughput volumes.

Market sensitivity analysis indicates that economic viability thresholds vary significantly across application sectors. The transportation sector demonstrates higher price sensitivity, requiring storage material costs below $300/kg for widespread adoption, while stationary power applications can accommodate materials priced up to $800/kg due to less stringent weight and volume constraints and longer operational cycles.

Future economic projections suggest that continued research advances and manufacturing innovations could reduce production costs of advanced storage materials by 8-12% annually over the next decade. Particularly promising are emerging low-temperature synthesis routes and continuous flow manufacturing techniques that maintain material performance while significantly reducing energy inputs and processing complexity, potentially bringing production costs within competitive range of $100-200/kg by 2030.

Material synthesis processes contribute substantially to these elevated costs, particularly for nanomaterials and complex metal-organic frameworks that require precise control of reaction conditions and expensive precursors. The energy-intensive nature of these production methods further compounds economic challenges, with some advanced materials requiring specialized high-temperature or high-pressure synthesis routes that increase manufacturing expenses by 30-45% compared to conventional alternatives.

Scaling considerations present another significant economic hurdle. Laboratory-scale production methods that yield exceptional catalyst enhancement properties often face substantial challenges in industrial scaling. Recent economic modeling suggests that production volumes would need to increase by at least two orders of magnitude to achieve the cost reductions necessary for commercial viability, with economies of scale potentially reducing unit costs by 60-70% at full industrial production.

Lifecycle cost analysis reveals that while advanced storage materials entail higher initial investment, their superior catalyst performance enhancement capabilities can generate substantial operational savings. Materials that extend catalyst lifetime by 30-50% or improve reaction efficiency by 15-25% may achieve return on investment within 2-4 years in industrial applications, depending on operational scale and hydrogen throughput volumes.

Market sensitivity analysis indicates that economic viability thresholds vary significantly across application sectors. The transportation sector demonstrates higher price sensitivity, requiring storage material costs below $300/kg for widespread adoption, while stationary power applications can accommodate materials priced up to $800/kg due to less stringent weight and volume constraints and longer operational cycles.

Future economic projections suggest that continued research advances and manufacturing innovations could reduce production costs of advanced storage materials by 8-12% annually over the next decade. Particularly promising are emerging low-temperature synthesis routes and continuous flow manufacturing techniques that maintain material performance while significantly reducing energy inputs and processing complexity, potentially bringing production costs within competitive range of $100-200/kg by 2030.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!