Evaluation of Hydrogen storage materials for grid scale energy storage

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical component in the global transition towards sustainable energy systems. The concept of utilizing hydrogen as an energy carrier dates back to the early 20th century, but significant research and development efforts have intensified over the past three decades. The evolution of hydrogen storage technologies has progressed from conventional physical storage methods to advanced material-based approaches, reflecting the growing recognition of hydrogen's potential in addressing grid-scale energy storage challenges.

The fundamental objective of hydrogen storage materials research for grid-scale applications is to develop efficient, cost-effective, and safe storage solutions that can accommodate the intermittent nature of renewable energy sources. These materials must enable high-density storage while facilitating rapid hydrogen uptake and release cycles to respond to fluctuating grid demands. Additionally, they should maintain stability over thousands of cycles under varying operational conditions.

Current technological trajectories indicate a shift from traditional compressed gas and liquid hydrogen storage towards solid-state materials that offer higher volumetric capacity and enhanced safety profiles. This evolution is driven by the increasing need for long-duration energy storage solutions that can bridge seasonal variations in renewable energy production, a capability that conventional battery technologies struggle to provide economically.

The hydrogen storage landscape encompasses diverse material classes, including metal hydrides, complex hydrides, chemical hydrides, adsorbent materials, and liquid organic hydrogen carriers. Each category presents unique advantages and limitations regarding storage capacity, operating conditions, kinetics, and system integration capabilities. Recent breakthroughs in nanomaterials and catalyst design have accelerated progress in overcoming historical barriers related to hydrogen binding energies and reaction kinetics.

Global research initiatives, such as the International Energy Agency's Hydrogen Technology Collaboration Program and various national hydrogen strategies, have established ambitious targets for hydrogen storage materials. These include achieving volumetric densities exceeding 40 g/L, gravimetric capacities above 6.5 wt%, operating temperatures below 100°C, and system costs under $10/kWh for grid applications by 2030.

The integration of hydrogen storage materials into grid-scale energy systems represents a pivotal element in creating resilient, decarbonized electricity networks. As renewable energy penetration increases, the ability to store vast amounts of energy over extended periods becomes increasingly valuable. Hydrogen storage materials offer a promising pathway to fulfill this requirement, potentially enabling seasonal energy shifting and providing critical grid services including frequency regulation, voltage support, and black start capabilities.

The fundamental objective of hydrogen storage materials research for grid-scale applications is to develop efficient, cost-effective, and safe storage solutions that can accommodate the intermittent nature of renewable energy sources. These materials must enable high-density storage while facilitating rapid hydrogen uptake and release cycles to respond to fluctuating grid demands. Additionally, they should maintain stability over thousands of cycles under varying operational conditions.

Current technological trajectories indicate a shift from traditional compressed gas and liquid hydrogen storage towards solid-state materials that offer higher volumetric capacity and enhanced safety profiles. This evolution is driven by the increasing need for long-duration energy storage solutions that can bridge seasonal variations in renewable energy production, a capability that conventional battery technologies struggle to provide economically.

The hydrogen storage landscape encompasses diverse material classes, including metal hydrides, complex hydrides, chemical hydrides, adsorbent materials, and liquid organic hydrogen carriers. Each category presents unique advantages and limitations regarding storage capacity, operating conditions, kinetics, and system integration capabilities. Recent breakthroughs in nanomaterials and catalyst design have accelerated progress in overcoming historical barriers related to hydrogen binding energies and reaction kinetics.

Global research initiatives, such as the International Energy Agency's Hydrogen Technology Collaboration Program and various national hydrogen strategies, have established ambitious targets for hydrogen storage materials. These include achieving volumetric densities exceeding 40 g/L, gravimetric capacities above 6.5 wt%, operating temperatures below 100°C, and system costs under $10/kWh for grid applications by 2030.

The integration of hydrogen storage materials into grid-scale energy systems represents a pivotal element in creating resilient, decarbonized electricity networks. As renewable energy penetration increases, the ability to store vast amounts of energy over extended periods becomes increasingly valuable. Hydrogen storage materials offer a promising pathway to fulfill this requirement, potentially enabling seasonal energy shifting and providing critical grid services including frequency regulation, voltage support, and black start capabilities.

Market Analysis for Grid-Scale Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. As of 2023, the grid-scale energy storage market is valued at approximately $27 billion, with projections indicating a compound annual growth rate of 24% through 2030. This remarkable expansion is primarily fueled by the urgent need to balance intermittent renewable energy generation and ensure grid stability.

Hydrogen storage technologies represent a significant segment within this market, currently accounting for about 8% of grid-scale storage solutions but expected to grow to 15% by 2028. The appeal of hydrogen as an energy storage medium stems from its high energy density, long-duration storage capabilities, and versatility across multiple sectors including power generation, transportation, and industrial applications.

Market demand for grid-scale energy storage is being shaped by several key factors. Regulatory frameworks promoting decarbonization, such as the European Green Deal and similar initiatives in North America and Asia, are creating favorable conditions for hydrogen storage adoption. Additionally, the declining costs of renewable electricity generation make green hydrogen production increasingly economically viable, with production costs expected to decrease by 40% over the next decade.

Regional analysis reveals distinct market characteristics. Europe leads in hydrogen storage implementation with numerous pilot projects, particularly in Germany, the Netherlands, and the UK. Asia-Pacific, especially Japan, South Korea, and Australia, shows the fastest growth rate at 32% annually, driven by national hydrogen strategies and limited land availability for other storage solutions. North America is rapidly catching up with substantial investments in hydrogen infrastructure, particularly in California and Texas.

Customer segments for grid-scale hydrogen storage include utility companies seeking long-duration storage capabilities, industrial facilities aiming to decarbonize operations, and renewable energy developers looking to enhance the value of their generation assets. The market is also witnessing increased interest from traditional oil and gas companies pivoting toward hydrogen as part of their energy transition strategies.

Competitive pricing analysis indicates that while hydrogen storage currently has higher upfront costs compared to battery technologies ($2,000-3,500/kWh vs. $250-500/kWh for lithium-ion), its advantages in long-duration applications and lower degradation rates offer compelling total cost of ownership benefits for specific use cases, particularly seasonal storage and applications requiring discharge durations exceeding 24 hours.

Hydrogen storage technologies represent a significant segment within this market, currently accounting for about 8% of grid-scale storage solutions but expected to grow to 15% by 2028. The appeal of hydrogen as an energy storage medium stems from its high energy density, long-duration storage capabilities, and versatility across multiple sectors including power generation, transportation, and industrial applications.

Market demand for grid-scale energy storage is being shaped by several key factors. Regulatory frameworks promoting decarbonization, such as the European Green Deal and similar initiatives in North America and Asia, are creating favorable conditions for hydrogen storage adoption. Additionally, the declining costs of renewable electricity generation make green hydrogen production increasingly economically viable, with production costs expected to decrease by 40% over the next decade.

Regional analysis reveals distinct market characteristics. Europe leads in hydrogen storage implementation with numerous pilot projects, particularly in Germany, the Netherlands, and the UK. Asia-Pacific, especially Japan, South Korea, and Australia, shows the fastest growth rate at 32% annually, driven by national hydrogen strategies and limited land availability for other storage solutions. North America is rapidly catching up with substantial investments in hydrogen infrastructure, particularly in California and Texas.

Customer segments for grid-scale hydrogen storage include utility companies seeking long-duration storage capabilities, industrial facilities aiming to decarbonize operations, and renewable energy developers looking to enhance the value of their generation assets. The market is also witnessing increased interest from traditional oil and gas companies pivoting toward hydrogen as part of their energy transition strategies.

Competitive pricing analysis indicates that while hydrogen storage currently has higher upfront costs compared to battery technologies ($2,000-3,500/kWh vs. $250-500/kWh for lithium-ion), its advantages in long-duration applications and lower degradation rates offer compelling total cost of ownership benefits for specific use cases, particularly seasonal storage and applications requiring discharge durations exceeding 24 hours.

Current Status and Challenges in Hydrogen Storage Technology

Hydrogen storage technology has evolved significantly over the past decades, yet remains a critical bottleneck in the hydrogen energy ecosystem, particularly for grid-scale applications. Currently, hydrogen storage methods can be categorized into physical-based (compression, liquefaction, and adsorption) and material-based (metal hydrides, chemical hydrides, and liquid organic hydrogen carriers) approaches. Compressed hydrogen storage, operating at 350-700 bar, represents the most mature technology but suffers from low volumetric density and high energy requirements for compression, limiting its grid-scale efficiency.

Liquefied hydrogen storage achieves higher density but requires cryogenic temperatures (-253°C), resulting in substantial energy penalties of 30-40% and continuous boil-off losses, making it challenging for long-duration grid storage applications. Metal hydride materials show promise with their high volumetric capacity and operational safety, but face limitations in kinetics, thermal management, and material degradation over multiple cycles.

The international landscape reveals uneven development, with Japan, Germany, and the United States leading in research investment and technological advancement. Japan's focus on metal hydrides through initiatives like NEDO has yielded significant breakthroughs in alloy compositions. The European Union, through Horizon Europe, emphasizes complex hydrides and hybrid systems, while China has rapidly expanded its research capacity in nanomaterial-based storage solutions.

Key technical challenges persist across all storage methods. Weight efficiency remains problematic, with the Department of Energy's target of 6.5 wt% for system-level storage still unmet by most practical solutions. Cycle stability presents another significant hurdle, as many promising materials demonstrate performance degradation after repeated hydrogen absorption-desorption cycles, particularly problematic for grid applications requiring thousands of cycles over decades of operation.

Thermal management represents perhaps the most significant challenge for grid-scale implementation. The exothermic nature of hydrogen absorption and endothermic desorption processes creates substantial heat management requirements that scale problematically at grid levels. Additionally, material costs remain prohibitive for many advanced storage materials, with rare earth elements and complex synthesis processes limiting commercial viability.

Regulatory frameworks and safety standards for large-scale hydrogen storage remain underdeveloped in many regions, creating uncertainty for deployment. Recent advancements in nanomaterial engineering and catalyst development show promise in addressing kinetic limitations, while computational materials science approaches are accelerating the discovery of novel storage materials with improved properties.

Liquefied hydrogen storage achieves higher density but requires cryogenic temperatures (-253°C), resulting in substantial energy penalties of 30-40% and continuous boil-off losses, making it challenging for long-duration grid storage applications. Metal hydride materials show promise with their high volumetric capacity and operational safety, but face limitations in kinetics, thermal management, and material degradation over multiple cycles.

The international landscape reveals uneven development, with Japan, Germany, and the United States leading in research investment and technological advancement. Japan's focus on metal hydrides through initiatives like NEDO has yielded significant breakthroughs in alloy compositions. The European Union, through Horizon Europe, emphasizes complex hydrides and hybrid systems, while China has rapidly expanded its research capacity in nanomaterial-based storage solutions.

Key technical challenges persist across all storage methods. Weight efficiency remains problematic, with the Department of Energy's target of 6.5 wt% for system-level storage still unmet by most practical solutions. Cycle stability presents another significant hurdle, as many promising materials demonstrate performance degradation after repeated hydrogen absorption-desorption cycles, particularly problematic for grid applications requiring thousands of cycles over decades of operation.

Thermal management represents perhaps the most significant challenge for grid-scale implementation. The exothermic nature of hydrogen absorption and endothermic desorption processes creates substantial heat management requirements that scale problematically at grid levels. Additionally, material costs remain prohibitive for many advanced storage materials, with rare earth elements and complex synthesis processes limiting commercial viability.

Regulatory frameworks and safety standards for large-scale hydrogen storage remain underdeveloped in many regions, creating uncertainty for deployment. Recent advancements in nanomaterial engineering and catalyst development show promise in addressing kinetic limitations, while computational materials science approaches are accelerating the discovery of novel storage materials with improved properties.

Current Hydrogen Storage Material Solutions for Grid Applications

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by hydrogen and various metals or metal alloys that can store hydrogen through chemical bonding. These materials can achieve high volumetric hydrogen storage capacity through absorption of hydrogen atoms into their crystal lattice. The hydrogen is typically released through heating or pressure reduction. Metal hydrides offer advantages such as safety and stability, though they often face challenges related to weight, cost, and thermal management during hydrogen charging and discharging cycles.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and metals or metal alloys that can store hydrogen through chemical bonding. These materials offer high volumetric storage capacity and can release hydrogen under controlled conditions of temperature and pressure. Various metal hydride systems including magnesium-based, aluminum-based, and transition metal-based hydrides have been developed to optimize hydrogen storage capacity while addressing challenges related to weight, reversibility, and kinetics.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon nanofibers can store hydrogen through physisorption mechanisms. These materials offer advantages including lightweight structure, high surface area, and tunable pore sizes that can enhance hydrogen adsorption. Various modification techniques including doping with metals or other elements can improve the hydrogen storage capacity of carbon-based materials at ambient conditions.

- Metal-organic frameworks (MOFs) for hydrogen storage: Metal-organic frameworks are crystalline porous materials composed of metal ions or clusters coordinated with organic ligands. Their high surface area, tunable pore size, and modifiable structure make them promising candidates for hydrogen storage. MOFs can store hydrogen through physisorption mechanisms, and their storage capacity can be enhanced through strategies such as increasing surface area, incorporating open metal sites, and optimizing pore size distribution.

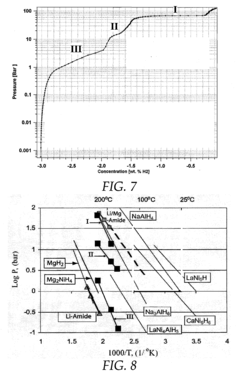

- Complex hydrides and chemical hydrogen storage: Complex hydrides including borohydrides, alanates, and amides can store hydrogen in chemical form with high gravimetric capacity. These materials release hydrogen through thermolysis or hydrolysis reactions. Research focuses on improving their reversibility, reducing dehydrogenation temperatures, and enhancing kinetics through catalysts and nanostructuring. Chemical hydrogen storage systems also include liquid organic hydrogen carriers that can be hydrogenated and dehydrogenated in reversible cycles.

- Nanostructured and composite hydrogen storage materials: Nanostructuring and creating composite materials can significantly enhance hydrogen storage properties by improving kinetics, thermodynamics, and cycling stability. These approaches include creating core-shell structures, nanoconfined hydrides, and multi-component systems that combine different storage mechanisms. Nanostructured materials offer shorter diffusion paths for hydrogen, while composites can leverage synergistic effects between different components to optimize overall storage performance.

02 Carbon-based hydrogen storage materials

Carbon-based materials including carbon nanotubes, graphene, and activated carbon can store hydrogen through physisorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb, particularly at low temperatures. The storage capacity can be enhanced through structural modifications, doping with metals, or creating defects in the carbon structure. Carbon-based materials offer advantages such as lightweight properties and potentially low cost, though they typically require cryogenic conditions to achieve commercially viable storage capacities.Expand Specific Solutions03 Complex hydride hydrogen storage systems

Complex hydrides, including alanates, borohydrides, and amides, can store significant amounts of hydrogen through chemical bonds. These materials often contain light elements like lithium, sodium, or magnesium combined with aluminum, boron, or nitrogen. They typically offer higher gravimetric hydrogen storage capacities compared to conventional metal hydrides. However, challenges include slow kinetics, high desorption temperatures, and reversibility issues. Research focuses on catalysts and compositional modifications to improve cycling stability and operating conditions.Expand Specific Solutions04 Nanostructured materials for hydrogen storage

Nanostructured materials with tailored architectures can significantly enhance hydrogen storage capacity through increased surface area and modified binding energies. These include nanoparticles, core-shell structures, and hierarchical porous frameworks. The nanoscale dimensions reduce diffusion distances for hydrogen, improving absorption and desorption kinetics. Various synthesis methods including ball milling, chemical vapor deposition, and template-assisted growth are employed to create these materials with controlled morphology and composition, optimizing the balance between gravimetric and volumetric storage capacity.Expand Specific Solutions05 Metal-organic frameworks for hydrogen storage

Metal-organic frameworks (MOFs) are crystalline materials consisting of metal ions or clusters coordinated to organic ligands, creating porous structures with exceptionally high surface areas. These materials can store hydrogen through physisorption mechanisms, with storage capacity directly related to surface area and pore characteristics. MOFs offer tunable properties through selection of metal centers and organic linkers, allowing optimization of pore size, binding energy, and stability. While they demonstrate promising gravimetric storage capacity, particularly at cryogenic temperatures, research continues to improve their performance under ambient conditions and address density limitations.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Ecosystem

The hydrogen storage materials market for grid-scale energy storage is in an early growth phase, characterized by increasing investments but limited commercial deployment. The global market is projected to expand significantly as renewable energy integration accelerates, with estimates suggesting multi-billion dollar potential by 2030. Technologically, the field shows varying maturity levels across different storage approaches. Leading players include EnerVenue developing metal-hydrogen batteries, GRZ Technologies commercializing dense hydrogen storage solutions, and research powerhouses like Fraunhofer-Gesellschaft and Alliance for Sustainable Energy advancing novel materials. State Grid Corporation of China and its subsidiaries are positioning for large-scale implementation, while academic institutions such as ShanghaiTech University and Wuhan University of Technology contribute fundamental research to overcome current density and efficiency limitations.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a comprehensive hydrogen storage infrastructure for grid-scale energy applications, focusing on integration with their vast electricity transmission network. Their approach combines underground hydrogen storage in salt caverns (capacity >100,000 m³) with advanced material-based storage systems for distributed applications. State Grid has pioneered large-scale metal hydride storage facilities utilizing low-cost Ti-Fe based alloys modified with transition metals to enhance kinetics and cycling stability. Their systems incorporate waste heat recovery from industrial processes to drive hydrogen desorption, improving overall system efficiency. State Grid has implemented pilot projects exceeding 10 MWh capacity that demonstrate integration with renewable energy sources, particularly addressing curtailment issues with wind and solar generation. Their hydrogen storage facilities achieve response times under 5 minutes for grid regulation services while maintaining storage durations extending to seasonal timeframes.

Strengths: Unparalleled experience in grid integration and system operation; massive deployment capability through existing infrastructure; strong financial resources for large-scale implementation; comprehensive approach spanning production, storage, and utilization. Weaknesses: Some technologies remain at demonstration scale; geographic limitations for certain storage approaches (e.g., salt caverns); complex regulatory environment; optimization challenges when balancing multiple grid services.

GRZ Technologies SA

Technical Solution: GRZ Technologies has developed a proprietary metal hydride-based hydrogen storage system specifically designed for grid-scale applications. Their technology utilizes specialized metal alloys that can absorb hydrogen under pressure and release it when heated, achieving storage densities significantly higher than compressed gas. The company's HYSTORE system integrates thermal management to control the exothermic absorption and endothermic desorption processes, enabling efficient energy recovery. GRZ's solution operates at moderate pressures (30-50 bar) compared to conventional compressed hydrogen storage (350-700 bar), enhancing safety while maintaining high volumetric energy density. Their systems incorporate advanced heat exchangers that facilitate rapid charging and discharging rates necessary for grid balancing applications, with response times under 30 seconds for full power delivery.

Strengths: Higher volumetric energy density than compressed hydrogen; operates at lower, safer pressures; excellent thermal integration capabilities; long cycle life (10,000+ cycles demonstrated); scalable modular design. Weaknesses: Higher capital costs than some competing technologies; requires thermal management systems; performance degrades at extreme temperatures; limited deployment history at utility scale.

Critical Patents and Research in Advanced Storage Materials

Hydrogen storage materials and related methods and systems

PatentInactiveUS8454855B1

Innovation

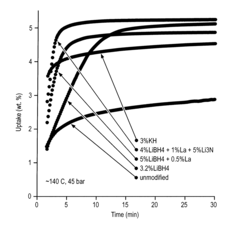

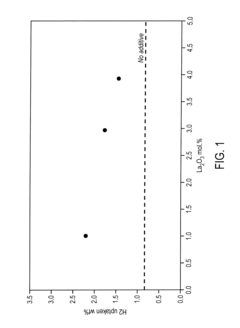

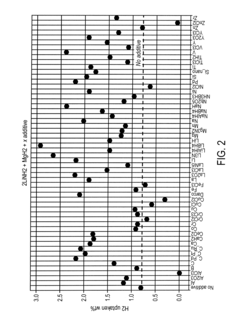

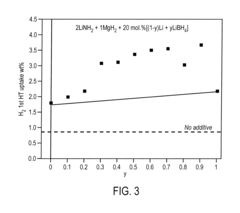

- Development of hydrogen storage materials with a mixed imide formula LiiMgiNkHl, combined with specific additives such as oxides, hydrides, nitrides, and supported metals, synthesized through ball milling, to achieve high gravimetric capacity, fast kinetics, and stability, allowing for efficient hydrogen absorption and retention under moderate temperatures and pressures.

Direct synthesis and methods of using hydrogen storage materials

PatentInactiveUS20070231254A1

Innovation

- A method involving the formation of a mixture including an alkali-metal hydride, an alkali-metal amide or imide, and aluminum or alkaline-earth-metal hydrides, followed by hydrogenation at elevated temperatures and pressures, to produce reversible hydrogen storage materials without the need for solvents or gaseous intermediates.

Environmental Impact and Sustainability Assessment

The environmental impact of hydrogen storage materials for grid-scale energy storage must be comprehensively evaluated across their entire lifecycle. When comparing different hydrogen storage technologies, metal hydrides demonstrate significant sustainability advantages over compressed and liquid hydrogen systems, primarily due to their lower energy requirements during operation. However, the production of advanced metal hydrides often involves rare earth elements and complex manufacturing processes that generate considerable carbon emissions and resource depletion.

Life cycle assessment (LCA) studies reveal that the environmental footprint of hydrogen storage systems is heavily influenced by the source of hydrogen production. Green hydrogen produced via electrolysis powered by renewable energy presents a substantially lower environmental impact compared to gray hydrogen derived from natural gas reforming. The carbon intensity differential between these production methods can exceed 90%, highlighting the importance of coupling hydrogen storage technologies with sustainable hydrogen generation.

Water consumption represents another critical environmental consideration, particularly in regions facing water scarcity. Electrolysis processes require approximately 9 kg of water to produce 1 kg of hydrogen, creating potential sustainability challenges in water-stressed areas. Additionally, the extraction of raw materials for certain storage technologies, such as lithium and cobalt for battery alternatives, raises significant environmental justice concerns in mining regions.

Recyclability and end-of-life management of hydrogen storage materials present both challenges and opportunities. While metal hydrides theoretically offer high recyclability potential, current recycling infrastructure remains underdeveloped. Research indicates that implementing closed-loop recycling systems could reduce the environmental impact of these materials by up to 40%, primarily through reduced primary resource extraction and manufacturing energy requirements.

Land use impacts vary significantly between storage technologies. Underground hydrogen storage in salt caverns or depleted gas fields generally requires minimal surface area compared to above-ground alternatives, though geological stability and potential groundwater contamination risks must be carefully assessed. Conversely, surface storage facilities may compete with agricultural land or natural habitats, necessitating thoughtful site selection and impact mitigation strategies.

Regulatory frameworks governing environmental standards for hydrogen storage technologies continue to evolve globally. The European Union's hydrogen strategy emphasizes sustainability criteria throughout the hydrogen value chain, while similar frameworks are emerging in North America and Asia. These regulations increasingly incorporate carbon intensity thresholds, recycled content requirements, and extended producer responsibility provisions that will shape the future development and deployment of hydrogen storage materials.

Life cycle assessment (LCA) studies reveal that the environmental footprint of hydrogen storage systems is heavily influenced by the source of hydrogen production. Green hydrogen produced via electrolysis powered by renewable energy presents a substantially lower environmental impact compared to gray hydrogen derived from natural gas reforming. The carbon intensity differential between these production methods can exceed 90%, highlighting the importance of coupling hydrogen storage technologies with sustainable hydrogen generation.

Water consumption represents another critical environmental consideration, particularly in regions facing water scarcity. Electrolysis processes require approximately 9 kg of water to produce 1 kg of hydrogen, creating potential sustainability challenges in water-stressed areas. Additionally, the extraction of raw materials for certain storage technologies, such as lithium and cobalt for battery alternatives, raises significant environmental justice concerns in mining regions.

Recyclability and end-of-life management of hydrogen storage materials present both challenges and opportunities. While metal hydrides theoretically offer high recyclability potential, current recycling infrastructure remains underdeveloped. Research indicates that implementing closed-loop recycling systems could reduce the environmental impact of these materials by up to 40%, primarily through reduced primary resource extraction and manufacturing energy requirements.

Land use impacts vary significantly between storage technologies. Underground hydrogen storage in salt caverns or depleted gas fields generally requires minimal surface area compared to above-ground alternatives, though geological stability and potential groundwater contamination risks must be carefully assessed. Conversely, surface storage facilities may compete with agricultural land or natural habitats, necessitating thoughtful site selection and impact mitigation strategies.

Regulatory frameworks governing environmental standards for hydrogen storage technologies continue to evolve globally. The European Union's hydrogen strategy emphasizes sustainability criteria throughout the hydrogen value chain, while similar frameworks are emerging in North America and Asia. These regulations increasingly incorporate carbon intensity thresholds, recycled content requirements, and extended producer responsibility provisions that will shape the future development and deployment of hydrogen storage materials.

Techno-Economic Analysis of Grid-Scale Implementation

The techno-economic analysis of grid-scale hydrogen storage implementation requires a comprehensive assessment of both capital and operational expenditures alongside potential revenue streams. Initial capital costs for hydrogen storage systems range from $500-1,500/kWh, significantly higher than competing technologies like lithium-ion batteries ($200-400/kWh) or pumped hydro storage ($75-200/kWh). However, when considering long-duration storage applications exceeding 24 hours, hydrogen systems become increasingly competitive due to their decoupled power and energy components.

Operational expenditures include maintenance costs (1-3% of capital expenditure annually), energy losses during conversion processes (round-trip efficiency of 30-45%), and replacement costs for critical components like electrolyzers and fuel cells (typically every 5-10 years). These factors contribute to a levelized cost of storage (LCOS) ranging from $0.15-0.30/kWh for grid-scale implementations, depending on utilization rates and system configurations.

Revenue potential stems from multiple value streams including energy arbitrage, grid balancing services, and capacity provision. Energy arbitrage yields approximately $20-50/kW-year in markets with high renewable penetration, while grid balancing services can generate $30-80/kW-year in regions with volatile electricity prices. Capacity payments vary significantly by market but typically range from $50-150/kW-year.

Sensitivity analysis reveals that electrolyzer and fuel cell costs have the most significant impact on economic viability, followed by electricity input costs and system efficiency. A 50% reduction in electrolyzer costs could improve project IRR by 3-5 percentage points, while efficiency improvements from current 30-45% to theoretical maximums of 60-70% would reduce LCOS by approximately 25%.

Deployment timelines indicate that grid-scale hydrogen storage projects require 2-4 years from planning to operation, with regulatory approvals representing a significant portion of this timeline. Economies of scale become apparent at installations exceeding 10MW/100MWh, where fixed costs can be distributed across larger energy capacity.

Market projections suggest that with continued cost reductions of 8-12% annually for key components, grid-scale hydrogen storage could reach economic parity with conventional alternatives in specific use cases by 2028-2030, particularly in markets with high renewable penetration and stringent decarbonization targets.

Operational expenditures include maintenance costs (1-3% of capital expenditure annually), energy losses during conversion processes (round-trip efficiency of 30-45%), and replacement costs for critical components like electrolyzers and fuel cells (typically every 5-10 years). These factors contribute to a levelized cost of storage (LCOS) ranging from $0.15-0.30/kWh for grid-scale implementations, depending on utilization rates and system configurations.

Revenue potential stems from multiple value streams including energy arbitrage, grid balancing services, and capacity provision. Energy arbitrage yields approximately $20-50/kW-year in markets with high renewable penetration, while grid balancing services can generate $30-80/kW-year in regions with volatile electricity prices. Capacity payments vary significantly by market but typically range from $50-150/kW-year.

Sensitivity analysis reveals that electrolyzer and fuel cell costs have the most significant impact on economic viability, followed by electricity input costs and system efficiency. A 50% reduction in electrolyzer costs could improve project IRR by 3-5 percentage points, while efficiency improvements from current 30-45% to theoretical maximums of 60-70% would reduce LCOS by approximately 25%.

Deployment timelines indicate that grid-scale hydrogen storage projects require 2-4 years from planning to operation, with regulatory approvals representing a significant portion of this timeline. Economies of scale become apparent at installations exceeding 10MW/100MWh, where fixed costs can be distributed across larger energy capacity.

Market projections suggest that with continued cost reductions of 8-12% annually for key components, grid-scale hydrogen storage could reach economic parity with conventional alternatives in specific use cases by 2028-2030, particularly in markets with high renewable penetration and stringent decarbonization targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!