What are the most effective Hydrogen storage materials for EV and grid systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical component in the global transition towards sustainable energy systems, particularly for electric vehicles (EVs) and grid applications. The concept of hydrogen as an energy carrier dates back to the early 20th century, but significant research momentum has only built over the past three decades as climate change concerns and energy security issues have intensified. The fundamental challenge lies in developing materials that can store hydrogen efficiently, safely, and economically at practical operating conditions.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based approaches. Early research focused primarily on physical storage methods, while recent decades have witnessed a shift toward chemical and materials-based storage solutions that offer higher volumetric and gravimetric capacities.

Current technological objectives center on meeting the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025, with ultimate targets of 7.5 wt% and 70 g/L respectively. These benchmarks are considered essential for hydrogen-powered vehicles to achieve driving ranges comparable to conventional vehicles while maintaining reasonable weight and volume constraints.

For grid applications, the objectives differ significantly, emphasizing long-duration storage capacity, cycle stability, and cost-effectiveness over weight and volume considerations. The ability to store large quantities of hydrogen for seasonal energy balancing represents a particularly valuable capability for integrating intermittent renewable energy sources into stable grid operations.

The research landscape encompasses diverse material classes including metal hydrides, complex hydrides, chemical hydrogen carriers, adsorbent materials, and hybrid systems. Each category presents unique advantages and limitations regarding storage capacity, operating conditions, kinetics, and system integration challenges.

International research efforts have accelerated dramatically, with significant programs established in the United States, European Union, Japan, South Korea, and China. The EU's Hydrogen Strategy and the U.S. Department of Energy's Hydrogen Program exemplify the growing governmental commitment to hydrogen technologies, including advanced storage materials.

The ultimate goal of current research is to identify and develop materials that can enable practical hydrogen storage solutions across different applications, from light-duty vehicles to heavy transport and stationary grid systems, thereby facilitating the broader adoption of hydrogen as a clean energy vector in a decarbonized economy.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based approaches. Early research focused primarily on physical storage methods, while recent decades have witnessed a shift toward chemical and materials-based storage solutions that offer higher volumetric and gravimetric capacities.

Current technological objectives center on meeting the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025, with ultimate targets of 7.5 wt% and 70 g/L respectively. These benchmarks are considered essential for hydrogen-powered vehicles to achieve driving ranges comparable to conventional vehicles while maintaining reasonable weight and volume constraints.

For grid applications, the objectives differ significantly, emphasizing long-duration storage capacity, cycle stability, and cost-effectiveness over weight and volume considerations. The ability to store large quantities of hydrogen for seasonal energy balancing represents a particularly valuable capability for integrating intermittent renewable energy sources into stable grid operations.

The research landscape encompasses diverse material classes including metal hydrides, complex hydrides, chemical hydrogen carriers, adsorbent materials, and hybrid systems. Each category presents unique advantages and limitations regarding storage capacity, operating conditions, kinetics, and system integration challenges.

International research efforts have accelerated dramatically, with significant programs established in the United States, European Union, Japan, South Korea, and China. The EU's Hydrogen Strategy and the U.S. Department of Energy's Hydrogen Program exemplify the growing governmental commitment to hydrogen technologies, including advanced storage materials.

The ultimate goal of current research is to identify and develop materials that can enable practical hydrogen storage solutions across different applications, from light-duty vehicles to heavy transport and stationary grid systems, thereby facilitating the broader adoption of hydrogen as a clean energy vector in a decarbonized economy.

Market Analysis for Hydrogen Storage in EV and Grid Applications

The hydrogen storage market for EV and grid applications is experiencing significant growth, driven by the global push towards decarbonization and renewable energy integration. Current market valuations place the global hydrogen storage market at approximately $15.4 billion in 2023, with projections indicating growth to reach $25.2 billion by 2030, representing a compound annual growth rate (CAGR) of 7.3%. This growth trajectory is particularly pronounced in regions with strong hydrogen strategies such as the European Union, Japan, South Korea, and increasingly, the United States and China.

For electric vehicle applications, the demand for efficient hydrogen storage solutions is primarily driven by the fuel cell electric vehicle (FCEV) segment. While battery electric vehicles currently dominate the zero-emission vehicle market, FCEVs offer distinct advantages in range, refueling time, and performance stability in extreme temperatures. The FCEV market, valued at approximately $2.5 billion in 2023, is expected to grow at a CAGR of 63.5% through 2030, creating substantial demand for advanced hydrogen storage materials.

In grid applications, hydrogen storage represents a critical solution for addressing the intermittency challenges of renewable energy sources. The market for grid-scale energy storage is projected to reach $15.1 billion by 2027, with hydrogen-based solutions capturing an increasing share as technology advances. Long-duration storage capabilities make hydrogen particularly valuable for seasonal energy balancing, a functionality that conventional battery technologies cannot efficiently provide.

Customer segmentation reveals distinct requirements across sectors. The transportation sector prioritizes volumetric and gravimetric efficiency, safety, and cost-effectiveness. Industrial users focus on scalability and integration with existing infrastructure. Utility companies emphasize long-duration storage capacity, reliability, and system efficiency.

Regional market analysis indicates that Asia-Pacific currently leads in hydrogen storage technology deployment, followed by Europe and North America. However, Europe is expected to demonstrate the highest growth rate in the coming decade due to aggressive decarbonization policies and substantial investments in hydrogen infrastructure.

Price sensitivity varies significantly across applications. While grid operators can accommodate higher capital costs for storage solutions that demonstrate superior efficiency and longevity, the automotive sector faces intense pressure to reduce costs to achieve price parity with conventional vehicles. Current hydrogen storage costs range from $500-1,500 per kilogram of storage capacity, with industry targets aiming to reduce this to below $300 per kilogram by 2030.

For electric vehicle applications, the demand for efficient hydrogen storage solutions is primarily driven by the fuel cell electric vehicle (FCEV) segment. While battery electric vehicles currently dominate the zero-emission vehicle market, FCEVs offer distinct advantages in range, refueling time, and performance stability in extreme temperatures. The FCEV market, valued at approximately $2.5 billion in 2023, is expected to grow at a CAGR of 63.5% through 2030, creating substantial demand for advanced hydrogen storage materials.

In grid applications, hydrogen storage represents a critical solution for addressing the intermittency challenges of renewable energy sources. The market for grid-scale energy storage is projected to reach $15.1 billion by 2027, with hydrogen-based solutions capturing an increasing share as technology advances. Long-duration storage capabilities make hydrogen particularly valuable for seasonal energy balancing, a functionality that conventional battery technologies cannot efficiently provide.

Customer segmentation reveals distinct requirements across sectors. The transportation sector prioritizes volumetric and gravimetric efficiency, safety, and cost-effectiveness. Industrial users focus on scalability and integration with existing infrastructure. Utility companies emphasize long-duration storage capacity, reliability, and system efficiency.

Regional market analysis indicates that Asia-Pacific currently leads in hydrogen storage technology deployment, followed by Europe and North America. However, Europe is expected to demonstrate the highest growth rate in the coming decade due to aggressive decarbonization policies and substantial investments in hydrogen infrastructure.

Price sensitivity varies significantly across applications. While grid operators can accommodate higher capital costs for storage solutions that demonstrate superior efficiency and longevity, the automotive sector faces intense pressure to reduce costs to achieve price parity with conventional vehicles. Current hydrogen storage costs range from $500-1,500 per kilogram of storage capacity, with industry targets aiming to reduce this to below $300 per kilogram by 2030.

Current State and Technical Barriers of Hydrogen Storage Materials

Hydrogen storage materials have evolved significantly over the past decade, yet remain a critical bottleneck in the widespread adoption of hydrogen as an energy carrier for both electric vehicles and grid applications. Currently, the most developed storage methods include compressed gas, liquid hydrogen, metal hydrides, complex hydrides, and physisorption materials. Compressed hydrogen (700 bar) represents the most commercially mature technology, deployed in most hydrogen fuel cell vehicles today, offering gravimetric densities of 5-6 wt% but suffering from low volumetric density and safety concerns.

Liquid hydrogen storage achieves higher volumetric density but requires cryogenic temperatures (-253°C), resulting in significant energy penalties with boil-off losses reaching 1-3% daily. This approach remains impractical for most EV applications due to insulation requirements and energy inefficiency.

Metal hydrides, particularly those based on magnesium, titanium, and aluminum alloys, demonstrate promising volumetric densities (80-150 kg H₂/m³) but face substantial challenges in kinetics and thermal management. Most conventional metal hydrides operate at temperatures exceeding 300°C for hydrogen release, making them impractical for on-board vehicle applications without significant system complexity.

Complex hydrides, including borohydrides and alanates, offer theoretical storage capacities exceeding 10 wt%, but their practical implementation is hindered by poor reversibility, slow kinetics, and high dehydrogenation temperatures. Recent research on catalyst integration and nanostructuring has improved performance, yet complete reversibility under moderate conditions remains elusive.

Physisorption materials, particularly metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), have demonstrated exceptional surface areas (>7000 m²/g) but require cryogenic temperatures to achieve meaningful storage capacities. At ambient temperatures, even the most advanced MOFs struggle to exceed 1-2 wt% hydrogen capacity.

The technical barriers across all material classes include insufficient gravimetric and volumetric capacities at practical operating conditions, with the U.S. Department of Energy targets (6.5 wt%, 50 g/L, -40 to 60°C operating range) remaining unmet by any single material system. Thermal management during hydrogen absorption/desorption presents another significant challenge, as most promising materials exhibit either strongly endothermic or exothermic reactions.

Material degradation over multiple cycling represents another critical barrier, with capacity losses of 20-30% observed after just 100 cycles in many advanced materials. Additionally, material costs remain prohibitive for many high-performance systems, with rare earth and platinum group metal catalysts increasing system costs well beyond commercial viability thresholds for mass-market applications.

Liquid hydrogen storage achieves higher volumetric density but requires cryogenic temperatures (-253°C), resulting in significant energy penalties with boil-off losses reaching 1-3% daily. This approach remains impractical for most EV applications due to insulation requirements and energy inefficiency.

Metal hydrides, particularly those based on magnesium, titanium, and aluminum alloys, demonstrate promising volumetric densities (80-150 kg H₂/m³) but face substantial challenges in kinetics and thermal management. Most conventional metal hydrides operate at temperatures exceeding 300°C for hydrogen release, making them impractical for on-board vehicle applications without significant system complexity.

Complex hydrides, including borohydrides and alanates, offer theoretical storage capacities exceeding 10 wt%, but their practical implementation is hindered by poor reversibility, slow kinetics, and high dehydrogenation temperatures. Recent research on catalyst integration and nanostructuring has improved performance, yet complete reversibility under moderate conditions remains elusive.

Physisorption materials, particularly metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), have demonstrated exceptional surface areas (>7000 m²/g) but require cryogenic temperatures to achieve meaningful storage capacities. At ambient temperatures, even the most advanced MOFs struggle to exceed 1-2 wt% hydrogen capacity.

The technical barriers across all material classes include insufficient gravimetric and volumetric capacities at practical operating conditions, with the U.S. Department of Energy targets (6.5 wt%, 50 g/L, -40 to 60°C operating range) remaining unmet by any single material system. Thermal management during hydrogen absorption/desorption presents another significant challenge, as most promising materials exhibit either strongly endothermic or exothermic reactions.

Material degradation over multiple cycling represents another critical barrier, with capacity losses of 20-30% observed after just 100 cycles in many advanced materials. Additionally, material costs remain prohibitive for many high-performance systems, with rare earth and platinum group metal catalysts increasing system costs well beyond commercial viability thresholds for mass-market applications.

Existing Hydrogen Storage Material Solutions

01 Metal hydrides for hydrogen storage

Metal hydrides are effective materials for hydrogen storage due to their high volumetric capacity and safety features. These compounds form when hydrogen reacts with various metals or metal alloys, creating stable hydrides that can release hydrogen when heated. Common metal hydrides include those based on magnesium, aluminum, and transition metals. These materials offer advantages such as moderate operating temperatures and pressures, making them suitable for various hydrogen storage applications.- Metal hydride-based hydrogen storage materials: Metal hydrides are effective materials for hydrogen storage due to their high hydrogen capacity and reversible absorption/desorption properties. These materials form chemical bonds with hydrogen atoms, allowing for dense storage at moderate pressures and temperatures. Various metal alloys and compounds can be engineered to optimize storage capacity, kinetics, and operating conditions for different applications. The effectiveness of metal hydrides is determined by factors such as gravimetric and volumetric storage density, cycling stability, and activation energy requirements.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon offer promising hydrogen storage capabilities through adsorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb, with effectiveness enhanced through structural modifications and doping with other elements. The effectiveness of carbon-based storage materials depends on their specific surface area, pore size distribution, and surface chemistry. They typically operate through physisorption processes that require less energy for hydrogen release compared to chemical hydrides.

- Complex hydrides and chemical hydrogen storage: Complex hydrides, including borohydrides, alanates, and amides, store hydrogen through chemical bonds in complex compounds. These materials can achieve high gravimetric hydrogen densities, making them attractive for mobile applications. Their effectiveness is measured by hydrogen content, release temperature, reaction kinetics, and reversibility. Catalysts are often incorporated to improve dehydrogenation kinetics and lower operating temperatures. Recent developments focus on multi-component systems that can operate under milder conditions while maintaining high storage capacities.

- Nanostructured materials for enhanced hydrogen storage: Nanostructuring of hydrogen storage materials significantly enhances their effectiveness by shortening diffusion paths, increasing surface area, and modifying thermodynamic properties. Nanoscale engineering creates materials with improved kinetics, lower operating temperatures, and enhanced cycling stability. Various approaches include nanoparticles, core-shell structures, and nanocomposites that combine different storage mechanisms. The effectiveness of these materials is characterized by faster absorption/desorption rates and often improved reversibility compared to their bulk counterparts.

- System integration and performance evaluation methods: The effectiveness of hydrogen storage materials must be evaluated in integrated systems that consider heat management, pressure control, and safety factors. Standardized testing protocols measure key performance indicators including gravimetric and volumetric capacity, cycle life, kinetics, and energy efficiency. Advanced characterization techniques such as in-situ diffraction, spectroscopy, and computational modeling help understand material behavior under operating conditions. System-level considerations include thermal management strategies, containment vessel design, and integration with fuel cells or other hydrogen utilization technologies.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon have shown promising hydrogen storage capabilities. These materials store hydrogen through adsorption mechanisms, where hydrogen molecules adhere to the surface of the carbon structure. The effectiveness of carbon-based materials depends on their surface area, pore structure, and surface modifications. Research has focused on enhancing the hydrogen storage capacity by doping with metals or creating hybrid structures to improve adsorption properties.Expand Specific Solutions03 Complex hydrides and chemical hydrogen storage

Complex hydrides, including borohydrides, alanates, and amides, offer high hydrogen storage capacity by weight. These materials store hydrogen through chemical bonds rather than physical adsorption, allowing for higher storage densities. The effectiveness of complex hydrides is determined by their hydrogen release kinetics, operating temperature, and reversibility. Research has focused on catalysts to improve dehydrogenation rates and lower the temperature required for hydrogen release, as well as enhancing the reversibility of the storage process.Expand Specific Solutions04 Nanostructured materials for hydrogen storage

Nanostructured materials offer enhanced hydrogen storage properties due to their high surface area and unique quantum effects. These include nanoparticles, nanoporous structures, and core-shell architectures that can improve hydrogen uptake and release kinetics. The effectiveness of nanostructured materials is influenced by their size, morphology, and composition. By controlling these parameters, researchers have developed materials with improved hydrogen storage capacity, faster kinetics, and better cycling stability compared to their bulk counterparts.Expand Specific Solutions05 Composite and hybrid hydrogen storage systems

Composite and hybrid hydrogen storage systems combine different materials to overcome limitations of individual storage methods. These systems may integrate metal hydrides with carbon materials, incorporate catalysts, or combine physical and chemical storage mechanisms. The effectiveness of these hybrid approaches lies in their ability to achieve synergistic effects, such as improved kinetics, enhanced capacity, or better thermal management. Research has demonstrated that carefully designed composite materials can offer superior hydrogen storage performance compared to single-component systems.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The hydrogen storage materials market for EV and grid systems is in a growth phase, with increasing demand driven by clean energy transitions. The market is expected to expand significantly as hydrogen becomes a key component in renewable energy strategies. Technologically, the field shows varying maturity levels across different storage approaches. Leading automotive companies like Toyota, Nissan, and GM are advancing metal hydride technologies, while academic institutions such as Zhejiang University and Caltech focus on novel materials research. Specialized players like EnerVenue and Japan Metals & Chemicals are developing commercial solutions, with BASF and GE contributing materials expertise. This competitive landscape reflects both established industrial players and emerging technology developers working to overcome efficiency and cost challenges.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered metal hydride hydrogen storage systems for automotive applications, developing proprietary alloys that optimize hydrogen absorption capacity and kinetics. Their technology utilizes specialized AB5-type alloys (typically containing rare earth metals, nickel, and other transition metals) that can store hydrogen at moderate pressures (35-70 MPa) with volumetric densities exceeding 40 g/L. Toyota's approach integrates thermal management systems that address heat generation during hydrogen absorption and consumption during desorption, maintaining optimal operating temperatures between -30°C and 50°C. Their latest systems incorporate nano-structured materials with enhanced surface areas and reduced diffusion distances, allowing for faster refueling times (under 5 minutes) while maintaining storage capacities sufficient for 500+ km driving ranges in their Mirai FCEV platform[1][3].

Strengths: Industry-leading practical implementation in commercial vehicles; excellent system integration with thermal management; proven durability over thousands of cycles. Weaknesses: Higher cost due to rare earth elements; weight penalties compared to compressed gas systems; thermal management complexity adds to system overhead.

EnerVenue Holdings Ltd.

Technical Solution: EnerVenue has commercialized metal-hydrogen battery technology originally developed for aerospace applications, creating grid-scale energy storage systems with exceptional cycling capabilities (30,000+ cycles) and operational lifespans exceeding 30 years. Their proprietary nickel-hydrogen electrochemical cells operate at moderate pressures (100-200 bar) and ambient temperatures, storing hydrogen in both gaseous form and within specialized metal electrodes. The technology achieves round-trip efficiencies of 80-85% and can operate across extreme temperature ranges (-40°C to 60°C) without active thermal management. EnerVenue's modular approach allows for scalable deployment from 100kWh to multi-MWh installations, with energy densities of approximately 50-60 Wh/kg at the system level. Their latest generation incorporates advanced catalysts that reduce activation overpotentials by 25%, improving charge acceptance rates and enabling faster response to grid fluctuations[9][10]. Unlike lithium-based systems, EnerVenue's technology uses abundant, non-toxic materials (primarily nickel, hydrogen, and potassium hydroxide electrolyte), avoiding supply chain constraints associated with critical minerals.

Strengths: Exceptional cycle life and calendar life; wide operating temperature range without degradation; inherent safety with no thermal runaway risk; uses non-toxic, abundant materials. Weaknesses: Lower energy density compared to lithium-ion alternatives; higher upfront capital costs; primarily suited for stationary applications rather than mobile/EV use due to weight considerations.

Critical Patents and Research in Hydrogen Storage Materials

High-capacity complex hydrogen storage materials and a process of releasing hydrogen

PatentInactiveUS8961819B2

Innovation

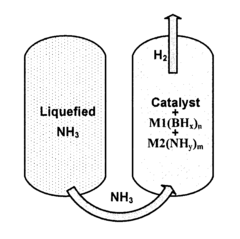

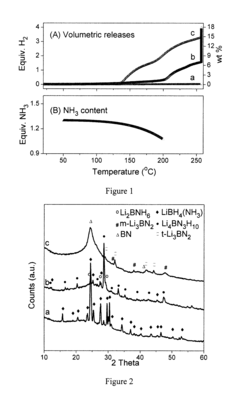

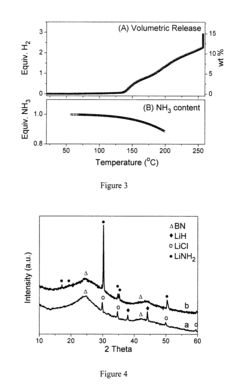

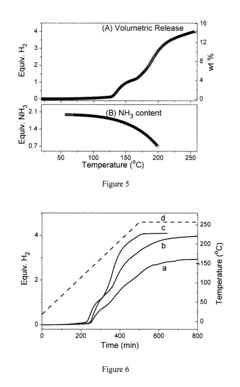

- A hydrogen storage system comprising borohydride and ammonia with a metal catalyst, where the molar ratio of ammonia to borohydride is optimized, and transition metal catalysts are introduced to improve dehydrogenation kinetics, allowing for hydrogen release in a closed system at mild conditions through equilibrium-vapor-pressure control.

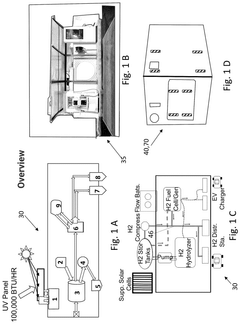

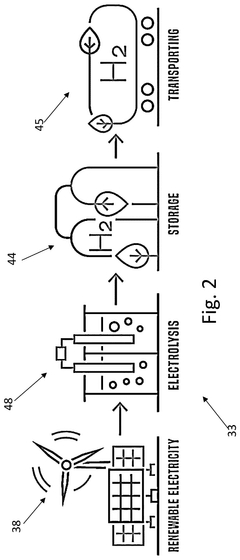

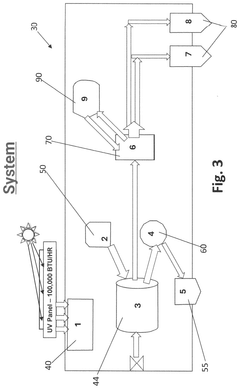

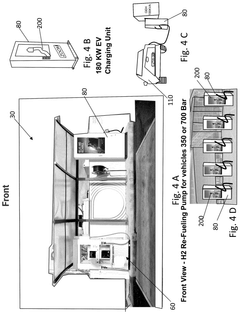

Combination Power Replenishment System for Off-Grid and 100% Carbon Free Re-fueling Station for HYDROGEN Vehicles and Re-Charging Station for Electric Vehicles

PatentPendingUS20250236195A1

Innovation

- A Combination Power Replenishment System comprising a Hydrogen Electrolyzer, hydrogen fuel cell, flow battery, hydrogen storage tanks, and hydrogen fueling pumps, supplemented by UV Thermal Solar Panels and sodium or magnesium flow batteries, providing a 100% carbon-free, off-grid hydrogen refueling solution.

Safety and Regulatory Framework for Hydrogen Storage Systems

The safety and regulatory landscape for hydrogen storage systems is complex and evolving rapidly as hydrogen gains prominence in clean energy applications. For hydrogen storage materials in EVs and grid systems, safety considerations are paramount due to hydrogen's wide flammability range (4-75% in air) and low ignition energy. Current regulatory frameworks address these risks through multiple layers of protection requirements, including leak detection systems, pressure relief devices, and ventilation protocols.

International standards such as ISO/TC 197 for hydrogen technologies and SAE J2579 for fuel cell vehicle safety provide foundational guidelines for hydrogen storage system design and operation. These standards specify material compatibility requirements, testing protocols for embrittlement resistance, and performance criteria under extreme conditions. The European Union's Regulation (EU) 2019/1242 and the United States' NFPA 2 (Hydrogen Technologies Code) further establish region-specific compliance pathways.

Material-specific regulations are particularly relevant for advanced storage solutions. Metal hydrides must meet thermal stability requirements under SAE J2579, while carbon-based materials face scrutiny regarding potential dust hazards during handling. Regulatory bodies increasingly require lifecycle safety assessments that address not only operational risks but also manufacturing and end-of-life considerations.

Grid-scale hydrogen storage faces additional regulatory challenges, with ASME Boiler and Pressure Vessel Code Section VIII governing large stationary storage systems. These installations must comply with land use regulations, setback requirements, and environmental impact assessments that vary significantly by jurisdiction. The International Fire Code provides additional guidance for large-scale hydrogen installations, particularly regarding separation distances and emergency response planning.

Certification processes for hydrogen storage materials involve rigorous testing regimes. Materials must demonstrate resistance to cycling degradation, thermal stability under rapid charging/discharging, and containment integrity during crash scenarios for vehicular applications. The UN Global Technical Regulation No. 13 establishes specific test protocols for hydrogen vehicle storage systems that material developers must consider from early research stages.

Emerging regulatory trends include performance-based approaches that focus on safety outcomes rather than prescriptive requirements, potentially accelerating innovation in novel storage materials. Harmonization efforts between major markets are underway through initiatives like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to create consistent regulatory frameworks that can facilitate global deployment of hydrogen technologies while maintaining rigorous safety standards.

International standards such as ISO/TC 197 for hydrogen technologies and SAE J2579 for fuel cell vehicle safety provide foundational guidelines for hydrogen storage system design and operation. These standards specify material compatibility requirements, testing protocols for embrittlement resistance, and performance criteria under extreme conditions. The European Union's Regulation (EU) 2019/1242 and the United States' NFPA 2 (Hydrogen Technologies Code) further establish region-specific compliance pathways.

Material-specific regulations are particularly relevant for advanced storage solutions. Metal hydrides must meet thermal stability requirements under SAE J2579, while carbon-based materials face scrutiny regarding potential dust hazards during handling. Regulatory bodies increasingly require lifecycle safety assessments that address not only operational risks but also manufacturing and end-of-life considerations.

Grid-scale hydrogen storage faces additional regulatory challenges, with ASME Boiler and Pressure Vessel Code Section VIII governing large stationary storage systems. These installations must comply with land use regulations, setback requirements, and environmental impact assessments that vary significantly by jurisdiction. The International Fire Code provides additional guidance for large-scale hydrogen installations, particularly regarding separation distances and emergency response planning.

Certification processes for hydrogen storage materials involve rigorous testing regimes. Materials must demonstrate resistance to cycling degradation, thermal stability under rapid charging/discharging, and containment integrity during crash scenarios for vehicular applications. The UN Global Technical Regulation No. 13 establishes specific test protocols for hydrogen vehicle storage systems that material developers must consider from early research stages.

Emerging regulatory trends include performance-based approaches that focus on safety outcomes rather than prescriptive requirements, potentially accelerating innovation in novel storage materials. Harmonization efforts between major markets are underway through initiatives like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to create consistent regulatory frameworks that can facilitate global deployment of hydrogen technologies while maintaining rigorous safety standards.

Environmental Impact and Sustainability Assessment

The environmental impact of hydrogen storage materials represents a critical dimension in evaluating their suitability for EV and grid applications. Life cycle assessments reveal that metal hydrides, while effective for storage, often require energy-intensive manufacturing processes that generate significant carbon emissions. The extraction of rare earth elements for certain complex hydrides raises additional environmental concerns related to habitat destruction and water pollution in mining regions.

Carbon footprint analysis indicates that liquid hydrogen storage systems, despite their high volumetric efficiency, consume substantial energy for liquefaction processes, requiring approximately 30% of the energy content of hydrogen itself. This energy penalty must be factored into overall sustainability calculations when comparing different storage technologies.

Material recyclability varies significantly across hydrogen storage solutions. Metal organic frameworks (MOFs) and certain carbon-based materials demonstrate promising recyclability profiles, with potential recovery rates exceeding 85% in controlled laboratory conditions. Conversely, complex metal hydrides present challenges for end-of-life management due to their reactive nature and specialized composition.

Water consumption represents another critical environmental consideration. Production of high-purity aluminum for alane-based storage materials requires approximately 20-40 cubic meters of water per ton of aluminum produced. This water footprint becomes particularly problematic in water-stressed regions where manufacturing facilities may be located.

Renewable energy integration potential differs across storage technologies. Cryo-compressed hydrogen systems can be effectively paired with intermittent renewable energy sources, utilizing excess generation for the energy-intensive compression and cooling processes. This synergy potentially improves the overall sustainability profile of these storage solutions when implemented within renewable-dominant grid systems.

Safety considerations intersect with environmental impact through potential release scenarios. Materials with high hydrogen desorption rates under ambient conditions present both safety hazards and potential greenhouse impacts, as hydrogen itself is an indirect greenhouse gas through atmospheric interactions. Engineered containment systems add material complexity but mitigate these risks.

Regulatory frameworks increasingly incorporate sustainability metrics in technology approval processes. The EU's proposed Battery Passport initiative, while primarily focused on battery technologies, establishes precedents for material traceability and environmental impact documentation that will likely extend to hydrogen storage technologies in transportation applications.

Carbon footprint analysis indicates that liquid hydrogen storage systems, despite their high volumetric efficiency, consume substantial energy for liquefaction processes, requiring approximately 30% of the energy content of hydrogen itself. This energy penalty must be factored into overall sustainability calculations when comparing different storage technologies.

Material recyclability varies significantly across hydrogen storage solutions. Metal organic frameworks (MOFs) and certain carbon-based materials demonstrate promising recyclability profiles, with potential recovery rates exceeding 85% in controlled laboratory conditions. Conversely, complex metal hydrides present challenges for end-of-life management due to their reactive nature and specialized composition.

Water consumption represents another critical environmental consideration. Production of high-purity aluminum for alane-based storage materials requires approximately 20-40 cubic meters of water per ton of aluminum produced. This water footprint becomes particularly problematic in water-stressed regions where manufacturing facilities may be located.

Renewable energy integration potential differs across storage technologies. Cryo-compressed hydrogen systems can be effectively paired with intermittent renewable energy sources, utilizing excess generation for the energy-intensive compression and cooling processes. This synergy potentially improves the overall sustainability profile of these storage solutions when implemented within renewable-dominant grid systems.

Safety considerations intersect with environmental impact through potential release scenarios. Materials with high hydrogen desorption rates under ambient conditions present both safety hazards and potential greenhouse impacts, as hydrogen itself is an indirect greenhouse gas through atmospheric interactions. Engineered containment systems add material complexity but mitigate these risks.

Regulatory frameworks increasingly incorporate sustainability metrics in technology approval processes. The EU's proposed Battery Passport initiative, while primarily focused on battery technologies, establishes precedents for material traceability and environmental impact documentation that will likely extend to hydrogen storage technologies in transportation applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!