Comparative analysis of Hydrogen storage materials for electronics applications

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage materials have evolved significantly over the past several decades, transitioning from conventional physical storage methods to advanced material-based solutions. Initially developed for energy applications, these materials have found increasing relevance in electronics as the industry seeks more efficient power sources for portable and autonomous devices. The evolution trajectory shows a clear shift from basic metal hydrides to complex nanomaterials and metal-organic frameworks, each offering unique advantages for specific applications.

The electronics industry presents distinct requirements for hydrogen storage materials compared to traditional energy sectors. While energy applications prioritize volumetric and gravimetric capacity, electronics demand additional characteristics such as rapid hydrogen release kinetics, operational safety at lower temperatures, and compatibility with miniaturized components. These requirements have driven specialized research directions focused on materials that can function effectively within the constraints of electronic devices.

Current technological objectives in this field center around developing hydrogen storage materials that can achieve high energy density while maintaining stability in diverse environmental conditions. Researchers aim to create materials capable of storing hydrogen at densities exceeding 5.5 wt% under ambient conditions, with release temperatures below 85°C to align with electronic component tolerances. Additionally, cycle stability exceeding 1000 charge-discharge cycles represents a critical threshold for practical electronic applications.

The intersection of hydrogen storage and electronics presents unique opportunities for innovation. As electronic devices continue to demand higher energy densities and longer operational lifespans, hydrogen-based power solutions offer theoretical advantages over conventional battery technologies. The potential for rapid recharging, longer service life, and higher energy density makes hydrogen storage materials particularly attractive for next-generation electronic applications ranging from consumer electronics to specialized industrial equipment.

Research objectives in this field have expanded beyond mere storage capacity to include integration challenges with electronic components. This includes developing materials with controlled hydrogen release mechanisms, minimizing electromagnetic interference, and ensuring compatibility with semiconductor manufacturing processes. The ultimate goal is to create hydrogen storage systems that can be seamlessly incorporated into electronic device architectures without compromising performance or reliability.

Global research initiatives have accelerated in recent years, with significant contributions from academic institutions and industrial laboratories across North America, Europe, and East Asia. These efforts reflect growing recognition of hydrogen storage materials as a strategic technology with implications for electronic device innovation, energy independence, and environmental sustainability.

The electronics industry presents distinct requirements for hydrogen storage materials compared to traditional energy sectors. While energy applications prioritize volumetric and gravimetric capacity, electronics demand additional characteristics such as rapid hydrogen release kinetics, operational safety at lower temperatures, and compatibility with miniaturized components. These requirements have driven specialized research directions focused on materials that can function effectively within the constraints of electronic devices.

Current technological objectives in this field center around developing hydrogen storage materials that can achieve high energy density while maintaining stability in diverse environmental conditions. Researchers aim to create materials capable of storing hydrogen at densities exceeding 5.5 wt% under ambient conditions, with release temperatures below 85°C to align with electronic component tolerances. Additionally, cycle stability exceeding 1000 charge-discharge cycles represents a critical threshold for practical electronic applications.

The intersection of hydrogen storage and electronics presents unique opportunities for innovation. As electronic devices continue to demand higher energy densities and longer operational lifespans, hydrogen-based power solutions offer theoretical advantages over conventional battery technologies. The potential for rapid recharging, longer service life, and higher energy density makes hydrogen storage materials particularly attractive for next-generation electronic applications ranging from consumer electronics to specialized industrial equipment.

Research objectives in this field have expanded beyond mere storage capacity to include integration challenges with electronic components. This includes developing materials with controlled hydrogen release mechanisms, minimizing electromagnetic interference, and ensuring compatibility with semiconductor manufacturing processes. The ultimate goal is to create hydrogen storage systems that can be seamlessly incorporated into electronic device architectures without compromising performance or reliability.

Global research initiatives have accelerated in recent years, with significant contributions from academic institutions and industrial laboratories across North America, Europe, and East Asia. These efforts reflect growing recognition of hydrogen storage materials as a strategic technology with implications for electronic device innovation, energy independence, and environmental sustainability.

Market Analysis for Hydrogen Storage in Electronics

The hydrogen storage materials market for electronics applications is experiencing significant growth, driven by the increasing demand for clean energy solutions and the miniaturization of electronic devices. Currently valued at approximately 2.3 billion USD, this market segment is projected to grow at a compound annual growth rate of 7.8% through 2030, according to recent industry analyses.

The electronics sector represents a unique application area for hydrogen storage technologies, with distinct requirements compared to automotive or stationary storage applications. Portable electronic devices, backup power systems, and specialized industrial electronics constitute the primary market segments. Among these, portable fuel cells for consumer electronics show the most promising growth trajectory, with market penetration increasing by 12% annually in regions like East Asia and North America.

Consumer electronics manufacturers are increasingly exploring hydrogen-based power solutions as alternatives to conventional lithium-ion batteries, particularly for applications requiring longer operational times without recharging. This trend is most evident in the professional equipment sector, where continuous operation requirements outweigh initial cost considerations.

Geographically, Japan and South Korea lead in commercial deployment of hydrogen storage technologies for electronics, with combined market share exceeding 45%. European markets follow at 28%, while North American adoption stands at 22%. Emerging markets in China and India are showing accelerated growth rates of 15% and 11% respectively, albeit from smaller base values.

Key market drivers include increasing power demands of modern electronic devices, growing concerns about battery disposal environmental impacts, and strategic investments in hydrogen infrastructure. The push for extended device operation times without compromising on weight or form factor has particularly strengthened the value proposition of advanced hydrogen storage materials in premium electronic products.

Market barriers remain significant, however. Cost premiums of 30-40% compared to conventional power solutions represent the primary obstacle to widespread adoption. Additional challenges include consumer unfamiliarity with hydrogen technologies, regulatory uncertainties regarding transport and storage of hydrogen-powered devices, and competition from rapidly improving battery technologies.

Industry forecasts suggest that metal hydride storage systems will dominate the electronics applications market in the near term, accounting for 58% of deployments due to their established safety profile and moderate cost structure. Emerging materials like MOFs (Metal-Organic Frameworks) are projected to gain market share rapidly, potentially reaching 25% of new deployments by 2028 as manufacturing scales improve and costs decrease.

The electronics sector represents a unique application area for hydrogen storage technologies, with distinct requirements compared to automotive or stationary storage applications. Portable electronic devices, backup power systems, and specialized industrial electronics constitute the primary market segments. Among these, portable fuel cells for consumer electronics show the most promising growth trajectory, with market penetration increasing by 12% annually in regions like East Asia and North America.

Consumer electronics manufacturers are increasingly exploring hydrogen-based power solutions as alternatives to conventional lithium-ion batteries, particularly for applications requiring longer operational times without recharging. This trend is most evident in the professional equipment sector, where continuous operation requirements outweigh initial cost considerations.

Geographically, Japan and South Korea lead in commercial deployment of hydrogen storage technologies for electronics, with combined market share exceeding 45%. European markets follow at 28%, while North American adoption stands at 22%. Emerging markets in China and India are showing accelerated growth rates of 15% and 11% respectively, albeit from smaller base values.

Key market drivers include increasing power demands of modern electronic devices, growing concerns about battery disposal environmental impacts, and strategic investments in hydrogen infrastructure. The push for extended device operation times without compromising on weight or form factor has particularly strengthened the value proposition of advanced hydrogen storage materials in premium electronic products.

Market barriers remain significant, however. Cost premiums of 30-40% compared to conventional power solutions represent the primary obstacle to widespread adoption. Additional challenges include consumer unfamiliarity with hydrogen technologies, regulatory uncertainties regarding transport and storage of hydrogen-powered devices, and competition from rapidly improving battery technologies.

Industry forecasts suggest that metal hydride storage systems will dominate the electronics applications market in the near term, accounting for 58% of deployments due to their established safety profile and moderate cost structure. Emerging materials like MOFs (Metal-Organic Frameworks) are projected to gain market share rapidly, potentially reaching 25% of new deployments by 2028 as manufacturing scales improve and costs decrease.

Current State and Challenges in Hydrogen Storage Technology

Hydrogen storage technology has evolved significantly over the past decades, with current research focusing on materials that can safely and efficiently store hydrogen for various applications, including electronics. The state-of-the-art hydrogen storage materials can be categorized into several types: metal hydrides, complex hydrides, chemical hydrides, carbon-based materials, and metal-organic frameworks (MOFs). Each category presents unique advantages and limitations when applied to electronic applications.

Metal hydrides, such as palladium hydride and magnesium hydride, offer high volumetric hydrogen density but often suffer from slow kinetics and high operating temperatures. For electronics applications, these limitations pose significant challenges as they require precise temperature control systems that add complexity and cost to device designs.

Complex hydrides, including alanates and borohydrides, demonstrate improved hydrogen storage capacity compared to conventional metal hydrides. However, their application in electronics remains limited due to their thermal stability issues and potential for releasing impurities that could damage sensitive electronic components.

Carbon-based materials, particularly graphene and carbon nanotubes, have gained attention for their potential in electronics due to their lightweight nature and compatibility with existing manufacturing processes. Nevertheless, their practical hydrogen storage capacity under ambient conditions remains below theoretical predictions, creating a gap between laboratory results and commercial viability.

Metal-organic frameworks represent one of the most promising recent developments, offering tunable pore sizes and high surface areas. Their adaptability makes them particularly interesting for miniaturized electronic applications, though challenges persist in their long-term stability and manufacturing scalability.

The geographical distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with significant research clusters in the United States, Germany, Japan, and South Korea. These regions have established robust research ecosystems combining academic institutions, government laboratories, and industrial partners.

Key technical challenges currently facing hydrogen storage materials for electronics include achieving sufficient gravimetric and volumetric storage density at ambient conditions, ensuring rapid hydrogen absorption/desorption kinetics, maintaining long-term cycling stability, and developing cost-effective manufacturing processes. Additionally, integration challenges exist in adapting these materials to the miniaturized and precise requirements of modern electronic devices.

Safety concerns represent another significant hurdle, particularly for consumer electronics applications, as some storage materials may present risks related to flammability, toxicity, or pressure management. Regulatory frameworks for such applications remain underdeveloped in many regions, creating uncertainty for commercial deployment.

Metal hydrides, such as palladium hydride and magnesium hydride, offer high volumetric hydrogen density but often suffer from slow kinetics and high operating temperatures. For electronics applications, these limitations pose significant challenges as they require precise temperature control systems that add complexity and cost to device designs.

Complex hydrides, including alanates and borohydrides, demonstrate improved hydrogen storage capacity compared to conventional metal hydrides. However, their application in electronics remains limited due to their thermal stability issues and potential for releasing impurities that could damage sensitive electronic components.

Carbon-based materials, particularly graphene and carbon nanotubes, have gained attention for their potential in electronics due to their lightweight nature and compatibility with existing manufacturing processes. Nevertheless, their practical hydrogen storage capacity under ambient conditions remains below theoretical predictions, creating a gap between laboratory results and commercial viability.

Metal-organic frameworks represent one of the most promising recent developments, offering tunable pore sizes and high surface areas. Their adaptability makes them particularly interesting for miniaturized electronic applications, though challenges persist in their long-term stability and manufacturing scalability.

The geographical distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with significant research clusters in the United States, Germany, Japan, and South Korea. These regions have established robust research ecosystems combining academic institutions, government laboratories, and industrial partners.

Key technical challenges currently facing hydrogen storage materials for electronics include achieving sufficient gravimetric and volumetric storage density at ambient conditions, ensuring rapid hydrogen absorption/desorption kinetics, maintaining long-term cycling stability, and developing cost-effective manufacturing processes. Additionally, integration challenges exist in adapting these materials to the miniaturized and precise requirements of modern electronic devices.

Safety concerns represent another significant hurdle, particularly for consumer electronics applications, as some storage materials may present risks related to flammability, toxicity, or pressure management. Regulatory frameworks for such applications remain underdeveloped in many regions, creating uncertainty for commercial deployment.

Comparative Analysis of Current Hydrogen Storage Technologies

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by metals or metal alloys that can absorb and release hydrogen under specific temperature and pressure conditions. These materials offer high volumetric hydrogen storage capacity and can be designed with various compositions to optimize storage properties. Common metal hydride systems include magnesium-based hydrides, aluminum-based hydrides, and transition metal-based hydrides that provide efficient and reversible hydrogen storage solutions.- Metal hydrides for hydrogen storage: Metal hydrides are compounds formed by hydrogen and metals, offering high volumetric hydrogen storage capacity. These materials can absorb and release hydrogen through chemical reactions under specific temperature and pressure conditions. Common metal hydrides include those based on magnesium, aluminum, and transition metals. They provide advantages such as safety and reversibility for hydrogen storage applications, though some face challenges with weight efficiency and reaction kinetics.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon can store hydrogen through physisorption mechanisms. These materials offer advantages including lightweight structure, high surface area, and tunable porosity. The hydrogen molecules are adsorbed onto the surface of the carbon structures through weak van der Waals forces. Research focuses on enhancing the hydrogen uptake capacity by modifying surface properties and incorporating dopants to increase binding energy with hydrogen.

- Complex hydrides for hydrogen storage: Complex hydrides, including borohydrides, alanates, and amides, offer high gravimetric hydrogen storage capacity. These materials store hydrogen through chemical bonds in complex structures and can release hydrogen through thermal decomposition or hydrolysis reactions. They typically contain light elements such as lithium, sodium, or aluminum combined with hydrogen and other elements. Research focuses on improving their reversibility, reducing dehydrogenation temperatures, and enhancing reaction kinetics for practical applications.

- Hydrogen storage in porous materials: Porous materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and zeolites can store hydrogen through physisorption in their pore structures. These materials feature extremely high surface areas and tunable pore sizes that can be optimized for hydrogen adsorption. The hydrogen storage capacity depends on factors such as pore volume, surface area, and binding energy. Research focuses on designing materials with optimal pore structures and incorporating metal sites to enhance hydrogen binding energy.

- Composite hydrogen storage systems: Composite hydrogen storage systems combine different types of storage materials to overcome limitations of individual materials. These systems may integrate metal hydrides with carbon materials, catalysts, or heat transfer enhancers to improve performance. Composite approaches can enhance reaction kinetics, thermal management, and overall system efficiency. Research focuses on optimizing the synergistic effects between different components and developing practical containment systems for various applications including vehicles and stationary storage.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon fibers can store hydrogen through adsorption mechanisms. These materials offer advantages including lightweight structure, high surface area, and tunable porosity. The hydrogen storage capacity can be enhanced through surface modifications, doping with metals, or creating hybrid structures that combine the benefits of different carbon morphologies.Expand Specific Solutions03 Complex hydrides for hydrogen storage

Complex hydrides, including borohydrides, alanates, and amides, offer high gravimetric hydrogen storage capacity. These materials store hydrogen through chemical bonds within complex structures and can release hydrogen through thermal decomposition or catalytic reactions. Research focuses on improving their reversibility, reducing dehydrogenation temperatures, and enhancing kinetics through catalysts and nanostructuring techniques.Expand Specific Solutions04 Composite and hybrid hydrogen storage systems

Composite and hybrid hydrogen storage materials combine different storage mechanisms or materials to overcome limitations of individual components. These systems may integrate metal hydrides with carbon materials, incorporate catalysts into porous frameworks, or create core-shell structures. The synergistic effects in these composites can improve hydrogen uptake/release kinetics, cycling stability, and overall storage capacity while operating under milder conditions.Expand Specific Solutions05 Novel nanomaterials for hydrogen storage

Nanomaterials with tailored structures offer enhanced hydrogen storage properties due to their high surface area, shortened diffusion paths, and unique surface properties. These include metal-organic frameworks (MOFs), covalent organic frameworks (COFs), nanostructured polymers, and various nanoparticle systems. The nanoscale architecture allows for improved hydrogen adsorption/absorption, faster kinetics, and better thermal management during hydrogen uptake and release cycles.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Solutions

The hydrogen storage materials market for electronics applications is in a growth phase, characterized by increasing demand driven by the transition to clean energy solutions. The market size is expanding as hydrogen gains traction as an energy carrier, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels across different material types. Japan Metals & Chemicals and Santoku Corp. lead in hydrogen storage alloy development, while Toyota, Hyundai, and Kia are advancing automotive applications. Research institutions like AIST, CNRS, and universities (Zhejiang, Case Western) are pushing fundamental innovations. Battery manufacturers including GS Yuasa, Panasonic, and FDK are exploring hydrogen storage integration with existing technologies, creating a competitive landscape balanced between established industrial players and emerging research-driven entities.

SANYO Electric Co., Ltd.

Technical Solution: SANYO has developed specialized hydrogen storage alloys optimized for electronics applications, focusing on AB2-type Laves phase materials (where A represents zirconium or titanium and B represents transition metals like vanadium, chromium, and nickel). Their proprietary composition achieves hydrogen storage capacities of approximately 1.8-2.2 wt% with excellent cycling stability exceeding 2000 charge-discharge cycles. SANYO's materials feature modified surface structures that facilitate hydrogen diffusion while minimizing oxidation, resulting in improved longevity in real-world applications. Their technology incorporates precise control of particle size distribution (typically 20-50 μm) and internal microstructure to optimize hydrogen absorption/desorption kinetics. SANYO has also developed composite materials that combine conventional metal hydrides with catalytic additives to lower activation energies and improve low-temperature performance, making their solutions particularly suitable for consumer electronics operating in variable environmental conditions.

Strengths: Exceptional cycling durability with minimal capacity degradation; rapid activation without complex pretreatment procedures; cost-effective manufacturing using established production methods. Weaknesses: Lower gravimetric capacity compared to some emerging materials; requires specific temperature management for optimal performance; susceptibility to performance degradation from certain impurities.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced metal hydride systems for hydrogen storage, particularly focusing on complex hydrides and their applications in electronics. Their proprietary technology utilizes intermetallic compounds based on rare earth elements, titanium, and zirconium to achieve high volumetric and gravimetric hydrogen densities. Toyota's research has yielded AB5-type alloys (where A represents rare earth elements and B represents transition metals) with improved cycling stability and reduced degradation over time. Their materials demonstrate hydrogen storage capacities of up to 2 wt% at near-ambient conditions, with rapid absorption/desorption kinetics suitable for electronics applications. Toyota has also developed nanostructured materials with enhanced surface properties to improve reaction kinetics and lower operating temperatures, making them particularly suitable for portable electronic devices requiring stable power sources.

Strengths: Superior cycling stability with over 1000 charge-discharge cycles without significant capacity loss; excellent safety profile with minimal risk of thermal runaway; integration capability with existing manufacturing processes. Weaknesses: Higher production costs compared to conventional battery materials; lower gravimetric energy density compared to some competing technologies; requires specialized handling infrastructure.

Critical Patents and Innovations in Hydrogen Storage Materials

Hydrogen storage materials, electrochemically active materials, electrochemical cells and electronic devices

PatentInactiveJP2010504430A

Innovation

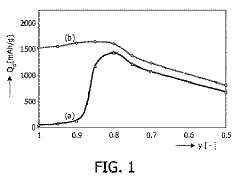

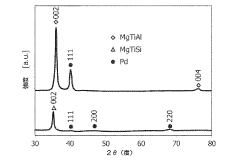

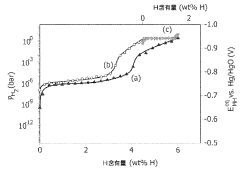

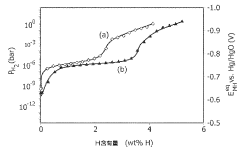

- Development of magnesium-based hydrogen storage alloys containing transition elements like titanium and covalent hydride-forming elements such as aluminum or silicon, which enhance hydrogen partial pressure and discharge rates at room temperature, maintaining a favorable crystal structure for efficient energy storage.

Hydrogen storage materials and hydrogen fuel cells

PatentActiveUS8883371B2

Innovation

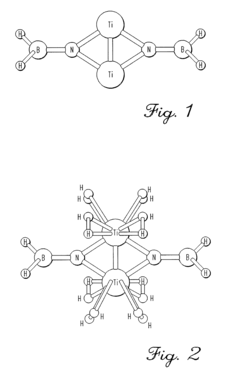

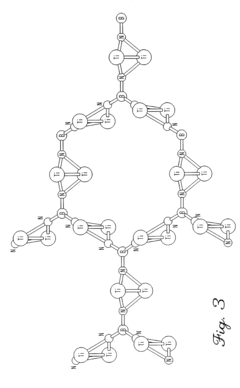

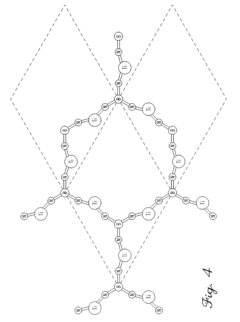

- Development of solid-state hydrogen storage materials comprising transition metal atoms bonded to elements from period 2 of the periodic table, which form stable hydrogenated states capable of adsorbing and desorbing hydrogen at temperatures below 200°C and pressures of 1 atm or less, achieving over 6.5% hydrogen weight percentage.

Safety and Regulatory Framework for Hydrogen Storage

The regulatory landscape for hydrogen storage in electronics applications is complex and evolving rapidly as hydrogen energy solutions gain prominence. International standards such as ISO/TC 197 specifically address hydrogen technologies, while IEC 62282 focuses on fuel cell technologies that often incorporate hydrogen storage systems. These standards establish baseline safety requirements for materials, containment systems, and operational protocols that manufacturers must adhere to when developing hydrogen storage solutions for electronic devices.

In the United States, the Department of Energy (DOE) has established stringent safety guidelines for hydrogen storage materials, requiring comprehensive risk assessments and failure mode analyses. The Code of Federal Regulations (CFR) Title 49 governs the transportation of hazardous materials, including hydrogen storage systems, imposing specific packaging, labeling, and handling requirements that impact the entire supply chain for electronic components utilizing hydrogen storage.

European regulations, particularly the ATEX Directive 2014/34/EU, impose additional requirements for equipment intended for use in potentially explosive atmospheres, directly affecting the design parameters for hydrogen storage in portable electronics. The Pressure Equipment Directive (PED) 2014/68/EU further regulates pressure vessels that may be used in hydrogen containment systems, establishing essential safety requirements for design, manufacture, and conformity assessment.

Material-specific regulations present another layer of complexity, with metal hydrides, carbon-based materials, and chemical hydrides each subject to different regulatory frameworks. For instance, rare earth metal hydrides face additional scrutiny under critical materials regulations, while certain chemical hydrides may trigger hazardous substance restrictions under regulations like RoHS in electronics applications.

Risk mitigation protocols constitute a critical component of the regulatory framework, with requirements for leak detection systems, pressure relief mechanisms, and thermal management solutions. The National Fire Protection Association (NFPA) code 2 specifically addresses hydrogen technologies and establishes fire safety requirements that influence material selection and system design for electronics applications.

Certification processes represent a significant hurdle for market entry, with UL, CSA, and TÜV certification often required before hydrogen storage systems can be integrated into commercial electronic products. These certification bodies evaluate not only the storage materials themselves but also their integration with electronic systems, focusing on thermal stability, pressure management, and failure containment.

Emerging regulations are increasingly focusing on end-of-life considerations, with the EU's Waste Electrical and Electronic Equipment (WEEE) Directive requiring manufacturers to establish recycling protocols for hydrogen storage materials used in electronic applications, adding another dimension to material selection decisions.

In the United States, the Department of Energy (DOE) has established stringent safety guidelines for hydrogen storage materials, requiring comprehensive risk assessments and failure mode analyses. The Code of Federal Regulations (CFR) Title 49 governs the transportation of hazardous materials, including hydrogen storage systems, imposing specific packaging, labeling, and handling requirements that impact the entire supply chain for electronic components utilizing hydrogen storage.

European regulations, particularly the ATEX Directive 2014/34/EU, impose additional requirements for equipment intended for use in potentially explosive atmospheres, directly affecting the design parameters for hydrogen storage in portable electronics. The Pressure Equipment Directive (PED) 2014/68/EU further regulates pressure vessels that may be used in hydrogen containment systems, establishing essential safety requirements for design, manufacture, and conformity assessment.

Material-specific regulations present another layer of complexity, with metal hydrides, carbon-based materials, and chemical hydrides each subject to different regulatory frameworks. For instance, rare earth metal hydrides face additional scrutiny under critical materials regulations, while certain chemical hydrides may trigger hazardous substance restrictions under regulations like RoHS in electronics applications.

Risk mitigation protocols constitute a critical component of the regulatory framework, with requirements for leak detection systems, pressure relief mechanisms, and thermal management solutions. The National Fire Protection Association (NFPA) code 2 specifically addresses hydrogen technologies and establishes fire safety requirements that influence material selection and system design for electronics applications.

Certification processes represent a significant hurdle for market entry, with UL, CSA, and TÜV certification often required before hydrogen storage systems can be integrated into commercial electronic products. These certification bodies evaluate not only the storage materials themselves but also their integration with electronic systems, focusing on thermal stability, pressure management, and failure containment.

Emerging regulations are increasingly focusing on end-of-life considerations, with the EU's Waste Electrical and Electronic Equipment (WEEE) Directive requiring manufacturers to establish recycling protocols for hydrogen storage materials used in electronic applications, adding another dimension to material selection decisions.

Environmental Impact and Sustainability Assessment

The environmental impact of hydrogen storage materials for electronics applications extends beyond their operational efficiency, encompassing their entire lifecycle from production to disposal. Traditional hydrogen storage methods often involve energy-intensive manufacturing processes that contribute significantly to carbon emissions. Materials such as metal hydrides require high temperatures and pressures during synthesis, resulting in substantial energy consumption and associated greenhouse gas emissions. Conversely, carbon-based materials like graphene and carbon nanotubes generally have lower production energy requirements, though their synthesis still involves chemical processes with potential environmental implications.

Water consumption represents another critical environmental consideration. The production of high-purity materials for hydrogen storage, particularly metal alloys and complex hydrides, often requires substantial water resources for processing and purification. This aspect becomes increasingly significant in regions facing water scarcity challenges, where industrial water usage competes with agricultural and domestic needs.

Resource depletion concerns are particularly relevant for storage solutions incorporating rare earth elements or precious metals. Materials such as palladium-based alloys, while offering excellent hydrogen absorption properties, rely on finite resources with geographically concentrated reserves. This raises sustainability questions regarding long-term viability and potential supply chain vulnerabilities. Alternative materials utilizing more abundant elements present more sustainable options from a resource conservation perspective.

End-of-life management presents both challenges and opportunities. Many hydrogen storage materials contain valuable components that could be recovered through appropriate recycling processes. However, current recycling infrastructure for these specialized materials remains underdeveloped. The complex compositions of some advanced storage materials, particularly multi-component systems, complicate separation and recovery efforts. Developing efficient recycling pathways represents a crucial aspect of improving the overall sustainability profile of these technologies.

Life cycle assessment (LCA) studies comparing different hydrogen storage materials reveal varying environmental footprints. When considering total environmental impact, materials with moderate performance but lower production energy requirements and better recyclability may outperform higher-capacity options with more intensive manufacturing processes. This highlights the importance of holistic evaluation approaches that consider environmental impacts across the entire material lifecycle rather than focusing exclusively on operational performance metrics.

Water consumption represents another critical environmental consideration. The production of high-purity materials for hydrogen storage, particularly metal alloys and complex hydrides, often requires substantial water resources for processing and purification. This aspect becomes increasingly significant in regions facing water scarcity challenges, where industrial water usage competes with agricultural and domestic needs.

Resource depletion concerns are particularly relevant for storage solutions incorporating rare earth elements or precious metals. Materials such as palladium-based alloys, while offering excellent hydrogen absorption properties, rely on finite resources with geographically concentrated reserves. This raises sustainability questions regarding long-term viability and potential supply chain vulnerabilities. Alternative materials utilizing more abundant elements present more sustainable options from a resource conservation perspective.

End-of-life management presents both challenges and opportunities. Many hydrogen storage materials contain valuable components that could be recovered through appropriate recycling processes. However, current recycling infrastructure for these specialized materials remains underdeveloped. The complex compositions of some advanced storage materials, particularly multi-component systems, complicate separation and recovery efforts. Developing efficient recycling pathways represents a crucial aspect of improving the overall sustainability profile of these technologies.

Life cycle assessment (LCA) studies comparing different hydrogen storage materials reveal varying environmental footprints. When considering total environmental impact, materials with moderate performance but lower production energy requirements and better recyclability may outperform higher-capacity options with more intensive manufacturing processes. This highlights the importance of holistic evaluation approaches that consider environmental impacts across the entire material lifecycle rather than focusing exclusively on operational performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!