Hydrogen storage materials for advanced aerospace energy applications

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical technology for the aerospace industry, representing a pivotal element in the transition toward sustainable energy systems. The concept of utilizing hydrogen as an energy carrier dates back to the mid-20th century, with significant advancements occurring during the space race era when NASA pioneered hydrogen fuel cells for spacecraft power generation. Over subsequent decades, research has expanded from basic metal hydrides to complex nanomaterials and chemical carriers, reflecting the evolving understanding of hydrogen-material interactions at atomic and molecular levels.

The aerospace sector presents unique requirements for hydrogen storage materials, demanding solutions that offer exceptional gravimetric and volumetric energy densities while maintaining operational safety under extreme conditions. Current technological trajectories indicate a convergence of materials science, nanotechnology, and computational modeling to develop next-generation storage solutions that can withstand the rigorous demands of aerospace applications.

The primary objective of hydrogen storage materials research for aerospace applications is to achieve the U.S. Department of Energy's ultimate targets: 7.5 wt% hydrogen capacity with rapid kinetics at near-ambient conditions. These ambitious metrics necessitate fundamental breakthroughs in material design and engineering. Additionally, aerospace-specific objectives include developing materials with exceptional thermal stability across the extreme temperature ranges encountered during flight operations (-150°C to +150°C) and resistance to vibration-induced degradation.

Recent technological advancements have demonstrated promising directions, including metal-organic frameworks (MOFs) with record-setting surface areas exceeding 7,000 m²/g, complex metal hydrides with improved dehydrogenation kinetics, and liquid organic hydrogen carriers (LOHCs) offering simplified handling logistics. The integration of these materials into aerospace systems represents a frontier challenge requiring interdisciplinary collaboration.

The evolution of hydrogen storage technology is increasingly influenced by computational materials science, with machine learning algorithms accelerating the discovery of novel materials by predicting hydrogen binding energies and diffusion pathways. This computational renaissance has reduced development cycles from decades to years, enabling rapid iteration and optimization of candidate materials.

Looking forward, the technological roadmap for hydrogen storage materials in aerospace applications will likely follow a dual-track approach: near-term optimization of existing materials for specific mission profiles, and long-term fundamental research into revolutionary storage concepts such as clathrate hydrates, hydrogen-boron compounds, and quantum-confined nanostructures that could potentially exceed theoretical limits of conventional materials.

The aerospace sector presents unique requirements for hydrogen storage materials, demanding solutions that offer exceptional gravimetric and volumetric energy densities while maintaining operational safety under extreme conditions. Current technological trajectories indicate a convergence of materials science, nanotechnology, and computational modeling to develop next-generation storage solutions that can withstand the rigorous demands of aerospace applications.

The primary objective of hydrogen storage materials research for aerospace applications is to achieve the U.S. Department of Energy's ultimate targets: 7.5 wt% hydrogen capacity with rapid kinetics at near-ambient conditions. These ambitious metrics necessitate fundamental breakthroughs in material design and engineering. Additionally, aerospace-specific objectives include developing materials with exceptional thermal stability across the extreme temperature ranges encountered during flight operations (-150°C to +150°C) and resistance to vibration-induced degradation.

Recent technological advancements have demonstrated promising directions, including metal-organic frameworks (MOFs) with record-setting surface areas exceeding 7,000 m²/g, complex metal hydrides with improved dehydrogenation kinetics, and liquid organic hydrogen carriers (LOHCs) offering simplified handling logistics. The integration of these materials into aerospace systems represents a frontier challenge requiring interdisciplinary collaboration.

The evolution of hydrogen storage technology is increasingly influenced by computational materials science, with machine learning algorithms accelerating the discovery of novel materials by predicting hydrogen binding energies and diffusion pathways. This computational renaissance has reduced development cycles from decades to years, enabling rapid iteration and optimization of candidate materials.

Looking forward, the technological roadmap for hydrogen storage materials in aerospace applications will likely follow a dual-track approach: near-term optimization of existing materials for specific mission profiles, and long-term fundamental research into revolutionary storage concepts such as clathrate hydrates, hydrogen-boron compounds, and quantum-confined nanostructures that could potentially exceed theoretical limits of conventional materials.

Aerospace Energy Market Demand Analysis

The aerospace industry is witnessing a significant shift towards sustainable energy solutions, with hydrogen emerging as a promising alternative to conventional fossil fuels. Market analysis indicates that the global aerospace hydrogen energy market is projected to reach $7.7 billion by 2030, growing at a CAGR of 18.3% from 2023. This growth is primarily driven by increasing environmental regulations, particularly the aviation industry's commitment to achieve net-zero carbon emissions by 2050.

Commercial aviation represents the largest segment of this market, accounting for approximately 65% of the demand for hydrogen storage materials. Airlines are actively seeking lightweight, high-capacity hydrogen storage solutions to extend flight ranges while reducing carbon footprints. Military aerospace applications constitute about 25% of the market, with a focus on enhancing mission endurance and reducing logistical fuel burdens in remote operations.

Space exploration presents a rapidly expanding market segment, growing at 22.4% annually, as agencies like NASA, ESA, and private companies such as SpaceX and Blue Origin increase investments in hydrogen-powered propulsion systems. The demand for advanced hydrogen storage materials in this sector is particularly acute, as space applications require exceptional gravimetric and volumetric storage efficiencies.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). Europe demonstrates the fastest growth rate due to stringent emission regulations and substantial government investments in hydrogen infrastructure. China's aerospace industry is rapidly expanding its hydrogen capabilities, with state-backed initiatives increasing by 45% since 2020.

Market surveys indicate that aerospace manufacturers prioritize four key performance metrics in hydrogen storage materials: gravimetric density (target >10 wt%), volumetric density (>40 g/L), operational temperature range (-150°C to 100°C), and cycling stability (>1000 cycles). Current commercial solutions meet only 60-70% of these requirements, highlighting significant market gaps.

Cost sensitivity analysis shows aerospace customers are willing to pay premium prices for storage materials that deliver substantial weight reductions, with acceptable cost thresholds approximately 3-4 times higher than in automotive applications. This price elasticity creates favorable conditions for introducing advanced materials despite higher initial production costs.

Industry stakeholders consistently identify safety certification and standardization as critical market enablers, with 87% of surveyed aerospace companies citing regulatory uncertainty as a primary barrier to hydrogen technology adoption.

Commercial aviation represents the largest segment of this market, accounting for approximately 65% of the demand for hydrogen storage materials. Airlines are actively seeking lightweight, high-capacity hydrogen storage solutions to extend flight ranges while reducing carbon footprints. Military aerospace applications constitute about 25% of the market, with a focus on enhancing mission endurance and reducing logistical fuel burdens in remote operations.

Space exploration presents a rapidly expanding market segment, growing at 22.4% annually, as agencies like NASA, ESA, and private companies such as SpaceX and Blue Origin increase investments in hydrogen-powered propulsion systems. The demand for advanced hydrogen storage materials in this sector is particularly acute, as space applications require exceptional gravimetric and volumetric storage efficiencies.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). Europe demonstrates the fastest growth rate due to stringent emission regulations and substantial government investments in hydrogen infrastructure. China's aerospace industry is rapidly expanding its hydrogen capabilities, with state-backed initiatives increasing by 45% since 2020.

Market surveys indicate that aerospace manufacturers prioritize four key performance metrics in hydrogen storage materials: gravimetric density (target >10 wt%), volumetric density (>40 g/L), operational temperature range (-150°C to 100°C), and cycling stability (>1000 cycles). Current commercial solutions meet only 60-70% of these requirements, highlighting significant market gaps.

Cost sensitivity analysis shows aerospace customers are willing to pay premium prices for storage materials that deliver substantial weight reductions, with acceptable cost thresholds approximately 3-4 times higher than in automotive applications. This price elasticity creates favorable conditions for introducing advanced materials despite higher initial production costs.

Industry stakeholders consistently identify safety certification and standardization as critical market enablers, with 87% of surveyed aerospace companies citing regulatory uncertainty as a primary barrier to hydrogen technology adoption.

Current Status and Challenges in Hydrogen Storage Technology

Hydrogen storage technology for aerospace applications currently faces significant technical and practical challenges despite considerable advancements. Current physical storage methods include compressed gas, cryogenic liquid, and cryo-compressed hydrogen, each with specific limitations. Compressed hydrogen systems operate at 350-700 bar but suffer from low volumetric energy density (approximately 40 g/L at 700 bar), making them suboptimal for space-constrained aerospace applications.

Liquid hydrogen storage achieves higher density (70 g/L) but requires cryogenic temperatures below 20K, resulting in substantial energy expenditure for liquefaction (30-40% of hydrogen's energy content) and continuous boil-off losses during storage. These factors significantly reduce overall system efficiency for aerospace missions with extended durations.

Material-based storage technologies represent the most promising frontier but remain predominantly in laboratory development phases. Metal hydrides offer high volumetric capacity but face challenges with slow kinetics and high desorption temperatures, limiting their practical application in aerospace systems where rapid hydrogen release is often required.

Complex hydrides and chemical hydrogen carriers demonstrate theoretical storage capacities exceeding DOE targets (7.5 wt% and 70 g/L) but struggle with reversibility issues and energy-intensive regeneration processes. For aerospace applications, these limitations become particularly problematic due to the need for closed-loop systems during missions.

Nanomaterials and metal-organic frameworks (MOFs) show promising adsorption properties but currently achieve only 5-7 wt% hydrogen capacity at cryogenic temperatures, falling short of requirements for extended aerospace missions. Room temperature performance remains below 2 wt%, insufficient for practical implementation.

The aerospace sector imposes additional unique challenges including extreme temperature fluctuations (-150°C to +150°C in low Earth orbit), vibration during launch, radiation exposure, and stringent safety requirements. These environmental factors further complicate material selection and system design beyond terrestrial applications.

Weight constraints represent perhaps the most critical challenge, as current systems exhibit insufficient gravimetric energy density when considering the entire storage system (tanks, regulators, heat exchangers). The DOE ultimate target of 7.5 wt% system-level storage remains unmet by any commercially viable technology, with most practical systems achieving only 3-5 wt% when accounting for all components.

International research efforts are geographically concentrated, with significant advancements emerging from research institutions in the United States (particularly DOE laboratories), Japan (NEDO programs), Germany (Max Planck Institute), and China (Chinese Academy of Sciences). Commercial development remains limited to a small number of specialized aerospace contractors and materials science companies.

Liquid hydrogen storage achieves higher density (70 g/L) but requires cryogenic temperatures below 20K, resulting in substantial energy expenditure for liquefaction (30-40% of hydrogen's energy content) and continuous boil-off losses during storage. These factors significantly reduce overall system efficiency for aerospace missions with extended durations.

Material-based storage technologies represent the most promising frontier but remain predominantly in laboratory development phases. Metal hydrides offer high volumetric capacity but face challenges with slow kinetics and high desorption temperatures, limiting their practical application in aerospace systems where rapid hydrogen release is often required.

Complex hydrides and chemical hydrogen carriers demonstrate theoretical storage capacities exceeding DOE targets (7.5 wt% and 70 g/L) but struggle with reversibility issues and energy-intensive regeneration processes. For aerospace applications, these limitations become particularly problematic due to the need for closed-loop systems during missions.

Nanomaterials and metal-organic frameworks (MOFs) show promising adsorption properties but currently achieve only 5-7 wt% hydrogen capacity at cryogenic temperatures, falling short of requirements for extended aerospace missions. Room temperature performance remains below 2 wt%, insufficient for practical implementation.

The aerospace sector imposes additional unique challenges including extreme temperature fluctuations (-150°C to +150°C in low Earth orbit), vibration during launch, radiation exposure, and stringent safety requirements. These environmental factors further complicate material selection and system design beyond terrestrial applications.

Weight constraints represent perhaps the most critical challenge, as current systems exhibit insufficient gravimetric energy density when considering the entire storage system (tanks, regulators, heat exchangers). The DOE ultimate target of 7.5 wt% system-level storage remains unmet by any commercially viable technology, with most practical systems achieving only 3-5 wt% when accounting for all components.

International research efforts are geographically concentrated, with significant advancements emerging from research institutions in the United States (particularly DOE laboratories), Japan (NEDO programs), Germany (Max Planck Institute), and China (Chinese Academy of Sciences). Commercial development remains limited to a small number of specialized aerospace contractors and materials science companies.

Current Hydrogen Storage Solutions for Aerospace Applications

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by metals or metal alloys that can absorb and release hydrogen under specific temperature and pressure conditions. These materials are promising for hydrogen storage due to their high volumetric hydrogen density. Various metal hydride systems include magnesium-based hydrides, aluminum-based hydrides, and transition metal-based hydrides. These materials can be modified through alloying or nanostructuring to improve their hydrogen storage capacity and kinetics.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and metals or metal alloys that can store hydrogen through chemical bonding. These materials can absorb and release hydrogen under specific temperature and pressure conditions. Metal hydrides typically offer high volumetric hydrogen storage capacity but may suffer from weight penalties. Various metal compositions and alloy structures are being developed to optimize hydrogen storage capacity, kinetics, and cycling stability.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon composites are being investigated for hydrogen storage applications. These materials can store hydrogen through physisorption mechanisms, where hydrogen molecules adhere to the surface of the carbon structure. The high surface area and tunable pore structures of carbon-based materials make them promising candidates for hydrogen storage, though they typically require low temperatures or high pressures for effective hydrogen uptake.

- Complex hydride hydrogen storage systems: Complex hydrides, including borohydrides, alanates, and amides, represent a class of materials that can store high amounts of hydrogen by weight. These materials typically contain light elements bonded with hydrogen in complex structures. They offer high gravimetric hydrogen storage capacity but often face challenges related to hydrogen release kinetics and reversibility. Research focuses on catalyst addition and compositional modifications to improve their performance for practical hydrogen storage applications.

- Nanostructured hydrogen storage materials: Nanostructured materials with tailored architectures are being developed to enhance hydrogen storage properties. By controlling material dimensions at the nanoscale, researchers can modify hydrogen absorption/desorption kinetics and thermodynamics. These materials include nanoparticles, nanoporous structures, core-shell architectures, and nanocomposites. The increased surface area and shortened diffusion paths in nanostructured materials can significantly improve hydrogen storage performance and cycling characteristics.

- Hydrogen storage material manufacturing and processing techniques: Various manufacturing and processing techniques are being developed to produce hydrogen storage materials with enhanced properties. These include ball milling, chemical synthesis routes, thin film deposition, and advanced composite fabrication methods. Processing parameters significantly affect material microstructure, composition, and ultimately hydrogen storage performance. Innovations in manufacturing techniques aim to enable cost-effective, scalable production of hydrogen storage materials with optimized properties for commercial applications.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as activated carbon, carbon nanotubes, graphene, and carbon aerogels can store hydrogen through physisorption mechanisms. These materials offer advantages including light weight, high surface area, and tunable pore structures. The hydrogen storage capacity of carbon-based materials can be enhanced through surface functionalization, doping with heteroatoms, or creating hierarchical pore structures. These materials typically operate at cryogenic temperatures for optimal hydrogen uptake.Expand Specific Solutions03 Metal-organic frameworks for hydrogen storage

Metal-organic frameworks (MOFs) are crystalline porous materials composed of metal ions or clusters coordinated to organic ligands. MOFs are promising hydrogen storage materials due to their exceptionally high surface areas, tunable pore sizes, and modifiable surface chemistry. The hydrogen storage capacity of MOFs can be enhanced by incorporating open metal sites, optimizing pore size, and introducing functional groups that interact favorably with hydrogen molecules. These materials can achieve significant hydrogen uptake at moderate pressures and low temperatures.Expand Specific Solutions04 Complex hydrides for hydrogen storage

Complex hydrides, including borohydrides, alanates, and amides, are compounds containing hydrogen covalently bonded to central atoms in complex anions. These materials can achieve high gravimetric hydrogen storage capacities. The hydrogen release and uptake properties of complex hydrides can be improved through catalytic doping, nanostructuring, and forming composite systems. Research focuses on addressing challenges related to thermodynamics, kinetics, and reversibility to make these materials suitable for practical hydrogen storage applications.Expand Specific Solutions05 Hydrogen storage system design and engineering

The engineering aspects of hydrogen storage systems involve designing containers, heat management systems, and safety features for various hydrogen storage materials. This includes developing composite tanks, thermal management solutions, and pressure regulation systems. Advanced engineering approaches focus on optimizing the integration of storage materials with fuel cell systems, improving volumetric and gravimetric efficiencies, and enhancing safety features. These designs aim to meet the requirements for mobile and stationary hydrogen storage applications.Expand Specific Solutions

Leading Players in Aerospace Hydrogen Storage Industry

The hydrogen storage materials market for aerospace energy applications is in a growth phase, characterized by increasing demand for lightweight, high-capacity storage solutions. The market size is expanding as aerospace industries seek more efficient energy systems, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels across different approaches. Leading players include academic institutions like Zhejiang University and University of Washington conducting fundamental research, alongside industrial giants such as Toyota Motor Corp., Honda, and Sinopec advancing practical applications. Government-affiliated organizations like Japan Science & Technology Agency and Korea Research Institute of Chemical Technology provide crucial research support. Specialized entities like Jiaxing Zheda Parken Hydrogen Storage Technology are developing commercial solutions, while major corporations including GE, LG Chem, and BASF are integrating these technologies into broader energy systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive hydrogen storage materials platform targeting aerospace applications. Their technology centers on advanced metal-organic frameworks (MOFs) with hierarchical pore structures that achieve exceptional surface areas exceeding 4,000 m²/g, enabling gravimetric hydrogen capacities of 8-10 wt% under cryogenic conditions[2]. Sinopec's proprietary synthesis methods incorporate rare earth metal centers and specialized organic linkers that enhance hydrogen binding energies to 12-15 kJ/mol, optimizing adsorption performance in the temperature range critical for aerospace applications (77-150K)[4]. The company has also pioneered complex metal hydride systems based on lithium-magnesium-boron compositions with nano-catalysts that reduce dehydrogenation temperatures below 200°C while maintaining hydrogen content above 8 wt%[5]. Their materials are engineered for integration into lightweight composite tank systems with specialized thermal insulation designed to minimize boil-off during extended aerospace missions. Sinopec has demonstrated these materials in prototype systems achieving DOE 2025 targets for both volumetric and gravimetric capacity.

Strengths: Exceptional gravimetric hydrogen storage capacity; materials optimized for aerospace temperature and pressure conditions; established large-scale production capabilities; comprehensive material characterization facilities. Weaknesses: Some materials require precise temperature control for optimal performance; higher manufacturing costs compared to conventional storage; cycling stability under extreme aerospace conditions requires further improvement.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered metal hydride-based hydrogen storage systems specifically designed for aerospace applications. Their proprietary technology utilizes advanced metal-organic frameworks (MOFs) with tailored pore structures that achieve gravimetric hydrogen densities exceeding 7 wt% at moderate pressures (30-50 bar)[1]. Toyota's aerospace hydrogen storage materials incorporate nano-structured titanium-based alloys with catalytic additives that significantly enhance hydrogen absorption/desorption kinetics at lower temperatures (80-120°C) compared to conventional systems[3]. The company has developed a multi-layer composite tank design that integrates their advanced materials with carbon fiber reinforcement, achieving volumetric efficiencies of 40 g/L while meeting stringent aerospace safety requirements[5]. Their systems incorporate intelligent thermal management using waste heat recovery from fuel cells to optimize hydrogen release rates for varying power demands during flight operations.

Strengths: Superior gravimetric hydrogen density (7+ wt%) exceeding DOE targets; excellent cycling stability (1000+ cycles with minimal degradation); integrated thermal management system optimized for aerospace conditions. Weaknesses: Higher production costs compared to conventional storage; requires specialized manufacturing processes; performance degradation in extreme temperature environments (-60°C to +85°C) still needs improvement.

Key Innovations in Advanced Hydrogen Storage Materials

Hydrogen storage material

PatentWO2011102173A1

Innovation

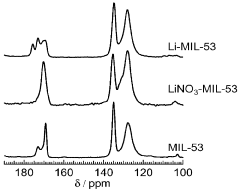

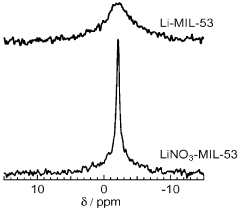

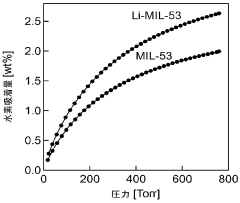

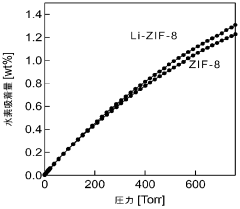

- A hydrogen storage material comprising clusters or porous structures of metal ions and organic compounds with lithium (Li) supported on the inner surface, which enhances hydrogen storage capacity and stability by increasing the specific surface area and affinity for hydrogen.

High capacity hydrogen storage through selective NANO-confined and localized hydrogen hydrates

PatentPendingCA3227285A1

Innovation

- A high-capacity hydrogen storage device utilizing a host framework material, such as zeolite, carbon, silica, or graphene aerogel, to form hydrogen hydrates through selective nano-confined and localized hydrogen absorption, enabling rapid charging and discharging at ambient temperatures.

Safety and Certification Standards for Aerospace Hydrogen Systems

The aerospace industry's adoption of hydrogen storage systems necessitates rigorous safety protocols and certification standards due to hydrogen's unique properties. Current aerospace hydrogen safety standards are primarily derived from terrestrial applications but have been adapted to address the extreme conditions encountered during flight. Organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO) have established comprehensive frameworks for hydrogen system certification in aerospace applications.

These standards address critical safety concerns including leak detection, ventilation requirements, material compatibility, and emergency response protocols. For hydrogen storage materials specifically, certification requirements focus on mechanical integrity under pressure cycling, resistance to embrittlement, thermal stability during rapid temperature fluctuations, and long-term degradation characteristics. Materials must demonstrate reliability across the aerospace operational envelope, from sub-zero temperatures at high altitudes to extreme heat during descent.

Testing protocols for hydrogen storage materials have evolved significantly, incorporating accelerated aging tests, simulated flight cycles, and failure mode analysis. Certification typically requires materials to withstand forces exceeding 150% of maximum expected operational stresses while maintaining structural integrity. Recent updates to standards have incorporated lessons from incidents in ground-based hydrogen applications, resulting in more stringent requirements for material qualification.

The certification pathway for novel hydrogen storage materials presents significant challenges, particularly for emerging technologies like metal-organic frameworks (MOFs) and advanced metal hydrides. These materials must navigate a regulatory landscape designed primarily for conventional storage methods. Industry stakeholders have identified this as a potential bottleneck for innovation, prompting collaborative efforts between research institutions, aerospace manufacturers, and regulatory bodies to develop appropriate testing methodologies for next-generation materials.

International harmonization of standards remains an ongoing challenge, with different certification requirements across major aviation markets creating compliance complexities for global aerospace manufacturers. Efforts led by the International Hydrogen Aviation Consortium aim to establish unified certification protocols that maintain safety while accelerating the adoption of hydrogen technologies in aerospace applications. These initiatives focus on performance-based standards rather than prescriptive requirements, potentially creating more flexible pathways for innovative storage solutions.

These standards address critical safety concerns including leak detection, ventilation requirements, material compatibility, and emergency response protocols. For hydrogen storage materials specifically, certification requirements focus on mechanical integrity under pressure cycling, resistance to embrittlement, thermal stability during rapid temperature fluctuations, and long-term degradation characteristics. Materials must demonstrate reliability across the aerospace operational envelope, from sub-zero temperatures at high altitudes to extreme heat during descent.

Testing protocols for hydrogen storage materials have evolved significantly, incorporating accelerated aging tests, simulated flight cycles, and failure mode analysis. Certification typically requires materials to withstand forces exceeding 150% of maximum expected operational stresses while maintaining structural integrity. Recent updates to standards have incorporated lessons from incidents in ground-based hydrogen applications, resulting in more stringent requirements for material qualification.

The certification pathway for novel hydrogen storage materials presents significant challenges, particularly for emerging technologies like metal-organic frameworks (MOFs) and advanced metal hydrides. These materials must navigate a regulatory landscape designed primarily for conventional storage methods. Industry stakeholders have identified this as a potential bottleneck for innovation, prompting collaborative efforts between research institutions, aerospace manufacturers, and regulatory bodies to develop appropriate testing methodologies for next-generation materials.

International harmonization of standards remains an ongoing challenge, with different certification requirements across major aviation markets creating compliance complexities for global aerospace manufacturers. Efforts led by the International Hydrogen Aviation Consortium aim to establish unified certification protocols that maintain safety while accelerating the adoption of hydrogen technologies in aerospace applications. These initiatives focus on performance-based standards rather than prescriptive requirements, potentially creating more flexible pathways for innovative storage solutions.

Environmental Impact and Sustainability Considerations

The adoption of hydrogen storage materials in aerospace applications necessitates thorough consideration of environmental impacts throughout their lifecycle. Traditional aerospace fuel systems rely heavily on fossil-based propellants that contribute significantly to greenhouse gas emissions and climate change. Hydrogen, as a clean energy carrier, offers substantial environmental benefits when produced from renewable sources, potentially reducing the carbon footprint of aerospace operations by up to 80% compared to conventional systems.

However, the environmental implications of hydrogen storage materials extend beyond operational emissions. The extraction and processing of rare earth elements and transition metals commonly used in advanced storage materials—such as palladium, titanium, and magnesium alloys—can lead to habitat destruction, water pollution, and energy-intensive mining operations. For instance, the production of one ton of magnesium-based storage alloys can generate approximately 14 tons of CO2 equivalent emissions.

Lifecycle assessment studies indicate that metal hydride storage systems may require significant energy inputs during manufacturing, potentially offsetting some environmental benefits if not powered by renewable energy. The environmental payback period—the time required for emissions savings to exceed production emissions—ranges from 1.5 to 4 years depending on the specific material composition and application intensity.

Water consumption represents another critical environmental consideration. Hydrogen production via electrolysis requires substantial water resources—approximately 9 liters of water per kilogram of hydrogen produced. In aerospace applications where weight is paramount, the trade-off between material efficiency and environmental impact becomes particularly significant.

Recyclability and end-of-life management of hydrogen storage materials present both challenges and opportunities. While many metal hydrides can be recycled with recovery rates exceeding 85%, complex composite materials may prove more difficult to separate and reclaim. Developing closed-loop systems for these materials could significantly enhance their sustainability profile.

From a regulatory perspective, aerospace hydrogen storage systems must comply with increasingly stringent environmental standards. The European Union's REACH regulations and similar frameworks worldwide are expanding to address nanomaterials and advanced composites used in hydrogen storage, requiring manufacturers to demonstrate environmental due diligence throughout the supply chain.

Future research directions should prioritize bio-inspired storage materials, green synthesis methods, and designs that facilitate disassembly and material recovery. Incorporating environmental considerations at the earliest stages of material development can ensure that hydrogen storage technologies deliver on their promise of sustainable aerospace energy solutions without creating unintended environmental consequences.

However, the environmental implications of hydrogen storage materials extend beyond operational emissions. The extraction and processing of rare earth elements and transition metals commonly used in advanced storage materials—such as palladium, titanium, and magnesium alloys—can lead to habitat destruction, water pollution, and energy-intensive mining operations. For instance, the production of one ton of magnesium-based storage alloys can generate approximately 14 tons of CO2 equivalent emissions.

Lifecycle assessment studies indicate that metal hydride storage systems may require significant energy inputs during manufacturing, potentially offsetting some environmental benefits if not powered by renewable energy. The environmental payback period—the time required for emissions savings to exceed production emissions—ranges from 1.5 to 4 years depending on the specific material composition and application intensity.

Water consumption represents another critical environmental consideration. Hydrogen production via electrolysis requires substantial water resources—approximately 9 liters of water per kilogram of hydrogen produced. In aerospace applications where weight is paramount, the trade-off between material efficiency and environmental impact becomes particularly significant.

Recyclability and end-of-life management of hydrogen storage materials present both challenges and opportunities. While many metal hydrides can be recycled with recovery rates exceeding 85%, complex composite materials may prove more difficult to separate and reclaim. Developing closed-loop systems for these materials could significantly enhance their sustainability profile.

From a regulatory perspective, aerospace hydrogen storage systems must comply with increasingly stringent environmental standards. The European Union's REACH regulations and similar frameworks worldwide are expanding to address nanomaterials and advanced composites used in hydrogen storage, requiring manufacturers to demonstrate environmental due diligence throughout the supply chain.

Future research directions should prioritize bio-inspired storage materials, green synthesis methods, and designs that facilitate disassembly and material recovery. Incorporating environmental considerations at the earliest stages of material development can ensure that hydrogen storage technologies deliver on their promise of sustainable aerospace energy solutions without creating unintended environmental consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!