How Hydrogen storage materials influence thermal stability in fuel cells

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Evolution and Objectives

Hydrogen storage materials have evolved significantly over the past decades, driven by the increasing demand for clean energy solutions and the pivotal role of hydrogen in the transition to a low-carbon economy. The journey began in the 1970s with conventional metal hydrides, which offered moderate hydrogen storage capacity but suffered from weight inefficiencies and thermal management challenges. These early materials, primarily based on intermetallic compounds like LaNi5 and TiFe, established the foundation for hydrogen storage research but revealed limitations in practical applications.

The 1990s witnessed a paradigm shift with the discovery of carbon-based materials, including carbon nanotubes and graphene, which promised enhanced surface area for hydrogen adsorption. Concurrently, complex hydrides emerged as potential high-capacity storage solutions, though they faced significant challenges regarding reversibility and kinetics. This period marked the transition from purely experimental approaches to more systematic material design strategies.

The early 2000s brought breakthrough developments in chemical hydrides and metal-organic frameworks (MOFs), offering unprecedented surface areas exceeding 6,000 m²/g and theoretical hydrogen capacities approaching the Department of Energy's ambitious targets. These advanced materials demonstrated improved thermal stability characteristics, critical for fuel cell applications where temperature management directly impacts system efficiency and longevity.

Recent advancements have focused on hybrid systems and nanoscale engineering of storage materials, with particular emphasis on enhancing thermal conductivity and stability under operational conditions. Researchers have developed core-shell nanostructures and doped materials that exhibit superior heat distribution properties, addressing one of the fundamental challenges in fuel cell technology: thermal management during hydrogen absorption and desorption processes.

The primary objective in this field remains developing hydrogen storage materials that can maintain structural integrity and performance across the wide temperature range experienced in fuel cell operations. Specifically, materials must withstand temperatures from ambient conditions to over 120°C during fuel cell operation while preventing thermal runaway scenarios. Additionally, these materials should facilitate rapid heat dissipation during exothermic absorption processes and provide efficient thermal energy during endothermic desorption.

Future research aims to achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% hydrogen capacity, 50 g H₂/L volumetric capacity, and operational stability across -40°C to 85°C for consumer applications and up to 150°C for specialized industrial applications. Meeting these objectives requires interdisciplinary approaches combining materials science, thermodynamics, and system engineering to develop next-generation storage solutions that enhance fuel cell thermal stability while maintaining high gravimetric and volumetric hydrogen capacities.

The 1990s witnessed a paradigm shift with the discovery of carbon-based materials, including carbon nanotubes and graphene, which promised enhanced surface area for hydrogen adsorption. Concurrently, complex hydrides emerged as potential high-capacity storage solutions, though they faced significant challenges regarding reversibility and kinetics. This period marked the transition from purely experimental approaches to more systematic material design strategies.

The early 2000s brought breakthrough developments in chemical hydrides and metal-organic frameworks (MOFs), offering unprecedented surface areas exceeding 6,000 m²/g and theoretical hydrogen capacities approaching the Department of Energy's ambitious targets. These advanced materials demonstrated improved thermal stability characteristics, critical for fuel cell applications where temperature management directly impacts system efficiency and longevity.

Recent advancements have focused on hybrid systems and nanoscale engineering of storage materials, with particular emphasis on enhancing thermal conductivity and stability under operational conditions. Researchers have developed core-shell nanostructures and doped materials that exhibit superior heat distribution properties, addressing one of the fundamental challenges in fuel cell technology: thermal management during hydrogen absorption and desorption processes.

The primary objective in this field remains developing hydrogen storage materials that can maintain structural integrity and performance across the wide temperature range experienced in fuel cell operations. Specifically, materials must withstand temperatures from ambient conditions to over 120°C during fuel cell operation while preventing thermal runaway scenarios. Additionally, these materials should facilitate rapid heat dissipation during exothermic absorption processes and provide efficient thermal energy during endothermic desorption.

Future research aims to achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% hydrogen capacity, 50 g H₂/L volumetric capacity, and operational stability across -40°C to 85°C for consumer applications and up to 150°C for specialized industrial applications. Meeting these objectives requires interdisciplinary approaches combining materials science, thermodynamics, and system engineering to develop next-generation storage solutions that enhance fuel cell thermal stability while maintaining high gravimetric and volumetric hydrogen capacities.

Market Analysis for Fuel Cell Applications

The global fuel cell market is experiencing significant growth, with projections indicating an expansion from $5.9 billion in 2022 to approximately $32 billion by 2030, representing a compound annual growth rate of 23.5%. This remarkable growth trajectory is primarily driven by increasing environmental concerns, stringent emission regulations, and the global push toward clean energy solutions.

Transportation remains the dominant application sector, accounting for nearly 45% of the fuel cell market. The automotive industry's shift toward hydrogen fuel cell vehicles (FCVs) is particularly notable in regions like Japan, South Korea, and parts of Europe where hydrogen infrastructure is developing rapidly. Commercial vehicles, including buses and trucks, represent the fastest-growing segment within transportation applications due to their predictable routes and centralized refueling capabilities.

Stationary power generation constitutes approximately 30% of the market, with significant adoption in backup power systems for telecommunications, data centers, and residential applications. Japan leads this segment following the implementation of its ENE-FARM program, which has deployed over 300,000 residential fuel cell systems.

Portable applications represent a smaller but growing segment at 15% of the market, primarily in military applications and emergency response equipment where reliability and extended operation are critical factors.

Regionally, Asia Pacific dominates the fuel cell market with approximately 45% share, led by Japan and South Korea's aggressive hydrogen economy initiatives. North America follows at 30%, with significant growth in California's zero-emission vehicle programs. Europe accounts for 20% of the market, with Germany, the UK, and Scandinavian countries leading adoption.

The market dynamics are heavily influenced by the thermal stability challenges in fuel cells, particularly related to hydrogen storage materials. End-users increasingly demand systems with improved thermal management capabilities, longer operational lifespans, and reduced degradation rates. This has created a premium market segment for advanced fuel cells incorporating thermally stable hydrogen storage materials, commanding 15-20% higher prices but offering 30-40% longer operational lifetimes.

Key customer requirements driving market growth include improved system reliability, reduced total cost of ownership, and enhanced safety profiles. The market increasingly values fuel cell systems that can maintain performance stability across wider temperature ranges, directly connecting to advancements in hydrogen storage materials that offer superior thermal stability characteristics.

Transportation remains the dominant application sector, accounting for nearly 45% of the fuel cell market. The automotive industry's shift toward hydrogen fuel cell vehicles (FCVs) is particularly notable in regions like Japan, South Korea, and parts of Europe where hydrogen infrastructure is developing rapidly. Commercial vehicles, including buses and trucks, represent the fastest-growing segment within transportation applications due to their predictable routes and centralized refueling capabilities.

Stationary power generation constitutes approximately 30% of the market, with significant adoption in backup power systems for telecommunications, data centers, and residential applications. Japan leads this segment following the implementation of its ENE-FARM program, which has deployed over 300,000 residential fuel cell systems.

Portable applications represent a smaller but growing segment at 15% of the market, primarily in military applications and emergency response equipment where reliability and extended operation are critical factors.

Regionally, Asia Pacific dominates the fuel cell market with approximately 45% share, led by Japan and South Korea's aggressive hydrogen economy initiatives. North America follows at 30%, with significant growth in California's zero-emission vehicle programs. Europe accounts for 20% of the market, with Germany, the UK, and Scandinavian countries leading adoption.

The market dynamics are heavily influenced by the thermal stability challenges in fuel cells, particularly related to hydrogen storage materials. End-users increasingly demand systems with improved thermal management capabilities, longer operational lifespans, and reduced degradation rates. This has created a premium market segment for advanced fuel cells incorporating thermally stable hydrogen storage materials, commanding 15-20% higher prices but offering 30-40% longer operational lifetimes.

Key customer requirements driving market growth include improved system reliability, reduced total cost of ownership, and enhanced safety profiles. The market increasingly values fuel cell systems that can maintain performance stability across wider temperature ranges, directly connecting to advancements in hydrogen storage materials that offer superior thermal stability characteristics.

Technical Challenges in Thermal Stability

The thermal stability of fuel cells represents a critical challenge in hydrogen energy systems, particularly when considering the complex interactions between hydrogen storage materials and the overall fuel cell architecture. Current fuel cell technologies face significant thermal management issues that directly impact performance, durability, and safety. Temperature fluctuations during operation can cause degradation of catalyst layers, membrane dehydration, and structural damage to critical components.

Hydrogen storage materials introduce unique thermal challenges to fuel cell systems. Metal hydrides, while offering high volumetric storage capacity, undergo exothermic absorption and endothermic desorption processes that generate substantial heat gradients. These temperature variations can exceed 30-50°C during rapid charging or discharging cycles, creating thermal stress points throughout the system. Complex hydrides and chemical hydrogen carriers present even more severe thermal management challenges, with some materials requiring temperatures above 300°C for hydrogen release.

The interface between storage materials and fuel cell components presents particular thermal stability concerns. Heat transfer across material boundaries often creates localized hotspots that accelerate degradation of polymer electrolyte membranes, which typically have operating temperature limitations of 80-90°C. Thermal cycling during start-up and shutdown operations further exacerbates these issues, leading to mechanical stress and potential failure points at material junctions.

Catalyst poisoning represents another thermal stability challenge, as temperature fluctuations can promote the migration of storage material components or impurities onto catalyst surfaces. This phenomenon is particularly problematic with borohydride-based storage materials, where boron compounds can irreversibly deactivate platinum catalysts at elevated temperatures, significantly reducing cell efficiency and lifespan.

Engineering solutions for thermal stability face contradictory requirements. While higher operating temperatures improve reaction kinetics and system efficiency, they simultaneously accelerate degradation mechanisms and materials aging. Current thermal management systems add significant weight, volume, and complexity to fuel cell designs, compromising the energy density advantages that hydrogen storage materials theoretically offer.

Advanced computational modeling has revealed that thermal conductivity mismatches between storage materials and fuel cell components create stress concentrations during thermal cycling. These mechanical stresses can lead to microcracking, delamination, and eventual failure of critical interfaces. The development of thermally resilient interface materials remains an active research challenge with few commercially viable solutions currently available.

Hydrogen storage materials introduce unique thermal challenges to fuel cell systems. Metal hydrides, while offering high volumetric storage capacity, undergo exothermic absorption and endothermic desorption processes that generate substantial heat gradients. These temperature variations can exceed 30-50°C during rapid charging or discharging cycles, creating thermal stress points throughout the system. Complex hydrides and chemical hydrogen carriers present even more severe thermal management challenges, with some materials requiring temperatures above 300°C for hydrogen release.

The interface between storage materials and fuel cell components presents particular thermal stability concerns. Heat transfer across material boundaries often creates localized hotspots that accelerate degradation of polymer electrolyte membranes, which typically have operating temperature limitations of 80-90°C. Thermal cycling during start-up and shutdown operations further exacerbates these issues, leading to mechanical stress and potential failure points at material junctions.

Catalyst poisoning represents another thermal stability challenge, as temperature fluctuations can promote the migration of storage material components or impurities onto catalyst surfaces. This phenomenon is particularly problematic with borohydride-based storage materials, where boron compounds can irreversibly deactivate platinum catalysts at elevated temperatures, significantly reducing cell efficiency and lifespan.

Engineering solutions for thermal stability face contradictory requirements. While higher operating temperatures improve reaction kinetics and system efficiency, they simultaneously accelerate degradation mechanisms and materials aging. Current thermal management systems add significant weight, volume, and complexity to fuel cell designs, compromising the energy density advantages that hydrogen storage materials theoretically offer.

Advanced computational modeling has revealed that thermal conductivity mismatches between storage materials and fuel cell components create stress concentrations during thermal cycling. These mechanical stresses can lead to microcracking, delamination, and eventual failure of critical interfaces. The development of thermally resilient interface materials remains an active research challenge with few commercially viable solutions currently available.

Current Thermal Management Solutions

01 Metal hydride-based hydrogen storage materials

Metal hydrides are widely used as hydrogen storage materials due to their high hydrogen storage capacity. These materials can be designed with enhanced thermal stability through various methods such as alloying, doping, or surface modification. The thermal stability of metal hydrides is crucial for practical applications as it determines the operating temperature range and safety of hydrogen storage systems. Improved thermal stability helps prevent hydrogen release at undesired temperatures and ensures consistent performance under varying conditions.- Metal hydride-based hydrogen storage materials: Metal hydrides are widely used for hydrogen storage due to their high volumetric hydrogen density. These materials can store hydrogen through chemical bonding, forming metal-hydrogen compounds. The thermal stability of metal hydrides is crucial for practical applications, as it determines the operating temperature range and hydrogen release characteristics. Various metal hydride systems have been developed with improved thermal stability through composition optimization and catalytic additives.

- Complex hydride systems for enhanced thermal stability: Complex hydrides, including borohydrides, alanates, and amides, offer promising hydrogen storage capabilities with tunable thermal stability properties. These materials typically contain light elements bonded with hydrogen, providing high gravimetric hydrogen capacity. Researchers have developed methods to enhance the thermal stability of complex hydrides through doping, nanostructuring, and creating composite systems. These approaches help control hydrogen desorption temperatures and improve cycling stability for practical applications.

- Nanomaterial-based hydrogen storage with controlled thermal properties: Nanomaterials offer unique advantages for hydrogen storage with tailored thermal stability. Carbon-based materials (nanotubes, graphene), metal-organic frameworks, and nanostructured metal alloys provide high surface area and tunable pore structures for hydrogen adsorption. The thermal stability of these nanomaterials can be engineered through surface functionalization, doping with heteroatoms, and creating hierarchical structures. These approaches allow for optimized hydrogen binding energies and controlled release temperatures.

- Testing and characterization methods for thermal stability: Various analytical techniques have been developed to evaluate the thermal stability of hydrogen storage materials. These include thermal desorption spectroscopy, differential scanning calorimetry, thermogravimetric analysis, and temperature-programmed desorption. Advanced in-situ characterization methods allow for real-time monitoring of structural changes during hydrogen absorption/desorption cycles under different temperature conditions. These testing methodologies are essential for understanding degradation mechanisms and improving the thermal stability of hydrogen storage materials.

- Composite and catalytically enhanced hydrogen storage materials: Composite hydrogen storage materials combine different components to achieve enhanced thermal stability and hydrogen storage properties. These materials often incorporate catalysts to lower activation energies for hydrogen absorption/desorption reactions and stabilize the material during thermal cycling. Transition metals, metal oxides, and nanostructured catalysts have been integrated into various hydrogen storage matrices to improve kinetics while maintaining thermal stability. These composite approaches allow for tailored thermal properties suitable for specific application requirements.

02 Complex hydride systems with improved thermal characteristics

Complex hydrides, including borohydrides, alanates, and amides, offer promising hydrogen storage properties with enhanced thermal stability. These materials can be engineered to release hydrogen at specific temperature ranges through catalyst addition or compositional modifications. The thermal decomposition pathways of complex hydrides can be controlled to achieve stepwise hydrogen release, providing better thermal management during operation. Nanostructuring of complex hydrides has been shown to significantly improve their thermal stability and hydrogen sorption kinetics.Expand Specific Solutions03 Carbon-based and composite hydrogen storage materials

Carbon-based materials such as graphene, carbon nanotubes, and activated carbon can be used as hydrogen storage media with excellent thermal stability. These materials can be combined with metal or complex hydrides to form composites that benefit from the thermal properties of both components. The porous structure of carbon materials provides pathways for heat dissipation, improving the overall thermal management of the storage system. Surface functionalization of carbon materials can enhance both hydrogen storage capacity and thermal stability by creating additional binding sites and reducing agglomeration.Expand Specific Solutions04 Testing and characterization methods for thermal stability

Various analytical techniques are employed to evaluate the thermal stability of hydrogen storage materials, including differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and temperature-programmed desorption (TPD). These methods help determine critical thermal parameters such as decomposition temperature, activation energy, and heat of reaction. Accelerated aging tests under controlled temperature and pressure conditions can predict the long-term thermal stability and cycling performance of hydrogen storage materials. Advanced in-situ characterization techniques allow for real-time monitoring of structural changes during thermal cycling.Expand Specific Solutions05 Encapsulation and protective strategies for thermal stabilization

Encapsulation techniques using core-shell structures, polymer coatings, or metal-organic frameworks can significantly enhance the thermal stability of hydrogen storage materials. These protective layers act as barriers against oxidation, moisture, and thermal degradation while allowing hydrogen permeation. Thermal management systems incorporating phase change materials or heat exchangers can be integrated with hydrogen storage materials to maintain optimal operating temperatures. Surface passivation treatments can reduce unwanted reactions at elevated temperatures, thereby improving the overall thermal stability and cycling performance of hydrogen storage systems.Expand Specific Solutions

Leading Companies and Research Institutions

The hydrogen storage materials market for fuel cell thermal stability is in a growth phase, with increasing market size driven by the automotive sector's shift towards clean energy. The technology is advancing from early-stage development to commercial applications, though still maturing. Key players demonstrate varying levels of technological maturity: automotive giants like Toyota, Hyundai, and Honda lead commercial implementation; Air Liquide and H2Go Power represent specialized expertise in hydrogen storage solutions; while academic institutions such as McGill University and Hiroshima University contribute fundamental research. Industrial collaborations between automotive manufacturers and materials specialists are accelerating development, with companies like Intelligent Energy and Toyota Industries focusing on lightweight, efficient storage systems that maintain thermal stability under operational conditions.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced hydrogen storage materials under their "HydroTech" initiative, focusing specifically on thermal stability challenges in automotive fuel cell applications. Their approach centers on complex borohydride-based materials (primarily Mg(BH4)2 and Ca(BH4)2 systems) with tailored additives that modify decomposition pathways and thermal properties[1]. GM's proprietary technology incorporates nanostructured frameworks with controlled porosity that facilitate heat dissipation during hydrogen charging/discharging cycles. Their materials feature thermally-responsive polymer interfaces that act as buffers during temperature fluctuations, preventing structural degradation of the storage medium. GM has pioneered composite systems that combine conventional metal hydrides with advanced carbon materials (graphene and carbon nanotubes), creating synergistic effects that improve thermal conductivity by up to 75% while maintaining high gravimetric capacity[3]. Additionally, their systems incorporate phase-change materials strategically positioned within the storage matrix to absorb excess heat during exothermic absorption processes, effectively regulating temperature profiles during operation.

Strengths: Superior thermal management under automotive duty cycles, excellent integration with vehicle cooling systems, and optimized weight-to-capacity ratios. Weaknesses: Higher initial costs compared to conventional storage technologies, and some materials show sensitivity to contaminants that can accelerate thermal degradation over time.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced metal hydride storage systems that significantly improve thermal stability in fuel cells. Their proprietary technology utilizes specialized alloys (primarily Ti-Cr-V based) with optimized microstructures that enable efficient hydrogen absorption/desorption while maintaining structural integrity during temperature fluctuations[1]. Toyota's approach incorporates a multi-layered thermal management system that integrates phase-change materials with their metal hydride tanks, allowing for controlled heat distribution during operation cycles. Their latest systems feature nano-structured composites with catalytic additives that reduce activation energy requirements and improve kinetics at lower temperatures, addressing the critical challenge of heat generation during hydrogen uptake and release[3]. Toyota has also developed specialized tank designs with integrated cooling channels that maintain optimal operating temperatures (60-120°C) even under rapid charge/discharge conditions, preventing thermal runaway scenarios that could compromise fuel cell efficiency and longevity.

Strengths: Industry-leading thermal management integration, proven reliability in commercial vehicles, and advanced alloy formulations with superior cycling stability. Weaknesses: Higher production costs compared to conventional storage, weight penalties in some applications, and dependence on rare earth elements in some alloy compositions.

Key Patents in Hydrogen Storage Materials

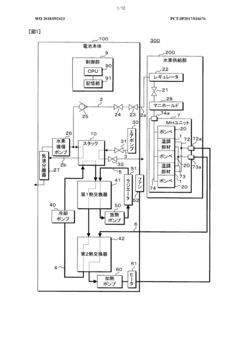

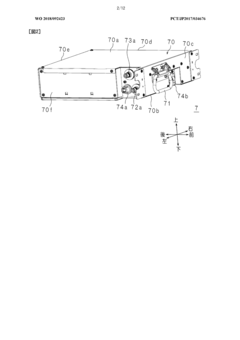

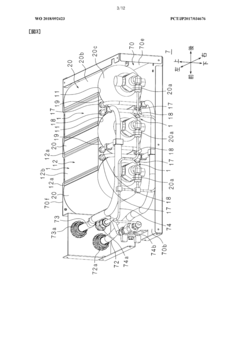

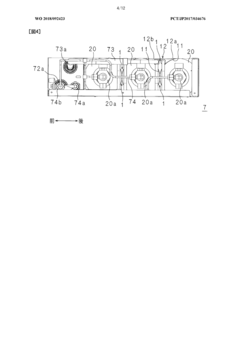

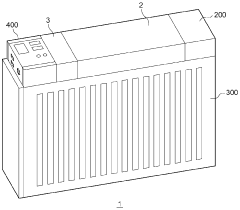

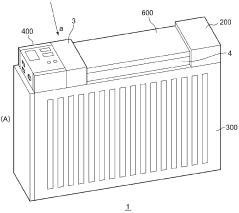

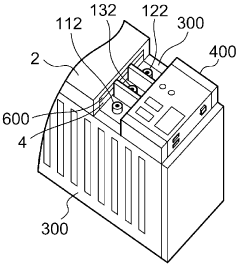

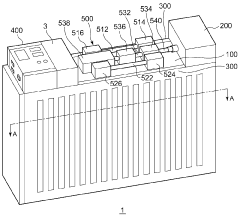

Hydrogen storage unit and fuel cell system

PatentWO2018092423A1

Innovation

- A hydrogen storage unit with a housing containing multiple MH cylinders, where a temperature control member allows a heat medium to flow through, effectively heating or cooling the storage container using a heat medium that has cooled the power generation section, thereby enhancing thermal efficiency.

Fuel cell system and control method thereof

PatentWO2012147318A1

Innovation

- A fuel cell system with two hydrogen storage alloy containers in thermal contact, a release control unit, and temperature detection units to manage hydrogen release based on temperature thresholds, ensuring efficient heat supply and rapid temperature adjustment for optimal operation.

Safety Standards and Regulations

The regulatory landscape governing hydrogen storage materials in fuel cells has evolved significantly to address the unique thermal stability challenges these systems present. International standards such as ISO/TS 15869 specifically address hydrogen storage systems for fuel cell vehicles, establishing critical parameters for thermal management and safety testing protocols. These standards mandate rigorous thermal cycling tests to ensure storage materials maintain integrity under varying temperature conditions, with particular emphasis on preventing catastrophic failures during thermal runaway scenarios.

In the United States, the Department of Energy's Technical Targets for Onboard Hydrogen Storage Systems establishes stringent requirements for thermal stability, requiring storage materials to withstand temperatures between -40°C and 85°C for normal operation, with excursion tolerances up to 125°C. These specifications directly influence material selection and system design, as metal hydrides, complex hydrides, and carbon-based adsorbents each present distinct thermal management challenges that must be addressed to achieve certification.

European regulations, particularly through the EU Hydrogen and Fuel Cell Joint Undertaking, have implemented comprehensive safety frameworks that specifically address the thermal behavior of storage materials. These regulations require manufacturers to demonstrate that hydrogen storage systems can maintain stability during rapid temperature fluctuations that occur during refueling processes, where temperatures can change by over 50°C in minutes.

The UN Global Technical Regulation No. 13 (GTR 13) has established harmonized testing procedures for hydrogen storage systems, including thermal cycling tests that subject materials to extreme temperature variations to verify their stability. These tests are particularly relevant for assessing how different storage materials respond to thermal stress, with specific provisions for metal hydride systems that may experience significant exothermic reactions during hydrogen absorption.

Japan's High Pressure Gas Safety Act includes specialized provisions for hydrogen storage materials, requiring comprehensive thermal stability documentation before certification. These regulations are particularly stringent regarding the thermal management systems that must accompany certain types of storage materials, especially those with known thermal instability issues during charging and discharging cycles.

Emerging regulations are increasingly focusing on the end-of-life considerations for hydrogen storage materials, with requirements for safe disposal or recycling processes that account for potential thermal reactivity even after the primary service life has concluded. This regulatory trend reflects growing awareness of the complete lifecycle safety implications of advanced storage materials used in fuel cell applications.

In the United States, the Department of Energy's Technical Targets for Onboard Hydrogen Storage Systems establishes stringent requirements for thermal stability, requiring storage materials to withstand temperatures between -40°C and 85°C for normal operation, with excursion tolerances up to 125°C. These specifications directly influence material selection and system design, as metal hydrides, complex hydrides, and carbon-based adsorbents each present distinct thermal management challenges that must be addressed to achieve certification.

European regulations, particularly through the EU Hydrogen and Fuel Cell Joint Undertaking, have implemented comprehensive safety frameworks that specifically address the thermal behavior of storage materials. These regulations require manufacturers to demonstrate that hydrogen storage systems can maintain stability during rapid temperature fluctuations that occur during refueling processes, where temperatures can change by over 50°C in minutes.

The UN Global Technical Regulation No. 13 (GTR 13) has established harmonized testing procedures for hydrogen storage systems, including thermal cycling tests that subject materials to extreme temperature variations to verify their stability. These tests are particularly relevant for assessing how different storage materials respond to thermal stress, with specific provisions for metal hydride systems that may experience significant exothermic reactions during hydrogen absorption.

Japan's High Pressure Gas Safety Act includes specialized provisions for hydrogen storage materials, requiring comprehensive thermal stability documentation before certification. These regulations are particularly stringent regarding the thermal management systems that must accompany certain types of storage materials, especially those with known thermal instability issues during charging and discharging cycles.

Emerging regulations are increasingly focusing on the end-of-life considerations for hydrogen storage materials, with requirements for safe disposal or recycling processes that account for potential thermal reactivity even after the primary service life has concluded. This regulatory trend reflects growing awareness of the complete lifecycle safety implications of advanced storage materials used in fuel cell applications.

Environmental Impact Assessment

The environmental implications of hydrogen storage materials in fuel cells extend far beyond their primary function of energy conversion. These materials significantly influence the ecological footprint of fuel cell technologies throughout their lifecycle. When examining thermal stability aspects, materials like metal hydrides and carbon-based structures demonstrate varying environmental impacts during production, operation, and disposal phases.

Manufacturing processes for advanced hydrogen storage materials often require energy-intensive methods and rare earth elements, contributing to resource depletion and carbon emissions. For instance, production of complex metal hydrides can generate substantial CO2 emissions, estimated at 5-15 kg CO2 equivalent per kilogram of material produced, depending on manufacturing techniques and energy sources utilized.

Thermal stability characteristics of storage materials directly affect the operational efficiency and lifespan of fuel cells. Materials with superior thermal stability properties reduce the frequency of replacement, thereby minimizing waste generation and resource consumption. Research indicates that extending the operational life of fuel cells by improving thermal stability could reduce lifecycle environmental impacts by 20-30% compared to conventional systems.

End-of-life considerations reveal further environmental dimensions. Some hydrogen storage materials contain potentially toxic components that require specialized disposal protocols. However, many advanced materials demonstrate promising recyclability profiles, with recovery rates exceeding 80% for certain metal hydrides, significantly reducing their environmental burden.

Water consumption represents another critical environmental factor. Thermally stable materials that enable efficient operation at lower temperatures can reduce cooling requirements, potentially decreasing water usage by 15-25% compared to less stable alternatives. This aspect becomes particularly significant in water-stressed regions where fuel cell deployment is expanding.

Land use impacts vary considerably among different hydrogen storage technologies. While some materials require extensive mining operations for raw material extraction, others utilize more abundant resources with lower ecological disruption. The land footprint for material production ranges from 0.5 to 3.5 square meters per kilowatt of fuel cell capacity, depending on the specific storage technology employed.

Emissions during operation present a complex environmental profile. While fuel cells themselves produce only water vapor during electricity generation, the thermal management systems necessitated by storage material characteristics may contribute to indirect emissions through energy consumption for cooling or heating processes.

Manufacturing processes for advanced hydrogen storage materials often require energy-intensive methods and rare earth elements, contributing to resource depletion and carbon emissions. For instance, production of complex metal hydrides can generate substantial CO2 emissions, estimated at 5-15 kg CO2 equivalent per kilogram of material produced, depending on manufacturing techniques and energy sources utilized.

Thermal stability characteristics of storage materials directly affect the operational efficiency and lifespan of fuel cells. Materials with superior thermal stability properties reduce the frequency of replacement, thereby minimizing waste generation and resource consumption. Research indicates that extending the operational life of fuel cells by improving thermal stability could reduce lifecycle environmental impacts by 20-30% compared to conventional systems.

End-of-life considerations reveal further environmental dimensions. Some hydrogen storage materials contain potentially toxic components that require specialized disposal protocols. However, many advanced materials demonstrate promising recyclability profiles, with recovery rates exceeding 80% for certain metal hydrides, significantly reducing their environmental burden.

Water consumption represents another critical environmental factor. Thermally stable materials that enable efficient operation at lower temperatures can reduce cooling requirements, potentially decreasing water usage by 15-25% compared to less stable alternatives. This aspect becomes particularly significant in water-stressed regions where fuel cell deployment is expanding.

Land use impacts vary considerably among different hydrogen storage technologies. While some materials require extensive mining operations for raw material extraction, others utilize more abundant resources with lower ecological disruption. The land footprint for material production ranges from 0.5 to 3.5 square meters per kilowatt of fuel cell capacity, depending on the specific storage technology employed.

Emissions during operation present a complex environmental profile. While fuel cells themselves produce only water vapor during electricity generation, the thermal management systems necessitated by storage material characteristics may contribute to indirect emissions through energy consumption for cooling or heating processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!