Hydrogen storage materials for electronics energy storage and hydrogen supply systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Evolution and Objectives

Hydrogen storage materials have evolved significantly over the past several decades, transitioning from conventional physical storage methods to advanced material-based solutions. The journey began in the 1970s with metal hydrides, which demonstrated the potential for solid-state hydrogen storage but suffered from weight limitations and slow kinetics. The 1990s witnessed the emergence of carbon-based materials, particularly after the discovery of carbon nanotubes, which promised higher storage capacities through adsorption mechanisms.

The early 2000s marked a pivotal shift with the development of complex hydrides and chemical hydrogen storage materials, offering improved gravimetric capacities. This period also saw increased research into metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), which provided tunable pore structures and surface areas for enhanced hydrogen uptake. Recent advancements have focused on hybrid systems combining different storage mechanisms and nanoscale engineering to overcome individual material limitations.

The evolution of hydrogen storage materials has been driven by both energy security concerns and environmental imperatives. Initially, research was primarily motivated by the oil crises of the 1970s, but has since expanded to address climate change mitigation and renewable energy integration challenges. The electronics industry has emerged as a significant driver in recent years, seeking compact and efficient energy storage solutions for portable and stationary applications.

Current technical objectives for hydrogen storage materials in electronics applications center on achieving the U.S. Department of Energy's targets: 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity, with rapid charging/discharging capabilities and operational stability across 1,500 cycles. For electronics energy storage, additional objectives include miniaturization, safety under various environmental conditions, and compatibility with existing electronic components.

The integration of hydrogen storage materials into electronics energy systems aims to overcome the limitations of conventional batteries, particularly regarding energy density and charging times. Research objectives now extend beyond mere storage capacity to include system-level considerations such as thermal management, pressure regulation, and interface compatibility with fuel cells and other hydrogen-consuming devices.

Looking forward, the field is targeting multifunctional materials that can simultaneously store hydrogen and perform additional functions within electronic systems, such as structural support or heat dissipation. The ultimate goal remains developing materials that enable practical, safe, and cost-effective hydrogen-based energy solutions for next-generation electronics and distributed energy systems.

The early 2000s marked a pivotal shift with the development of complex hydrides and chemical hydrogen storage materials, offering improved gravimetric capacities. This period also saw increased research into metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), which provided tunable pore structures and surface areas for enhanced hydrogen uptake. Recent advancements have focused on hybrid systems combining different storage mechanisms and nanoscale engineering to overcome individual material limitations.

The evolution of hydrogen storage materials has been driven by both energy security concerns and environmental imperatives. Initially, research was primarily motivated by the oil crises of the 1970s, but has since expanded to address climate change mitigation and renewable energy integration challenges. The electronics industry has emerged as a significant driver in recent years, seeking compact and efficient energy storage solutions for portable and stationary applications.

Current technical objectives for hydrogen storage materials in electronics applications center on achieving the U.S. Department of Energy's targets: 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity, with rapid charging/discharging capabilities and operational stability across 1,500 cycles. For electronics energy storage, additional objectives include miniaturization, safety under various environmental conditions, and compatibility with existing electronic components.

The integration of hydrogen storage materials into electronics energy systems aims to overcome the limitations of conventional batteries, particularly regarding energy density and charging times. Research objectives now extend beyond mere storage capacity to include system-level considerations such as thermal management, pressure regulation, and interface compatibility with fuel cells and other hydrogen-consuming devices.

Looking forward, the field is targeting multifunctional materials that can simultaneously store hydrogen and perform additional functions within electronic systems, such as structural support or heat dissipation. The ultimate goal remains developing materials that enable practical, safe, and cost-effective hydrogen-based energy solutions for next-generation electronics and distributed energy systems.

Market Analysis for Hydrogen-Based Energy Storage Solutions

The global market for hydrogen-based energy storage solutions is experiencing significant growth, driven by the increasing demand for clean energy alternatives and the push towards decarbonization across various sectors. The market was valued at approximately $13.8 billion in 2022 and is projected to reach $25.4 billion by 2027, growing at a CAGR of 13.2% during the forecast period.

The electronics sector represents a particularly promising application area for hydrogen storage materials, with portable electronic devices and backup power systems emerging as key market segments. The demand for longer-lasting, more efficient power sources in consumer electronics has created a substantial opportunity for hydrogen-based solutions that offer higher energy density compared to conventional lithium-ion batteries.

In the industrial sector, hydrogen storage systems are gaining traction for applications requiring uninterrupted power supply, such as data centers and telecommunications infrastructure. These markets value the reliability and scalability of hydrogen-based systems, particularly in regions with unstable grid connections or frequent power outages.

Geographically, Asia-Pacific dominates the market, accounting for approximately 42% of global demand, with China, Japan, and South Korea leading in both production and consumption. Europe follows closely, driven by aggressive climate policies and substantial investments in hydrogen infrastructure, particularly in Germany, France, and the United Kingdom.

The transportation sector represents another significant market opportunity, with hydrogen fuel cells increasingly adopted in commercial vehicles, forklifts, and emerging applications in maritime and aviation industries. This segment is expected to grow at the fastest rate, with a projected CAGR of 16.8% through 2027.

Key market drivers include government incentives and subsidies for clean energy technologies, declining costs of renewable hydrogen production, and corporate commitments to carbon neutrality. The integration of hydrogen storage with renewable energy sources such as solar and wind power is creating new market opportunities for grid-scale energy storage solutions.

Market challenges include high initial capital costs, limited infrastructure for hydrogen distribution, and competition from other energy storage technologies such as advanced batteries and compressed air energy storage. Safety concerns and regulatory hurdles also present barriers to widespread adoption in certain applications, particularly in densely populated areas.

Customer segments show varying priorities, with industrial users focusing on reliability and total cost of ownership, while consumer electronics manufacturers prioritize energy density and form factor considerations. The automotive sector emphasizes refueling speed and range capabilities as critical factors in adoption decisions.

The electronics sector represents a particularly promising application area for hydrogen storage materials, with portable electronic devices and backup power systems emerging as key market segments. The demand for longer-lasting, more efficient power sources in consumer electronics has created a substantial opportunity for hydrogen-based solutions that offer higher energy density compared to conventional lithium-ion batteries.

In the industrial sector, hydrogen storage systems are gaining traction for applications requiring uninterrupted power supply, such as data centers and telecommunications infrastructure. These markets value the reliability and scalability of hydrogen-based systems, particularly in regions with unstable grid connections or frequent power outages.

Geographically, Asia-Pacific dominates the market, accounting for approximately 42% of global demand, with China, Japan, and South Korea leading in both production and consumption. Europe follows closely, driven by aggressive climate policies and substantial investments in hydrogen infrastructure, particularly in Germany, France, and the United Kingdom.

The transportation sector represents another significant market opportunity, with hydrogen fuel cells increasingly adopted in commercial vehicles, forklifts, and emerging applications in maritime and aviation industries. This segment is expected to grow at the fastest rate, with a projected CAGR of 16.8% through 2027.

Key market drivers include government incentives and subsidies for clean energy technologies, declining costs of renewable hydrogen production, and corporate commitments to carbon neutrality. The integration of hydrogen storage with renewable energy sources such as solar and wind power is creating new market opportunities for grid-scale energy storage solutions.

Market challenges include high initial capital costs, limited infrastructure for hydrogen distribution, and competition from other energy storage technologies such as advanced batteries and compressed air energy storage. Safety concerns and regulatory hurdles also present barriers to widespread adoption in certain applications, particularly in densely populated areas.

Customer segments show varying priorities, with industrial users focusing on reliability and total cost of ownership, while consumer electronics manufacturers prioritize energy density and form factor considerations. The automotive sector emphasizes refueling speed and range capabilities as critical factors in adoption decisions.

Current Hydrogen Storage Technologies and Barriers

Hydrogen storage technologies have evolved significantly over the past decades, yet substantial challenges remain in developing efficient, safe, and economically viable storage solutions for electronic applications. Currently, hydrogen storage methods can be categorized into physical-based and material-based approaches, each with distinct advantages and limitations.

Physical storage methods include compressed gas and liquid hydrogen storage. Compressed hydrogen typically operates at 350-700 bar in carbon-fiber reinforced tanks, offering relatively simple technology but suffering from low volumetric energy density (approximately 40 g/L at 700 bar) and energy-intensive compression processes. Liquid hydrogen storage achieves higher density (70 g/L) but requires cryogenic temperatures (-253°C), resulting in significant energy losses through boiling-off and the substantial energy required for liquefaction (30-40% of hydrogen's energy content).

Material-based storage has gained prominence for electronic applications due to potentially higher safety profiles and energy densities. Metal hydrides store hydrogen through chemical bonding, offering high volumetric densities (up to 150 g/L) but often suffering from slow kinetics, high operating temperatures, and material degradation over multiple cycles. Complex hydrides like alanates and borohydrides provide higher gravimetric capacities but face even more severe kinetic limitations.

Carbon-based materials and metal-organic frameworks (MOFs) represent promising physisorption-based alternatives, operating through weak van der Waals interactions. These materials offer rapid absorption/desorption kinetics but typically require cryogenic temperatures to achieve meaningful storage capacities, limiting their practical application in portable electronics.

The primary barriers to widespread implementation include insufficient gravimetric and volumetric storage densities, with the U.S. Department of Energy targeting 6.5 wt% and 50 g/L for practical applications—metrics few current technologies can achieve under ambient conditions. Thermal management presents another significant challenge, as hydrogen release is often highly endothermic or exothermic, requiring complex heat exchange systems that add weight and complexity.

Cycling stability remains problematic for many material-based systems, with performance degradation occurring after repeated hydrogen loading/unloading cycles. Cost factors also present substantial barriers, with expensive catalyst materials and complex manufacturing processes driving up system prices well beyond commercially viable levels for consumer electronics applications.

Safety concerns further complicate implementation, particularly for portable electronic devices where user proximity increases risk factors associated with high-pressure systems or reactive hydride materials. Additionally, system integration challenges persist, as hydrogen storage systems must interface effectively with fuel cells or other utilization technologies while maintaining compact form factors suitable for modern electronic devices.

Physical storage methods include compressed gas and liquid hydrogen storage. Compressed hydrogen typically operates at 350-700 bar in carbon-fiber reinforced tanks, offering relatively simple technology but suffering from low volumetric energy density (approximately 40 g/L at 700 bar) and energy-intensive compression processes. Liquid hydrogen storage achieves higher density (70 g/L) but requires cryogenic temperatures (-253°C), resulting in significant energy losses through boiling-off and the substantial energy required for liquefaction (30-40% of hydrogen's energy content).

Material-based storage has gained prominence for electronic applications due to potentially higher safety profiles and energy densities. Metal hydrides store hydrogen through chemical bonding, offering high volumetric densities (up to 150 g/L) but often suffering from slow kinetics, high operating temperatures, and material degradation over multiple cycles. Complex hydrides like alanates and borohydrides provide higher gravimetric capacities but face even more severe kinetic limitations.

Carbon-based materials and metal-organic frameworks (MOFs) represent promising physisorption-based alternatives, operating through weak van der Waals interactions. These materials offer rapid absorption/desorption kinetics but typically require cryogenic temperatures to achieve meaningful storage capacities, limiting their practical application in portable electronics.

The primary barriers to widespread implementation include insufficient gravimetric and volumetric storage densities, with the U.S. Department of Energy targeting 6.5 wt% and 50 g/L for practical applications—metrics few current technologies can achieve under ambient conditions. Thermal management presents another significant challenge, as hydrogen release is often highly endothermic or exothermic, requiring complex heat exchange systems that add weight and complexity.

Cycling stability remains problematic for many material-based systems, with performance degradation occurring after repeated hydrogen loading/unloading cycles. Cost factors also present substantial barriers, with expensive catalyst materials and complex manufacturing processes driving up system prices well beyond commercially viable levels for consumer electronics applications.

Safety concerns further complicate implementation, particularly for portable electronic devices where user proximity increases risk factors associated with high-pressure systems or reactive hydride materials. Additionally, system integration challenges persist, as hydrogen storage systems must interface effectively with fuel cells or other utilization technologies while maintaining compact form factors suitable for modern electronic devices.

Mainstream Hydrogen Storage Solutions for Electronics

01 Metal hydrides for hydrogen storage

Metal hydrides are compounds formed by hydrogen and metals that can store hydrogen at high densities. These materials can absorb and release hydrogen through chemical reactions, offering advantages such as high volumetric storage capacity and safety. Various metal hydride systems, including magnesium-based, aluminum-based, and transition metal-based hydrides, have been developed to optimize hydrogen storage capacity while addressing challenges related to weight, operating temperatures, and cycling stability.- Metal hydrides for hydrogen storage: Metal hydrides are compounds that can absorb and release hydrogen under specific temperature and pressure conditions. These materials offer high volumetric hydrogen storage capacity and safety advantages. Various metal hydride systems, including magnesium-based, aluminum-based, and transition metal-based hydrides, have been developed to optimize hydrogen storage capacity while addressing challenges related to weight, reversibility, and kinetics of hydrogen absorption/desorption.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon aerogels can store hydrogen through physisorption mechanisms. These materials offer advantages including light weight, tunable porosity, and potentially high specific surface areas. Research focuses on enhancing hydrogen storage capacity through surface modifications, doping with metals, and optimizing pore structures to increase adsorption sites for hydrogen molecules.

- Metal-organic frameworks (MOFs) for hydrogen storage: Metal-organic frameworks are crystalline porous materials composed of metal ions coordinated to organic ligands. Their exceptionally high surface areas, tunable pore sizes, and modifiable structures make them promising candidates for hydrogen storage. MOFs can store hydrogen through both physisorption and chemisorption mechanisms, with research focusing on increasing binding energy and optimizing pore architecture to enhance storage capacity at practical operating conditions.

- Complex hydrides and chemical hydrogen storage: Complex hydrides, including borohydrides, alanates, and amides, store hydrogen through chemical bonds rather than physical adsorption. These materials can achieve high gravimetric hydrogen storage capacities but often face challenges with reversibility and reaction kinetics. Research focuses on catalyst development, nanostructuring, and creating composite systems to improve hydrogen release and uptake properties while maintaining high storage capacity.

- Nanostructured and composite hydrogen storage materials: Nanostructuring and creating composite materials represent strategies to enhance hydrogen storage capacity by combining the advantages of different storage mechanisms. These approaches include core-shell structures, doped nanomaterials, and multi-component systems that can overcome limitations of individual materials. By engineering interfaces and creating synergistic effects between components, these materials aim to achieve improved kinetics, reduced operating temperatures, and enhanced overall storage capacity.

02 Carbon-based hydrogen storage materials

Carbon-based materials, including carbon nanotubes, graphene, activated carbon, and carbon composites, offer promising hydrogen storage capabilities through adsorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb, with storage capacity dependent on surface area, pore structure, and surface functionalization. Research focuses on enhancing the hydrogen binding energy and optimizing pore structures to increase storage capacity at practical temperatures and pressures.Expand Specific Solutions03 Metal-organic frameworks (MOFs) for hydrogen storage

Metal-organic frameworks are crystalline porous materials composed of metal ions or clusters coordinated with organic ligands, creating structures with exceptionally high surface areas and tunable pore sizes. These characteristics make MOFs promising for hydrogen storage through physisorption mechanisms. Their modular nature allows for rational design to optimize hydrogen binding affinity and storage capacity, with some MOFs demonstrating impressive gravimetric hydrogen storage capacities under cryogenic conditions or moderate pressures.Expand Specific Solutions04 Complex hydrides and chemical hydrogen storage

Complex hydrides, including borohydrides, alanates, and amides, store hydrogen through chemical bonds rather than physical adsorption. These materials can achieve high gravimetric and volumetric hydrogen storage capacities through reversible chemical reactions. Research focuses on improving their thermodynamics and kinetics to enable hydrogen release at moderate temperatures, enhancing reversibility, and addressing challenges related to heat management during hydrogen absorption and desorption cycles.Expand Specific Solutions05 Composite and hybrid hydrogen storage materials

Composite and hybrid hydrogen storage materials combine different storage mechanisms or materials to overcome limitations of individual approaches. These include metal hydride composites, nanostructured materials with catalysts, and multi-component systems designed to optimize hydrogen storage capacity, kinetics, and thermodynamics simultaneously. By integrating complementary materials, these systems can achieve enhanced storage capacities, improved cycling stability, and better operating conditions compared to single-component storage materials.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Storage

The hydrogen storage materials market for electronics energy storage and hydrogen supply systems is currently in a growth phase, characterized by increasing demand for clean energy solutions. The market size is expanding rapidly due to global shifts toward renewable energy and hydrogen economies, with projections indicating substantial growth over the next decade. Technologically, the field shows varying maturity levels across applications. Leading players include Nissan Motor Co. and Hyundai Motor Co., who are advancing automotive hydrogen storage solutions, while Toshiba Energy Systems and Form Energy focus on stationary energy storage systems. Research institutions like Zhejiang University, California Institute of Technology, and CNRS are driving fundamental innovations, while specialized companies such as Nanotek Instruments and EnerVenue are commercializing next-generation materials with improved capacity and efficiency.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered advanced hydrogen storage materials specifically designed for automotive and portable electronics applications. Their proprietary technology focuses on metal-organic frameworks (MOFs) with tailored pore structures achieving volumetric capacities exceeding 40 g/L at ambient temperatures. Hyundai's approach incorporates surface-modified nanomaterials that demonstrate rapid hydrogen uptake and release kinetics, with complete cycling possible in under 5 minutes at moderate temperatures (80-120°C). Their system utilizes a multi-layer composite structure that integrates hydrogen storage with thermal management, allowing for efficient heat distribution during charging/discharging cycles. Hyundai has developed specialized alloys with reduced sensitivity to contaminants, extending operational lifetime in real-world conditions where gas purity may vary. Their technology platform includes intelligent pressure regulation systems that dynamically adjust to power demand from electronic devices or vehicle systems, optimizing hydrogen delivery rates based on instantaneous requirements[2][5].

Strengths: Integrated system approach combining storage materials with complete fuel cell systems, extensive real-world testing through commercial vehicle deployments, and established supply chain for materials. Weaknesses: Higher initial system costs compared to conventional battery technologies, and current dependence on precious metal catalysts for optimal performance.

General Motors LLC

Technical Solution: General Motors has developed advanced metal hydride storage systems for hydrogen applications in electronics and vehicles. Their technology utilizes complex metal hydrides with enhanced gravimetric capacity (>6 wt%) and improved kinetics through catalytic doping. GM's approach incorporates nanostructured materials with optimized particle size distribution to enhance hydrogen absorption/desorption rates while maintaining structural stability during cycling. Their system integrates thermal management solutions that address heat generation during hydrogen charging and extraction, critical for electronic applications. GM has pioneered composite materials combining conventional metal hydrides with carbon nanostructures to improve thermal conductivity and reduce degradation over multiple cycles. Their hydrogen storage solutions feature pressure management systems that operate at moderate pressures (30-100 bar) suitable for integration with fuel cells and electronic power systems[1][3].

Strengths: Extensive automotive integration experience, established manufacturing infrastructure, and proven safety protocols for hydrogen systems. Weaknesses: Higher system weight compared to some newer materials, and relatively higher cost structure due to use of rare earth elements in some formulations.

Key Patents and Breakthroughs in Hydrogen Storage Materials

Hydrogen storage materials and hydrogen fuel cells

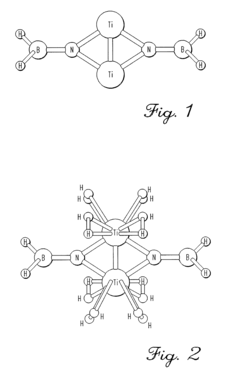

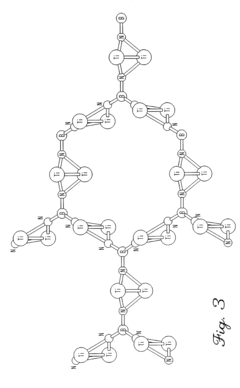

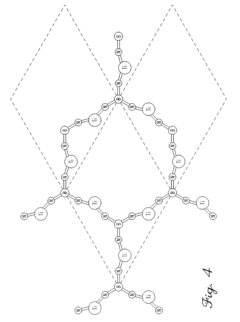

PatentActiveUS8883371B2

Innovation

- Development of solid-state hydrogen storage materials comprising transition metal atoms bonded to elements from period 2 of the periodic table, which form stable hydrogenated states capable of adsorbing and desorbing hydrogen at temperatures below 200°C and pressures of 1 atm or less, achieving over 6.5% hydrogen weight percentage.

Hydrogen storage materials comprising gallium

PatentInactiveHK1093533A

Innovation

- A hydrogen storage material comprising a liquid metal alloy that transitions from a solid in its charged state to a liquid in its discharged state, specifically using alloys like Li3Ga and Na3Ga, which can be hydrogenated to achieve high hydrogen content and facilitate efficient rehydrogenation, and methods such as direct synthesis or two-step crown ether complex exchange for material preparation.

Safety and Regulatory Framework for Hydrogen Systems

The regulatory landscape for hydrogen storage systems in electronics applications is complex and evolving rapidly as hydrogen technologies gain prominence. International standards such as ISO/TC 197 specifically address hydrogen technologies, while IEC standards cover the electrical safety aspects of hydrogen systems integrated with electronics. These frameworks establish crucial parameters for pressure vessel design, material compatibility, leak detection systems, and ventilation requirements that manufacturers must adhere to.

National regulations vary significantly across jurisdictions, creating compliance challenges for global deployment. The United States implements regulations through DOE and DOT guidelines, while the European Union follows the Pressure Equipment Directive (PED) and ATEX directives for explosive atmospheres. Japan and South Korea have developed specialized regulatory frameworks reflecting their advanced hydrogen economies, particularly for consumer electronics applications.

Risk assessment methodologies for hydrogen storage materials require specialized approaches due to hydrogen's unique properties. HAZOP (Hazard and Operability) studies and FMEA (Failure Mode and Effects Analysis) have been adapted specifically for hydrogen systems, with particular attention to embrittlement risks in metal hydride storage systems and thermal management in chemical hydride solutions.

Certification processes present significant barriers to market entry, with testing requirements for cycle durability, thermal stability, and pressure resistance adding substantial development costs. Third-party certification bodies like TÜV and UL have developed specialized testing protocols for hydrogen storage materials in electronic applications, though harmonization efforts remain ongoing.

Insurance considerations represent another critical dimension, with many insurers requiring additional risk assessments and safety measures for facilities utilizing hydrogen storage systems. The development of specialized insurance products for hydrogen technologies remains in nascent stages, creating potential cost barriers for implementation.

Looking forward, regulatory frameworks are evolving toward performance-based approaches rather than prescriptive requirements, allowing greater innovation in storage materials. International harmonization efforts through organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) aim to reduce regulatory fragmentation. Emerging regulations increasingly focus on lifecycle considerations, including end-of-life management and recycling of hydrogen storage materials, particularly for rare earth elements used in certain storage alloys.

National regulations vary significantly across jurisdictions, creating compliance challenges for global deployment. The United States implements regulations through DOE and DOT guidelines, while the European Union follows the Pressure Equipment Directive (PED) and ATEX directives for explosive atmospheres. Japan and South Korea have developed specialized regulatory frameworks reflecting their advanced hydrogen economies, particularly for consumer electronics applications.

Risk assessment methodologies for hydrogen storage materials require specialized approaches due to hydrogen's unique properties. HAZOP (Hazard and Operability) studies and FMEA (Failure Mode and Effects Analysis) have been adapted specifically for hydrogen systems, with particular attention to embrittlement risks in metal hydride storage systems and thermal management in chemical hydride solutions.

Certification processes present significant barriers to market entry, with testing requirements for cycle durability, thermal stability, and pressure resistance adding substantial development costs. Third-party certification bodies like TÜV and UL have developed specialized testing protocols for hydrogen storage materials in electronic applications, though harmonization efforts remain ongoing.

Insurance considerations represent another critical dimension, with many insurers requiring additional risk assessments and safety measures for facilities utilizing hydrogen storage systems. The development of specialized insurance products for hydrogen technologies remains in nascent stages, creating potential cost barriers for implementation.

Looking forward, regulatory frameworks are evolving toward performance-based approaches rather than prescriptive requirements, allowing greater innovation in storage materials. International harmonization efforts through organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) aim to reduce regulatory fragmentation. Emerging regulations increasingly focus on lifecycle considerations, including end-of-life management and recycling of hydrogen storage materials, particularly for rare earth elements used in certain storage alloys.

Environmental Impact and Sustainability Assessment

The environmental footprint of hydrogen storage materials represents a critical dimension in evaluating their viability for electronics energy storage and hydrogen supply systems. Life cycle assessment (LCA) studies indicate that different hydrogen storage technologies exhibit varying environmental impacts across production, use, and disposal phases. Metal hydrides, while offering high storage density, often require energy-intensive manufacturing processes and utilize rare earth elements that pose extraction-related environmental concerns.

Carbon-based materials such as activated carbon and carbon nanotubes present lower production energy requirements compared to metal hydrides, but their synthesis may involve hazardous chemicals. The environmental advantage of these materials lies in their potential recyclability and lower toxicity profiles when properly managed at end-of-life stages.

Greenhouse gas emissions associated with hydrogen storage materials vary significantly based on production methods. Research indicates that materials requiring high-temperature processing contribute substantially to carbon footprints unless renewable energy sources power manufacturing facilities. Conversely, bio-derived storage materials offer promising sustainability credentials, though current production scales remain limited.

Water consumption represents another crucial environmental consideration, particularly for metal hydride production processes that require substantial water resources for purification and cooling. This aspect becomes especially relevant in water-stressed regions where electronics manufacturing hubs are often located.

From a sustainability perspective, the recyclability of hydrogen storage materials presents both challenges and opportunities. Advanced metal hydrides can potentially be recovered and reprocessed, reducing primary resource demands. However, current recycling infrastructure remains underdeveloped for these specialized materials, creating a gap between theoretical and practical sustainability benefits.

The environmental trade-offs between different hydrogen storage technologies must be evaluated within specific application contexts. For portable electronics applications, materials with lower environmental impacts during production may be preferable despite potentially reduced performance characteristics. Conversely, stationary applications might justify materials with higher initial environmental costs if operational efficiency and longevity deliver superior lifecycle benefits.

Regulatory frameworks increasingly influence material selection decisions, with restrictions on hazardous substances driving innovation toward environmentally benign alternatives. Forward-looking companies are proactively developing hydrogen storage materials that align with circular economy principles, anticipating stricter future environmental regulations.

Carbon-based materials such as activated carbon and carbon nanotubes present lower production energy requirements compared to metal hydrides, but their synthesis may involve hazardous chemicals. The environmental advantage of these materials lies in their potential recyclability and lower toxicity profiles when properly managed at end-of-life stages.

Greenhouse gas emissions associated with hydrogen storage materials vary significantly based on production methods. Research indicates that materials requiring high-temperature processing contribute substantially to carbon footprints unless renewable energy sources power manufacturing facilities. Conversely, bio-derived storage materials offer promising sustainability credentials, though current production scales remain limited.

Water consumption represents another crucial environmental consideration, particularly for metal hydride production processes that require substantial water resources for purification and cooling. This aspect becomes especially relevant in water-stressed regions where electronics manufacturing hubs are often located.

From a sustainability perspective, the recyclability of hydrogen storage materials presents both challenges and opportunities. Advanced metal hydrides can potentially be recovered and reprocessed, reducing primary resource demands. However, current recycling infrastructure remains underdeveloped for these specialized materials, creating a gap between theoretical and practical sustainability benefits.

The environmental trade-offs between different hydrogen storage technologies must be evaluated within specific application contexts. For portable electronics applications, materials with lower environmental impacts during production may be preferable despite potentially reduced performance characteristics. Conversely, stationary applications might justify materials with higher initial environmental costs if operational efficiency and longevity deliver superior lifecycle benefits.

Regulatory frameworks increasingly influence material selection decisions, with restrictions on hazardous substances driving innovation toward environmentally benign alternatives. Forward-looking companies are proactively developing hydrogen storage materials that align with circular economy principles, anticipating stricter future environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!