Comparative evaluation of Hydrogen storage materials catalysts and coatings

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Evolution and Research Objectives

Hydrogen storage technology has evolved significantly over the past decades, driven by the global push towards clean energy solutions and the recognition of hydrogen as a versatile energy carrier. The journey began in the 1970s with conventional storage methods such as compressed gas and cryogenic liquid hydrogen, which despite their simplicity, presented significant challenges in terms of energy density and safety concerns. The 1990s marked a pivotal shift with increased research into solid-state storage materials, including metal hydrides and complex hydrides, offering improved volumetric capacity and safety profiles.

The early 2000s witnessed accelerated development in nanomaterials and carbon-based structures for hydrogen storage, including carbon nanotubes, graphene, and metal-organic frameworks (MOFs). These materials demonstrated promising adsorption properties but often struggled with practical implementation challenges such as operating conditions and reversibility issues. Recent years have seen the emergence of hybrid systems combining different storage mechanisms and materials to overcome individual limitations.

Current research objectives in hydrogen storage are multifaceted, focusing primarily on addressing the U.S. Department of Energy's technical targets for onboard automotive applications: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity at near-ambient conditions. Beyond these metrics, researchers aim to develop materials with improved kinetics, allowing for faster charging and discharging cycles without significant energy penalties.

Enhancing cyclability represents another critical objective, as practical applications require thousands of storage-release cycles without substantial degradation in performance. This necessitates materials with robust structural stability and resistance to contamination effects. Cost reduction remains a paramount concern, with current advanced storage systems being prohibitively expensive for widespread commercial adoption.

Safety considerations drive research into materials with inherently safer properties, reducing risks associated with high pressure or extreme temperature conditions. Additionally, researchers are exploring catalysts that can significantly lower operating temperatures and pressures for hydrogen absorption and desorption processes, thereby improving overall system efficiency.

The integration of storage materials with end-use applications constitutes an emerging research direction, with particular emphasis on optimizing interfaces between storage systems and fuel cells or combustion systems. This includes developing coatings that can prevent material degradation while facilitating hydrogen transport across boundaries.

Environmental sustainability has also become a key objective, with increasing focus on materials that can be synthesized using abundant, non-toxic elements and processes with reduced environmental footprints. This holistic approach aims to ensure that hydrogen storage solutions contribute positively to overall sustainability goals rather than creating new environmental challenges.

The early 2000s witnessed accelerated development in nanomaterials and carbon-based structures for hydrogen storage, including carbon nanotubes, graphene, and metal-organic frameworks (MOFs). These materials demonstrated promising adsorption properties but often struggled with practical implementation challenges such as operating conditions and reversibility issues. Recent years have seen the emergence of hybrid systems combining different storage mechanisms and materials to overcome individual limitations.

Current research objectives in hydrogen storage are multifaceted, focusing primarily on addressing the U.S. Department of Energy's technical targets for onboard automotive applications: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity at near-ambient conditions. Beyond these metrics, researchers aim to develop materials with improved kinetics, allowing for faster charging and discharging cycles without significant energy penalties.

Enhancing cyclability represents another critical objective, as practical applications require thousands of storage-release cycles without substantial degradation in performance. This necessitates materials with robust structural stability and resistance to contamination effects. Cost reduction remains a paramount concern, with current advanced storage systems being prohibitively expensive for widespread commercial adoption.

Safety considerations drive research into materials with inherently safer properties, reducing risks associated with high pressure or extreme temperature conditions. Additionally, researchers are exploring catalysts that can significantly lower operating temperatures and pressures for hydrogen absorption and desorption processes, thereby improving overall system efficiency.

The integration of storage materials with end-use applications constitutes an emerging research direction, with particular emphasis on optimizing interfaces between storage systems and fuel cells or combustion systems. This includes developing coatings that can prevent material degradation while facilitating hydrogen transport across boundaries.

Environmental sustainability has also become a key objective, with increasing focus on materials that can be synthesized using abundant, non-toxic elements and processes with reduced environmental footprints. This holistic approach aims to ensure that hydrogen storage solutions contribute positively to overall sustainability goals rather than creating new environmental challenges.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition away from fossil fuels. As of 2023, the market was valued at approximately 15.4 billion USD, with projections indicating a compound annual growth rate (CAGR) of 9.7% through 2030. This growth trajectory is primarily fueled by governmental policies promoting hydrogen as a key component in achieving carbon neutrality targets across major economies.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation and industrial applications leading the way. The automotive industry, particularly fuel cell electric vehicles (FCEVs), represents a major market segment, with countries like Japan, South Korea, and Germany making substantial investments in hydrogen refueling infrastructure. In 2022, over 25,000 FCEVs were in operation globally, with this number expected to reach 1 million by 2030 according to the International Energy Agency.

Industrial applications constitute another significant market segment, where hydrogen is increasingly used for power generation, chemical production, and as a feedstock in various manufacturing processes. The steel industry alone could potentially consume 18.5 million tons of hydrogen annually by 2050 if widespread adoption of hydrogen-based direct reduction processes occurs.

Regionally, Asia-Pacific dominates the hydrogen storage market, accounting for 42% of global market share, followed by Europe at 31% and North America at 21%. China's ambitious hydrogen strategy aims to have 50,000 hydrogen fuel cell vehicles on its roads by 2025, creating substantial demand for storage solutions. Similarly, the European Union's hydrogen strategy targets 40 GW of electrolyzer capacity by 2030, necessitating extensive storage infrastructure.

Market segmentation by storage type reveals that physical-based storage methods (compressed gas, liquid hydrogen, and cryo-compressed) currently hold 78% of the market share, while material-based solutions (metal hydrides, chemical hydrides, and carbon-based materials) account for the remaining 22%. However, material-based storage is growing at a faster rate due to its potential for higher volumetric and gravimetric capacities.

Key market drivers include decreasing renewable energy costs, which make green hydrogen production more economical; stringent emission regulations across industries; and substantial public and private investments in hydrogen infrastructure. Challenges include high costs associated with advanced storage materials, safety concerns, and the need for standardization across the hydrogen value chain.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized hydrogen technology providers such as Hydrogenics (Cummins) and ITM Power, and automotive manufacturers including Toyota and Hyundai, all actively developing proprietary storage technologies to gain competitive advantages in this rapidly evolving market.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation and industrial applications leading the way. The automotive industry, particularly fuel cell electric vehicles (FCEVs), represents a major market segment, with countries like Japan, South Korea, and Germany making substantial investments in hydrogen refueling infrastructure. In 2022, over 25,000 FCEVs were in operation globally, with this number expected to reach 1 million by 2030 according to the International Energy Agency.

Industrial applications constitute another significant market segment, where hydrogen is increasingly used for power generation, chemical production, and as a feedstock in various manufacturing processes. The steel industry alone could potentially consume 18.5 million tons of hydrogen annually by 2050 if widespread adoption of hydrogen-based direct reduction processes occurs.

Regionally, Asia-Pacific dominates the hydrogen storage market, accounting for 42% of global market share, followed by Europe at 31% and North America at 21%. China's ambitious hydrogen strategy aims to have 50,000 hydrogen fuel cell vehicles on its roads by 2025, creating substantial demand for storage solutions. Similarly, the European Union's hydrogen strategy targets 40 GW of electrolyzer capacity by 2030, necessitating extensive storage infrastructure.

Market segmentation by storage type reveals that physical-based storage methods (compressed gas, liquid hydrogen, and cryo-compressed) currently hold 78% of the market share, while material-based solutions (metal hydrides, chemical hydrides, and carbon-based materials) account for the remaining 22%. However, material-based storage is growing at a faster rate due to its potential for higher volumetric and gravimetric capacities.

Key market drivers include decreasing renewable energy costs, which make green hydrogen production more economical; stringent emission regulations across industries; and substantial public and private investments in hydrogen infrastructure. Challenges include high costs associated with advanced storage materials, safety concerns, and the need for standardization across the hydrogen value chain.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized hydrogen technology providers such as Hydrogenics (Cummins) and ITM Power, and automotive manufacturers including Toyota and Hyundai, all actively developing proprietary storage technologies to gain competitive advantages in this rapidly evolving market.

Current Challenges in Hydrogen Storage Technologies

Despite significant advancements in hydrogen storage technologies, several critical challenges continue to impede widespread adoption. The volumetric and gravimetric energy density limitations remain paramount concerns across all storage methods. Compressed hydrogen systems, while commercially available, struggle with energy-intensive compression requirements and safety concerns related to high-pressure storage (350-700 bar). The substantial energy penalty during compression—approximately 10-15% of hydrogen's energy content—significantly reduces overall system efficiency.

Liquid hydrogen storage faces equally daunting challenges, primarily the cryogenic temperatures required (-253°C) and the associated boil-off losses, which can reach 1-3% daily in non-actively cooled systems. The liquefaction process itself consumes approximately 30% of hydrogen's energy content, creating substantial efficiency barriers for widespread implementation.

Material-based storage systems present their own unique obstacles. Metal hydrides offer promising volumetric density but suffer from inadequate gravimetric capacity (typically below 2 wt%), slow kinetics at practical operating temperatures, and heat management issues during absorption/desorption cycles. Complex hydrides and chemical hydrogen carriers face challenges with regeneration efficiency and often require high dehydrogenation temperatures exceeding 300°C.

Carbon-based adsorbents and MOFs demonstrate inadequate performance at ambient conditions, requiring cryogenic temperatures to achieve meaningful storage capacities. Their low volumetric densities and sensitivity to contaminants further limit practical applications. Additionally, the cyclability and long-term stability of many advanced materials remain unproven at commercial scales.

Catalyst development faces challenges in balancing activity, selectivity, and durability while minimizing precious metal content. Current catalysts for hydrogen release from chemical carriers often contain platinum-group metals, raising cost and sustainability concerns. Similarly, protective coatings for storage vessels must simultaneously address hydrogen embrittlement, permeation, and mechanical integrity under cycling conditions.

System integration presents multifaceted challenges, including thermal management during charging/discharging, weight and volume of auxiliary components, and compatibility with varying discharge rates required by different applications. The balance between storage capacity, system complexity, and cost effectiveness remains difficult to optimize across diverse use cases from stationary to mobile applications.

Cost remains perhaps the most significant barrier, with current hydrogen storage systems ranging from $15-23/kWh for compressed systems to potentially higher costs for advanced material-based solutions—significantly above the US DOE target of $8/kWh for automotive applications.

Liquid hydrogen storage faces equally daunting challenges, primarily the cryogenic temperatures required (-253°C) and the associated boil-off losses, which can reach 1-3% daily in non-actively cooled systems. The liquefaction process itself consumes approximately 30% of hydrogen's energy content, creating substantial efficiency barriers for widespread implementation.

Material-based storage systems present their own unique obstacles. Metal hydrides offer promising volumetric density but suffer from inadequate gravimetric capacity (typically below 2 wt%), slow kinetics at practical operating temperatures, and heat management issues during absorption/desorption cycles. Complex hydrides and chemical hydrogen carriers face challenges with regeneration efficiency and often require high dehydrogenation temperatures exceeding 300°C.

Carbon-based adsorbents and MOFs demonstrate inadequate performance at ambient conditions, requiring cryogenic temperatures to achieve meaningful storage capacities. Their low volumetric densities and sensitivity to contaminants further limit practical applications. Additionally, the cyclability and long-term stability of many advanced materials remain unproven at commercial scales.

Catalyst development faces challenges in balancing activity, selectivity, and durability while minimizing precious metal content. Current catalysts for hydrogen release from chemical carriers often contain platinum-group metals, raising cost and sustainability concerns. Similarly, protective coatings for storage vessels must simultaneously address hydrogen embrittlement, permeation, and mechanical integrity under cycling conditions.

System integration presents multifaceted challenges, including thermal management during charging/discharging, weight and volume of auxiliary components, and compatibility with varying discharge rates required by different applications. The balance between storage capacity, system complexity, and cost effectiveness remains difficult to optimize across diverse use cases from stationary to mobile applications.

Cost remains perhaps the most significant barrier, with current hydrogen storage systems ranging from $15-23/kWh for compressed systems to potentially higher costs for advanced material-based solutions—significantly above the US DOE target of $8/kWh for automotive applications.

Comparative Analysis of Current Storage Materials and Catalysts

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds that can store hydrogen through chemical bonding. These materials can absorb and release hydrogen under specific temperature and pressure conditions, making them suitable for hydrogen storage applications. Various metal alloys and compounds, including magnesium-based alloys, titanium-based compounds, and rare earth metal hydrides, have been developed to improve hydrogen storage capacity, kinetics, and cycling stability.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds that can absorb and release hydrogen under specific temperature and pressure conditions. These materials are promising for hydrogen storage due to their high volumetric hydrogen density. Various metal alloys and compounds, including magnesium-based alloys, titanium-based alloys, and complex hydrides, can be engineered to optimize hydrogen storage capacity, kinetics, and cycling stability. These materials often require catalyst additives to improve hydrogen absorption and desorption rates.

- Catalysts for hydrogen storage and release: Specialized catalysts play a crucial role in enhancing the performance of hydrogen storage systems by improving absorption/desorption kinetics and reducing operating temperatures. These catalysts typically include transition metals, noble metals, and their alloys or compounds. Nanostructured catalysts with high surface area are particularly effective for hydrogen storage applications. Catalyst design focuses on optimizing activity, selectivity, and stability while minimizing the amount of expensive materials required.

- Nanostructured materials for hydrogen storage: Nanostructured materials offer enhanced hydrogen storage properties due to their high surface area and unique quantum effects. These include carbon-based materials (nanotubes, graphene), metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and nanoporous materials. The nanoscale architecture allows for increased hydrogen adsorption sites and improved diffusion pathways. Surface functionalization and doping can further enhance the hydrogen storage capacity and kinetics of these materials.

- Protective coatings for hydrogen storage systems: Specialized coatings are developed to protect hydrogen storage materials and containers from degradation caused by environmental factors, impurities, and hydrogen embrittlement. These coatings can include barrier layers, corrosion-resistant materials, and functional surface treatments. Advanced coating technologies such as atomic layer deposition, plasma spraying, and electrochemical deposition are employed to create uniform and defect-free protective layers. These coatings extend the operational lifetime of hydrogen storage systems while maintaining performance.

- Composite and hybrid hydrogen storage materials: Composite and hybrid materials combine different hydrogen storage mechanisms to overcome limitations of single-component systems. These materials integrate chemical and physical storage approaches, often combining metal hydrides with carbon materials, polymers, or other substrates. The synergistic effects between components can lead to improved hydrogen capacity, faster kinetics, and better thermal management. These materials are engineered at multiple scales to optimize hydrogen diffusion pathways and reaction interfaces.

02 Catalysts for hydrogen storage and release

Catalysts play a crucial role in enhancing the kinetics of hydrogen absorption and desorption processes in storage materials. These catalysts typically include transition metals, noble metals, and their compounds that can reduce activation energy barriers and improve reaction rates. Nanostructured catalysts with high surface area and specific morphologies have shown superior performance in facilitating hydrogen storage and release under milder conditions.Expand Specific Solutions03 Carbon-based hydrogen storage materials

Carbon-based materials, including carbon nanotubes, graphene, activated carbon, and metal-organic frameworks (MOFs), offer promising hydrogen storage capabilities through physical adsorption mechanisms. These materials feature high surface areas, tunable pore structures, and lightweight properties that make them attractive for hydrogen storage applications. Surface functionalization and doping with heteroatoms or metal nanoparticles can further enhance their hydrogen uptake capacity.Expand Specific Solutions04 Protective coatings for hydrogen storage systems

Protective coatings are essential for hydrogen storage systems to prevent corrosion, hydrogen embrittlement, and degradation of storage materials. These coatings can include polymer-based barriers, ceramic layers, metal alloy films, and composite materials that provide resistance against hydrogen permeation while maintaining structural integrity. Advanced coating technologies help extend the service life of hydrogen storage containers and improve safety during hydrogen storage and transportation.Expand Specific Solutions05 Nanostructured materials for enhanced hydrogen storage

Nanostructured materials offer improved hydrogen storage properties due to their high surface-to-volume ratio, shortened diffusion paths, and unique surface properties. These materials include nanoparticles, nanowires, nanocomposites, and core-shell structures that can be engineered to optimize hydrogen storage capacity and kinetics. The nanoscale architecture allows for better control over material properties, leading to enhanced hydrogen storage performance under practical operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Storage

The hydrogen storage materials market is currently in a growth phase, with increasing demand driven by clean energy transitions. The market size is expanding rapidly, projected to reach significant scale by 2030 as hydrogen economies develop globally. Technologically, the field shows varying maturity levels across different storage approaches. Leading players like China Petroleum & Chemical Corp. and Shell are advancing conventional storage technologies, while specialized firms such as Hydrogenious LOHC Technologies focus on innovative liquid carriers. Academic institutions (Zhejiang University, Kyoto University) collaborate with industrial partners (Nissan, Hyundai, GE) to develop next-generation materials. Research organizations like Fraunhofer-Gesellschaft and ITRI bridge fundamental research and commercialization, creating a competitive landscape where materials-based solutions compete with physical storage approaches for different applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced metal-organic frameworks (MOFs) for hydrogen storage with exceptional surface areas exceeding 6,000 m²/g. Their proprietary MOF materials feature optimized pore structures and functionalized binding sites that enhance hydrogen adsorption capacity at moderate pressures (30-100 bar). Sinopec has integrated these materials into composite systems combining physisorption and chemisorption mechanisms, achieving volumetric densities approaching 40 g/L at ambient temperatures. Their research also extends to catalytic systems for hydrogen release from liquid organic hydrogen carriers (LOHCs), where they've developed novel ruthenium-based catalysts supported on carbon nanostructures that demonstrate dehydrogenation efficiencies exceeding 95% at temperatures below 250°C. Sinopec has established pilot-scale production facilities for these materials, demonstrating scalability potential for commercial hydrogen infrastructure applications.

Strengths: Exceptional surface area and adsorption capacity in their MOF materials; integrated production capabilities from material synthesis to system integration; extensive testing infrastructure. Weaknesses: Higher production costs compared to conventional storage methods; thermal management challenges during rapid hydrogen charging/discharging; requires further optimization for low-temperature performance.

Hydrogenious LOHC Technologies GmbH

Technical Solution: Hydrogenious LOHC Technologies has pioneered a revolutionary approach to hydrogen storage using Liquid Organic Hydrogen Carriers (LOHC). Their proprietary technology employs benzyltoluene as the carrier medium, which can absorb and release hydrogen through reversible hydrogenation/dehydrogenation reactions. The company has developed specialized ruthenium-based catalysts that enable hydrogen loading at 50 bar and 150-200°C with storage densities reaching 57 kg H₂/m³. Their StorageBOX and ReleaseBOX systems integrate these catalysts with optimized heat management systems, allowing for safe hydrogen storage at ambient conditions without pressurization or cryogenic requirements. The catalyst coatings demonstrate exceptional stability, maintaining over 90% activity after 1000+ loading/unloading cycles. Hydrogenious has successfully scaled their technology from laboratory to industrial applications, with commercial units capable of handling 5-12 tons of hydrogen per day, representing one of the most mature LOHC technologies available for commercial deployment.

Strengths: Ambient pressure and temperature storage eliminates need for compression or liquefaction; inherently safe carrier medium with high flash point; compatible with existing liquid fuel infrastructure; long-term storage capability without losses. Weaknesses: Energy intensity of dehydrogenation process requires significant heat input; catalyst systems still rely on precious metals; complete system efficiency needs improvement compared to compressed hydrogen for short-term storage applications.

Key Patents and Breakthroughs in Storage Materials Science

Hydrogen storage material and method for manufacturing the same

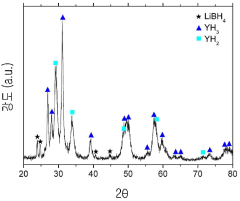

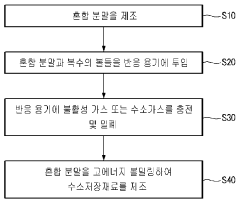

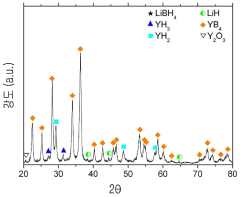

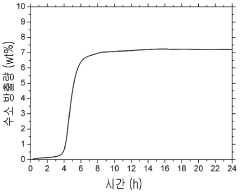

PatentInactiveKR1020110032928A

Innovation

- A hydrogen storage material composed of lithium borohydride and yttrium hydride is manufactured through high-energy ball milling, which lowers the dehydrogenation reaction temperature and maintains high hydrogen storage capacity without requiring additional catalysts.

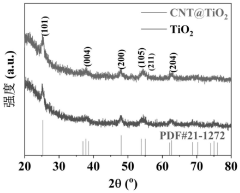

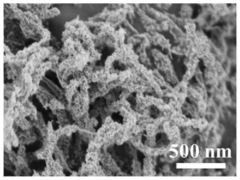

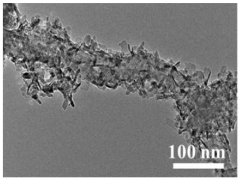

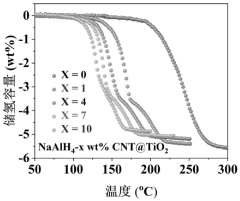

CNT-coated TiO2 doped NaAlH4 composite hydrogen storage material and preparation method thereof

PatentPendingCN118004965A

Innovation

- CNT@TiO2 with a three-dimensional nested structure is used as the catalyst and doped with NaAlH4. The composite material is prepared through ultrasonic dispersion, heat treatment and ball milling to achieve uniform contact between the catalyst and the matrix material, significantly reduce the hydrogen absorption and release temperature and improve cycle stability.

Safety Standards and Risk Assessment for Hydrogen Systems

The implementation of hydrogen storage systems necessitates rigorous safety standards and comprehensive risk assessment protocols due to hydrogen's unique physical and chemical properties. Current international standards such as ISO/TC 197 and IEC/TC 105 provide foundational guidelines for hydrogen systems, covering aspects from production to end-use applications. These standards specifically address the safety requirements for hydrogen storage materials, catalysts, and protective coatings, with particular emphasis on material compatibility, pressure resistance, and leak prevention.

Risk assessment methodologies for hydrogen storage systems typically follow a structured approach that includes hazard identification, risk analysis, and mitigation strategies. For materials-based storage solutions, key safety considerations include thermal management during hydrogen absorption/desorption processes, potential for dust explosions with metal hydrides, and chemical stability of complex hydrides under various environmental conditions. The reactivity of catalysts used in hydrogen storage systems also presents specific safety challenges that must be addressed through proper material selection and system design.

Regulatory frameworks across different regions show varying degrees of maturity regarding hydrogen safety. The European Union has established the Hydrogen Safety Panel and implemented regulations such as the Alternative Fuels Infrastructure Directive, while the United States relies on codes developed by organizations like NFPA and ASME. Japan and South Korea have also developed comprehensive hydrogen safety regulations, particularly focused on mobile applications.

Material-specific safety considerations reveal significant differences among storage options. Metal hydrides require careful thermal management and protection against contamination, while liquid organic hydrogen carriers (LOHCs) present challenges related to the handling of aromatic compounds. Carbon-based materials generally exhibit favorable safety profiles but may present dust hazards during handling. Coatings applied to storage vessels must maintain integrity under repeated hydrogen cycling and prevent hydrogen embrittlement of underlying materials.

Recent technological advancements have improved safety monitoring capabilities, including the development of advanced sensors for hydrogen leak detection, real-time monitoring systems for material degradation, and predictive modeling tools for risk assessment. These innovations enable more proactive safety management approaches and contribute to the overall risk reduction in hydrogen storage systems, facilitating broader adoption across various applications from stationary power to transportation.

Risk assessment methodologies for hydrogen storage systems typically follow a structured approach that includes hazard identification, risk analysis, and mitigation strategies. For materials-based storage solutions, key safety considerations include thermal management during hydrogen absorption/desorption processes, potential for dust explosions with metal hydrides, and chemical stability of complex hydrides under various environmental conditions. The reactivity of catalysts used in hydrogen storage systems also presents specific safety challenges that must be addressed through proper material selection and system design.

Regulatory frameworks across different regions show varying degrees of maturity regarding hydrogen safety. The European Union has established the Hydrogen Safety Panel and implemented regulations such as the Alternative Fuels Infrastructure Directive, while the United States relies on codes developed by organizations like NFPA and ASME. Japan and South Korea have also developed comprehensive hydrogen safety regulations, particularly focused on mobile applications.

Material-specific safety considerations reveal significant differences among storage options. Metal hydrides require careful thermal management and protection against contamination, while liquid organic hydrogen carriers (LOHCs) present challenges related to the handling of aromatic compounds. Carbon-based materials generally exhibit favorable safety profiles but may present dust hazards during handling. Coatings applied to storage vessels must maintain integrity under repeated hydrogen cycling and prevent hydrogen embrittlement of underlying materials.

Recent technological advancements have improved safety monitoring capabilities, including the development of advanced sensors for hydrogen leak detection, real-time monitoring systems for material degradation, and predictive modeling tools for risk assessment. These innovations enable more proactive safety management approaches and contribute to the overall risk reduction in hydrogen storage systems, facilitating broader adoption across various applications from stationary power to transportation.

Environmental Impact and Sustainability of Storage Materials

The environmental impact of hydrogen storage materials, catalysts, and coatings represents a critical dimension in evaluating their overall viability for sustainable energy systems. Life cycle assessment (LCA) studies reveal significant variations in environmental footprints across different storage technologies. Metal hydrides, while offering high storage densities, often require energy-intensive manufacturing processes and utilize rare earth elements that pose extraction-related environmental challenges. The mining operations associated with these materials frequently result in habitat disruption, water pollution, and substantial carbon emissions.

Chemical hydrogen carriers such as ammonia and organic liquid carriers demonstrate more favorable environmental profiles in certain aspects, particularly regarding recyclability and reduced dependency on scarce resources. However, their production processes still generate considerable greenhouse gas emissions, necessitating cleaner synthesis pathways to maximize their sustainability benefits.

Carbon-based materials, including activated carbon and carbon nanotubes, present promising alternatives with potentially lower environmental impacts during production. Their primary advantages include abundant carbon sources and less environmentally damaging extraction processes compared to metal-based alternatives. Nevertheless, the energy requirements for nanomaterial synthesis remain substantial, offsetting some of these benefits.

Water consumption represents another significant environmental consideration across storage technologies. Catalyst production, particularly for platinum group metals, involves water-intensive processes that can strain local water resources in manufacturing regions. Recent innovations in catalyst design have focused on reducing precious metal content while maintaining performance, thereby addressing both resource scarcity and environmental impact concerns.

End-of-life management presents varying challenges across different storage materials. While metal hydrides offer excellent recyclability potential, recovering high-value materials from complex composite structures remains technically challenging and energy-intensive. Developing closed-loop recycling systems for these materials constitutes an essential research direction for improving their sustainability profiles.

The environmental trade-offs between different storage technologies must be evaluated within specific application contexts. For stationary storage applications, where weight and volume constraints are less critical, materials with lower energy densities but better environmental profiles may prove optimal. Conversely, mobile applications may necessitate higher-performing materials despite potentially greater environmental impacts, highlighting the importance of application-specific sustainability assessments.

Emerging research on bio-inspired catalysts and environmentally benign coating processes demonstrates promising pathways toward more sustainable hydrogen storage solutions. These approaches aim to minimize toxic chemical usage, reduce energy requirements, and utilize renewable feedstocks, potentially transforming the environmental footprint of next-generation hydrogen storage technologies.

Chemical hydrogen carriers such as ammonia and organic liquid carriers demonstrate more favorable environmental profiles in certain aspects, particularly regarding recyclability and reduced dependency on scarce resources. However, their production processes still generate considerable greenhouse gas emissions, necessitating cleaner synthesis pathways to maximize their sustainability benefits.

Carbon-based materials, including activated carbon and carbon nanotubes, present promising alternatives with potentially lower environmental impacts during production. Their primary advantages include abundant carbon sources and less environmentally damaging extraction processes compared to metal-based alternatives. Nevertheless, the energy requirements for nanomaterial synthesis remain substantial, offsetting some of these benefits.

Water consumption represents another significant environmental consideration across storage technologies. Catalyst production, particularly for platinum group metals, involves water-intensive processes that can strain local water resources in manufacturing regions. Recent innovations in catalyst design have focused on reducing precious metal content while maintaining performance, thereby addressing both resource scarcity and environmental impact concerns.

End-of-life management presents varying challenges across different storage materials. While metal hydrides offer excellent recyclability potential, recovering high-value materials from complex composite structures remains technically challenging and energy-intensive. Developing closed-loop recycling systems for these materials constitutes an essential research direction for improving their sustainability profiles.

The environmental trade-offs between different storage technologies must be evaluated within specific application contexts. For stationary storage applications, where weight and volume constraints are less critical, materials with lower energy densities but better environmental profiles may prove optimal. Conversely, mobile applications may necessitate higher-performing materials despite potentially greater environmental impacts, highlighting the importance of application-specific sustainability assessments.

Emerging research on bio-inspired catalysts and environmentally benign coating processes demonstrates promising pathways toward more sustainable hydrogen storage solutions. These approaches aim to minimize toxic chemical usage, reduce energy requirements, and utilize renewable feedstocks, potentially transforming the environmental footprint of next-generation hydrogen storage technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!