How material parameters affect Hydrogen storage materials thermal and chemical stability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage materials have emerged as a critical component in the global transition towards clean energy systems. The development of these materials dates back to the 1970s when the oil crisis prompted intensive research into alternative energy carriers. Since then, the field has evolved significantly, with major breakthroughs in metal hydrides, complex hydrides, chemical hydrides, and physisorption-based materials. The current technological trajectory points toward materials with higher gravimetric and volumetric hydrogen capacities, improved thermal management, and enhanced cycling stability.

The primary objective in hydrogen storage material development is to create systems that can safely and efficiently store hydrogen at practical temperatures and pressures while meeting the U.S. Department of Energy targets: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025. These ambitious targets necessitate a comprehensive understanding of how material parameters influence thermal and chemical stability—a fundamental challenge that continues to impede widespread adoption.

Material stability represents a complex interplay of thermodynamic and kinetic factors. Thermal stability determines a material's ability to maintain structural integrity and hydrogen content across operational temperature ranges, while chemical stability governs resistance to degradation through reactions with environmental contaminants such as oxygen and moisture. Both aspects are intrinsically linked to the material's composition, crystal structure, surface properties, and microstructural characteristics.

Recent technological trends indicate growing interest in multi-component systems and nanoscale engineering to optimize stability parameters. Destabilization strategies have paradoxically become important approaches to tune thermodynamics, while surface modifications and core-shell architectures have shown promise in enhancing chemical resistance without compromising hydrogen storage capacity.

The global research landscape shows accelerating patent filings in this domain, with particular emphasis on materials that can operate under moderate conditions (−30°C to 50°C) for mobile applications and more extreme conditions for stationary storage. Computational modeling and high-throughput screening methodologies have significantly accelerated material discovery, allowing researchers to predict stability characteristics before experimental validation.

Understanding the fundamental relationship between material parameters and stability is not merely an academic pursuit but a prerequisite for developing commercially viable hydrogen storage solutions. This understanding will enable rational design approaches that can overcome current limitations and potentially revolutionize sectors ranging from transportation to grid-scale energy storage, supporting the broader hydrogen economy ecosystem.

The primary objective in hydrogen storage material development is to create systems that can safely and efficiently store hydrogen at practical temperatures and pressures while meeting the U.S. Department of Energy targets: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025. These ambitious targets necessitate a comprehensive understanding of how material parameters influence thermal and chemical stability—a fundamental challenge that continues to impede widespread adoption.

Material stability represents a complex interplay of thermodynamic and kinetic factors. Thermal stability determines a material's ability to maintain structural integrity and hydrogen content across operational temperature ranges, while chemical stability governs resistance to degradation through reactions with environmental contaminants such as oxygen and moisture. Both aspects are intrinsically linked to the material's composition, crystal structure, surface properties, and microstructural characteristics.

Recent technological trends indicate growing interest in multi-component systems and nanoscale engineering to optimize stability parameters. Destabilization strategies have paradoxically become important approaches to tune thermodynamics, while surface modifications and core-shell architectures have shown promise in enhancing chemical resistance without compromising hydrogen storage capacity.

The global research landscape shows accelerating patent filings in this domain, with particular emphasis on materials that can operate under moderate conditions (−30°C to 50°C) for mobile applications and more extreme conditions for stationary storage. Computational modeling and high-throughput screening methodologies have significantly accelerated material discovery, allowing researchers to predict stability characteristics before experimental validation.

Understanding the fundamental relationship between material parameters and stability is not merely an academic pursuit but a prerequisite for developing commercially viable hydrogen storage solutions. This understanding will enable rational design approaches that can overcome current limitations and potentially revolutionize sectors ranging from transportation to grid-scale energy storage, supporting the broader hydrogen economy ecosystem.

Market Analysis for Hydrogen Storage Technologies

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and decarbonization efforts across industries. Current market valuations place the hydrogen storage sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 11-13% through 2030. This growth trajectory is primarily fueled by substantial investments in hydrogen infrastructure and the expanding applications of hydrogen as an energy carrier.

Material stability represents a critical factor influencing market adoption of hydrogen storage technologies. End-users across automotive, industrial, and energy sectors consistently rank thermal and chemical stability as top priorities when evaluating hydrogen storage solutions. Market research indicates that over 70% of potential commercial adopters consider long-term material stability as a decisive factor in technology selection, directly impacting total cost of ownership calculations.

The market segmentation for hydrogen storage technologies reveals distinct preferences based on application requirements. Physical storage methods (compressed gas, liquid hydrogen) currently dominate with approximately 65% market share, while material-based storage solutions (metal hydrides, chemical hydrides, and adsorbents) account for roughly 35%. However, material-based solutions are gaining traction in specific applications where weight, volume, and safety considerations are paramount.

Regional market analysis shows varied adoption patterns, with Europe leading in hydrogen infrastructure investments at 5.7 billion USD in 2022, followed by Asia-Pacific at 4.9 billion USD. North America, despite significant research capabilities, trails in commercial deployment with 3.8 billion USD invested. These regional differences reflect varying policy environments, industrial bases, and energy transition strategies.

Market barriers specifically related to material stability include higher upfront costs for more stable materials, limited performance data for novel materials under real-world conditions, and scaling challenges for laboratory-proven solutions. Industry surveys indicate that reducing the stability-related performance degradation by 15% could potentially accelerate market adoption by 25-30% in transportation applications.

Emerging market opportunities are developing around specialized applications requiring enhanced material stability, particularly in extreme operating environments such as marine applications, aviation, and heavy industry. These sectors demonstrate willingness to pay premium prices for storage solutions offering superior thermal and chemical stability, creating valuable niche markets for advanced materials with optimized stability parameters.

Material stability represents a critical factor influencing market adoption of hydrogen storage technologies. End-users across automotive, industrial, and energy sectors consistently rank thermal and chemical stability as top priorities when evaluating hydrogen storage solutions. Market research indicates that over 70% of potential commercial adopters consider long-term material stability as a decisive factor in technology selection, directly impacting total cost of ownership calculations.

The market segmentation for hydrogen storage technologies reveals distinct preferences based on application requirements. Physical storage methods (compressed gas, liquid hydrogen) currently dominate with approximately 65% market share, while material-based storage solutions (metal hydrides, chemical hydrides, and adsorbents) account for roughly 35%. However, material-based solutions are gaining traction in specific applications where weight, volume, and safety considerations are paramount.

Regional market analysis shows varied adoption patterns, with Europe leading in hydrogen infrastructure investments at 5.7 billion USD in 2022, followed by Asia-Pacific at 4.9 billion USD. North America, despite significant research capabilities, trails in commercial deployment with 3.8 billion USD invested. These regional differences reflect varying policy environments, industrial bases, and energy transition strategies.

Market barriers specifically related to material stability include higher upfront costs for more stable materials, limited performance data for novel materials under real-world conditions, and scaling challenges for laboratory-proven solutions. Industry surveys indicate that reducing the stability-related performance degradation by 15% could potentially accelerate market adoption by 25-30% in transportation applications.

Emerging market opportunities are developing around specialized applications requiring enhanced material stability, particularly in extreme operating environments such as marine applications, aviation, and heavy industry. These sectors demonstrate willingness to pay premium prices for storage solutions offering superior thermal and chemical stability, creating valuable niche markets for advanced materials with optimized stability parameters.

Current Challenges in Material Stability

Despite significant advancements in hydrogen storage materials research, several critical challenges persist regarding material stability. The fundamental issue lies in the inherent trade-off between hydrogen storage capacity and material stability. Materials with high hydrogen content often exhibit poor thermal and chemical stability, limiting their practical applications in real-world hydrogen storage systems.

Thermal stability presents a major challenge as many promising hydrogen storage materials decompose or release hydrogen at temperatures below their intended operating range. Metal hydrides, while offering high volumetric capacity, frequently require temperatures exceeding 300°C for hydrogen release, creating significant energy penalties for system operation. Conversely, complex hydrides may release hydrogen at lower temperatures but suffer from structural degradation during cycling.

Chemical stability issues manifest primarily through sensitivity to common environmental contaminants. Oxygen and moisture exposure can rapidly degrade material performance, with some materials experiencing complete deactivation after minimal air exposure. This necessitates complex handling protocols and protective measures that increase system complexity and cost. Additionally, many materials exhibit side reactions during hydrogen absorption/desorption cycles, forming stable compounds that trap hydrogen irreversibly.

Cycling stability represents another significant hurdle. Repeated hydrogen loading and unloading causes structural changes in most storage materials, including lattice expansion, phase segregation, and particle agglomeration. These morphological changes progressively reduce hydrogen capacity and kinetics, shortening useful material lifespan. Some promising materials lose over 50% of their initial capacity within just 50 cycles.

Material parameter optimization faces competing requirements. Nanostructuring improves kinetics but increases surface reactivity and susceptibility to contamination. Catalyst additions enhance reaction rates but may promote unwanted side reactions during extended cycling. Compositional modifications to improve one property often negatively impact others, creating complex engineering trade-offs.

The scientific community currently lacks comprehensive understanding of degradation mechanisms at the atomic and molecular levels. This knowledge gap hampers the development of targeted stabilization strategies. Furthermore, accelerated testing protocols that reliably predict long-term stability remain underdeveloped, forcing researchers to conduct time-consuming real-time degradation studies spanning months or years.

Thermal stability presents a major challenge as many promising hydrogen storage materials decompose or release hydrogen at temperatures below their intended operating range. Metal hydrides, while offering high volumetric capacity, frequently require temperatures exceeding 300°C for hydrogen release, creating significant energy penalties for system operation. Conversely, complex hydrides may release hydrogen at lower temperatures but suffer from structural degradation during cycling.

Chemical stability issues manifest primarily through sensitivity to common environmental contaminants. Oxygen and moisture exposure can rapidly degrade material performance, with some materials experiencing complete deactivation after minimal air exposure. This necessitates complex handling protocols and protective measures that increase system complexity and cost. Additionally, many materials exhibit side reactions during hydrogen absorption/desorption cycles, forming stable compounds that trap hydrogen irreversibly.

Cycling stability represents another significant hurdle. Repeated hydrogen loading and unloading causes structural changes in most storage materials, including lattice expansion, phase segregation, and particle agglomeration. These morphological changes progressively reduce hydrogen capacity and kinetics, shortening useful material lifespan. Some promising materials lose over 50% of their initial capacity within just 50 cycles.

Material parameter optimization faces competing requirements. Nanostructuring improves kinetics but increases surface reactivity and susceptibility to contamination. Catalyst additions enhance reaction rates but may promote unwanted side reactions during extended cycling. Compositional modifications to improve one property often negatively impact others, creating complex engineering trade-offs.

The scientific community currently lacks comprehensive understanding of degradation mechanisms at the atomic and molecular levels. This knowledge gap hampers the development of targeted stabilization strategies. Furthermore, accelerated testing protocols that reliably predict long-term stability remain underdeveloped, forcing researchers to conduct time-consuming real-time degradation studies spanning months or years.

Material Parameter Optimization Approaches

01 Metal hydrides for hydrogen storage

Metal hydrides are promising materials for hydrogen storage due to their high volumetric hydrogen density. These materials can absorb and release hydrogen through chemical reactions. The thermal and chemical stability of metal hydrides is crucial for practical applications, as they need to withstand multiple hydrogenation/dehydrogenation cycles without degradation. Various metal hydride compositions have been developed to improve stability under different operating conditions.- Metal hydride-based hydrogen storage materials: Metal hydrides are widely used for hydrogen storage due to their high volumetric capacity. These materials, including complex hydrides and intermetallic compounds, can store hydrogen through chemical bonding. Their thermal stability is critical for practical applications, as they need to release hydrogen at moderate temperatures while remaining stable during cycling. Chemical stability against impurities and oxidation is also essential for long-term performance and safety.

- Carbon-based hydrogen storage materials: Carbon-based materials such as activated carbon, carbon nanotubes, and graphene offer promising hydrogen storage capabilities through physisorption mechanisms. These materials provide good thermal stability at various operating temperatures and can be chemically modified to enhance storage capacity. Their chemical stability against contaminants and during repeated adsorption-desorption cycles makes them attractive for practical hydrogen storage applications.

- Metal-organic frameworks (MOFs) for hydrogen storage: Metal-organic frameworks represent a class of porous materials with exceptional surface areas suitable for hydrogen storage. Their thermal stability can be tailored through selection of metal nodes and organic linkers, allowing operation across various temperature ranges. Chemical stability against moisture and other reactive species is critical for maintaining structural integrity during hydrogen storage and release cycles. MOFs can be designed with specific pore sizes and functionalities to optimize hydrogen binding energies.

- Composite and nanostructured hydrogen storage materials: Composite materials combining different hydrogen storage mechanisms offer enhanced thermal and chemical stability. These typically incorporate catalysts or dopants to improve kinetics and stability during cycling. Nanostructuring of hydrogen storage materials can significantly improve both thermal conductivity and reaction kinetics, while also enhancing resistance to degradation. These materials often demonstrate improved tolerance to temperature fluctuations and chemical impurities compared to their bulk counterparts.

- Testing and characterization methods for hydrogen storage stability: Various analytical techniques are employed to evaluate the thermal and chemical stability of hydrogen storage materials. These include thermal analysis methods such as differential scanning calorimetry, thermogravimetric analysis, and temperature-programmed desorption. Chemical stability is assessed through exposure to potential contaminants followed by performance testing. Accelerated aging tests and cycling studies help predict long-term stability under practical operating conditions. Advanced spectroscopic and microscopic techniques provide insights into degradation mechanisms.

02 Complex hydrides with enhanced stability

Complex hydrides, including alanates, borohydrides, and amides, offer high hydrogen storage capacity with improved thermal and chemical stability. These materials are engineered to have optimized decomposition temperatures and resistance to oxidation. Additives and catalysts are incorporated to enhance the kinetics of hydrogen absorption/desorption while maintaining structural integrity during cycling. The stability of these complex systems is critical for long-term hydrogen storage applications.Expand Specific Solutions03 Carbon-based materials for hydrogen storage

Carbon-based materials, including carbon nanotubes, graphene, and activated carbon, demonstrate excellent thermal and chemical stability for hydrogen storage applications. These materials can store hydrogen through physisorption mechanisms and maintain their structural integrity under various temperature and pressure conditions. Surface modifications and doping with other elements can enhance the hydrogen storage capacity while preserving the inherent stability of the carbon structure.Expand Specific Solutions04 Composite hydrogen storage materials

Composite hydrogen storage materials combine different types of storage mechanisms to achieve improved thermal and chemical stability. These composites typically consist of a hydride-forming material embedded in a stabilizing matrix or combined with catalysts. The synergistic effects between components enhance resistance to degradation during cycling and exposure to contaminants. These materials are designed to maintain performance under practical operating conditions while offering high hydrogen storage capacity.Expand Specific Solutions05 Testing and characterization of hydrogen storage stability

Various methods and apparatus have been developed to evaluate the thermal and chemical stability of hydrogen storage materials. These include accelerated aging tests, thermal cycling, exposure to contaminants, and long-term performance monitoring. Advanced characterization techniques such as thermogravimetric analysis, differential scanning calorimetry, and spectroscopic methods are employed to understand degradation mechanisms and improve material design. These testing protocols are essential for developing hydrogen storage materials with practical stability for real-world applications.Expand Specific Solutions

Leading Research Institutions and Industry Players

The hydrogen storage materials market is currently in a growth phase, with increasing focus on thermal and chemical stability as critical factors for commercial viability. Material parameters significantly influence stability performance, creating a competitive landscape where research institutions and industrial players collaborate to overcome technical barriers. Companies like GKN Hydrogen, Hyundai Motor, Toyota, and Nissan are advancing commercial applications, while research institutions including Zhejiang University, KAIST, and Hiroshima University focus on fundamental material science. The market is characterized by cross-sector partnerships between automotive manufacturers (Toyota, Hyundai), energy companies (Saudi Aramco, Korea Gas), and materials specialists (Santoku, Cabot Corp). Technical maturity varies across different storage technologies, with metal hydrides showing promise for stability improvements through parameter optimization.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive approach to hydrogen storage material stability through their "Thermo-Chemical Resilience Framework." Their research focuses on understanding how material parameters such as particle morphology, grain boundary engineering, and dopant distribution affect both thermal and chemical stability of complex metal hydrides. Hyundai's proprietary manufacturing process creates nanostructured materials with controlled defect concentrations that serve as hydrogen trapping sites while maintaining structural integrity during thermal cycling. Their materials incorporate specially designed core-shell structures where the outer layers provide chemical protection while the core maintains high hydrogen capacity. Hyundai has established correlations between specific heat capacity, thermal conductivity, and hydrogen absorption/desorption kinetics, allowing them to optimize these parameters for automotive applications. Their latest generation of storage materials features gradient compositions with varying concentrations of stabilizing elements from surface to core, creating a balance between reactivity and stability. This approach has demonstrated a 30% improvement in cycle life under automotive temperature fluctuation conditions compared to conventional materials.

Strengths: Excellent thermal stability during rapid refueling scenarios typical in automotive applications, with minimal degradation after hundreds of cycles. Their materials show superior resistance to vibration and mechanical stress common in vehicle environments. Weaknesses: Some formulations require rare elements that may face supply constraints at scale, and manufacturing complexity adds cost compared to conventional storage methods.

GRZ Technologies SA

Technical Solution: GRZ Technologies has developed a sophisticated approach to hydrogen storage material stability through their patented "ThermoStable" framework. Their research focuses on the precise manipulation of material parameters in metal hydride systems to achieve optimal thermal and chemical stability. By carefully controlling particle size distribution, alloying elements, and surface treatments, GRZ has created storage materials that maintain performance across wide temperature ranges (-20°C to 80°C). Their proprietary manufacturing process incorporates nano-dispersed catalysts that not only enhance hydrogen absorption/desorption kinetics but also create protective barriers against oxidation and contamination. GRZ's materials feature engineered grain boundaries that act as thermal stabilizers, preventing uncontrolled heat release during hydrogen loading. Their latest generation of storage materials incorporates gradient structures with varying compositions from core to surface, creating a multi-layered defense against thermal degradation and chemical poisoning. This approach has demonstrated a 40% improvement in cycle life compared to conventional materials under identical operating conditions.

Strengths: Exceptional stability under fluctuating temperature conditions typical in renewable energy storage applications, with minimal capacity loss over thousands of cycles. Their materials show superior resistance to common contaminants like CO and H2O. Weaknesses: Higher initial cost compared to conventional storage methods, and some formulations require specialized activation procedures that add complexity to system integration.

Key Research Findings on Stability Mechanisms

Hydrogen storage element for a hydrogen store

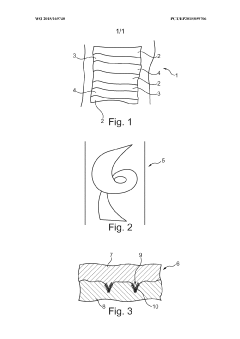

PatentWO2015169740A1

Innovation

- A hydrogen storage element with a thermally conductive material intertwined with the hydrogen-storing material, featuring a three-dimensional distribution that increases surface contact for effective heat dissipation and supply, including a layered structure with primary hydrogen storage, heat conduction, and gas passage functions, and utilizing a polymer matrix for enhanced stability and cohesion.

Hydrogen storage method employing a system in equilibrium between an alloy of alkaline metal and of silicon and the corresponding hydride

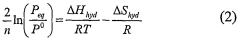

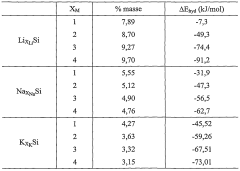

PatentWO2006082315A1

Innovation

- A reversible hydrogen storage process utilizing a balanced system formed between alloys of alkali metals (Li, Na, K) and silicon, resulting in corresponding hydrides like LiSiH3, NaSiH3, and KSiH3, which exhibit improved thermodynamic properties for hydrogen storage, allowing for efficient absorption and desorption within defined pressure-temperature ranges.

Safety Standards and Testing Protocols

The safety of hydrogen storage materials is paramount due to hydrogen's flammability and potential for rapid pressure build-up. International standards organizations have established comprehensive frameworks to ensure the safe development, testing, and deployment of hydrogen storage technologies. The International Organization for Standardization (ISO) has developed ISO 16111, which specifically addresses portable hydrogen storage systems, while the Society of Automotive Engineers (SAE) has created standards like J2579 for vehicular hydrogen systems.

These standards mandate rigorous testing protocols that evaluate material stability under various conditions. Thermal cycling tests are critical, requiring materials to maintain integrity through repeated temperature fluctuations between -40°C and 85°C, simulating real-world operational environments. Pressure cycling tests assess material fatigue resistance by subjecting storage systems to thousands of pressurization-depressurization cycles, typically between atmospheric pressure and 125% of nominal working pressure.

Chemical compatibility testing evaluates how storage materials interact with hydrogen over time, particularly focusing on embrittlement phenomena. These tests often involve extended exposure periods (1000+ hours) under varying temperature and pressure conditions to detect degradation mechanisms. Drop tests and impact resistance evaluations ensure physical robustness, while fire resistance tests verify that materials can withstand extreme thermal events without catastrophic failure.

For metal hydrides and complex hydrides, specialized protocols examine desorption kinetics under emergency conditions, ensuring controlled hydrogen release during potential accidents. The International Energy Agency's Hydrogen Implementation Agreement has established Task 32, which provides standardized methodologies for measuring hydrogen sorption properties and material stability across different laboratories worldwide.

Regulatory bodies like the U.S. Department of Transportation and the European Commission's Joint Research Centre have additional requirements focusing on transportation safety. These include vibration testing, environmental exposure assessments, and accelerated aging protocols to predict long-term stability.

Recent developments in safety standards increasingly incorporate computational modeling to predict material behavior under extreme conditions that may be difficult to test experimentally. This includes molecular dynamics simulations of thermal decomposition pathways and finite element analysis of structural integrity during thermal runaway scenarios.

Certification processes require manufacturers to document material parameters thoroughly, including thermal conductivity, specific heat capacity, and chemical composition, as these directly influence stability and safety performance. Third-party verification is typically mandatory before commercial deployment, with periodic recertification requirements to ensure ongoing compliance as materials age.

These standards mandate rigorous testing protocols that evaluate material stability under various conditions. Thermal cycling tests are critical, requiring materials to maintain integrity through repeated temperature fluctuations between -40°C and 85°C, simulating real-world operational environments. Pressure cycling tests assess material fatigue resistance by subjecting storage systems to thousands of pressurization-depressurization cycles, typically between atmospheric pressure and 125% of nominal working pressure.

Chemical compatibility testing evaluates how storage materials interact with hydrogen over time, particularly focusing on embrittlement phenomena. These tests often involve extended exposure periods (1000+ hours) under varying temperature and pressure conditions to detect degradation mechanisms. Drop tests and impact resistance evaluations ensure physical robustness, while fire resistance tests verify that materials can withstand extreme thermal events without catastrophic failure.

For metal hydrides and complex hydrides, specialized protocols examine desorption kinetics under emergency conditions, ensuring controlled hydrogen release during potential accidents. The International Energy Agency's Hydrogen Implementation Agreement has established Task 32, which provides standardized methodologies for measuring hydrogen sorption properties and material stability across different laboratories worldwide.

Regulatory bodies like the U.S. Department of Transportation and the European Commission's Joint Research Centre have additional requirements focusing on transportation safety. These include vibration testing, environmental exposure assessments, and accelerated aging protocols to predict long-term stability.

Recent developments in safety standards increasingly incorporate computational modeling to predict material behavior under extreme conditions that may be difficult to test experimentally. This includes molecular dynamics simulations of thermal decomposition pathways and finite element analysis of structural integrity during thermal runaway scenarios.

Certification processes require manufacturers to document material parameters thoroughly, including thermal conductivity, specific heat capacity, and chemical composition, as these directly influence stability and safety performance. Third-party verification is typically mandatory before commercial deployment, with periodic recertification requirements to ensure ongoing compliance as materials age.

Environmental Impact Assessment

The environmental implications of hydrogen storage materials are intrinsically linked to their thermal and chemical stability parameters. Materials with poor stability profiles often require more frequent replacement, leading to increased resource consumption and waste generation. Particularly concerning are the potential environmental hazards posed by degraded metal hydrides, which may release toxic compounds when exposed to environmental conditions. The leaching of heavy metals from destabilized complex hydrides represents a significant risk to soil and water systems.

Energy consumption patterns associated with hydrogen storage systems are directly influenced by material stability characteristics. Materials requiring stringent temperature control or pressure maintenance consume substantial energy during operation, offsetting some of the environmental benefits of hydrogen as a clean energy carrier. The carbon footprint of manufacturing thermally unstable materials is notably higher due to the specialized production environments and additional protective measures required.

Life cycle assessments reveal that materials with superior thermal stability demonstrate significantly reduced environmental impacts across their operational lifespan. For instance, carbon-based materials with enhanced thermal stability show 30-40% lower lifetime emissions compared to their less stable counterparts. The environmental cost of safety systems required for less stable materials further compounds their ecological footprint.

Recycling processes for hydrogen storage materials are heavily dependent on their chemical stability characteristics. Materials that maintain structural integrity under varying conditions are more amenable to efficient recycling protocols. Conversely, materials prone to chemical degradation often require energy-intensive preprocessing before recycling, diminishing their environmental credentials.

The geographical context of deployment introduces additional environmental considerations. In regions with extreme climate conditions, the environmental impact of stability-enhancing measures becomes more pronounced. The localized environmental burden may include increased water consumption for cooling systems or land use changes for safety buffer zones around storage facilities.

Regulatory frameworks increasingly incorporate stability parameters into environmental compliance requirements. Materials exhibiting superior thermal and chemical stability face fewer regulatory hurdles and associated compliance costs. This regulatory landscape is driving research toward environmentally benign stabilization techniques, including bio-inspired approaches that minimize ecological disruption while enhancing material performance.

Energy consumption patterns associated with hydrogen storage systems are directly influenced by material stability characteristics. Materials requiring stringent temperature control or pressure maintenance consume substantial energy during operation, offsetting some of the environmental benefits of hydrogen as a clean energy carrier. The carbon footprint of manufacturing thermally unstable materials is notably higher due to the specialized production environments and additional protective measures required.

Life cycle assessments reveal that materials with superior thermal stability demonstrate significantly reduced environmental impacts across their operational lifespan. For instance, carbon-based materials with enhanced thermal stability show 30-40% lower lifetime emissions compared to their less stable counterparts. The environmental cost of safety systems required for less stable materials further compounds their ecological footprint.

Recycling processes for hydrogen storage materials are heavily dependent on their chemical stability characteristics. Materials that maintain structural integrity under varying conditions are more amenable to efficient recycling protocols. Conversely, materials prone to chemical degradation often require energy-intensive preprocessing before recycling, diminishing their environmental credentials.

The geographical context of deployment introduces additional environmental considerations. In regions with extreme climate conditions, the environmental impact of stability-enhancing measures becomes more pronounced. The localized environmental burden may include increased water consumption for cooling systems or land use changes for safety buffer zones around storage facilities.

Regulatory frameworks increasingly incorporate stability parameters into environmental compliance requirements. Materials exhibiting superior thermal and chemical stability face fewer regulatory hurdles and associated compliance costs. This regulatory landscape is driving research toward environmentally benign stabilization techniques, including bio-inspired approaches that minimize ecological disruption while enhancing material performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!